Paper grabbing mechanism of paper unloading machine

A paper machine and paper technology, which is applied in the field of unloading machine paper grabbing mechanism, can solve the problems of unfavorable effects of stacked paper packaging, inability to ensure the consistency of paper stacks, and paper stack offsets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

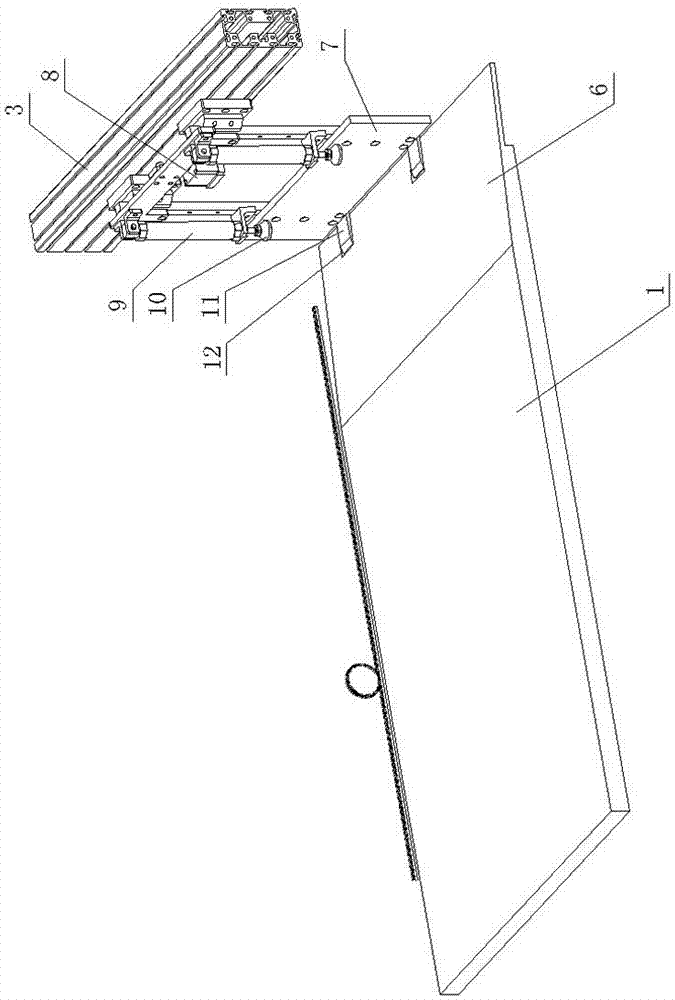

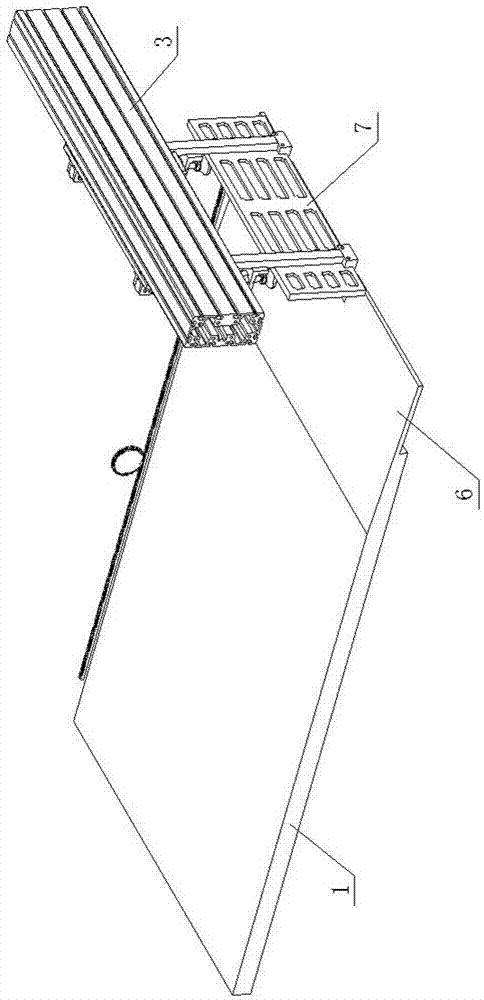

[0011] As shown in the figure, the paper grabbing mechanism of the paper unloader of the present invention includes a lifting beam, a paper transfer table 1 and a right paper retaining arm 3, and the paper transfer table 1 and the right paper retaining arm 3 are installed on the lifting beam and respectively Driven by the driving motor, it moves independently in the left and right directions. The table top of the paper transfer table 1 has a downwardly inclined paper unloading guide surface 6 at the right end. The right paper stop arm 3 is connected to the right paper stop plate 7. The rightmost end of the paper unloading guide surface 6 is set There are two gaps 12 at the front and back, and a paper-picking block 11 is movable in the gap 12. The paper-picking block 11 is arranged at the bottom of the right paper blocking plate 7 and is fixedly connected with the right paper blocking plate 7. The paper picking block 11 and the right paper blocking plate 7 are jointly formed by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com