High-blocking corrosion-resisting lithium battery composite packaging film and preparation method thereof

A composite packaging film and corrosion-resistant technology, which is applied in the field of lithium battery composite film and its preparation, can solve the problems of complex production process, broken thick aluminum foil, difficult operation, etc., achieve high safety, reduce the possibility of delamination, Lightweight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

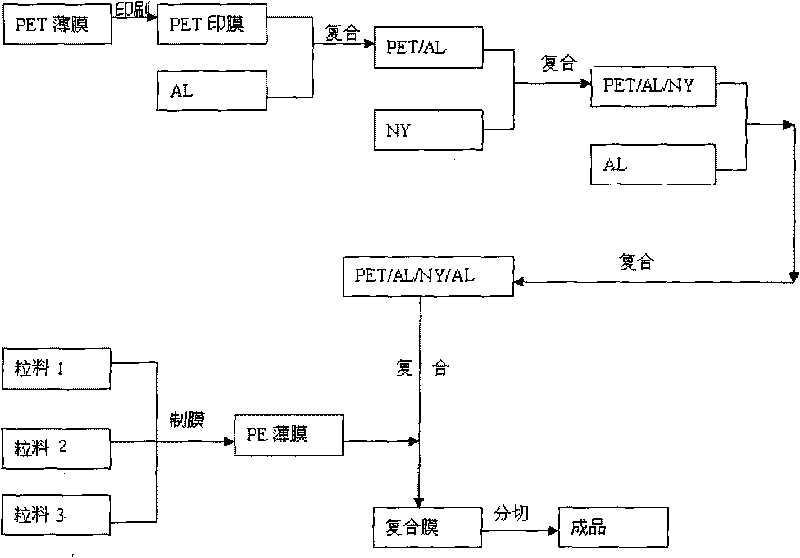

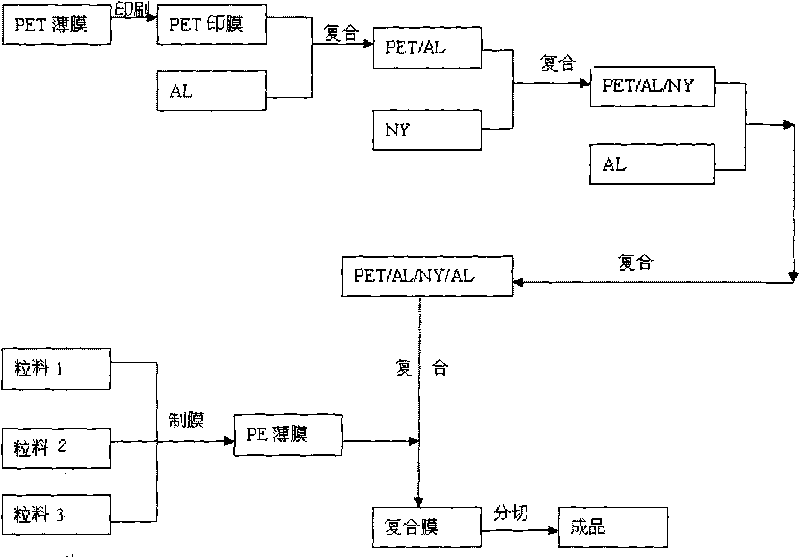

[0050] a. Polyethylene terephthalate (PET) layer printing process: in the case of 20 ℃, the PET film is printed in color to form a PET film;

[0051] b. The preparation process of the composite polyethylene (PE) layer: each layer of polyethylene resin is placed in its own barrel according to the proportion, and after being extruded by an extruder, a composite polyethylene film is made:

[0052] The proportioning ratios of the present invention are all weight percent concentrations.

[0053] The specific ratio is:

[0054] Composite layer: 66% MDPE (2038.68G of Dow Chemical) + 34% LDPE (150BW of Exxon Mobil)

[0055] Core layer: 33% HDPE (F920A of Samsung Total) + 33% MDPE (2038.68G of Dow Chemical) + 34% LDPE (150BW of Exxon Mobil)

[0056] Seal layer: 50% MLLDPE (SP2520) + 25% MDPE (2038.68G of Dow Chemical) + 25% (150BW of ExxonMobil)

[0057] c. Dry compounding: compound the PET printing film (step 1), AL, NY, and ALPE (step 2) that have been printed with patterns and text...

Embodiment 2

[0061] remove

[0062] b. The preparation process of the composite polyethylene (PE) layer: each layer of polyethylene resin is placed in its own barrel according to the proportion, and after being extruded by an extruder, a composite polyethylene film is made:

[0063] The specific ratio is:

[0064] Composite layer: 50% MDPE (2038.68G of Dow Chemical) + 50% LDPE (150BW of Exxon Mobil)

[0065] Core layer: 25% HDPE (F920A of Samsung Total) + 37.5% MDPE (2038.68G of Dow Chemical) + 37.5% LDPE (150BW of Exxon Mobil)

[0066] Seal layer: 50% MLLDPE (SP2520) + 25% MDPE (2038.68G of Dow Chemical) + 25% (150BW of ExxonMobil)

[0067] c. Dry compounding: compound the PET printing film (step 1), AL, NY, AL, PE (step 2) with the printed pattern and text in sequence through the dry compounding machine in order of structure, and the glue used is NC285A ( Novaco Company), the operating concentration of the adhesive is controlled in No. 3 Zahn cup for 17-20 seconds, and the coating amo...

Embodiment 3

[0070] remove

[0071] b. In the preparation process of the composite polyethylene (PE) layer,

[0072] Composite layer: 66% MDPE (2038.68G of Dow Chemical)+33.0% LDPE (150BW of Exxon Mobil)+1.0% zirconium dioxide, and the rest are the same as in Example 1.

[0073] The main technical index of embodiment 1,2,3

[0074]

[0075] Wherein the water vapor transmission rate of embodiment 3 is 0g / m 2 48h, the oxygen transmission rate is 0cm 3 / m 2 ·48h·0.15Mpa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com