Manufacturing method of thin film touch sensor and thin film touch sensor

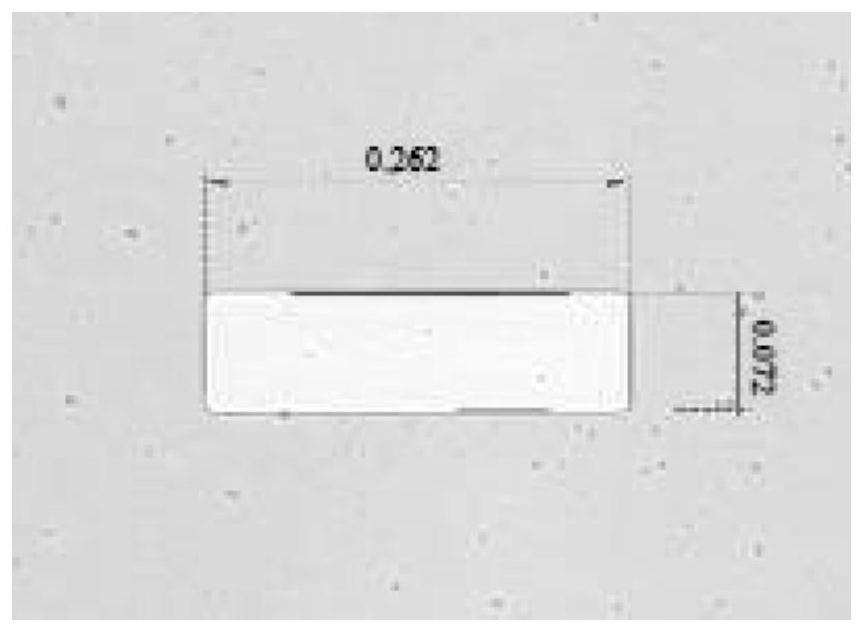

A technology of touch sensing and manufacturing methods, which is applied in the input/output process of instruments, data processing, calculation, etc., and can solve the problems of stacking offset of each layer, small stacking offset of lines, and low efficiency of exposure alignment , to achieve the effects of small line stack offset, precise exposure alignment, stable and controllable shape and size changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

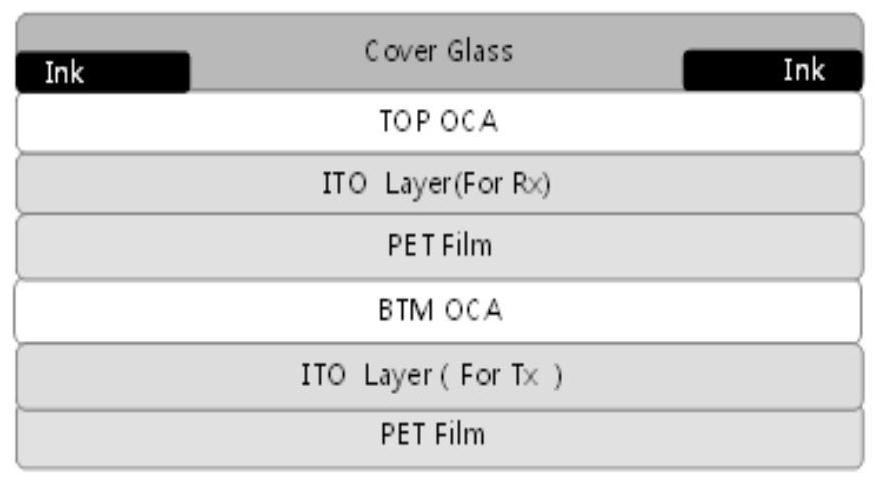

[0068] A manufacturing method of a thin film touch sensor, comprising the following steps:

[0069] (a) Bake the rigid carrier covered with the film substrate, the baking temperature is 130°C, and the baking time is 60min; wherein the film substrate is a PET film substrate, the rigid carrier is a glass plate, and the film substrate The adhesive between the material and the rigid carrier is acrylic adhesive;

[0070] (b) Making multi-layer touch circuits:

[0071] The first ITO coating;

[0072] The first ITO line process: photoresist coating, soft baking, exposure, development, hard baking, etching and stripping photoresist, the soft baking temperature is 110 ℃, after baking, let it stand for 3 minutes, and the exposure table temperature is controlled at 25 ℃;

[0073] The first OC line process: OC photoresist coating, soft baking, exposure, development and solid baking, the soft baking temperature is 110 ° C, the soft baking time is 3 minutes, after baking, let stand for 3 ...

Embodiment 2

[0081] A manufacturing method of a thin-film touch sensor is different from Embodiment 1 in that the baking temperature is 140° C., the baking time is 40 minutes, and other steps and parameters are the same as those in Embodiment 1.

Embodiment 3

[0083] A manufacturing method of a thin-film touch sensor is different from Embodiment 1 in that the baking temperature is 120° C., the baking time is 60 minutes, and other steps and parameters are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com