High-separation multilayer joint-extrusion shrink film

A heat-shrinkable film and multi-layer co-extrusion technology, which is applied in the direction of layered products, synthetic resin layered products, flexible coverings, etc., can solve the problems of affecting the product's aesthetics, high breakage rate, and insufficient heat resistance. Achieve high oxygen and water vapor barrier properties, good anti-puncture effect, and overcome the effect of high breakage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

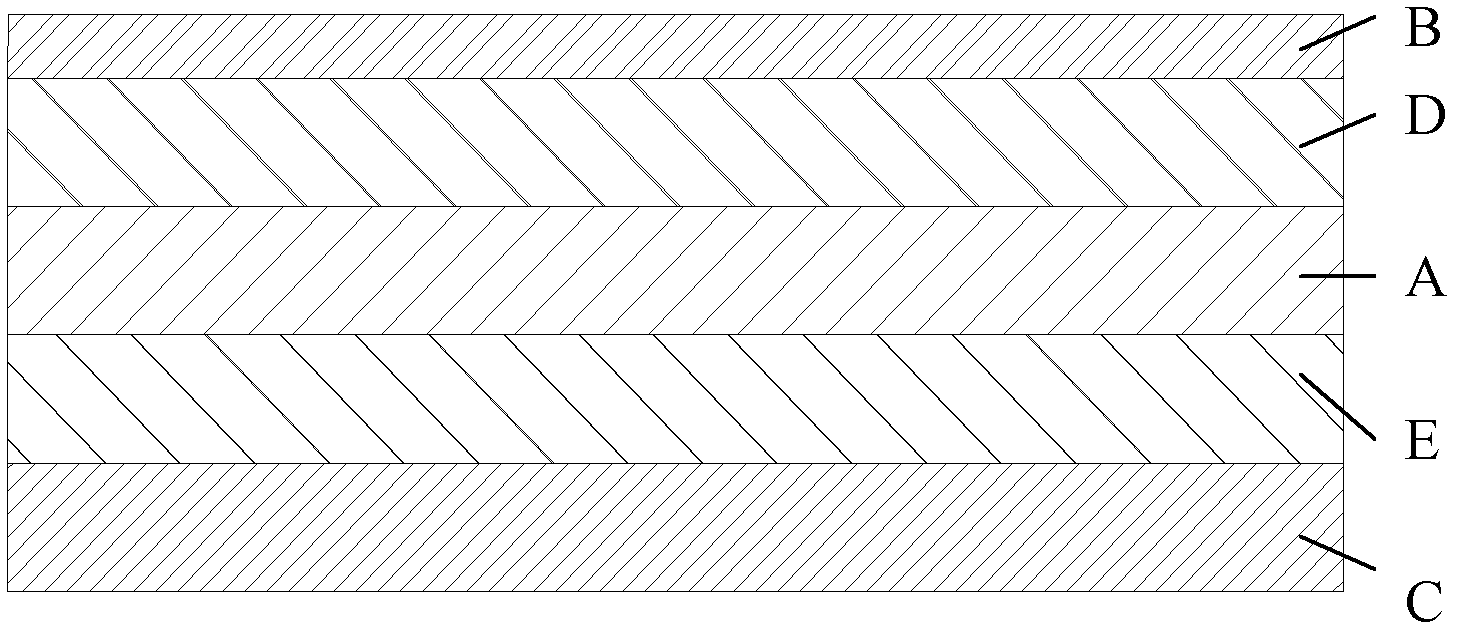

Embodiment 1

[0031] Prepare the raw materials for each layer first, barrier layer A: 20kg EVOH resin, specific gravity 1.13, melt index 2.0, melting point 161°C; outer surface layer B: 30kg PETG resin, specific gravity 1.27, vacuum drying at 65°C for 5 hours; heat sealing Layer C: 70kg of VLDPE and 30kg of MLLDPE, the density of VLDPE is 0.90g / cm 3 , The density of MLLDPE is 0.91g / cm 3 ; Adhesive layer D and adhesive layer E respectively use 20kg maleic anhydride grafted LLDPE, with a density of 0.917g / cm 3 , The melt index is 2.0.

[0032] After pretreatment of each layer of raw materials, they are added to the extruder of each layer to melt and plasticize, and then enter a five-layer co-extrusion round die for melt forming; the round melt tube blank becomes non-free after cold quenching. Tube embryo in a finalized state. Amorphous tube blanks are processed by online radiation cross-linking with an electron accelerator, and the radiation dose is 2.5MR~6.0MR. Then the amorphous tube blanks ar...

Embodiment 2

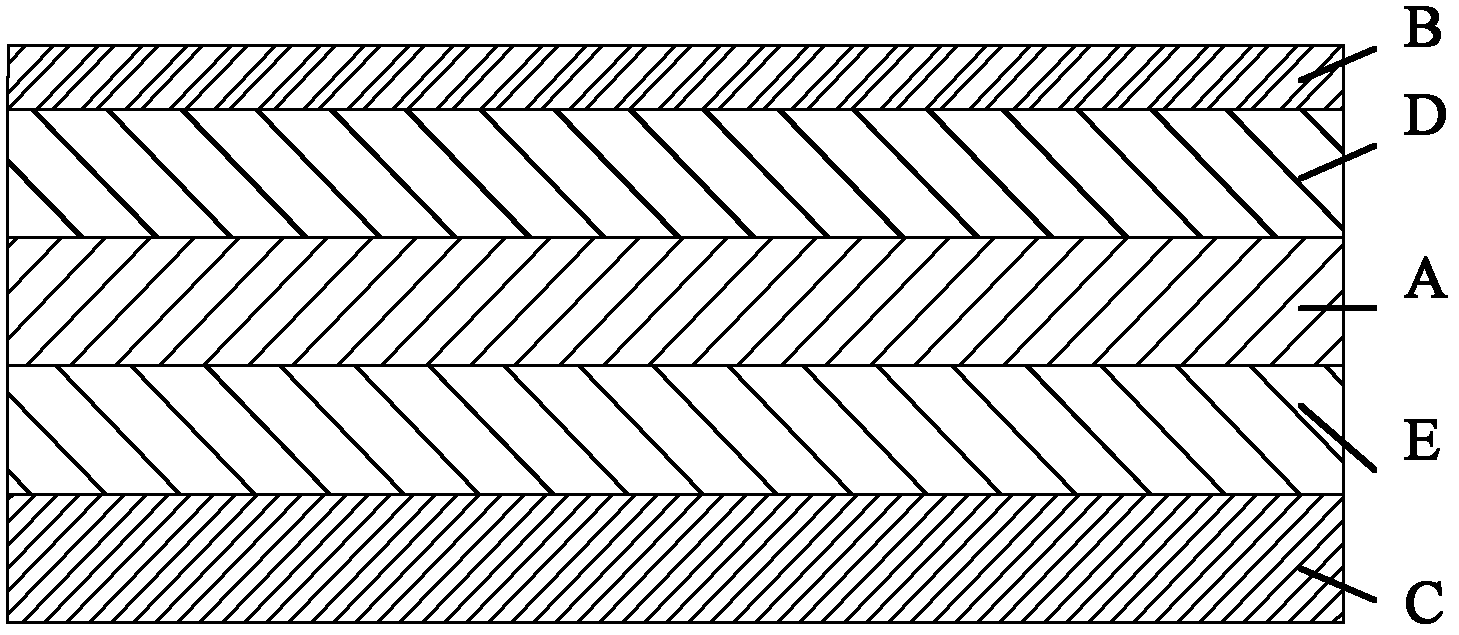

[0034] Prepare the raw materials for each layer first, barrier layer A: 20kg polyvinylidene chloride resin, specific gravity 1.70, melting point 150℃; outer surface layer B: 3kg PP resin, 12kg VLDPE resin and 15kg EVA resin, of which PP resin has a specific gravity of 0.90 , VLDPE resin specific gravity 0.90, EVA specific gravity 0.936; heat seal layer C: 80kg VLDPE and 20kg MLLDPE, the density of VLDPE is 0.90g / cm 3 , The density of MLLDPE is 0.91g / cm 3 ; Adhesive layer D and adhesive layer E: Weigh 20kg of EVA resin, the density is 0.935g / cm 3 , The melt index is 1.0.

[0035] Other methods and structures are the same as in Example 1.

[0036] After testing, the high barrier multilayer co-extruded heat-shrinkable film obtained by adopting the technical scheme of the present invention, its main performance indicators are shown in Table 1.

[0037] Table 1

[0038] Test items

[0039] Test items

[0040] From the data in Table 1, it can be seen that the hot water shrinkage ind...

Embodiment 3

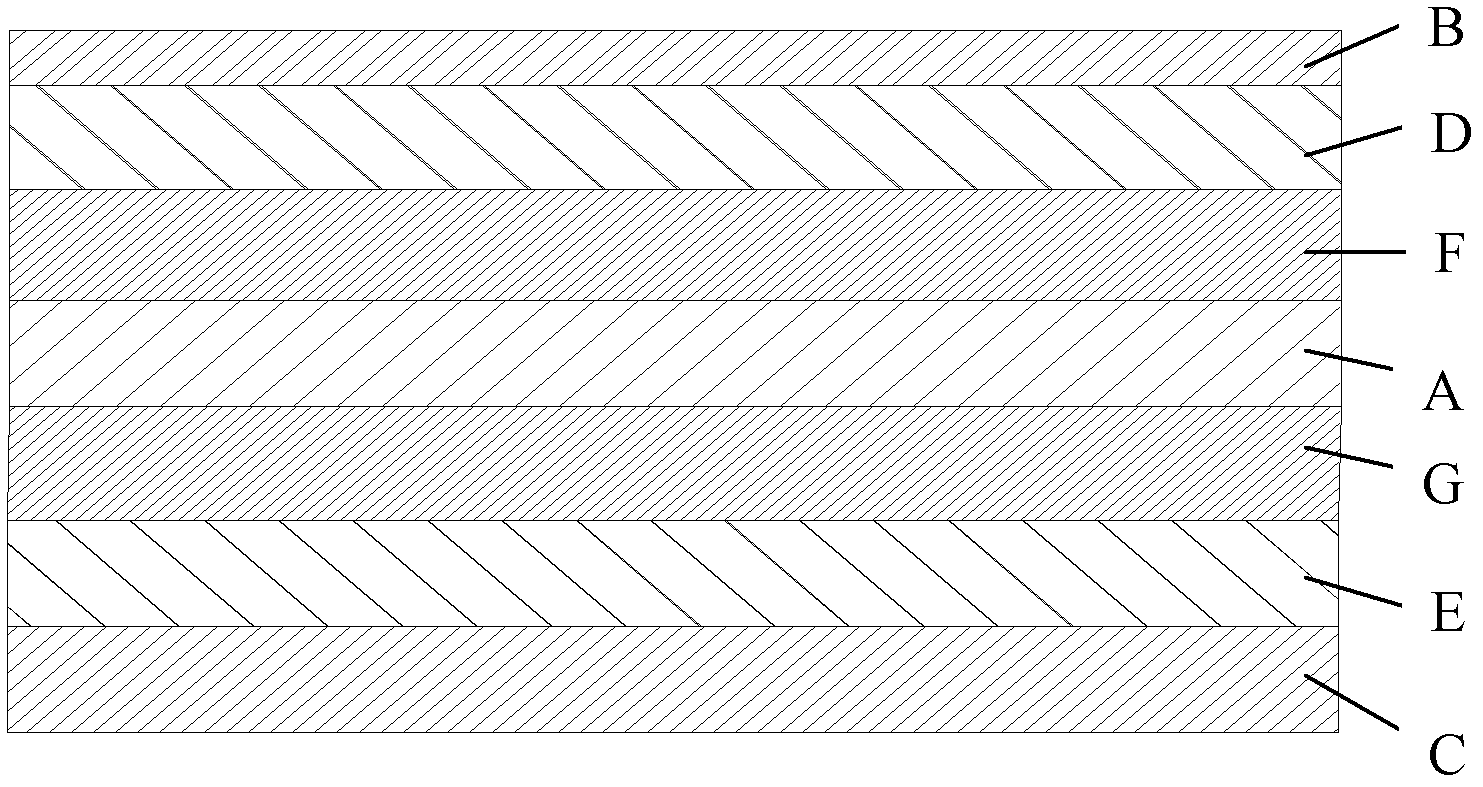

[0042] Such as figure 2 As shown, the multi-layer co-extruded heat shrinkable film has a seven-layer structure, and the structure is: B / / D / / F / / A / / G / / E / / C. Including outer surface layer B, barrier layers F, A, G and heat sealing layer C, outer surface layer B is bonded to barrier layer F through adhesive layer D, and heat sealing layer C is bonded to barrier layer G through adhesive layer E . The thickness of the barrier layer A accounts for 3% to 5% of the total thickness; the thickness of the barrier layers F and G account for 10% to 18% of the total thickness; the thickness of the outer surface layer B accounts for 3% to 5% of the total thickness; heat The thickness of the sealing layer C accounts for 25% to 35% of the total thickness; the thickness of the adhesive layers D and E account for 10% to 30% of the total thickness respectively.

[0043] Prepare each layer of raw materials first, barrier layer A: 20kg EVOH resin, specific gravity 1.13, melt index 2.0, melting point...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com