Horizontal bobbin case of sewing machine

A technology for horizontal shuttles and sewing machines, which is applied to sewing machine components, sewing machine ring mechanisms, sewing equipment, etc., and can solve problems such as inconvenient, difficult to adjust precision, and bending deformation of the needle retainer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] An embodiment of the present invention will be described with reference to FIGS. 1 to 6 . In addition, because the basic structure of the horizontal bobbin case of the sewing machine of this embodiment and Figure 11 is the same as the conventional example described in the above-mentioned Figure 8- Figure 11 The same parts as those described in are denoted by the same symbols, and explanations are omitted.

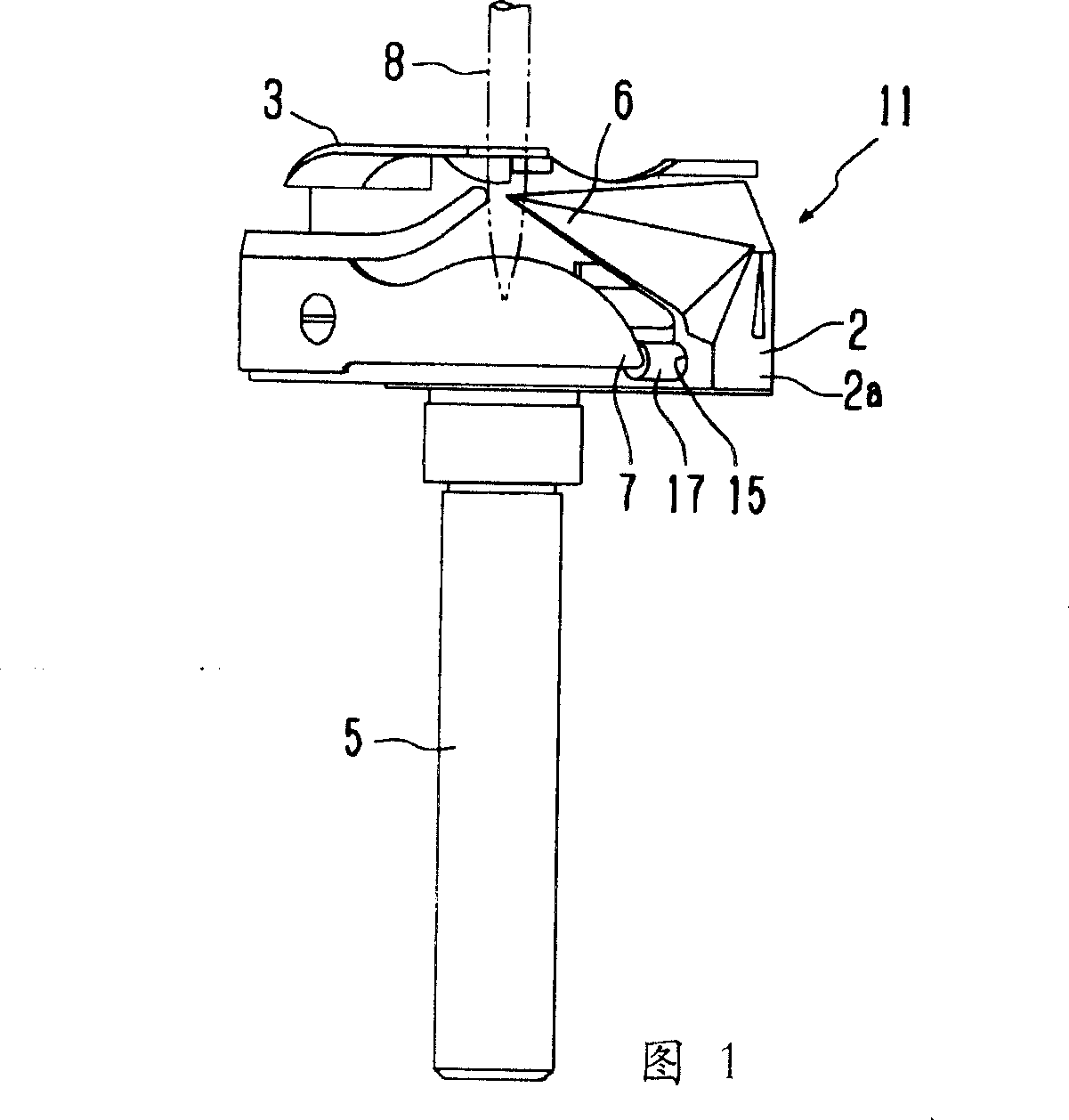

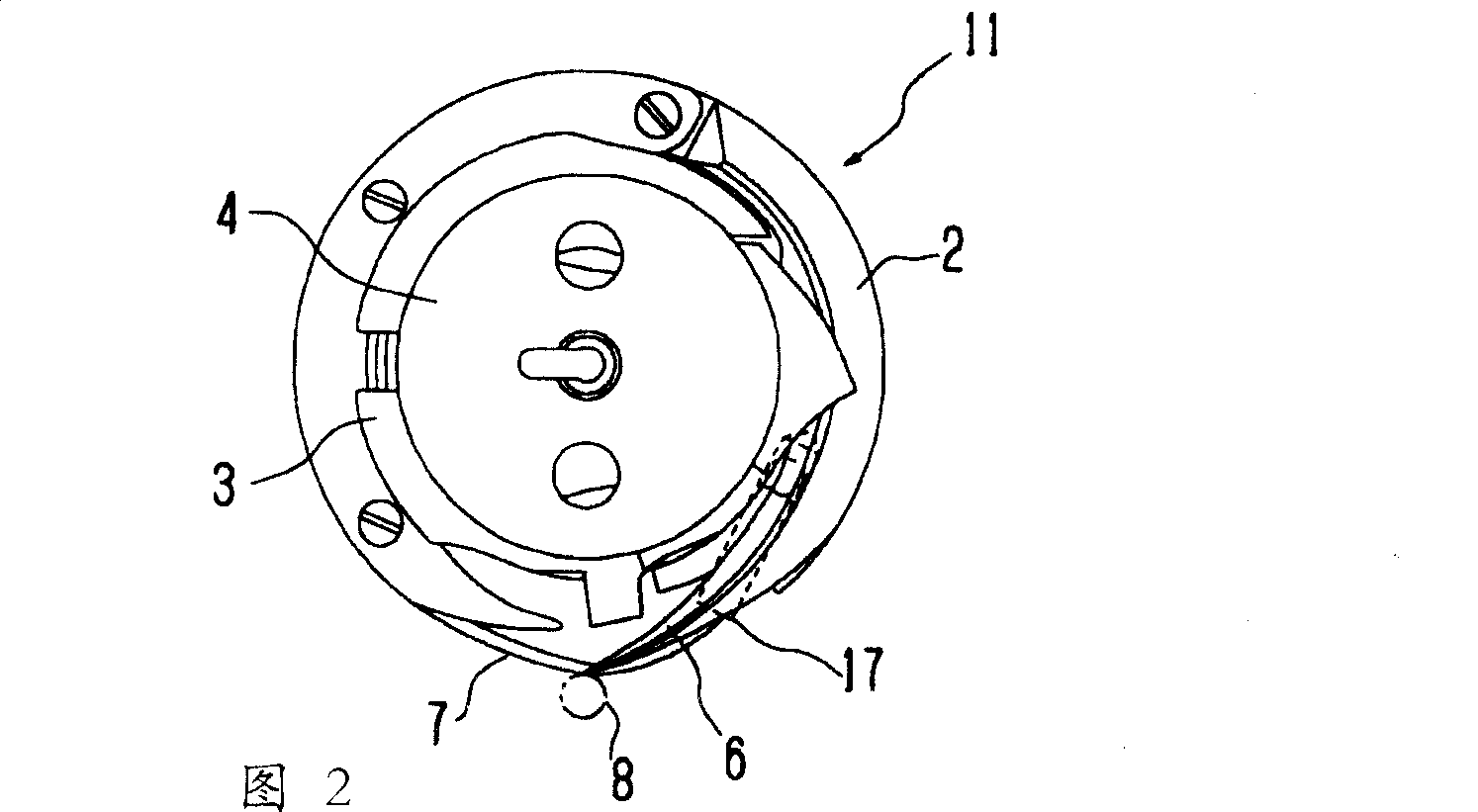

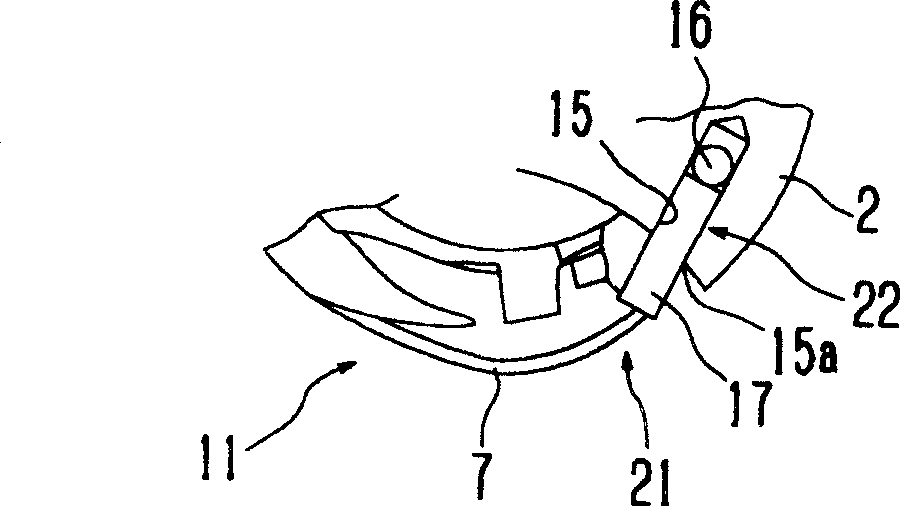

[0036] Fig. 1 is a front view showing a horizontal bobbin case of a sewing machine according to this embodiment, and Fig. 2 is a plan view thereof. A horizontal bobbin case 11 of a sewing machine according to an embodiment of the present invention has an outer case 2 and an inner case 3 , etc., and the inner case 3 is accommodated in an inner case receiving portion 12 formed inside the outer case 2 . Inside the inner casing 3, the bobbin 4 on which the lower thread is wound is accommodated.

[0037] An annular rail groove 13 is formed on the inner peripheral surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com