Annealed steel coil quick stacking device and operation method thereof

A stacking device and technology for annealing steel, used in furnaces, heat treatment equipment, heat treatment furnaces, etc., can solve the problems of steel coil rib damage, low stacking efficiency, stacking irregularity and other problems, so as to reduce the damage and improve the stacking. Efficient, telepresence effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Hereinafter, exemplary embodiments of the present invention will be described in detail with reference to the accompanying drawings.

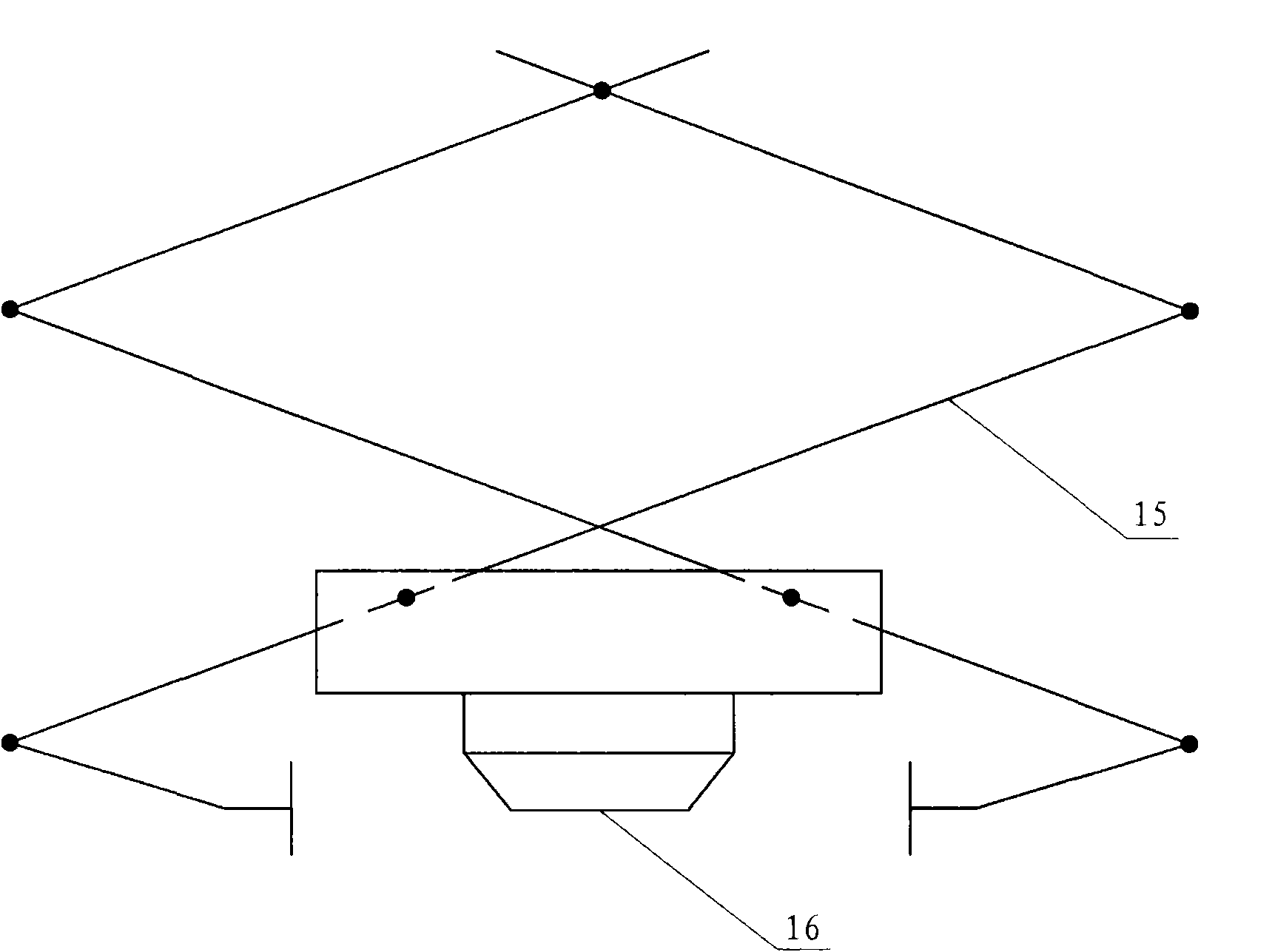

[0041] figure 1 It is a schematic diagram showing a steel coil hanger 15 of a rapid stacking device for annealed steel coils according to an exemplary embodiment of the present invention, wherein a guide cone 16 is installed in the steel coil hanger 15 . According to an exemplary embodiment of the present invention, when lifting a steel coil, the upper end of the steel coil hanger 15 is connected to the crown block, and the crown block lifts the steel coil through the steel coil hanger 15 under the guidance of the guide cone 16, And place the steel coil precisely in the desired position.

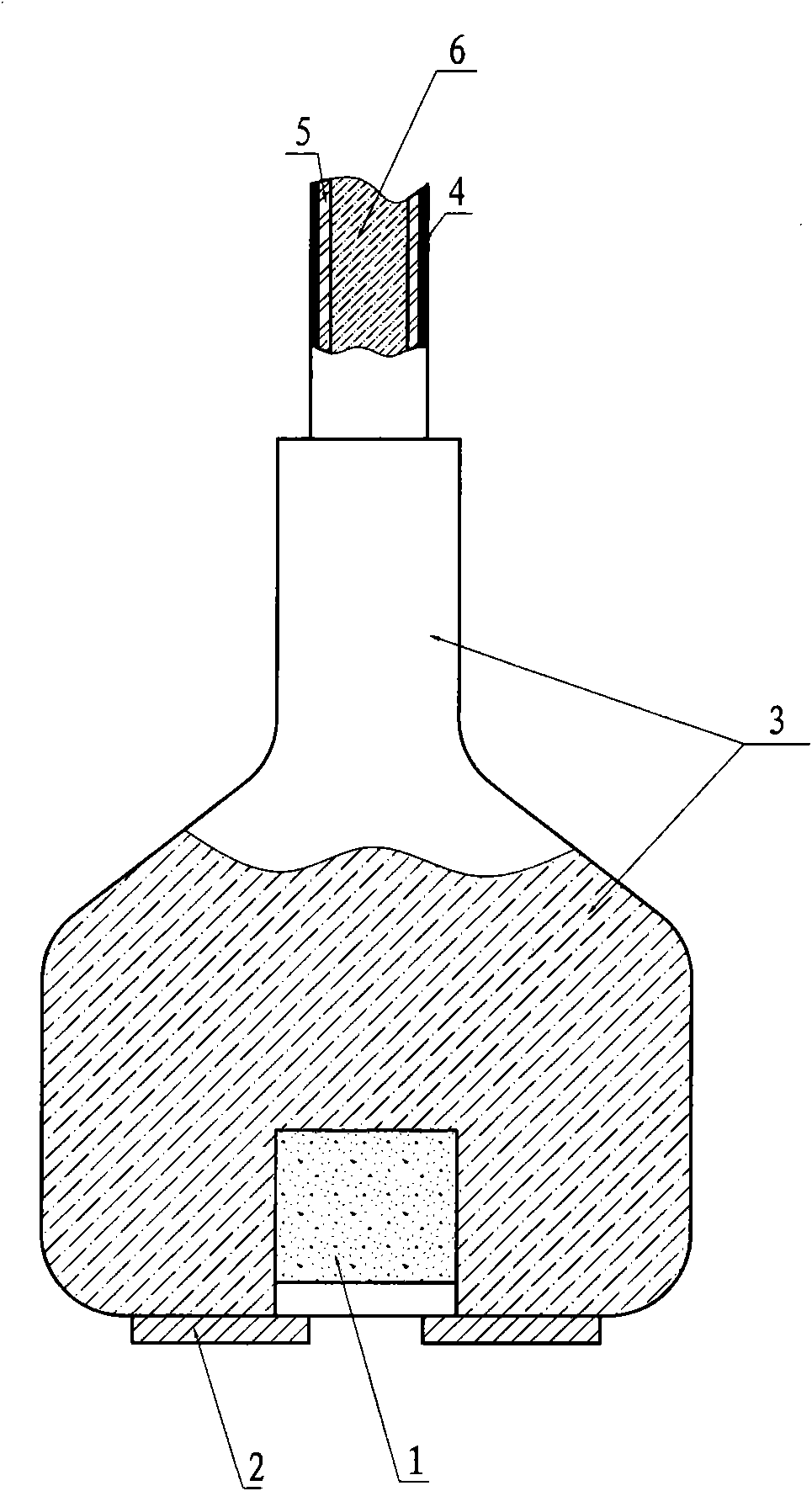

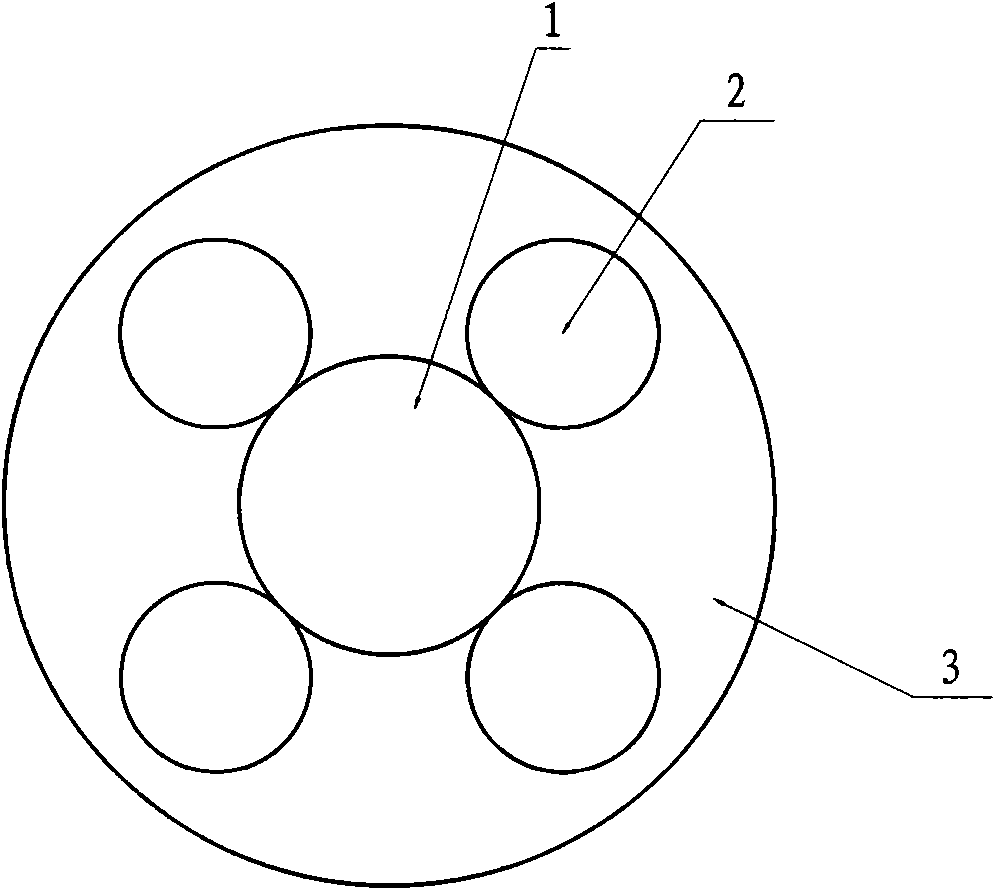

[0042] Such as Figure 2 to Figure 5 As shown, the rapid stacking device for annealed steel coils according to an exemplary embodiment of the present invention includes the above-mentioned crane (preferably, the crane can move in three speeds and fou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com