A stacking device for proton exchange membrane fuel cells

A proton exchange membrane and fuel cell technology, applied in fuel cells, fuel cell groups, circuits, etc., can solve problems affecting production efficiency, bulky battery stacking devices, and low control precision of fuel cell plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

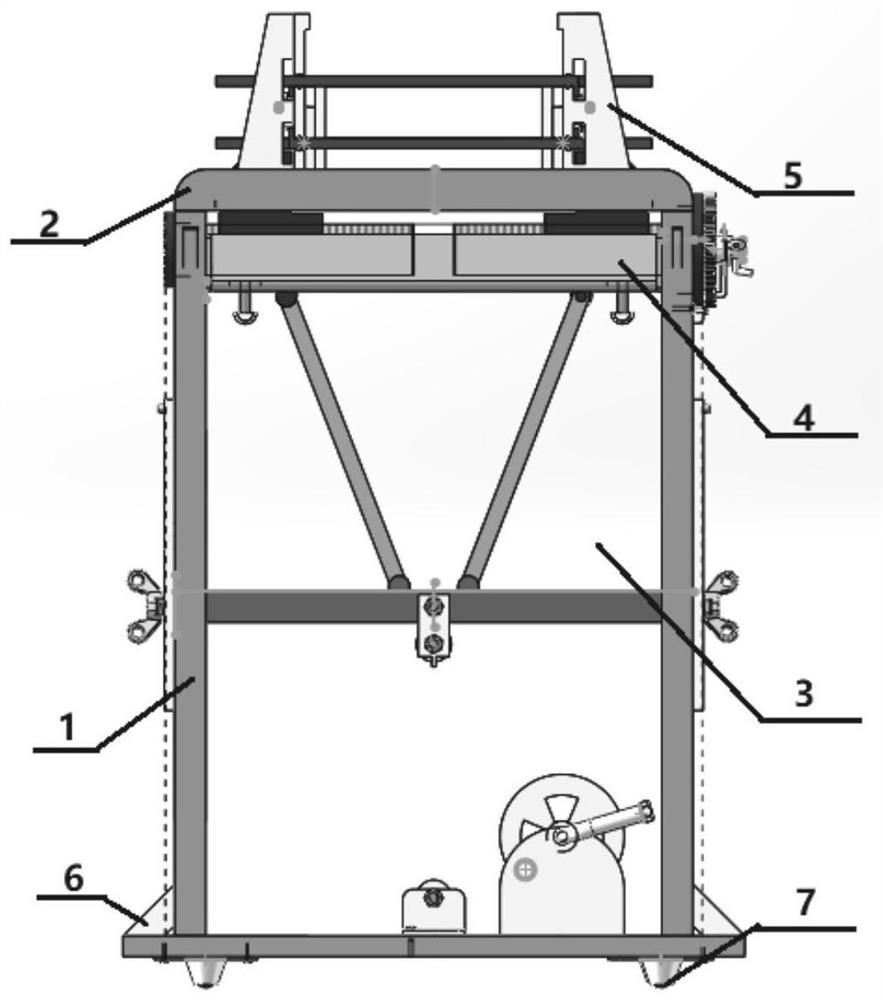

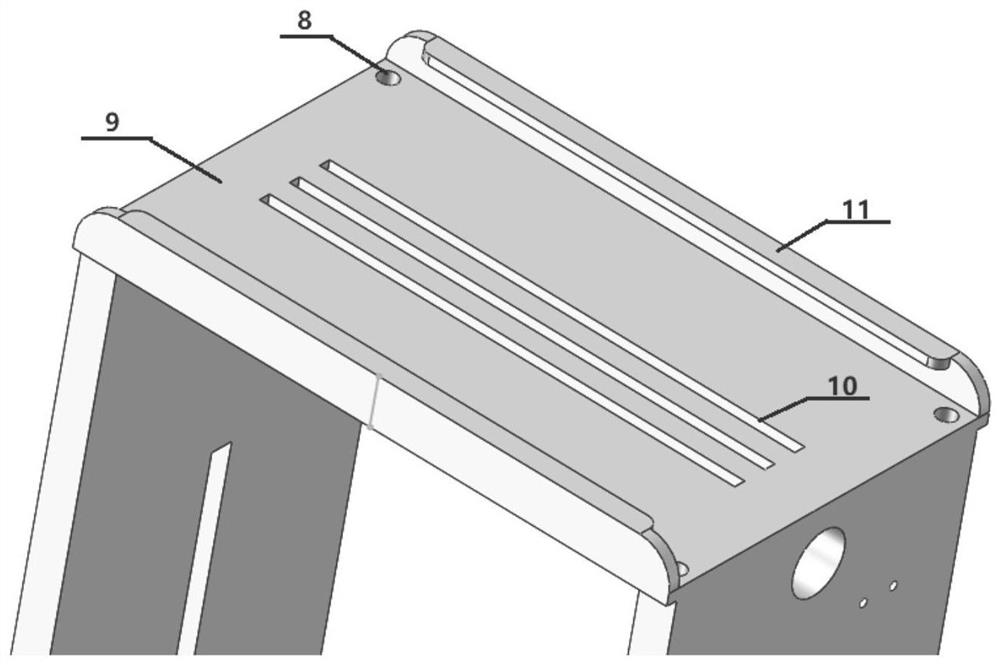

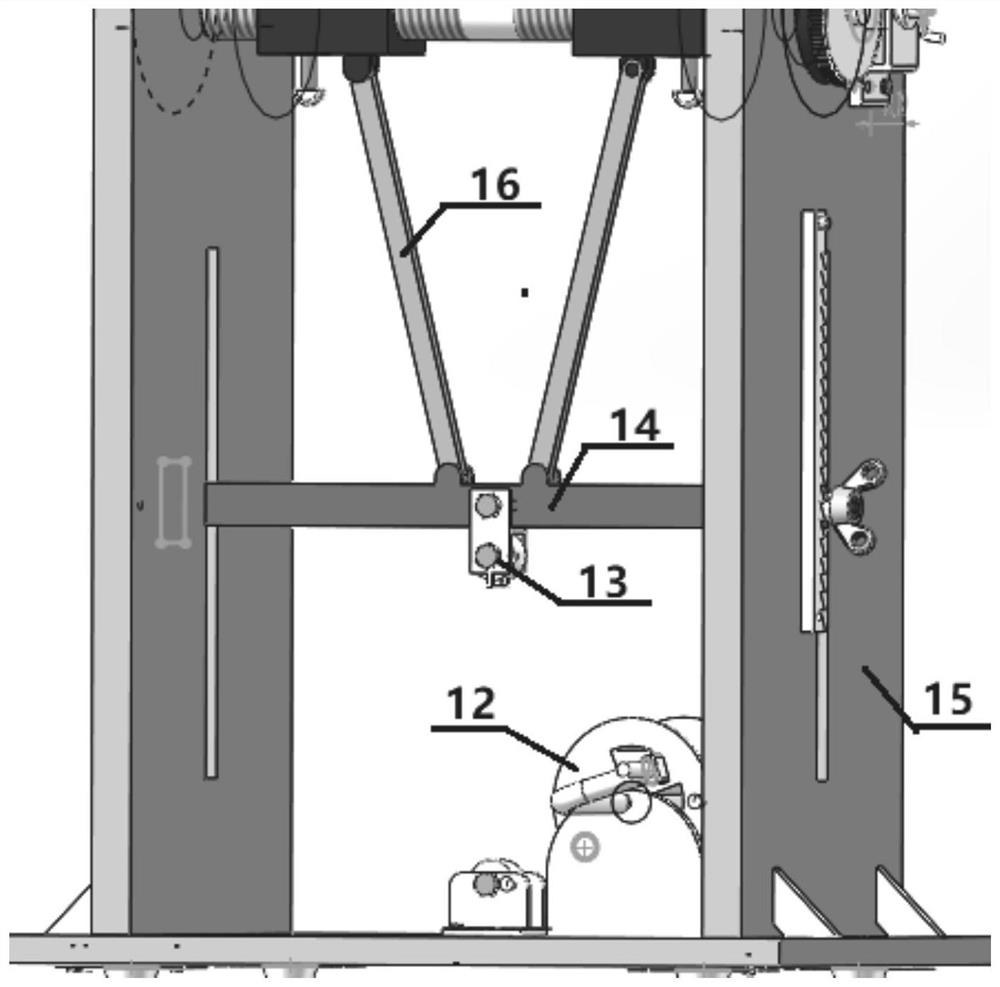

[0052] figure 1 shows a schematic diagram of the overall structure according to an embodiment of the present invention, figure 2 shows a schematic structural view of a workbench according to an embodiment of the present invention, image 3 shows a schematic structural view of a primary pressing mechanism according to an embodiment of the present invention, Figure 4 shows a schematic structural view of a secondary pressing mechanism according to an embodiment of the present invention, Figure 5 shows a schematic structural diagram of a slider according to an embodiment of the present invention, Figure 6 shows a schematic structural view of a pressure plate set according to an embodiment of the present invention, Figure 7 A schematic structural diagram of a limiting device for a pressure applying plate according to an embodiment of the present invention is shown.

[0053] Such as figure 1 Shown is a mechanical stacking device suitable for proton exchange membrane fuel c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com