Lens unit and method for manufacturing lens unit

A technology of lens unit and manufacturing method, which is applied in the direction of electrical components, optical components, installation, etc., and can solve the problems of high cost, high mechanical strength, and low mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Hereinafter, embodiments of the present invention will be described in detail using the drawings.

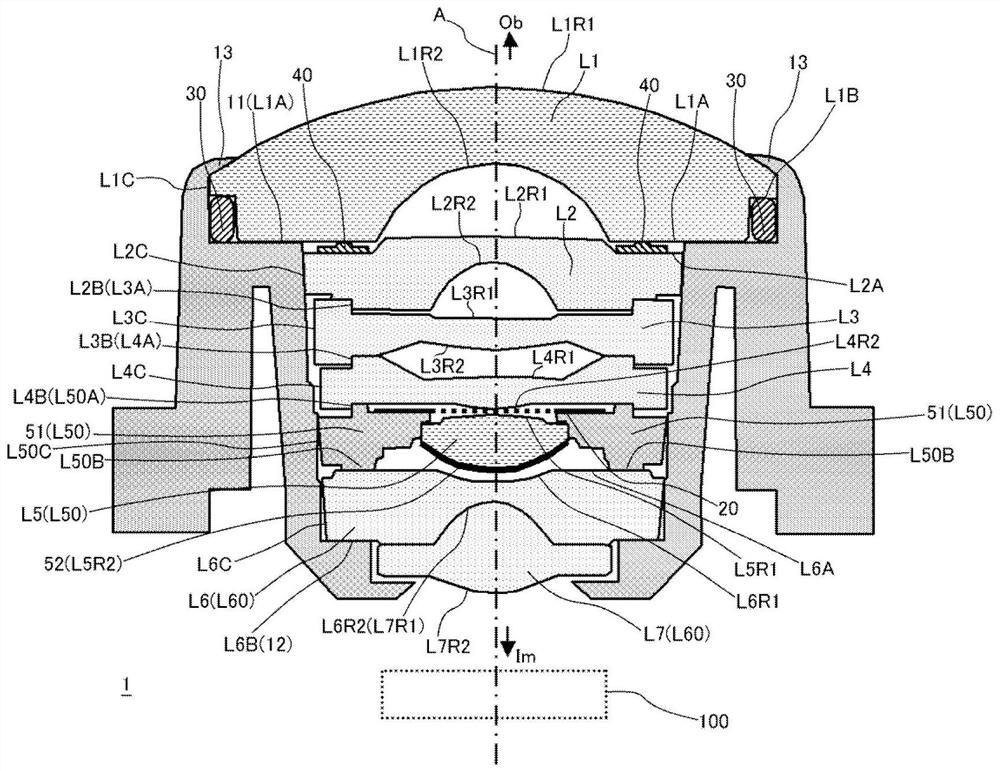

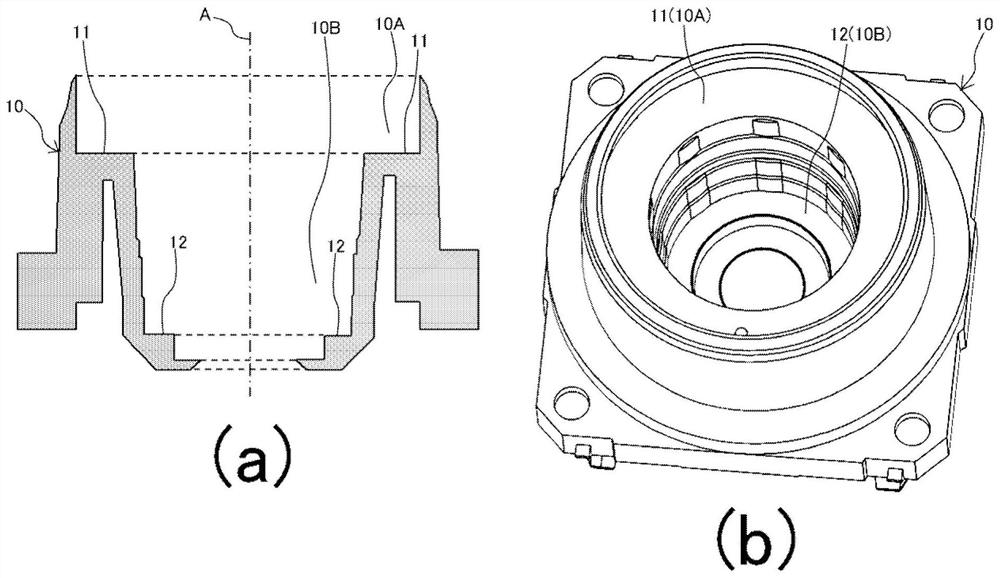

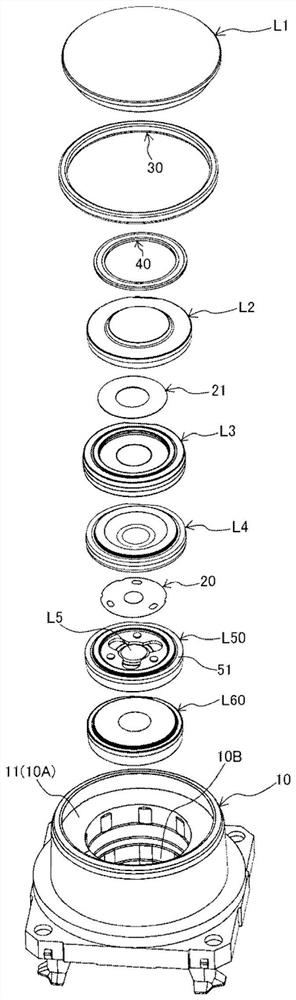

[0042] figure 1 It is a sectional view along the optical axis A of the lens unit 1 according to this embodiment. Here, the object (Ob) side is the upper side in the figure, the image (Im) side is the lower side in the figure, and the imaging element 100 is located at the bottom in the figure. The lenses L1 to L7 are respectively fixed directly or indirectly on the lens barrel 10 . exist figure 1 In the description, it is mainly described that each lens, the diaphragm 20, or the structure for fixing each lens and the lens barrel 10, but actually also has a structure for fixing the positional relationship between the imaging element 100 and the lens barrel 10, but it is omitted. recorded.

[0043] The imaging element 100 is a two-dimensional CMOS image sensor, and pixels are arranged two-dimensionally in a plane perpendicular to the optical axis A. Actually, the imaging...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com