Method for guaranteeing stack mounting precision of straight-slot iron cores of motor and stack mounting die employed in method

A technology of stacking molds and iron cores, which is applied in the manufacture of stator/rotor bodies, etc., can solve the problems of increasing the friction between the key plate and the punching plate, the surface of the key plate cannot be ground, and the dimensional accuracy is difficult to guarantee. Achieve the effects of avoiding iron core deformation, reducing measurement links, and improving stacking quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

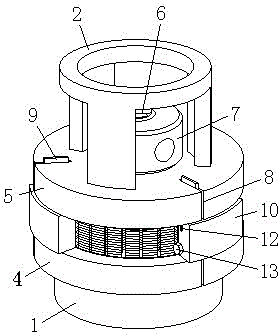

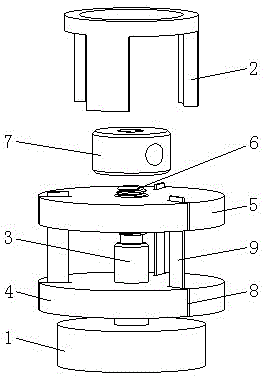

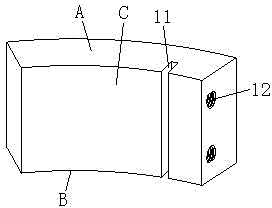

[0025] The stacked mold of the present invention is as figure 1 As shown, the idea is ingenious but the structure is simple, which is based on the original multi-key positioning stacked mold (see figure 2 ) on the basis of which a limit block 10 is added to lock the key plate 9. limit block such as image 3 As shown, the shape of the limiting block 10 is tile-like, and the inner arc surface C of the limiting block 10 should be the same as the outer arc of the iron core punching piece 15 . The tile-shaped two-end surfaces are positioning surfaces, and the positioning surface A and the positioning surface B are processed by grinding, and the parallelism tolerance of the positioning surface A and the positioning surface B is not greater than 0.02. The height of the limiting block 10 is the same as the lamination thickness of the iron core punching sheet 15, and the consistency of the height of each limiting block 10 must be ensured during processing. There is a card slot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com