Interval batch liquid adding device

A liquid-feeding device and batch-based technology, applied in feeding devices, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as increasing workload, reducing work efficiency, and large errors in time and quantity. Achieve the effect of reducing human error and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following description serves to disclose the invention to enable those skilled in the art to practice the invention. The preferred embodiments described below are given by way of example only, and other obvious modifications will occur to those skilled in the art.

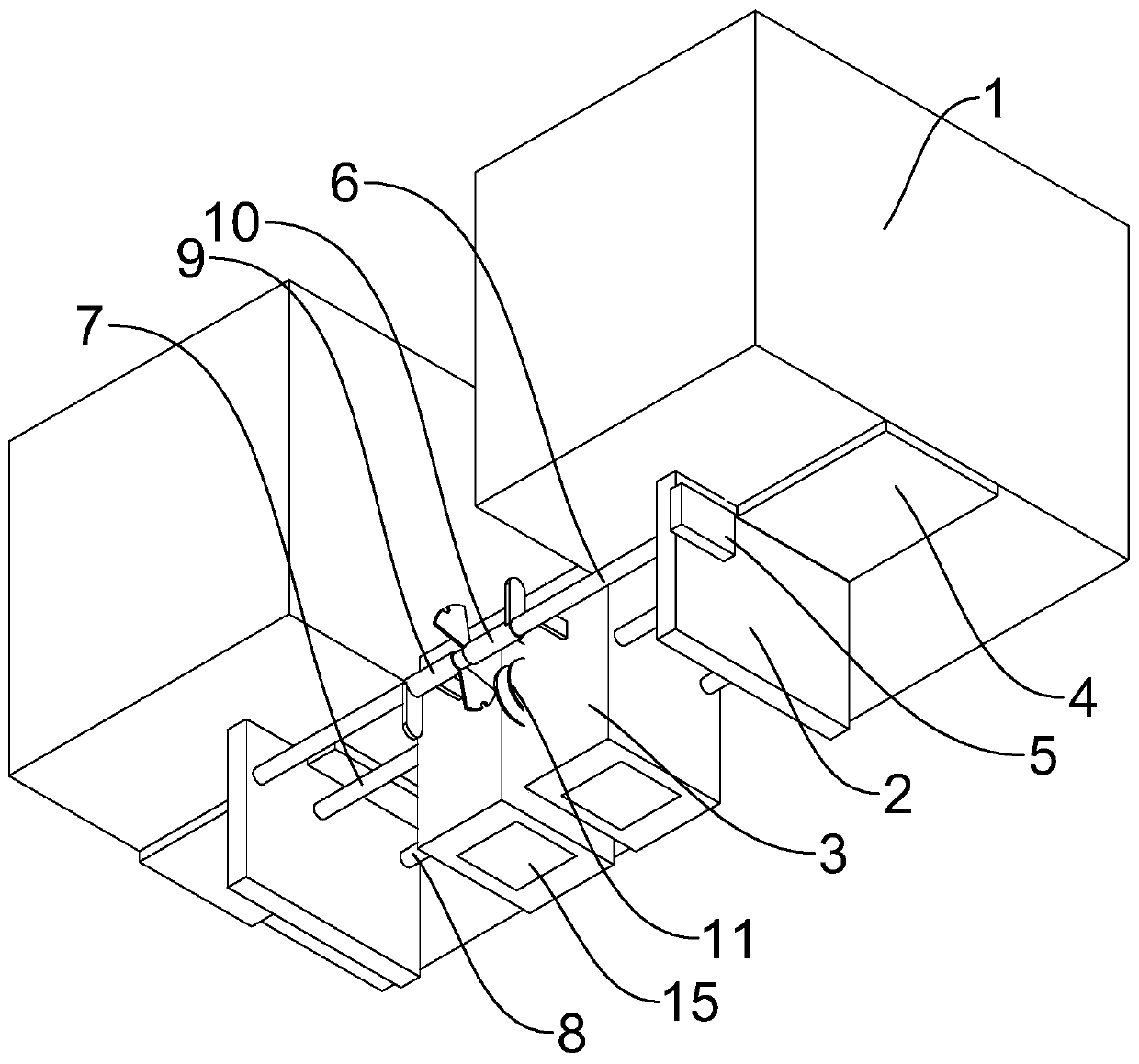

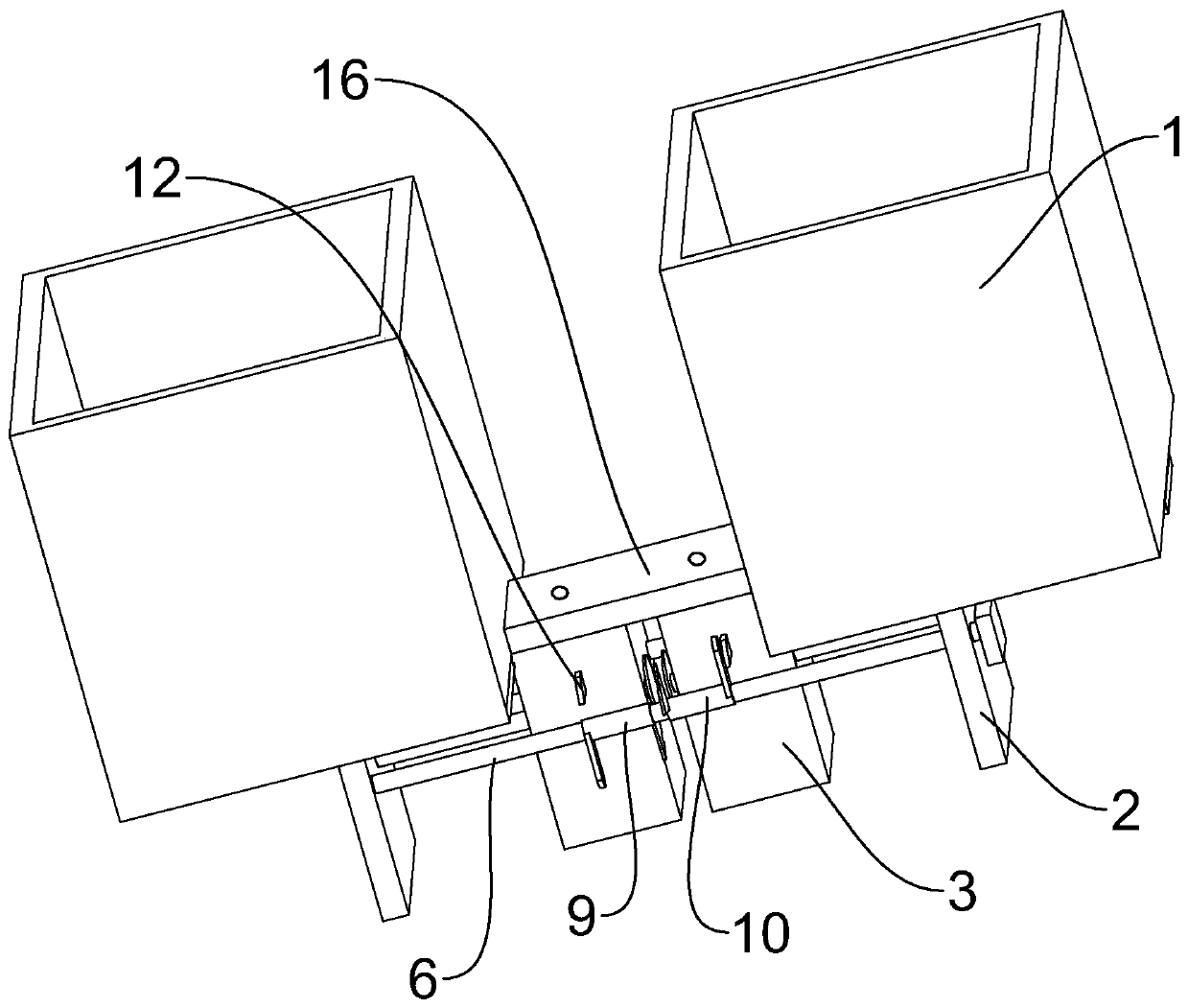

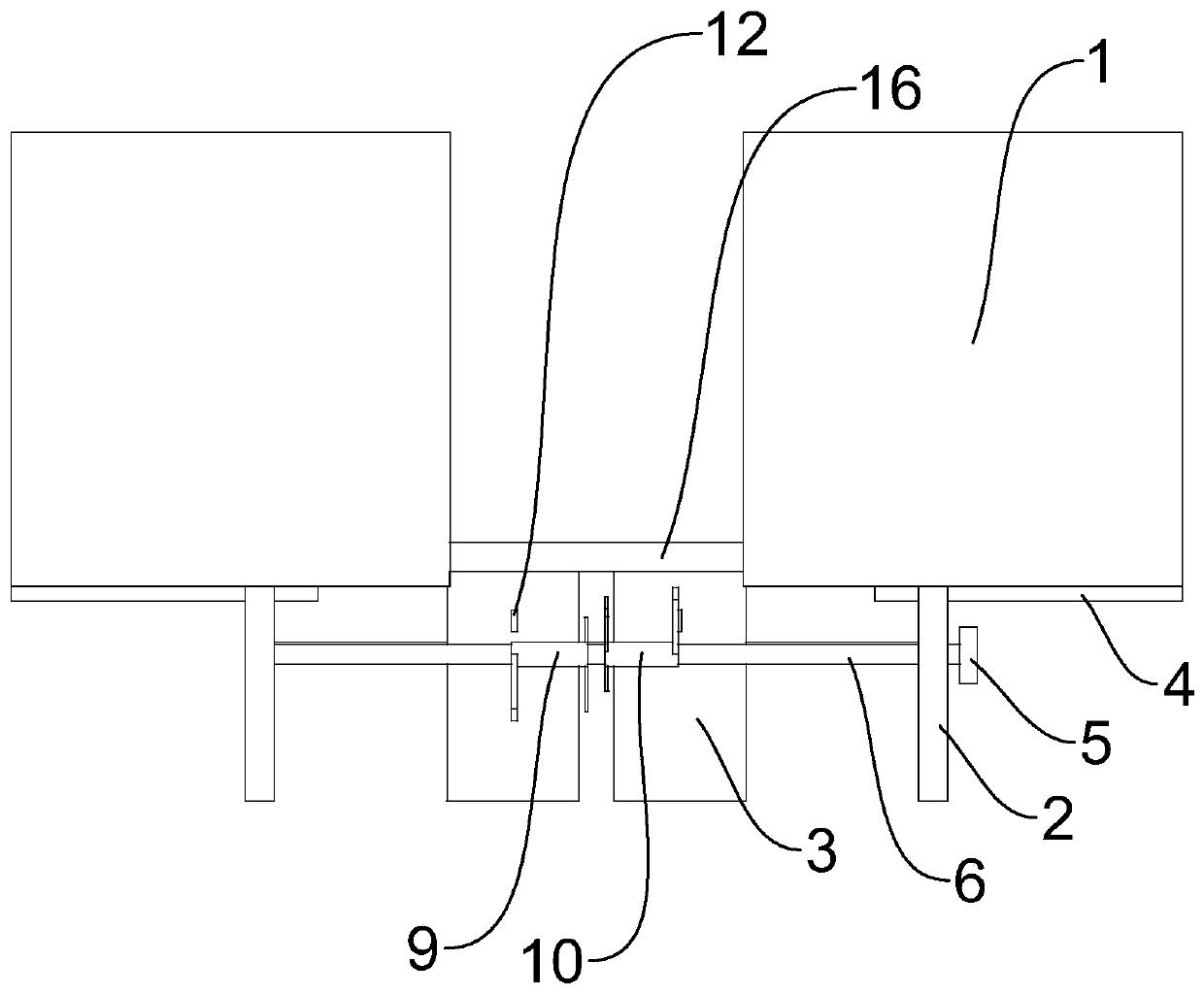

[0021] like Figure 1 to Figure 8 As shown, a liquid adding device in batches at intervals includes a storage box 1 arranged symmetrically on the left and right, a cover plate 16 connecting two storage boxes 1, a fixing block 4 is arranged at the bottom of the storage box 1, the storage box 1, the fixing block 4 The lower end is provided with a stable block 2, a long axis 6 and a limit rod 8 are arranged between the two stable blocks 2 from front to back, and the right end of the right stable block 2 is provided with a stepping motor 5 keyed to the long axis 6, The long shaft 6 is provided with a left rotating member 9 and a right rotating member 10. The lower end of the cover plate 16 is symmetrically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com