Accurate batching commercial concrete mixing production system

A technology of production system and commercial concrete, which is applied in the direction of batching storage, mixing operation control, mixing operation control device, etc., can solve the problems of inaccurate weighing of weighing modules, changing the distribution of stones, etc., to solve the problem of inaccurate weighing accuracy , The effect of improving weighing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

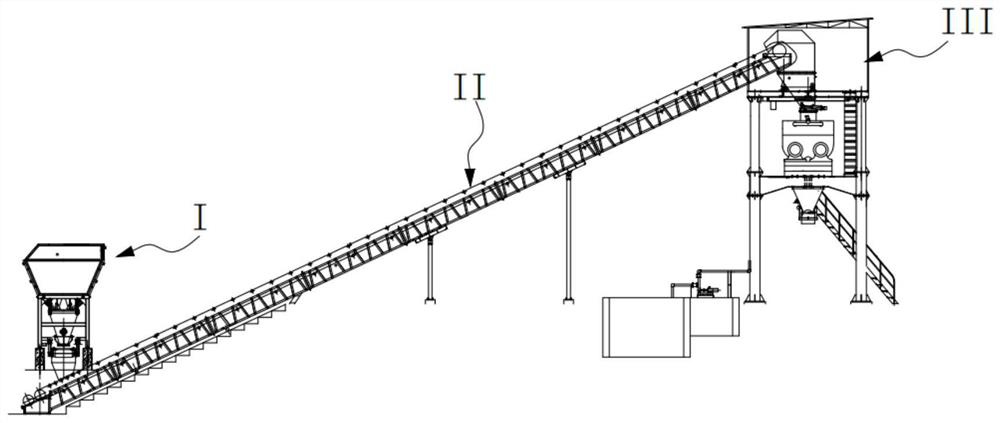

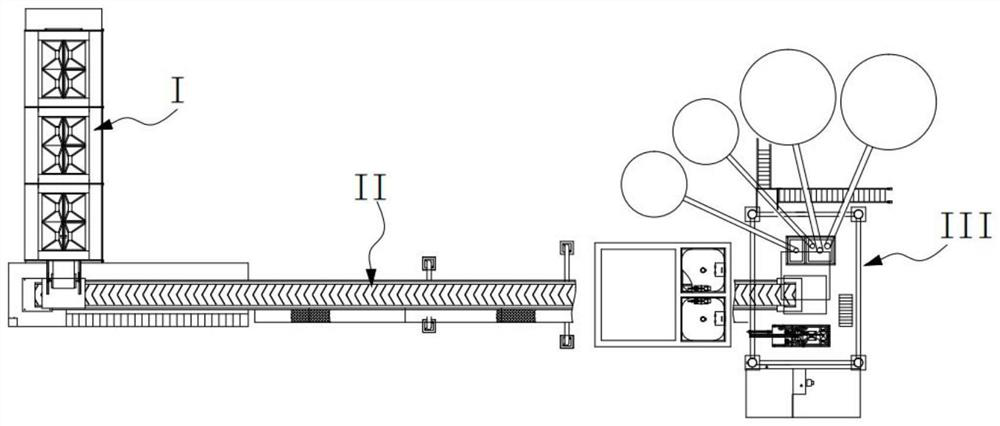

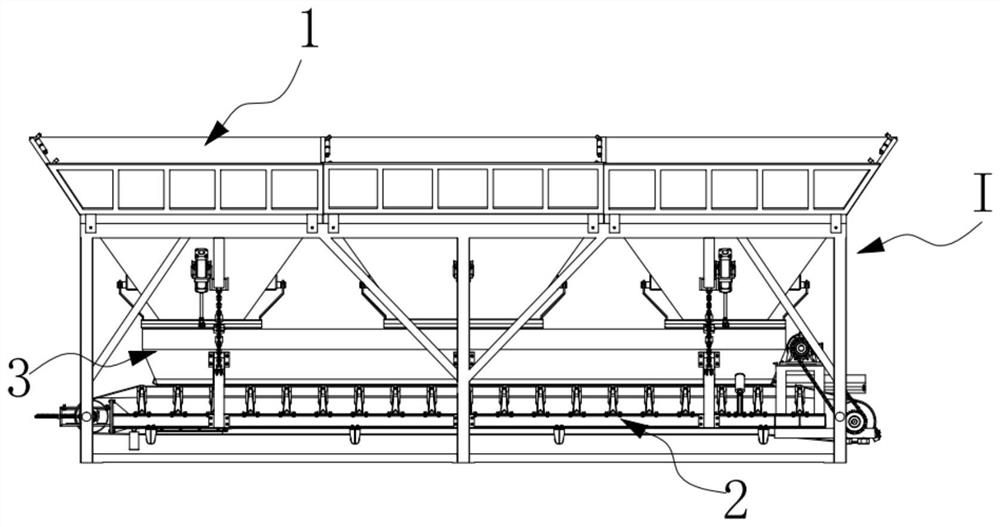

[0066] Such as Figures 1 to 6 As shown, a precise batching commercial concrete mixing production system includes a proportioning device I, a lifting device II and a mixing device III, the proportioning device I communicates with the mixing device III through the lifting device II, and the Proportioning device 1 comprises a number of feed bins 1, a belt conveyor 2 positioned directly below the feed bin 1, and a weighing device 3 that is arranged in one-to-one correspondence with the feed bin 1, and the weighing device 3 is located in the Between the silo 1 and the belt conveyor 2, it is characterized in that the weighing device 3 includes:

[0067] A hopper 31, the hopper 31 is installed at the lower outlet of the corresponding silo 1, and the hopper 31 is opened from the top;

[0068] Weighing bin 32, the weighing bin 32 is fixedly installed in the lower part of the hopper 31, the top of the weighing bin 32 is provided with a feed port 321, and the bottom of the weighing bin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com