Self-adaptive centering stacking equipment

A stacking device and self-adaptive technology, applied in sustainable manufacturing/processing, electrochemical generators, electrical components, etc., can solve the problems of poor stacking progress and inappropriate stacking technology, and achieve the effect of improving efficiency and stacking accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

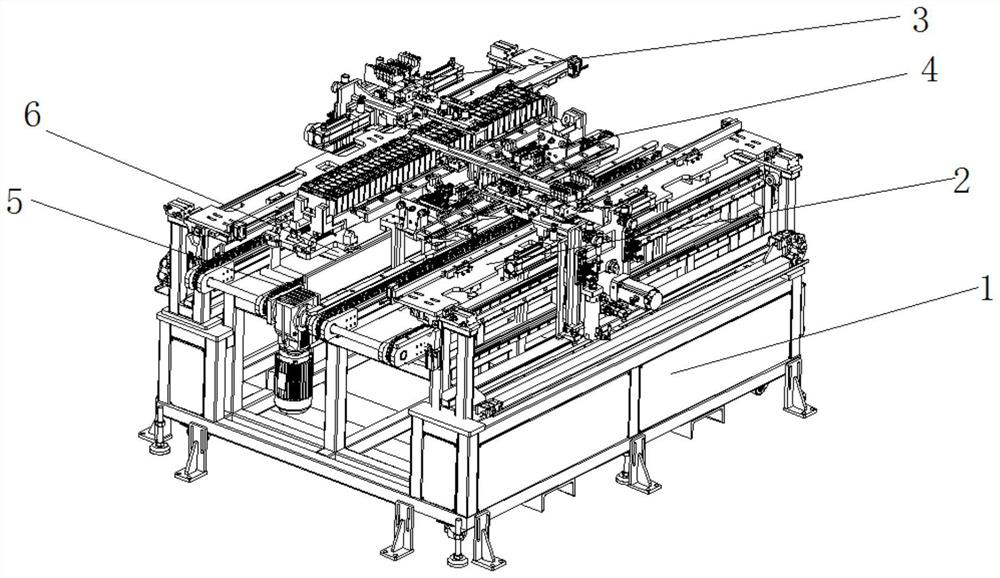

[0039] refer to figure 1 Shown, a kind of self-adaptive center stacking equipment of the present invention comprises:

[0040] Machine platform 1, is provided with on described machine platform 1:

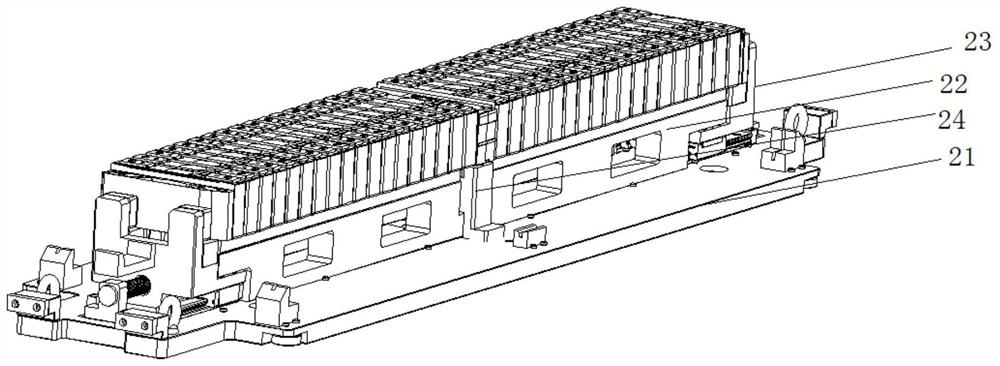

[0041] Stacking tray 2 for placing batteries;

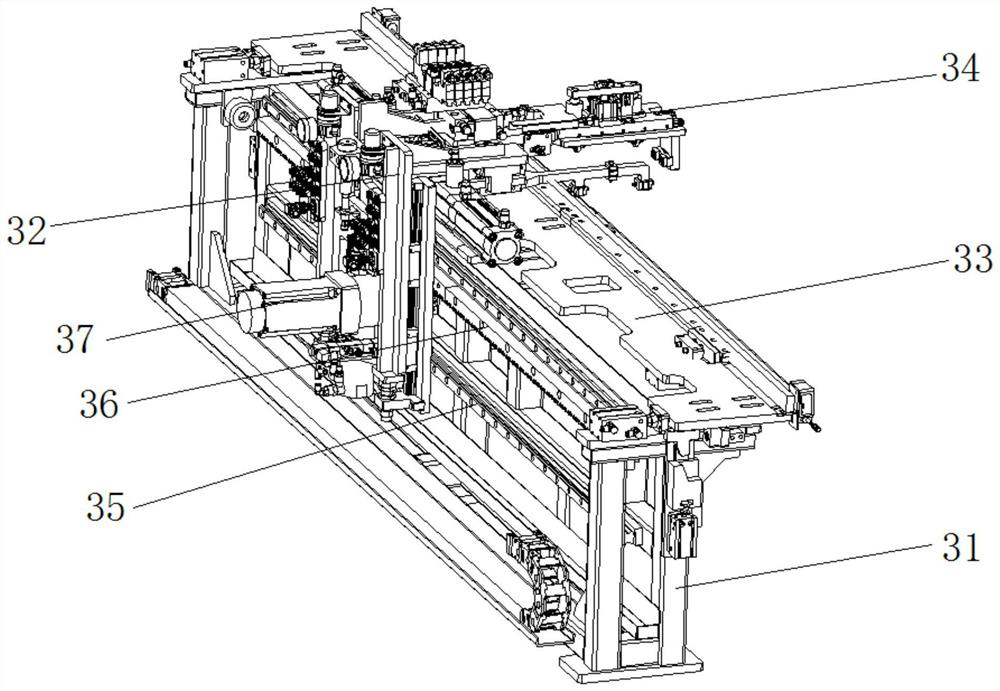

[0042]The self-adaptive reference stacking mechanism 3 is arranged on one side of the stacking tray 2. According to the placement position of the stacking tray 2, the stacking reference plane 333 for stacking the power supply cores is formed, and the batteries are abutted against the stacking reference plane 333 and the stacking tray 2. stacking a plurality of electric cores side by side along the stacking reference plane 333 and the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com