Surface treatment device and manufacture method of lower electrode assembly body of the device

A surface treatment device and assembly technology, which is applied in semiconductor/solid-state device manufacturing, circuits, discharge tubes, etc., can solve problems such as inability to release, damage, and drop, and achieve the effects of easy maintenance, easy manufacturing, and damage prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

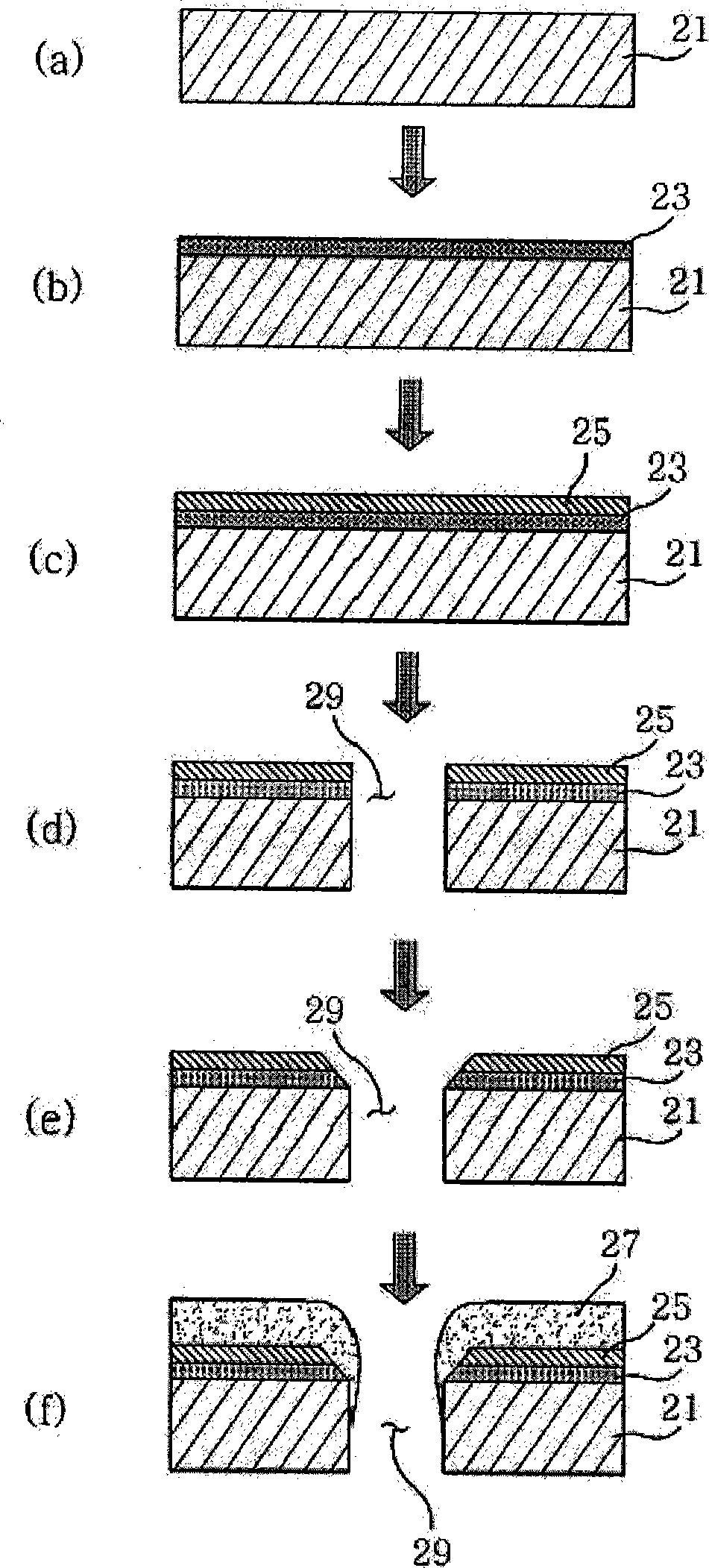

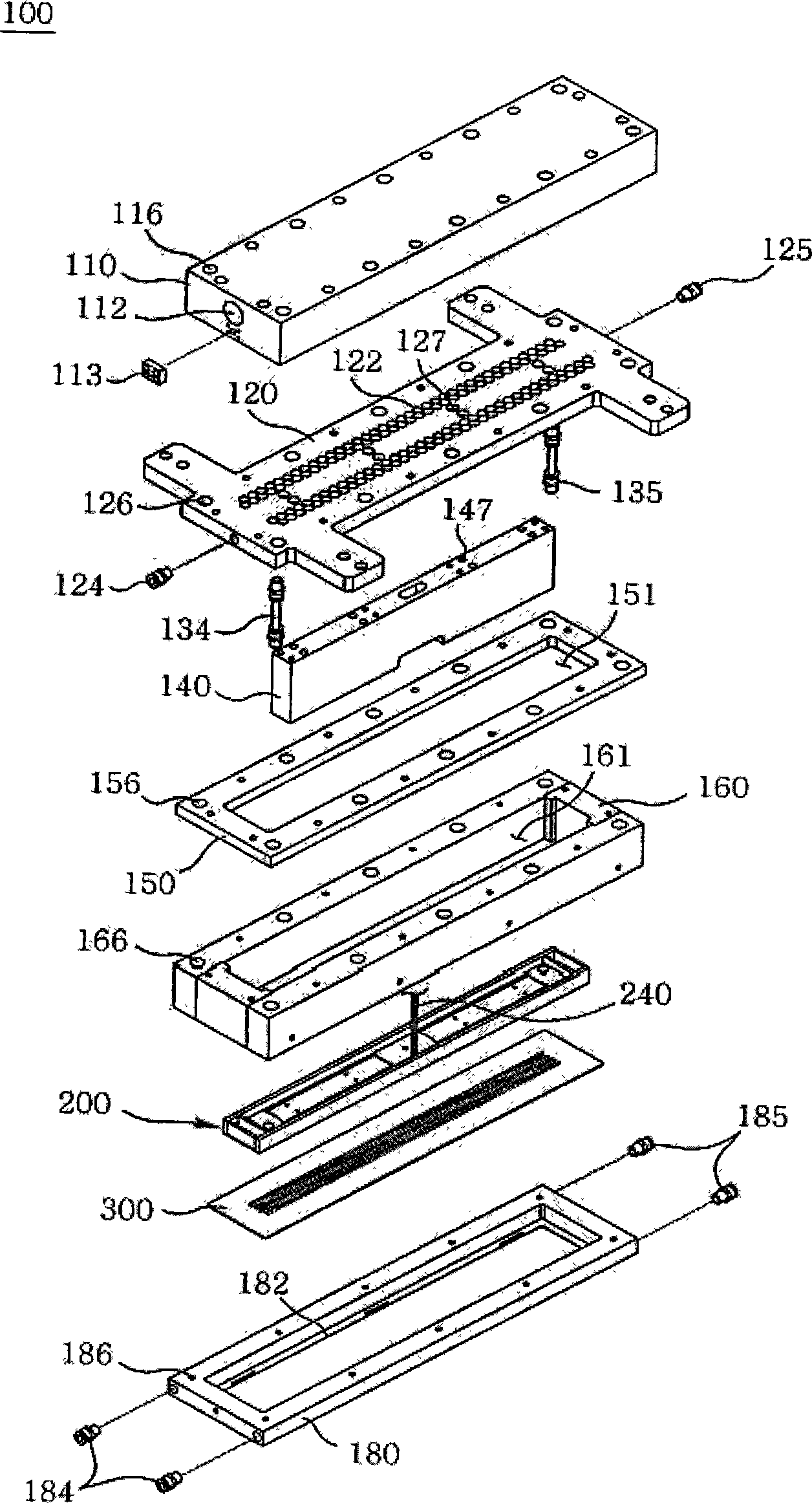

[0046] Preferred embodiments of the surface treatment apparatus using atmospheric pressure plasma and the method of manufacturing the lower electrode assembly used in the apparatus according to the present invention will be described in detail below with reference to the accompanying drawings. image 3 is an exploded perspective view of the surface treatment device utilizing atmospheric pressure plasma of the present invention; Figure 4 is a perspective view of the surface treatment device utilizing atmospheric pressure plasma of the present invention; Figure 8 yes Figure 4 The I-I' line cut perspective view; Figure 9 yes Figure 8 Partial front view of ;

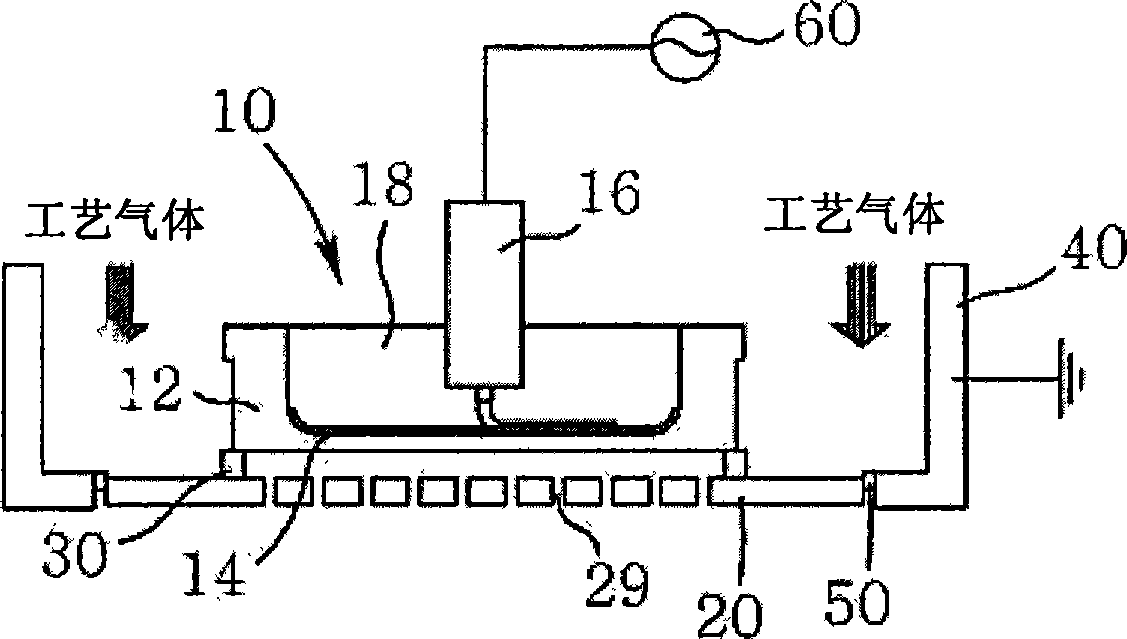

[0047] First, refer to image 3 , Figure 4 , Figure 8 and Figure 9 The surface treatment apparatus using atmospheric pressure plasma of the present invention will be described. The above-mentioned surface treatment apparatus 100 has a gas chamber 110 for storing gas supplied from a gas supply unit (not shown)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com