Packaging film for milk and method for manufacturing same

A technology for packaging film and milk, applied in the field of packaging materials, can solve the problems of loss of barrier properties, pinholes in aluminum foil, and high cost, and achieve the effects of good food hygiene performance, high heat sealing strength, and chemical stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

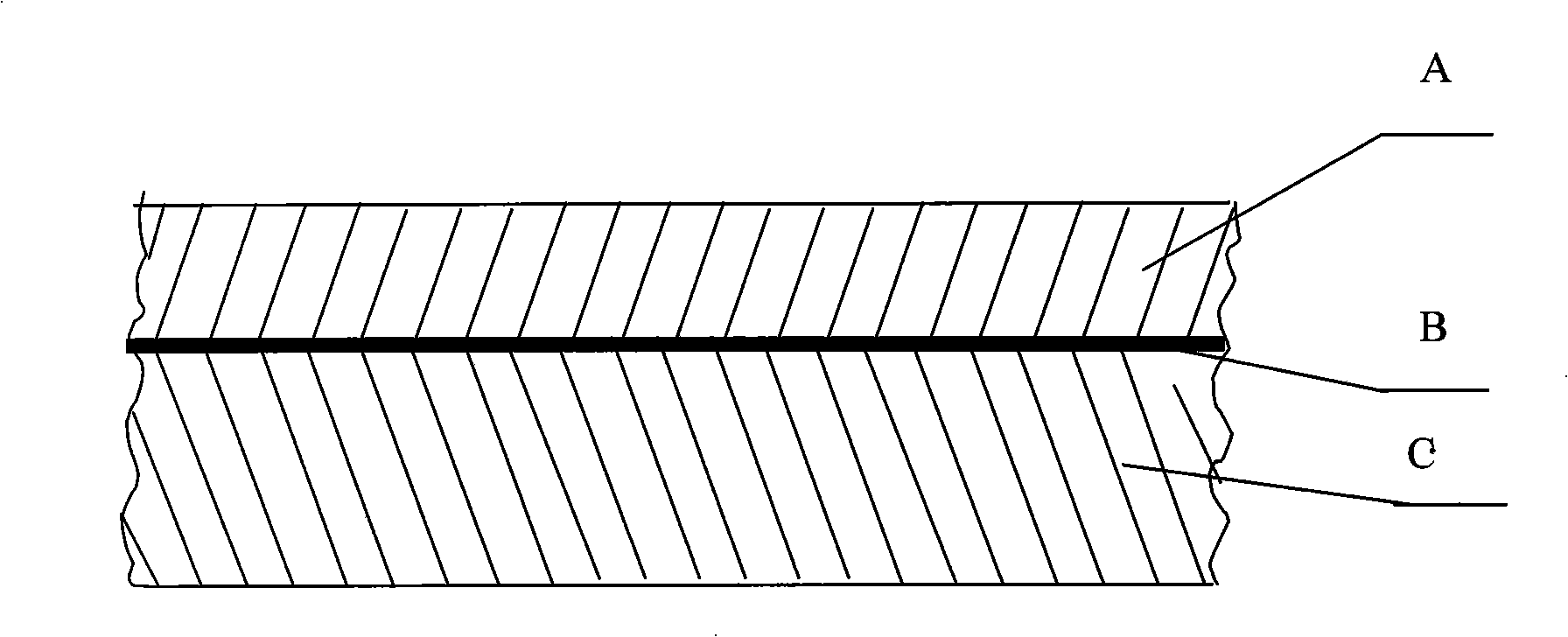

[0019] like figure 1 As shown, this embodiment is a composite film composed of an outer film A connected to an inner film C through an adhesive layer B. The outer film is a polyvinylidene chloride film (PVDC), and the adhesive is a two-component Polyurethane solvent-free adhesive, the inner film is black and white polyethylene film.

[0020] The cross-sectional thickness of each layer of the composite film from outside to inside is: 10 μm, 2 μm, 45 μm.

[0021] The manufacturing method of this composite film is as follows: first heat-treat the outer layer of polyvinylidene chloride film through an infrared heating device, and use a solvent-free composite production method for production. The steps are as follows:

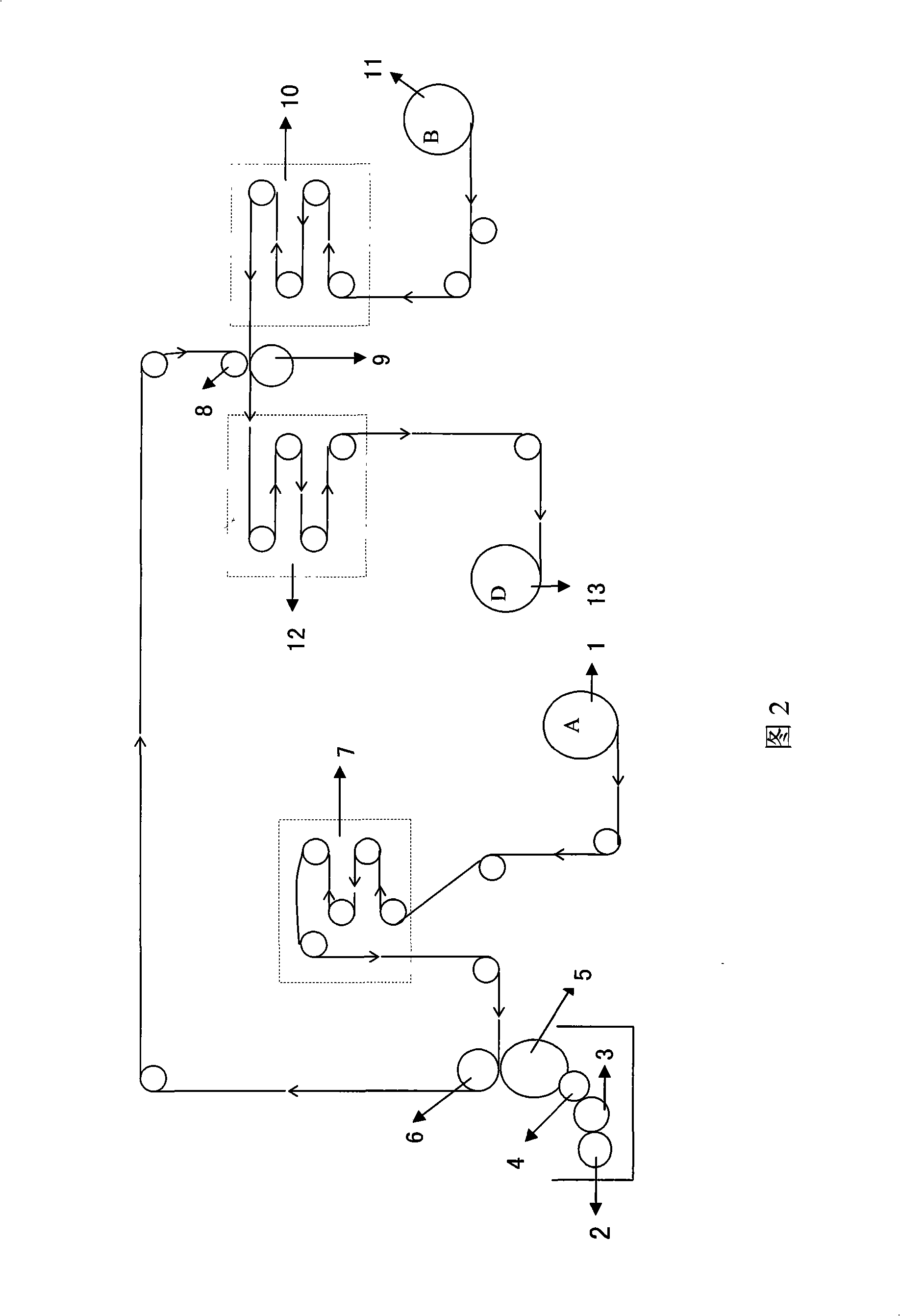

[0022] The polyvinylidene chloride film is heat-treated by an infrared heating device, the temperature of the heat treatment is 190°C, and the time is 1-3 seconds, and then the heat-treated polyvinylidene chloride film (PVDC) A is placed on the composite machine. ...

Embodiment 2

[0030] In this embodiment, the outer film is a polyvinylidene chloride film (PVDC), the adhesive is a two-component polyurethane solvent-based adhesive, and the inner film is a black and white polyethylene film.

[0031] The cross-sectional thickness of each layer of the composite film from the outside to the inside is: 20 μm, 6 μm, 85 μm.

[0032] The manufacturing method of this composite film is as follows: first heat-treat the outer layer of polyvinylidene chloride film through an infrared heating device, and use a solvent-type dry composite production method to produce it. The steps are as follows:

[0033] The polyvinylidene chloride film is heat-treated to the PVDC film, the heat treatment temperature is 160°C, and the time is 6-9 seconds, and then the polyvinylidene chloride film (PVDC) A after heat treatment by the infrared heating device is placed in the composite On the unwinding shaft 1 on the machine, the film passes through the unwinding machine and is sent to th...

Embodiment 3

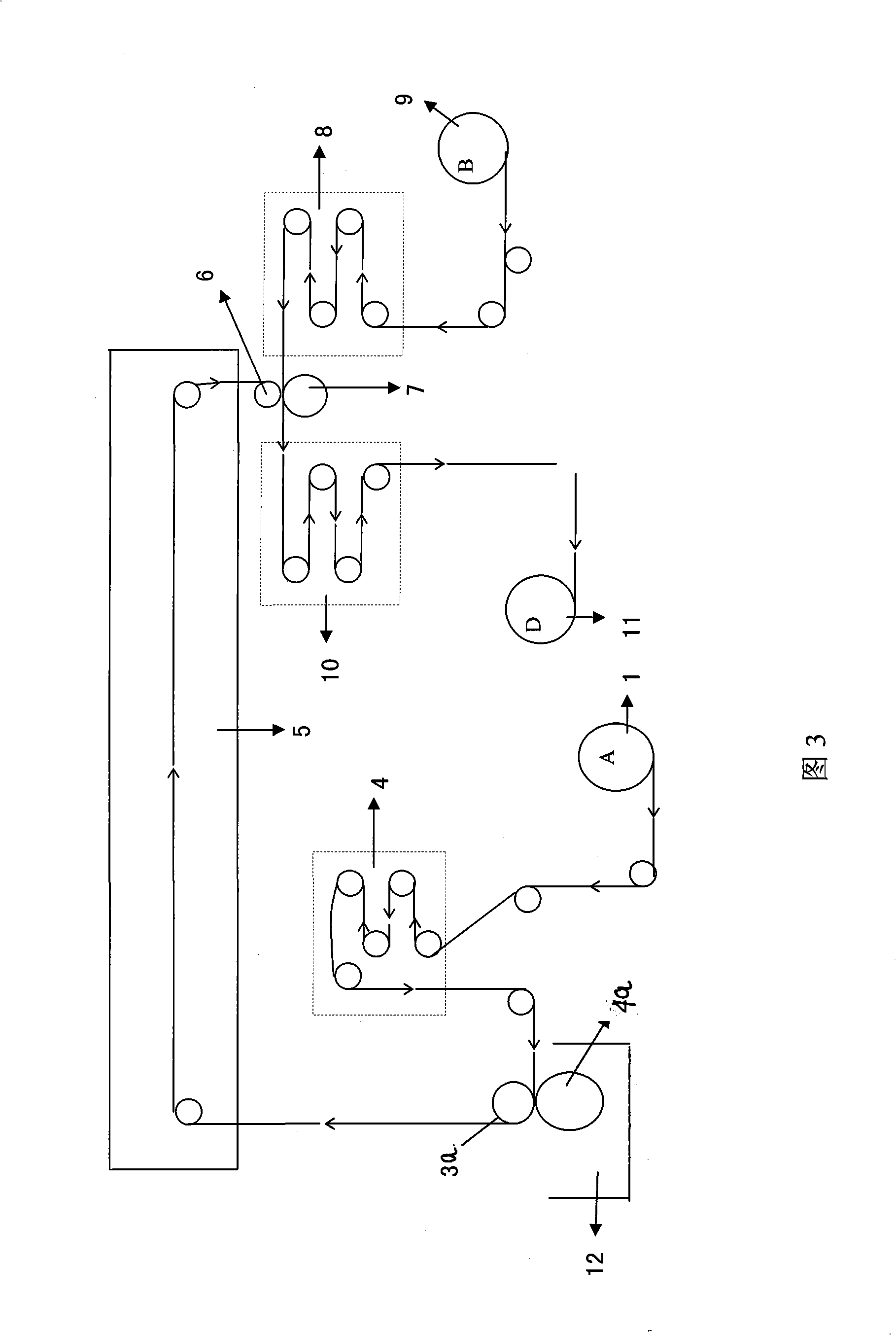

[0039] Embodiment 3: the material of the outer and inner layer of milk packaging film in the present embodiment is identical with embodiment 2, and adhesive is one-component polyurethane type solvent-based adhesive, and this adhesive contains isocyanate functional group, Such as DuPont (Herberts-1K-LF190X3); the cross-sectional thickness of each layer of the packaging film is: 11-14 μm, 3-5 μm, 46-50 μm. Its manufacturing method is the same as that of Example 2, but in this example, the temperature of the drying oven through which the coated outer layer PVDC (polyvinylidene chloride) film A passes is 47-50°C; The temperature of the roller and the composite roller is 47-50°C, the pressure of the composite pressure roller is 6kgf, and the pressure is generated by the compressed air cylinder at both ends of the roller.

[0040] On the compound machine, the tension of PE film is controlled at 7kgf, the tension of PVDC film is controlled at 5-7kgf, the tension of compounding machin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com