Piece sorting machine

A technology of inspection and cutting, which is applied in metal processing and other directions, can solve the problems of increasing the cost of the processor, time-consuming process, and unsmooth copper foil substrate processing procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

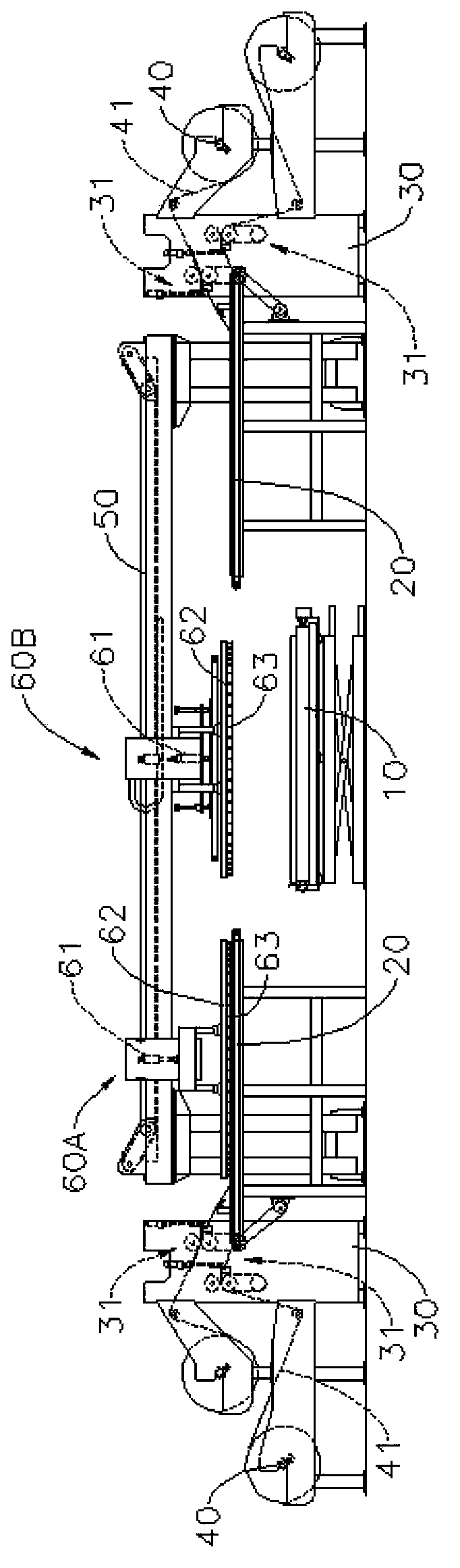

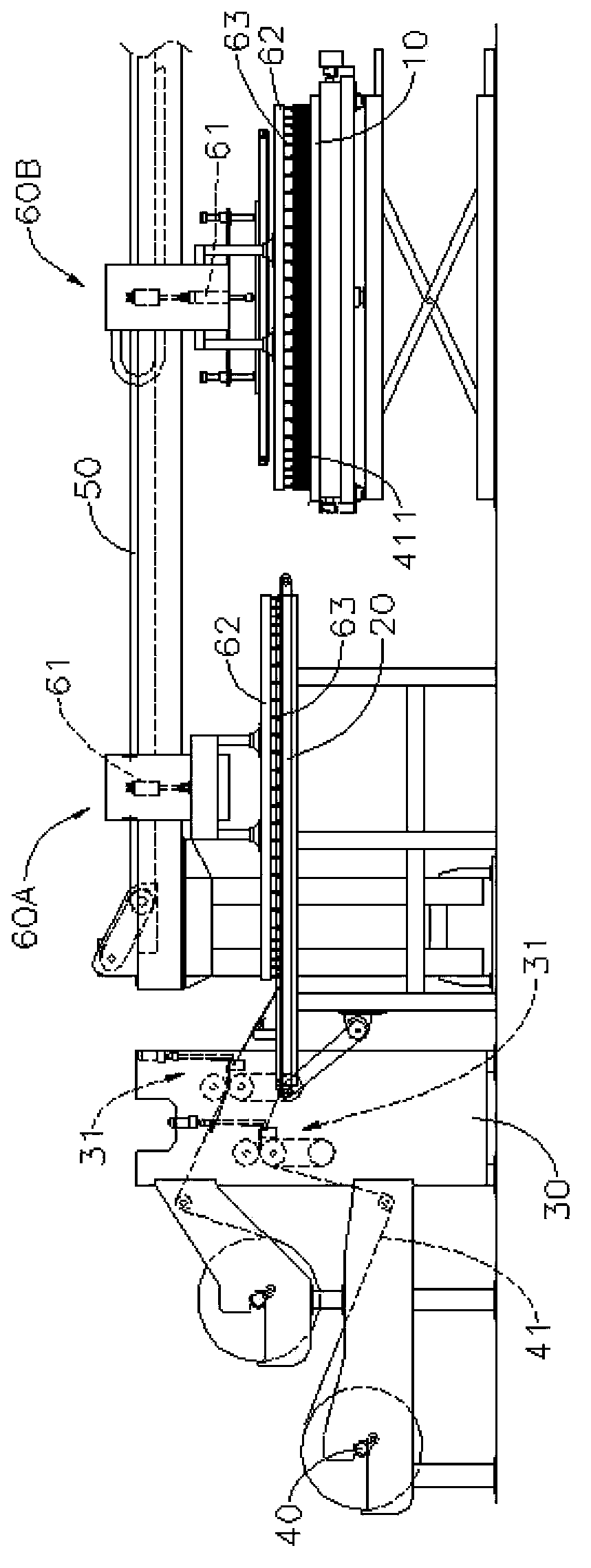

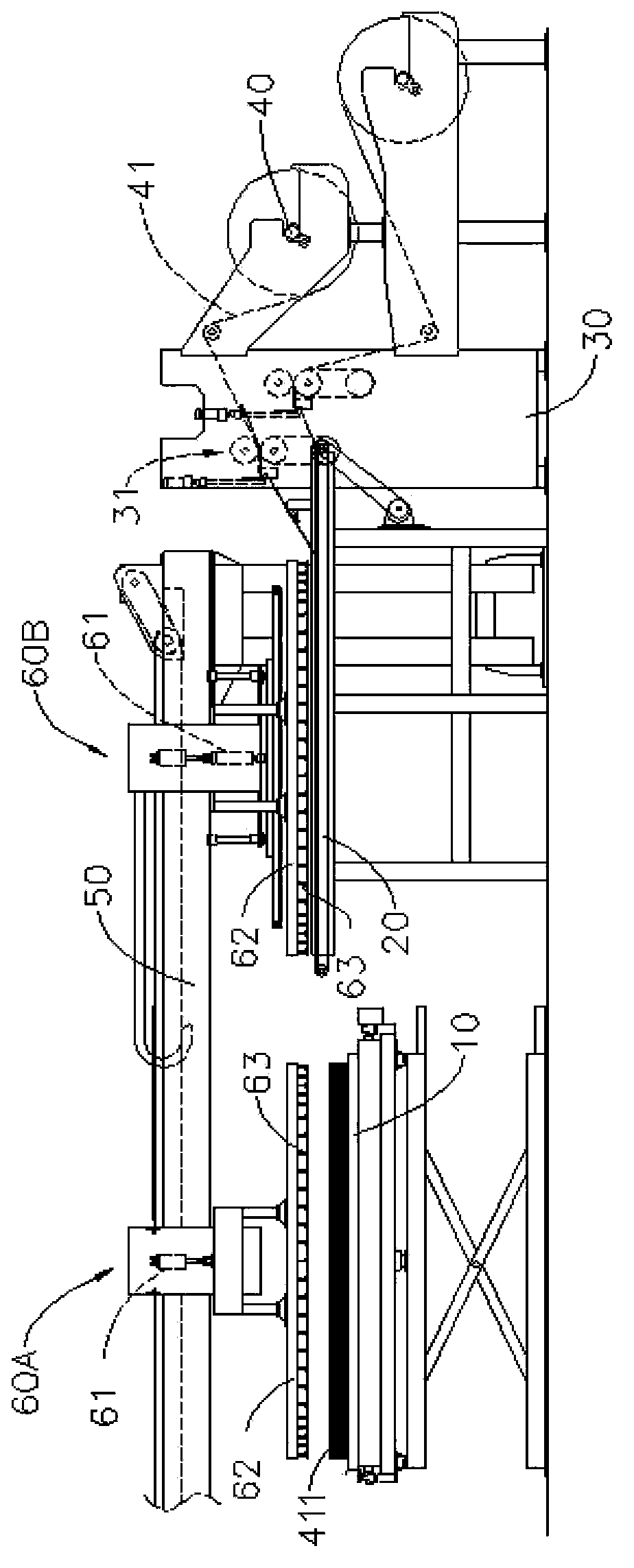

[0026] Embodiment: A film inspection machine, including a stacking platform 10, a feeding table 20, a cutting device 30, a feeding shaft 40, a guide rail 50, and first and second material moving devices 60A and 60B, and the two feeding tables 20 are respectively Located on two opposite sides of the stacking platform 10, two cutting devices 30 are respectively arranged on the outer sides of the two discharging platforms 20 facing away from the stacking platform, and each cutting device 30 is provided with at least one cutting assembly 31 , at least two discharge shafts 40 are respectively located on the outside of the two cutting devices 30 facing away from the discharge platform, that is, at least one discharge shaft 40 is provided on the outside of each cutting device 30, and each discharge shaft 40 There is a long sheet 41 to be cut, which can be a thin sheet of aluminum foil, glass fiber cloth, copper foil, optical film, etc., and the long sheet 41 is connected to the corres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com