Plate stacking device for bagged materials

A technology for stacking boards and materials, which is applied in the field of material bag coding board devices, can solve the problems of artificial physical strength and inapplicability, and achieve the effects of improving stacking quality, improving work efficiency, and ensuring storage quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

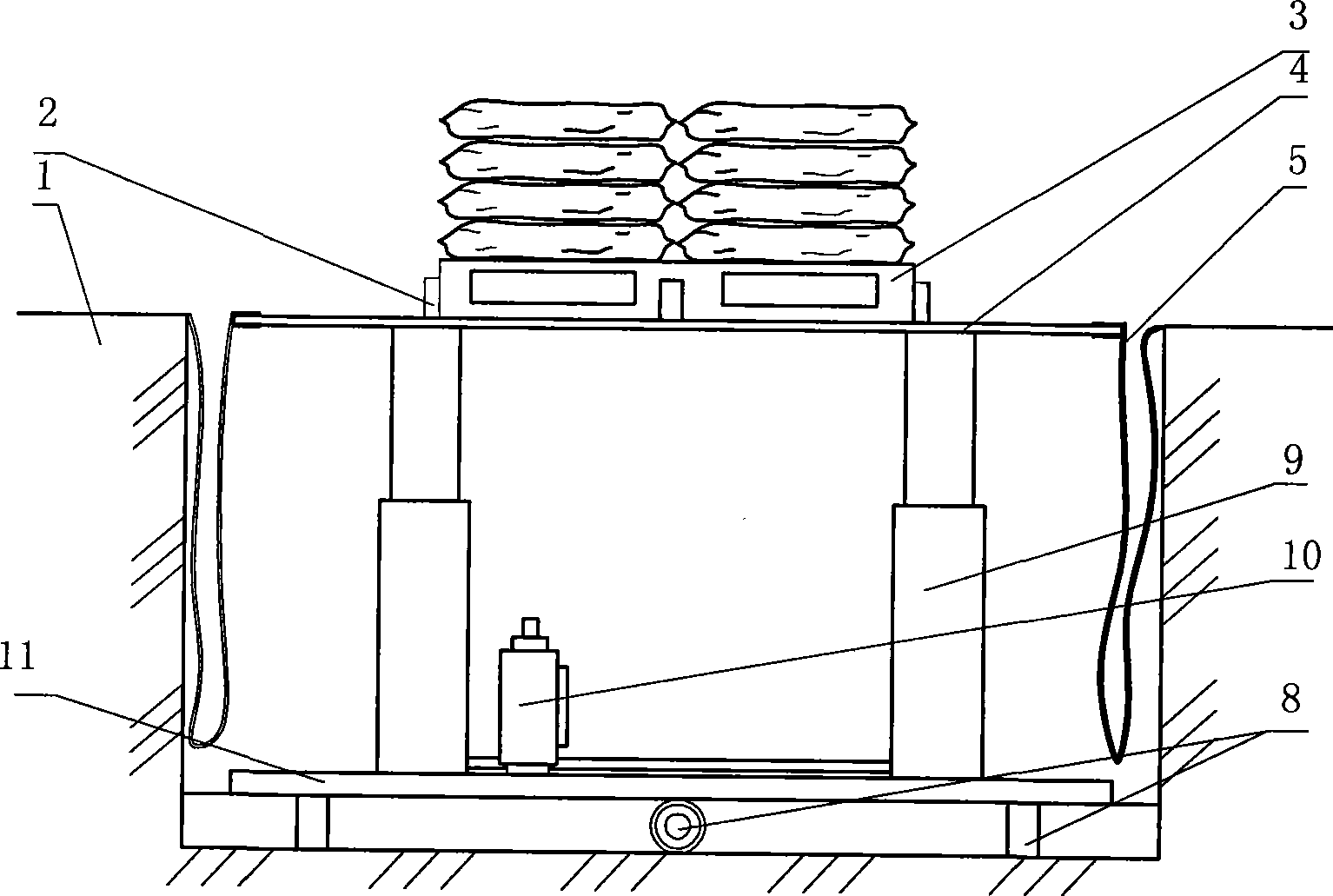

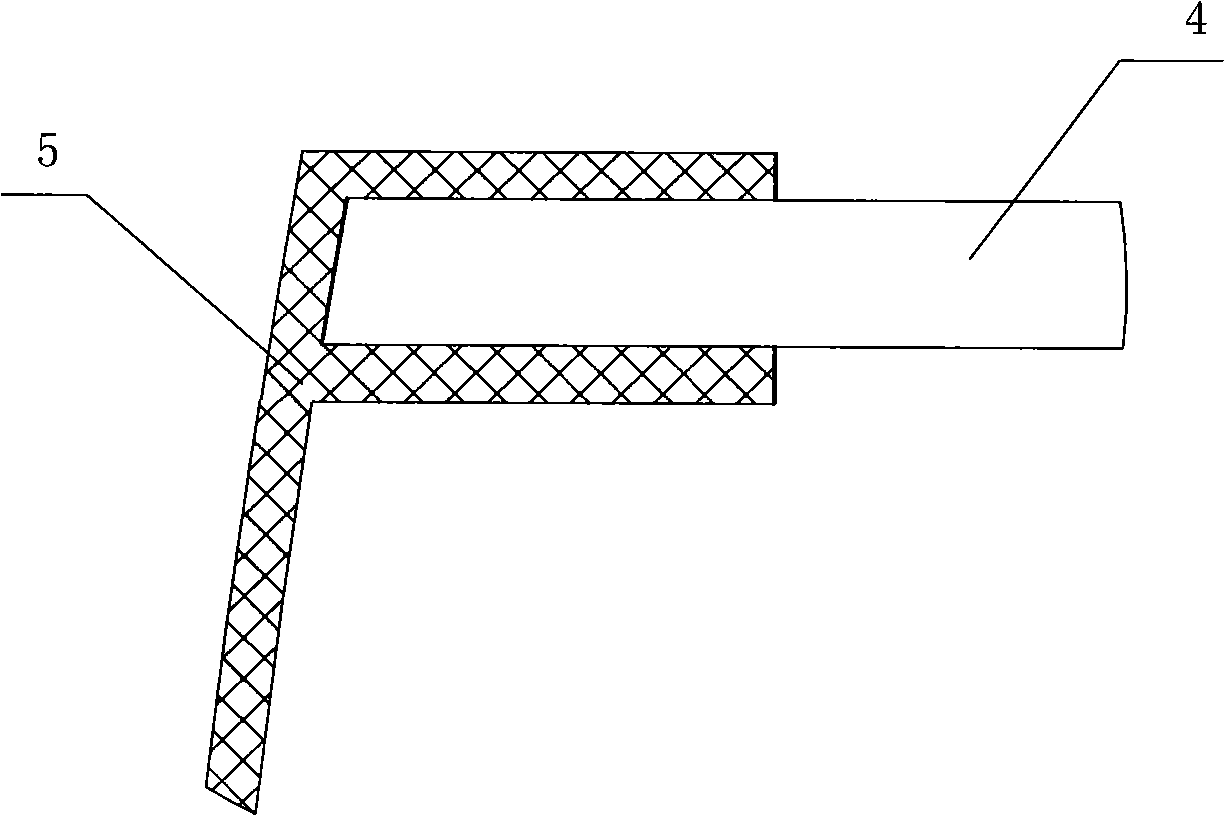

[0026] Refer to attached figure 2 , a bagged material palletizing device, comprising a ground 1 and a cushion plate 4, a round pit is set up on the ground 1, a rotary table 11 is arranged at the bottom of the round pit, and a lifting mechanism is arranged on the rotary table 11. A code plate platform 4 matching the diameter of the round pit is placed on the top of the mechanism, and the lifting mechanism is a vertical hydraulic cylinder 9 driven by a hydraulic oil pump 11 . The bottom of the turntable 9 is provided with four concentrically rotating rolling bearings 8 . Set soft skin 5 on the edge circumference of code plate platform 4 and round pit, the length of soft skin 5 up and down direction is that code plate platform 4 is lowered to the bottom of round pit to code plate platform 4 and rises to the top all can protect, and soft skin 5 and The edge of code board platform 4 is as attached image 3 The horizontal n-shaped slidable clamping shown. On the code board platf...

Embodiment 2

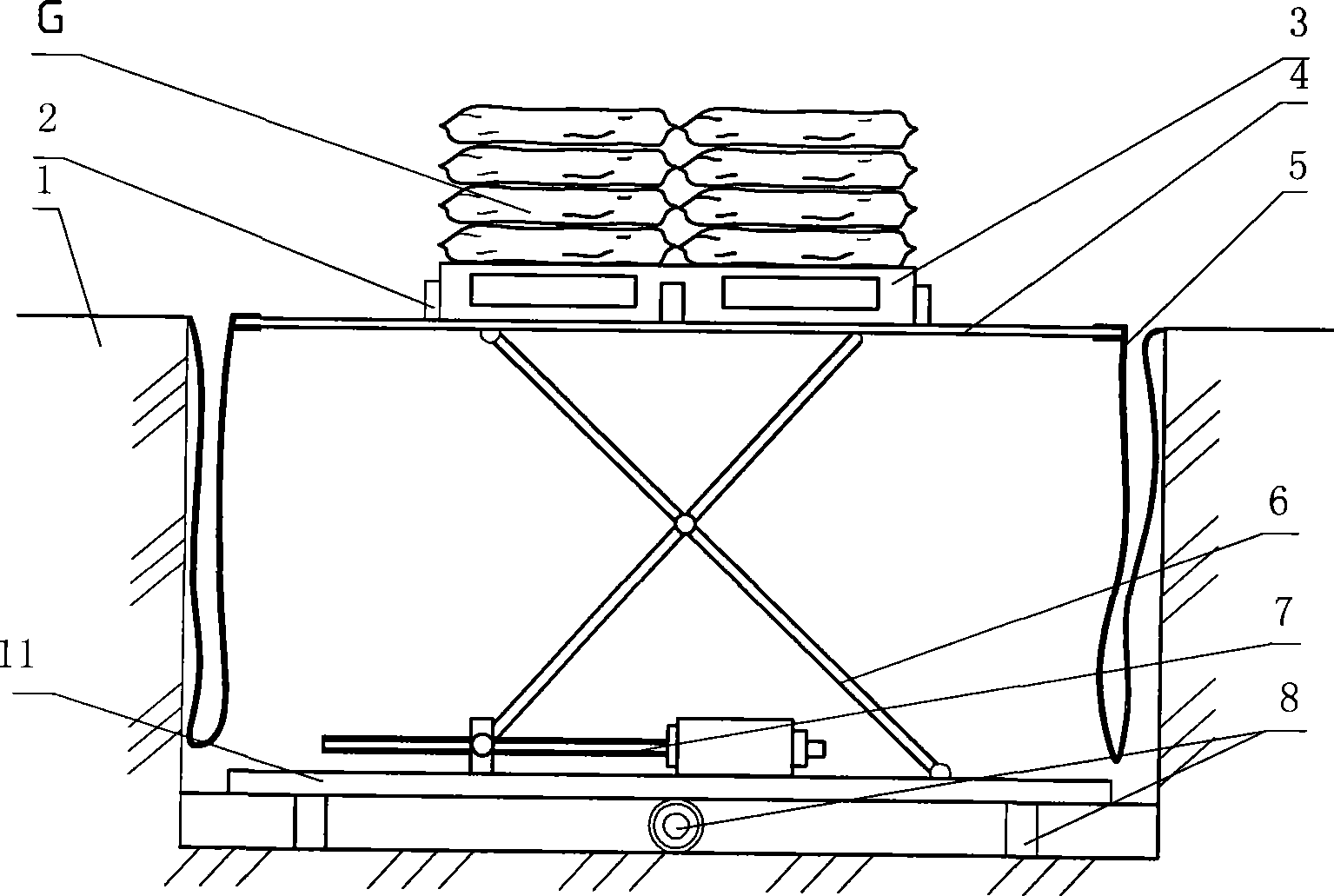

[0028] Refer to attached figure 1 , the lifting mechanism is that the horizontal screw pair 7 is driven by a motor to change the angle between the upper and lower cross brackets, so that the code plate platform 4 rises or falls.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com