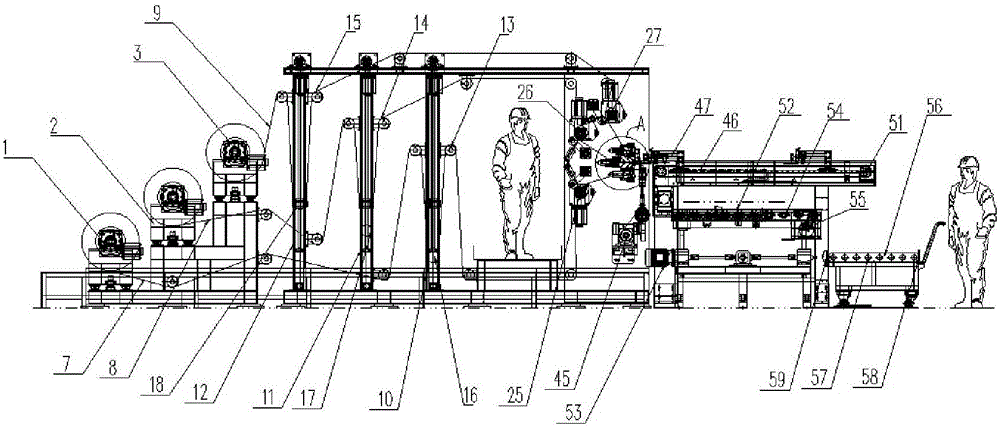

Three-axis type PP cropping and stacking machine

A stacking machine and cutting technology, which is applied in the direction of stacking receiving device, winding strip, sending objects, etc., can solve the problems of size difference of three PP sheets, difficulty in forming stacking effect, time-consuming and labor-intensive, etc., to achieve Low production cost, small space occupation and labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

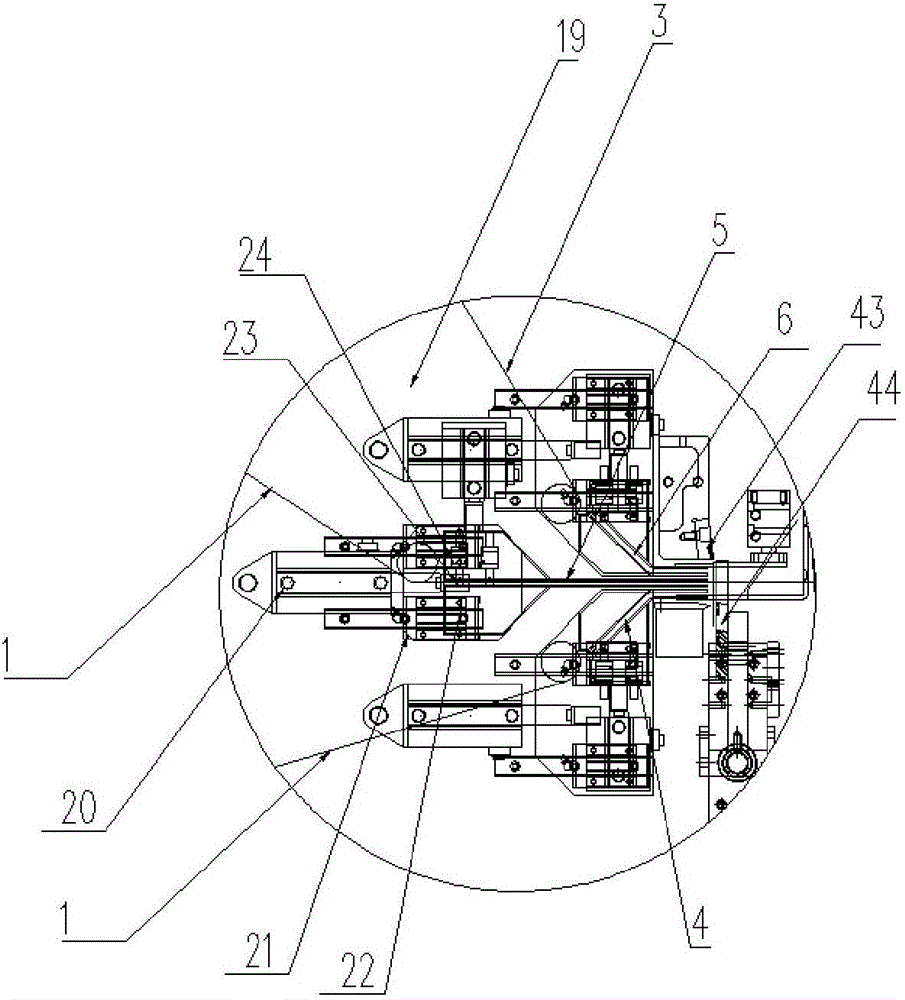

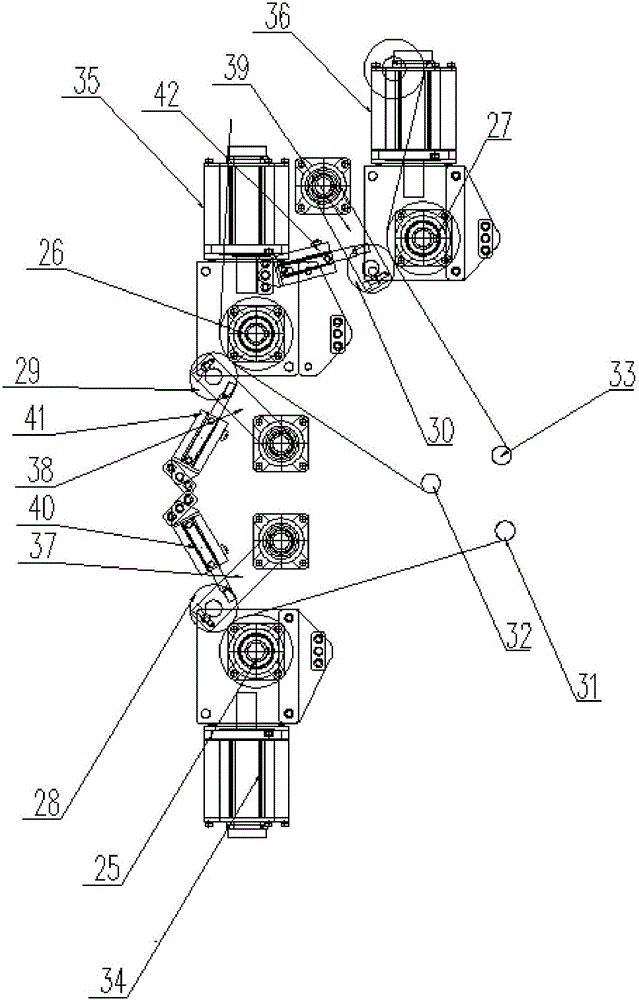

[0023] Embodiment: A three-axis PP cutting and stacking machine, including the first, second, and third delivery mechanisms 1, 2, and 3, the first, second, and third strip extraction mechanisms, and the first, second, and third strip conveying channels 4, 5, 6, tape cutting mechanism, sheet clamping and transferring mechanism and lifting and staggered stacking mechanism, the first, second, and third materials sent by the first, second, and third sending mechanisms 1, 2, and 3 The belts 7, 8, and 9 are respectively introduced into the first, second, and third material belt delivery channels 4, 5, and 6 by the first, second, and third material belt delivery channels, and the first, second, and third material belt delivery channels 4, 5, 6 are arranged at intervals along the longitudinal direction, and the ends of the first, second, and third belt conveying channels 4, 5, and 6 are aligned, and the material belt cutting mechanism is just located at the ends of the first, second, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com