Deduster

A technology for dust collectors and housings, applied in chemical instruments and methods, separation of dispersed particles, and use of liquid separation agents, etc., can solve the problems of inability to freely adjust the gas throughput of dust collectors, increased pressure loss, and inconspicuous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

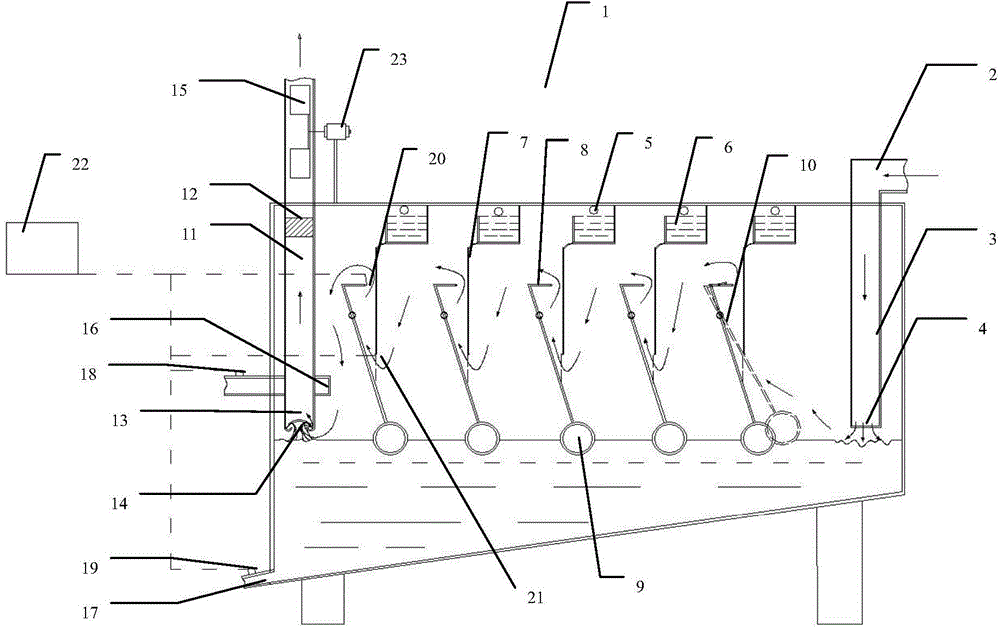

[0017] The present invention will be further described below in conjunction with accompanying drawing:

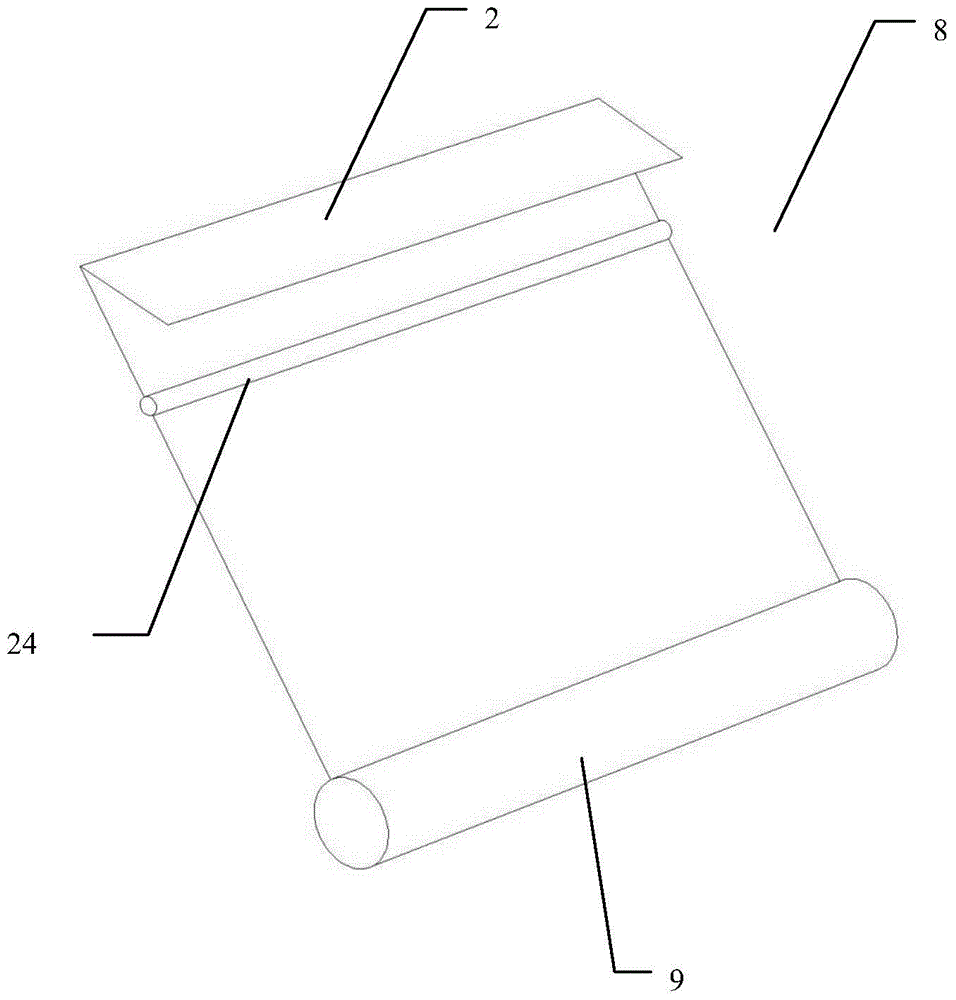

[0018] Such as figure 1 As shown, the dust collector of the present invention includes a housing 1, an air inlet pipe 3, an air outlet pipe 11, an overflow tank 6, an overflow plate 7, a liquid replenishment pipe 5, a rotating partition 8, a buoy 9, a rotating beam 10, and a liquid inlet pipe 16. Liquid outlet pipe 17, liquid inlet pipe control valve 18, liquid outlet pipe control valve 19, rotating partition contact 20, overflow plate contact 21, demister 12, fan blade 15, motor 23, controller 22 . Wherein the air intake pipe 3 enters from the upper end of the housing 1 side, the air intake pipe 3 extends downwards, the air intake pipe outlet 4 at the lower end of the air intake pipe 3 is close to the water surface, and a plurality of overflow grooves 6 are arranged on the top of the housing, and a plurality of overflow grooves 6 are arranged side by side, the overflow t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com