Integrated type electric turnover box and production method

An integrated, turnover box technology, applied in the direction of preventing mechanical damage, rigid containers, containers, etc., can solve the problems of reduced production and transportation safety performance, unfavorable product status maintenance, difference in turnover box specifications, etc., to improve stacking stability. stability, avoid the difference in structure and size, and achieve the effect of accurate product size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

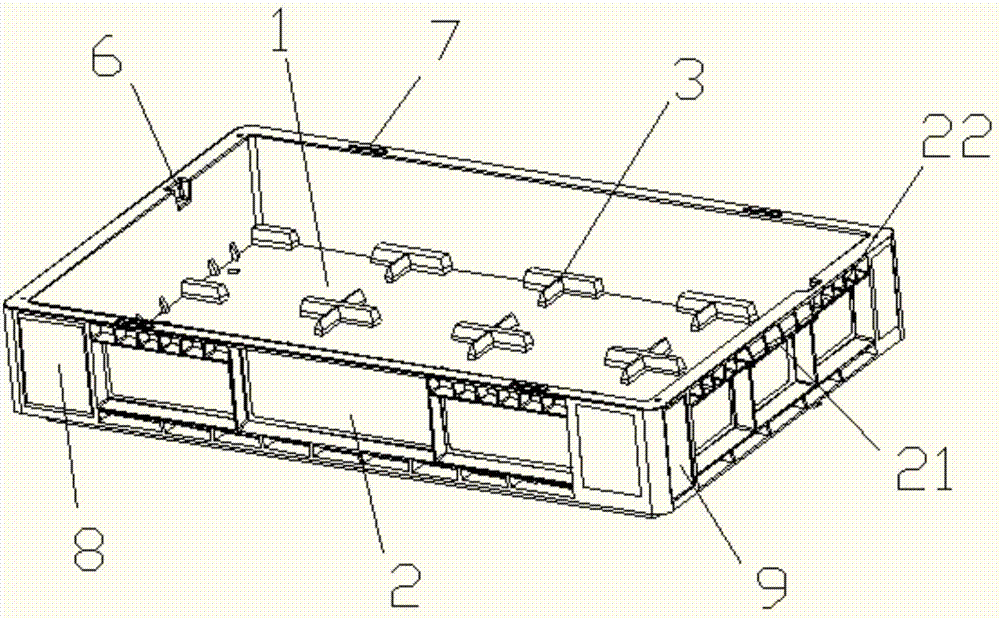

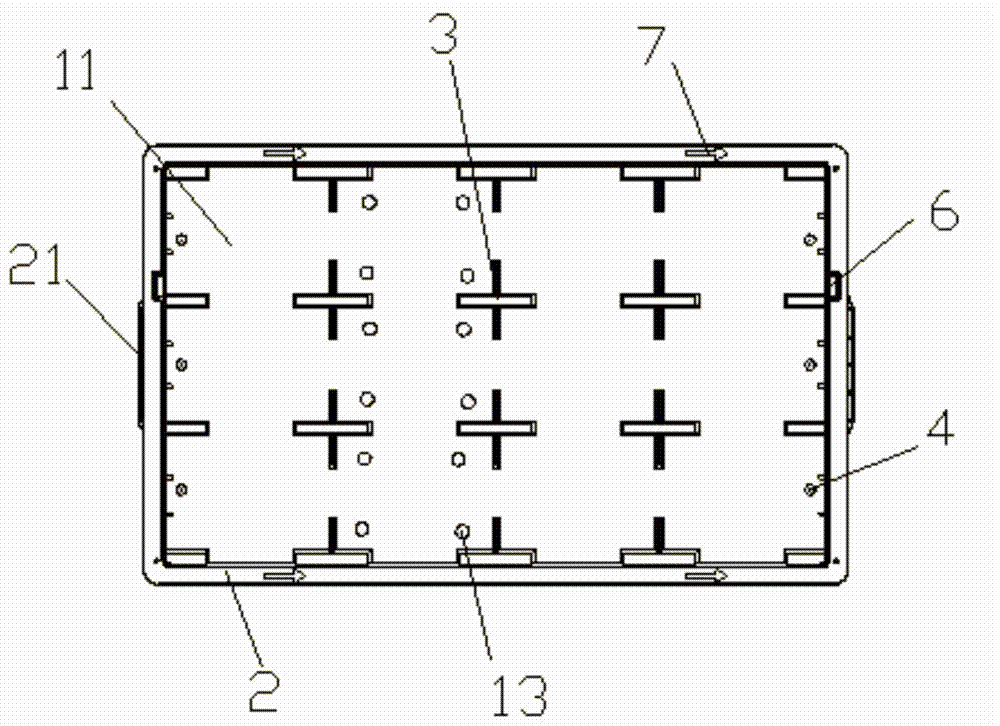

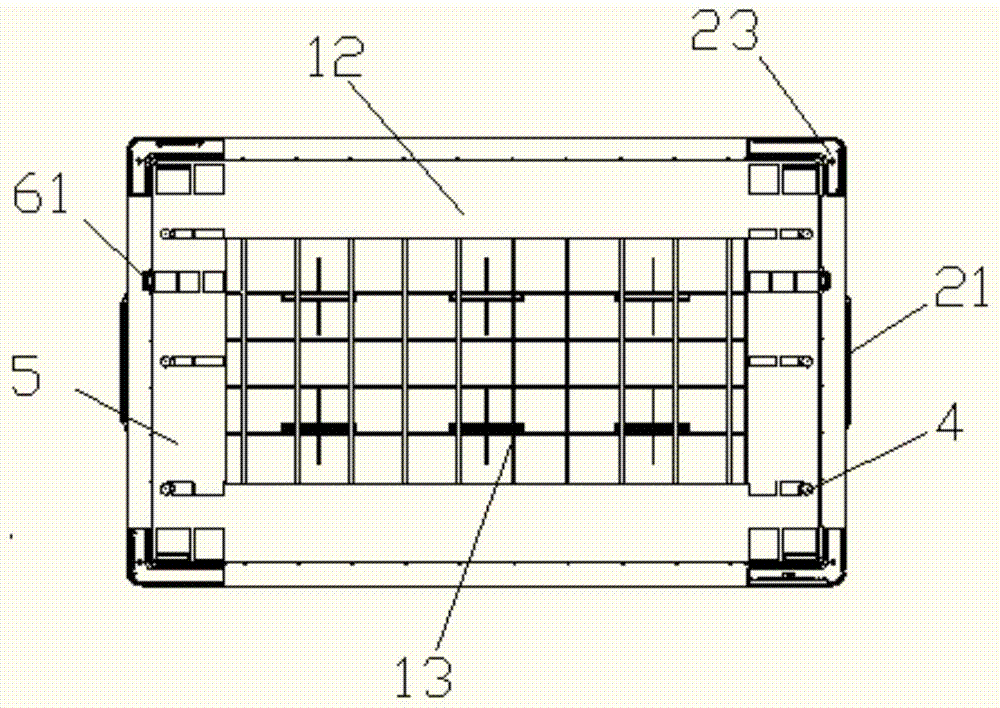

[0042] The turnover box is composed of a side plate 2 and a bottom plate 1 , and the side plate 2 is vertically connected to the upper surface 11 of the bottom plate 1 . This moment, this side plate 2 and base plate 1 surround and form the placement area for accommodating tools, and its structure is as follows: figure 1 shown. The forming method of the side plate 2 and the bottom plate 1 of this application adopts integral injection molding, which saves the connection process of the side plate 2 and the bottom plate 1. According to different customer needs, the change of the finished structure of the turnover box can be realized by changing the shape of the mold, and the improvement can be improved. Improve the production efficiency of the turnover box. And the overall injection molding method is made by model, which makes the product size mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com