Glass stacking device and control method thereof

A stacking device and glass technology, applied in transportation and packaging, conveyor objects, furnaces, etc., can solve problems such as limiting the efficient and accurate stacking of manipulators, and achieve the effects of ensuring reliability, improving production efficiency, and improving stacking quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to better illustrate the technical content of the present invention, the following specific examples are given for further illustration.

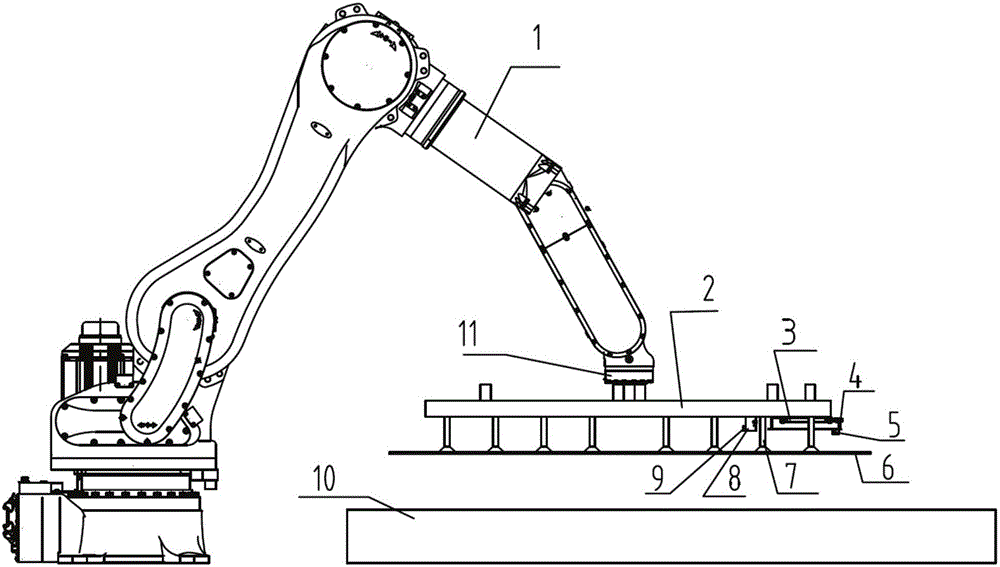

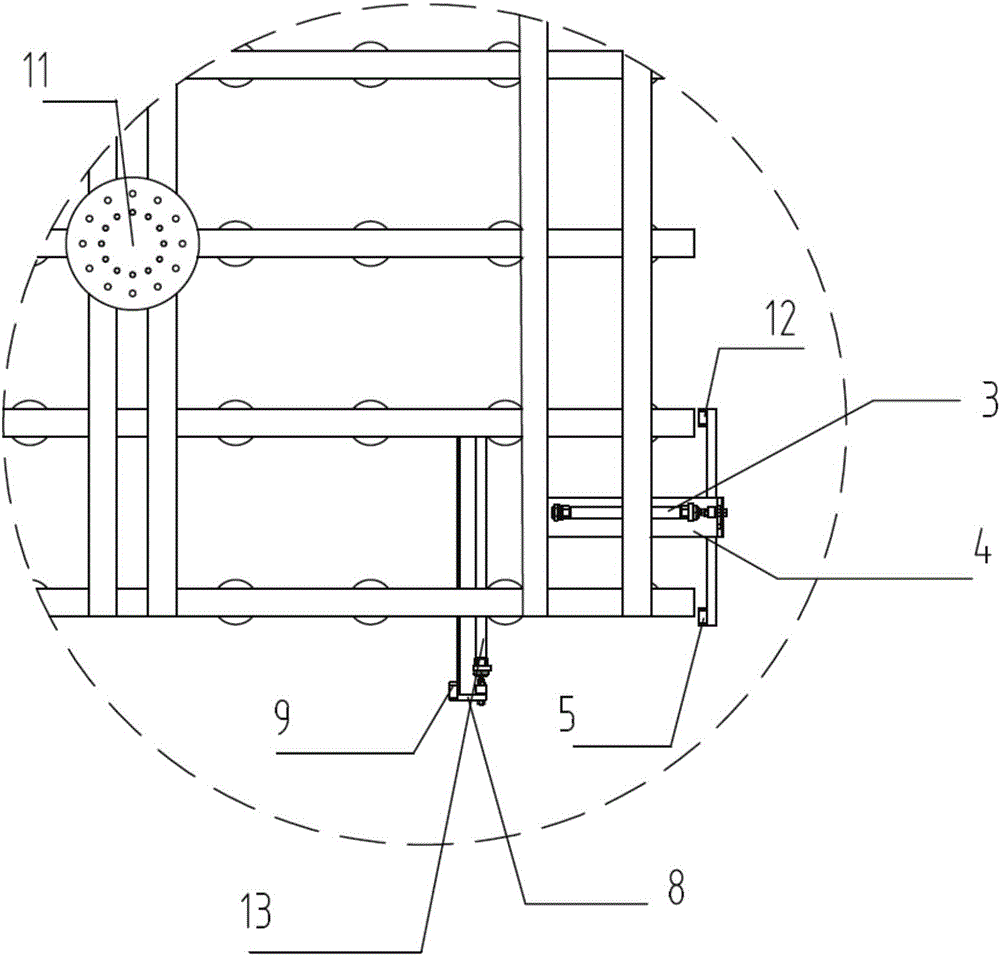

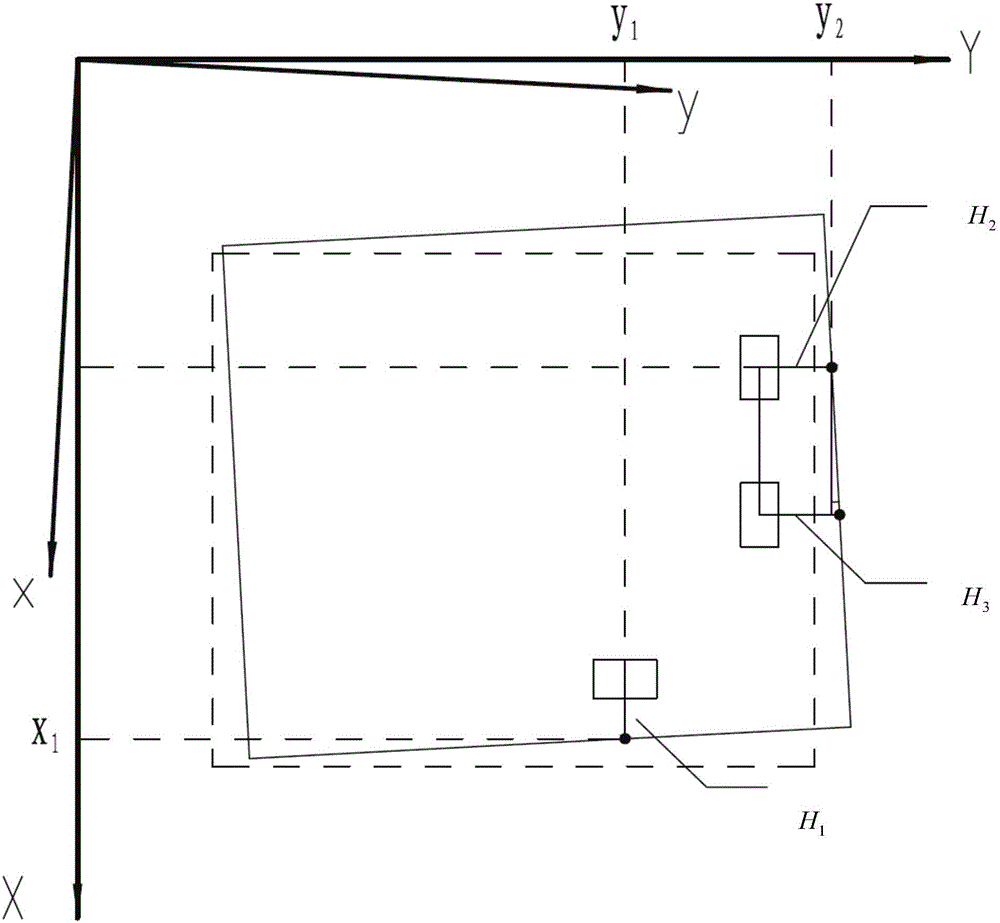

[0052] see figure 1 , the glass stacking device includes a stacking robot and a pallet, its main feature is that the stacking robot includes a mechanical arm and a pallet, the first end of the mechanical arm is connected to a base, and the base Make the mechanical arm upright in the glass grabbing area, and the second end of the mechanical arm is connected with a suction cup frame, the suction cup frame is also fixed with a cylinder group, and the piston rod of the cylinder group is connected with a photoelectric sensor group, the side of the tray is parallel to the speed direction of the assembly line.

[0053] The cylinder group includes a horizontal cylinder and a vertical cylinder, and the photoelectric sensor group includes two horizontal photoelectric sensors and a vertical photoelectric sensor, and the moving directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com