Full-automatic paperboard stacking equipment and paperboard stacking method

A fully automatic, cardboard technology, used in the stacking of objects, destacking of objects, and flipping objects, etc., can solve the problems of low degree of automation and inability to meet the needs of mass production, saving labor, saving production costs, adapting to strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

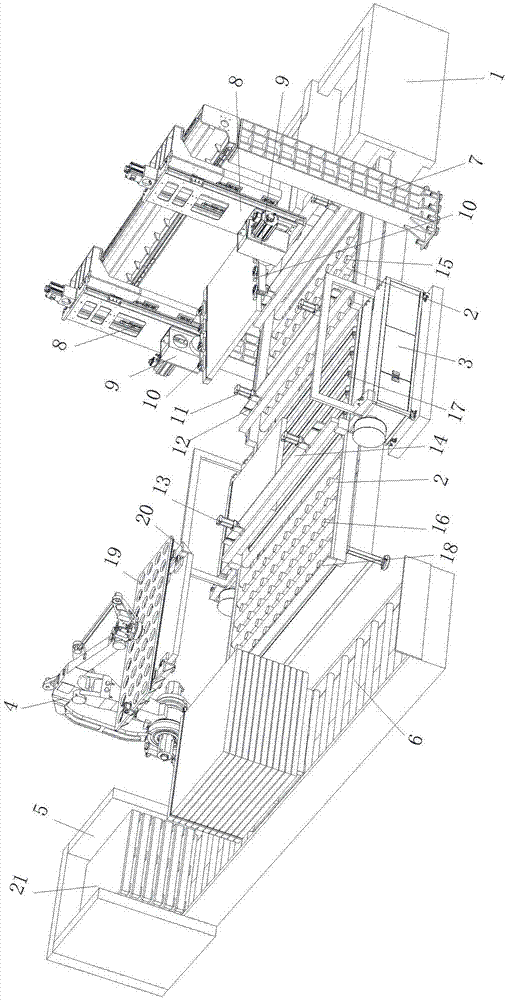

[0028] Example: see figure 1 , the present embodiment provides a fully automatic cardboard palletizing equipment, which includes a cardboard machine 1 sequentially connected from back to front, a stacking mechanism, a cable tie mechanism, a palletizing mechanism and a feeding mechanism, and the stacking mechanism, the cable tie mechanism and the palletizing mechanism are sequentially connected through the conveying line 2; wherein, the stacking mechanism includes a stacking manipulator, a first positioning device and a first jacking device; the strapping mechanism includes a strapping machine 3, a second positioning device and a lifting The conveying device; the stacking mechanism includes a second jacking device and a stacking manipulator 4; the feeding mechanism includes a pallet machine 5 and a pallet conveying line 6.

[0029] The stacked manipulator includes a gantry 7, on the gantry 7, perpendicular to the beam of the gantry 7, two mechanical arms 8 moving in the Z-axis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com