A welding and forging composite process and device for surface remanufacturing of metallurgical roller table

A composite device and composite process technology, which is applied in the direction of manufacturing tools, metal rolling, metal rolling, etc., can solve the problems of coarse structure in the weld bead superposition area, precipitation of weld bead traces, and uneven composition, so as to reduce the amount of processing, Improve crack resistance and counteract shrinkage deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

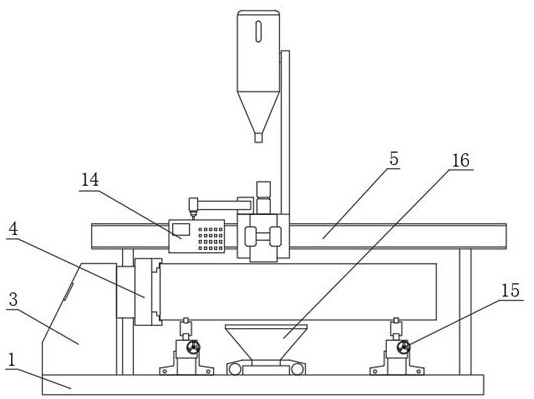

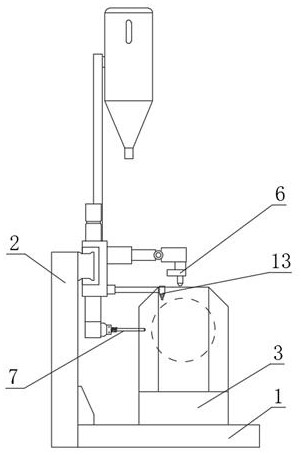

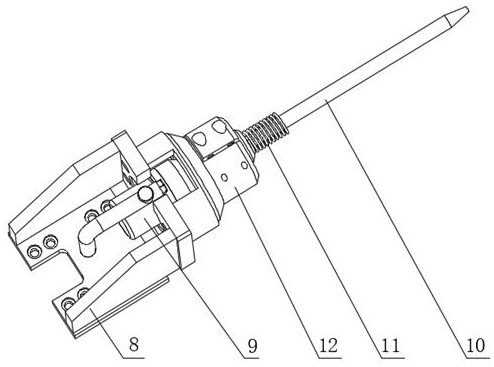

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0032] A welding and forging composite process for remanufacturing the surface of a metallurgical roller table in this specific embodiment includes the following steps:

[0033] 1) The roller table is pre-treated first, and then the multi-material arc additive welding is performed on the roller table;

[0034] 2) When the weld bead formed by welding is cooled to the preset temperature, the forging device starts to work to forge the weld bead area cooled to the preset temperature;

[0035] 3) Finally, the repaired roller table is subjected to post-weld treatment and finishing, that is, the surface of the roller table is remanufactured.

[0036] In this scheme, by intervening a low-frequency follow-up forging device at a reasonable temperature of the weld bead to forge the weld bead, the coarse grain structure caused by staying in the high temperature region f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com