Rotary quantitative material stacking system

A rotating shaft and hopper technology, applied in the field of rotary quantitative stacking system, can solve the problems of slow manual stacking speed, affecting production efficiency, poor stacking effect, etc., to achieve good applicability, good stacking quality, and structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

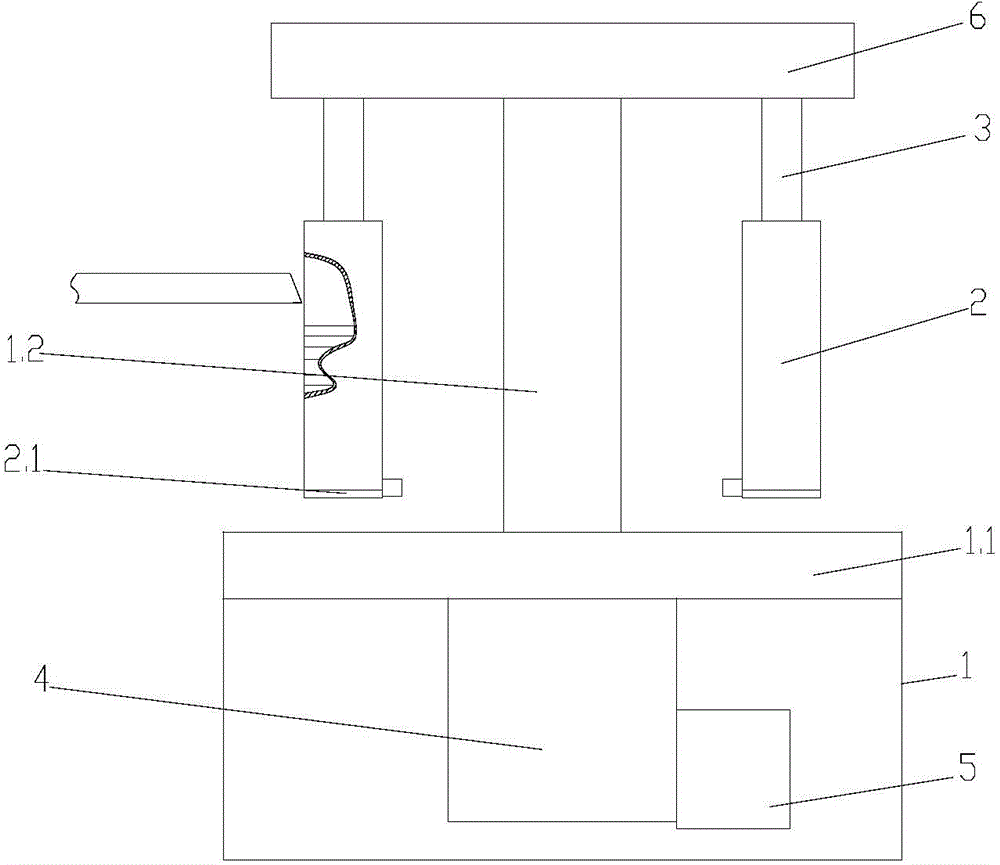

[0012] Such as figure 1 A rotary quantitative stacking system shown includes a frame 1, a trough hopper 2, an elastic sensor 3, a motor 4, and a controller 5 that drives the motor 4 to rotate. The motor 4 is arranged at the inner axis of the frame 1, and the motor 4 The output end passes through the workbench 1.1 set on the frame 1 and is connected to the rotating shaft 1.2 set on the top axis of the workbench 1.1, the controller 5 is set on the side of the motor 4, the top of the rotating shaft 1.2 is provided with a turntable 6, and the hopper 2 is elastically The sensor 3 is suspended on the turntable. One end of the elastic force controller 3 is connected to the turntable 6, and the other end is detachably connected to the hopper 2. There are multiple hoppers 2 that are evenly distributed along the circumference of the turntable 6. The upper side wall of the hopper 2 is provided with a feeding port. The feed port corresponds to the feeding mechanism, the bottom of the hopp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com