Multi-perception rubber lamination robot device

A robot and lamination technology, applied in the field of robotics, can solve the problems of affecting health, uneven film stacking, odor, etc., and achieve the effect of increasing production and improving the quality of lamination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

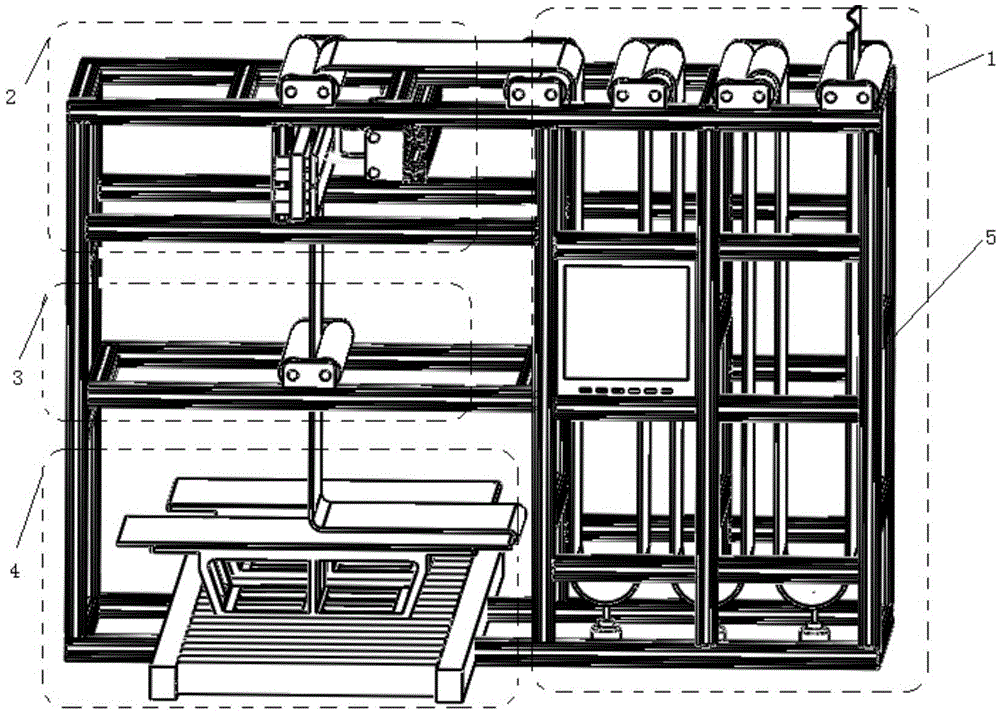

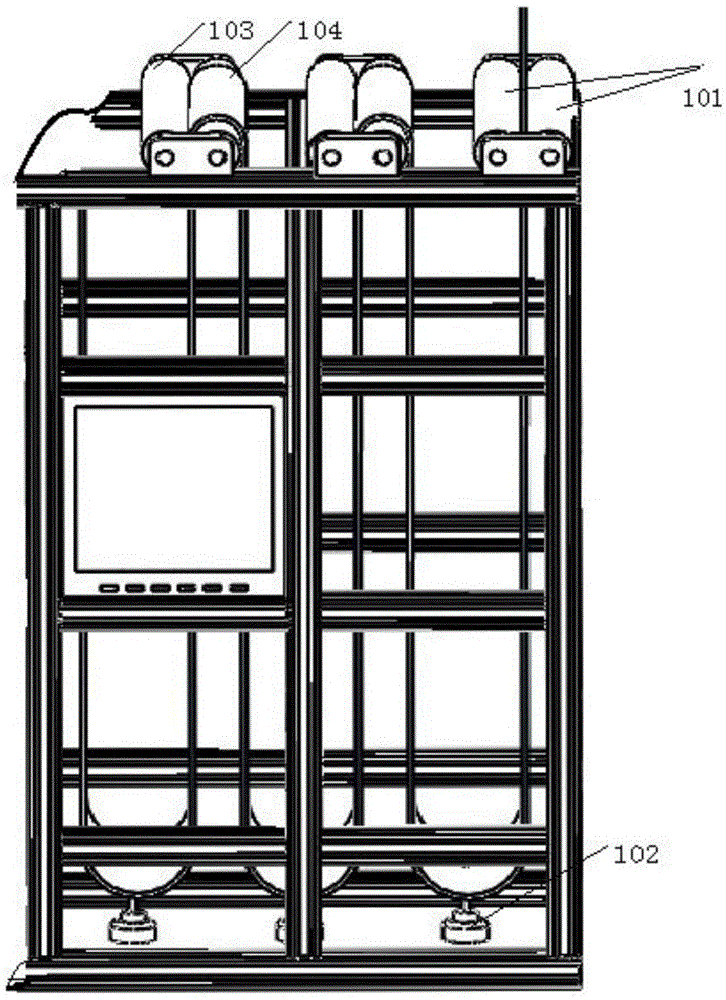

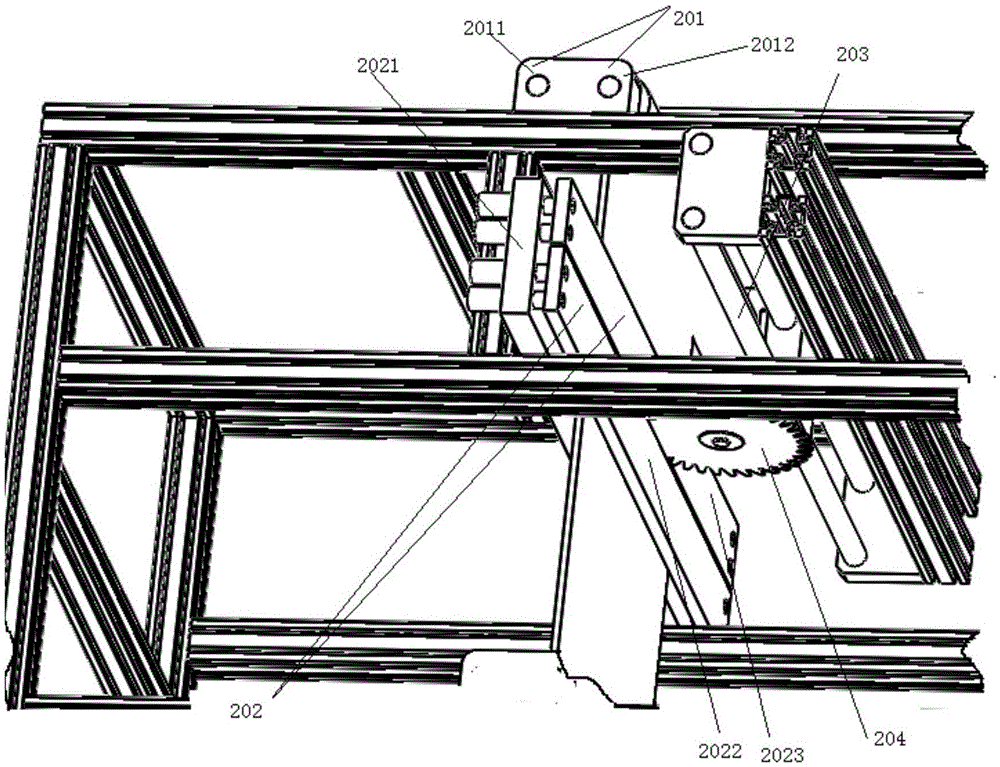

[0025] Such as figure 1 As shown, a multi-sensory raw rubber lamination robot device according to an embodiment of the present invention includes a buffer mechanism 1, a cutting mechanism 2, a lamination mechanism 3, a loading mechanism 4 and a bracket 5, and the buffer mechanism 1 is arranged on the side of the bracket 5. At one end, the cutting mechanism 2, the stacking mechanism 3 and the loading mechanism 4 are arranged at the other end of the bracket 5, and the cutting mechanism 2, the stacking mechanism 3 and the loading mechanism 4 are arranged sequentially from top to bottom.

[0026] Raw rubber is extruded from the film production line into tapes. Then use the multi-sensory raw rubber lamination robot device with the above structure to stack the tapes and transport them out. Buffer mechanism 1 is used for carding tape. The stack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com