Automatic paper-gathering device of roll paper splitting machine

A technology of slitting machine and roll paper, which is applied in the direction of transportation and packaging, sending objects, and thin material processing, etc. It can solve the problems of high stacking processing cost, uneven stacked paper, and low work efficiency, and achieve the goal of reducing stacking. Heaping processing cost, tidy paper arrangement and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

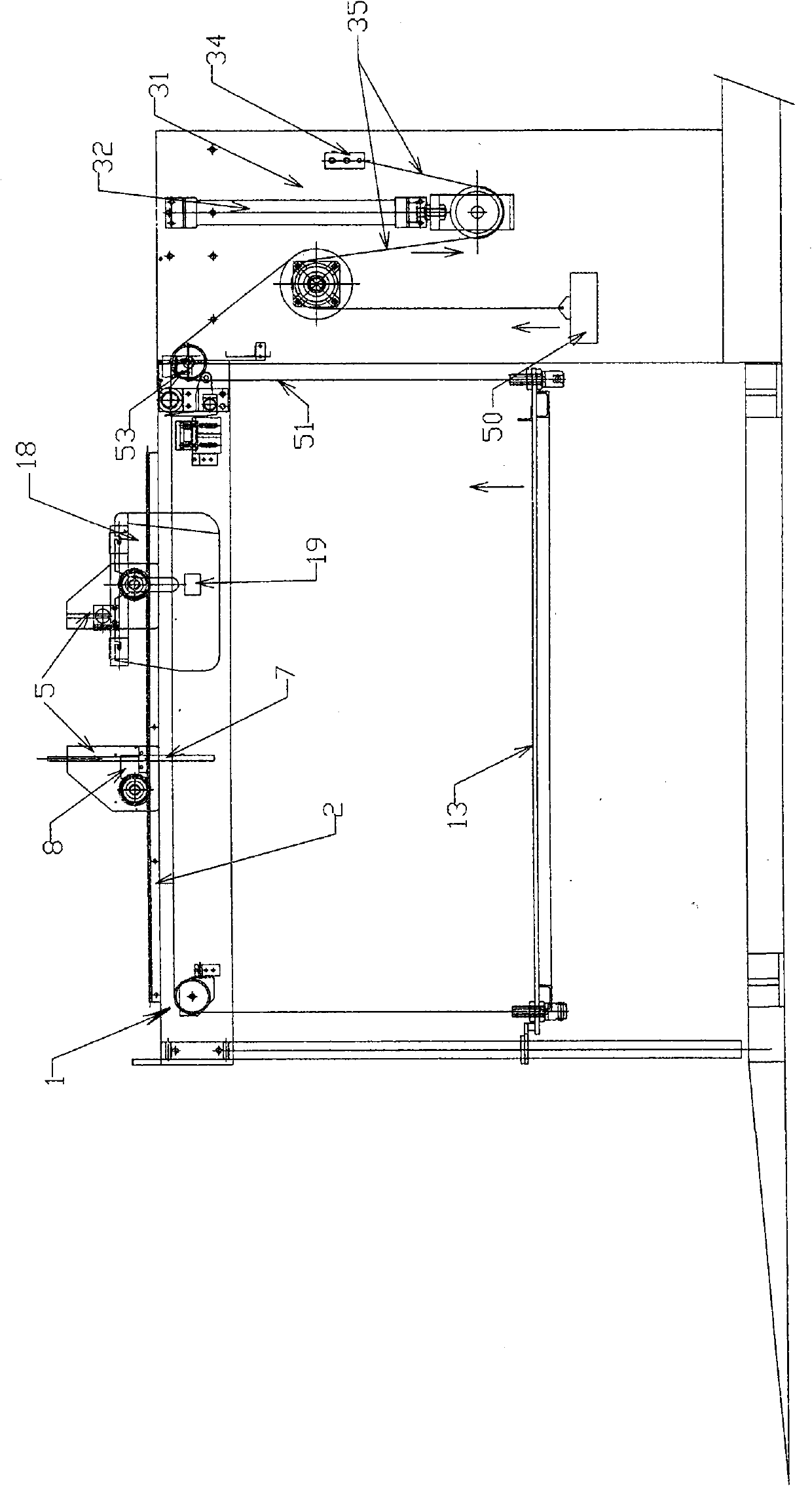

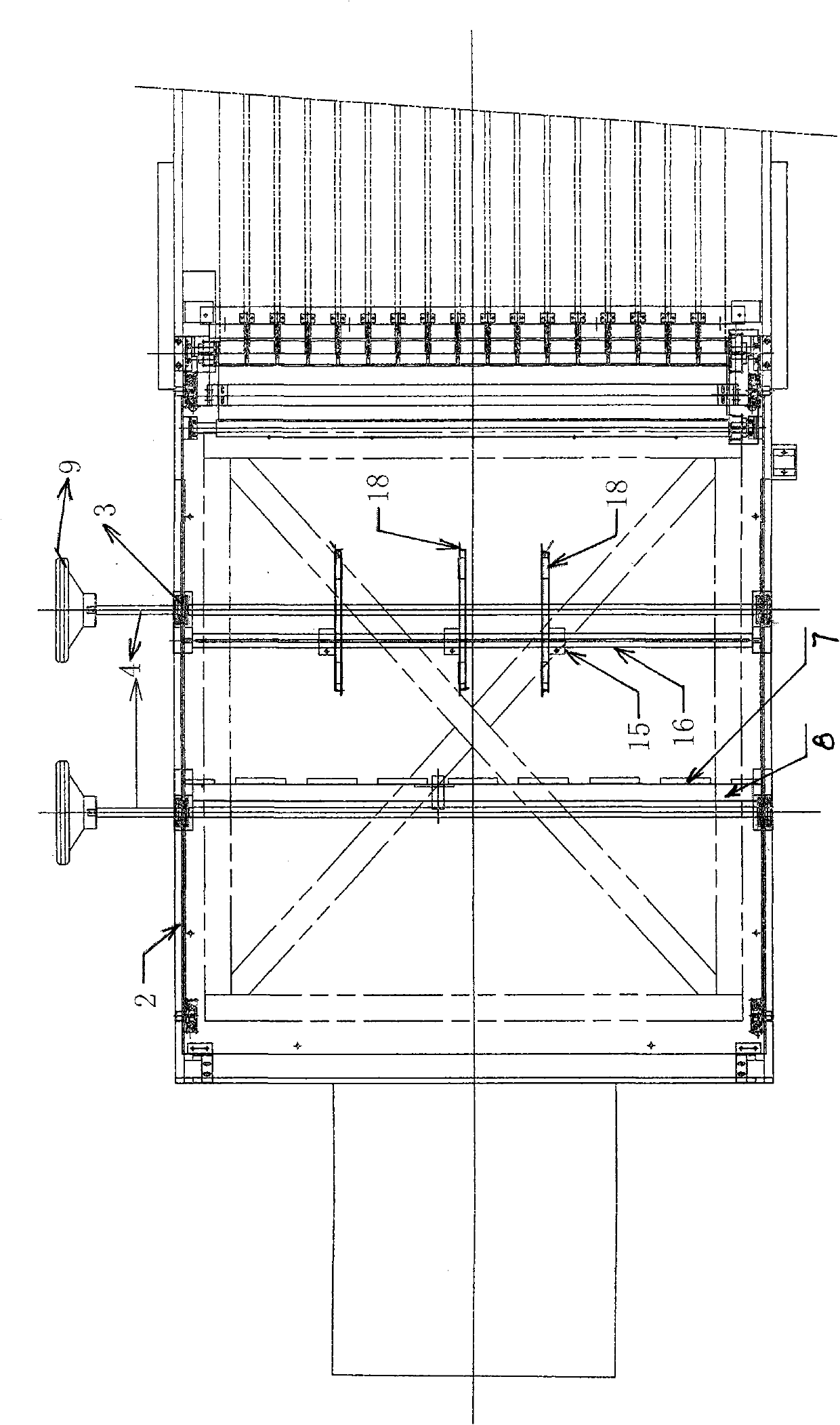

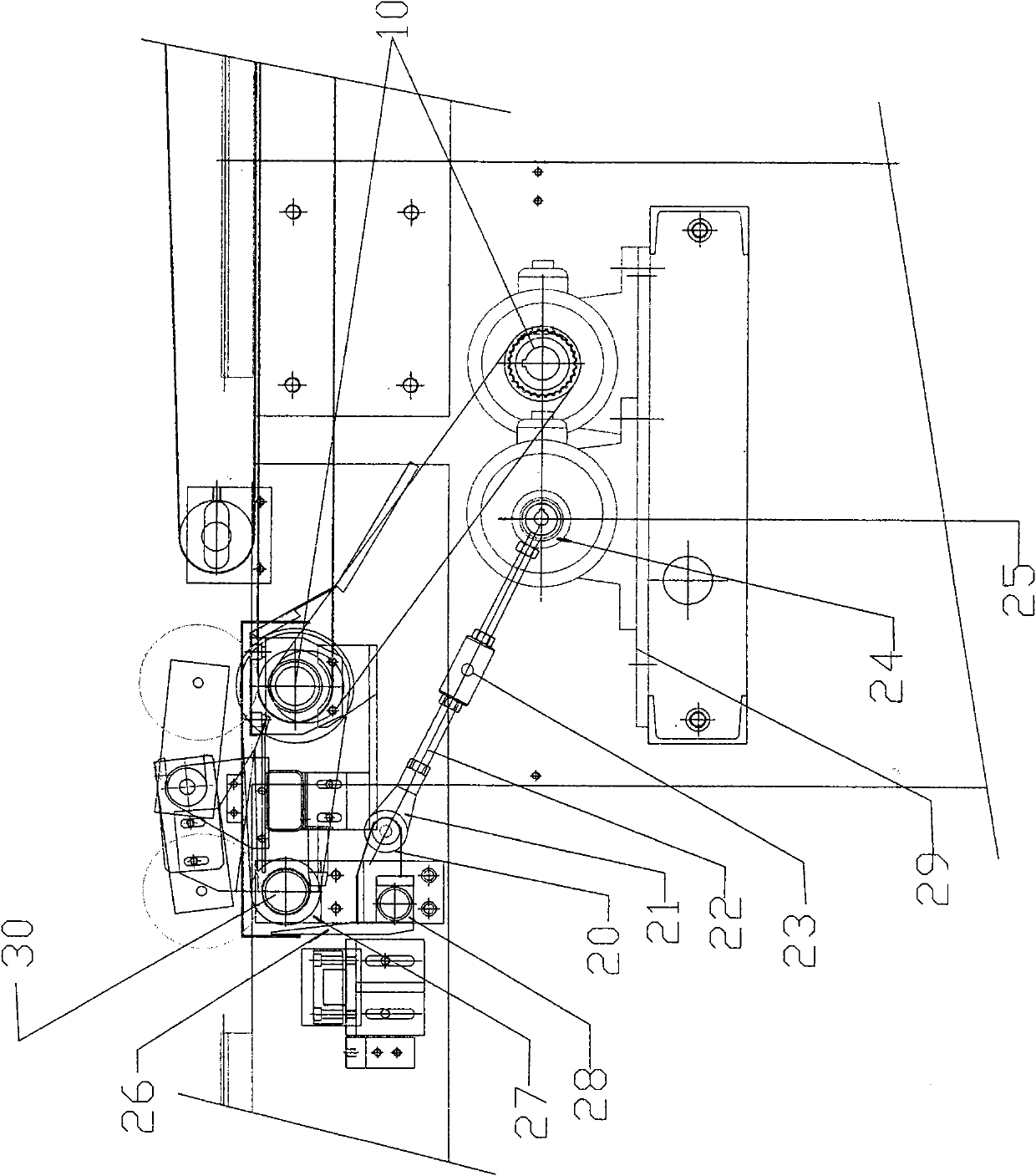

[0012] refer to figure 1 , figure 2 It can be seen that the automatic paper finishing device of the web slitting machine of the present invention includes a frame 1, and a lifting delivery table 13 is installed at the bottom of the frame 1, and the lifting delivery table 13 is connected with the lifting control mechanism; Two sets of cardboard back seats 5 are installed on the top of the frame 1 described above, a horizontal cardboard seat 8 and a horizontal cardboard 7 are installed between one group of cardboard back seats, and a horizontal cardboard seat 7 is installed between the other group of cardboard back seats. There is a paper stopper shaft 16, on the paper stopper shaft 16 (both sides and the middle part) (through the longitudinal paper stopper seat 15) a longitudinal paper stopper 18 (three pieces) is installed, and a vibrator 19 is installed on the longitudinal paper stopper 18 ( for three pieces). On the front end of described frame 1 (being the right side, la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com