Production technology of cell phone case, film pressing device and produced cell phone case

A mobile phone casing and production process technology, which is applied in the direction of telephone structure, telephone communication, electrical components, etc., can solve the problems of increasing the difficulty of skinning, reducing the aesthetics of mobile phone casings, and reducing production efficiency, so as to overcome easy separation or falling off. , Beautiful mobile phone shell, the effect of reducing the difficulty of attaching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

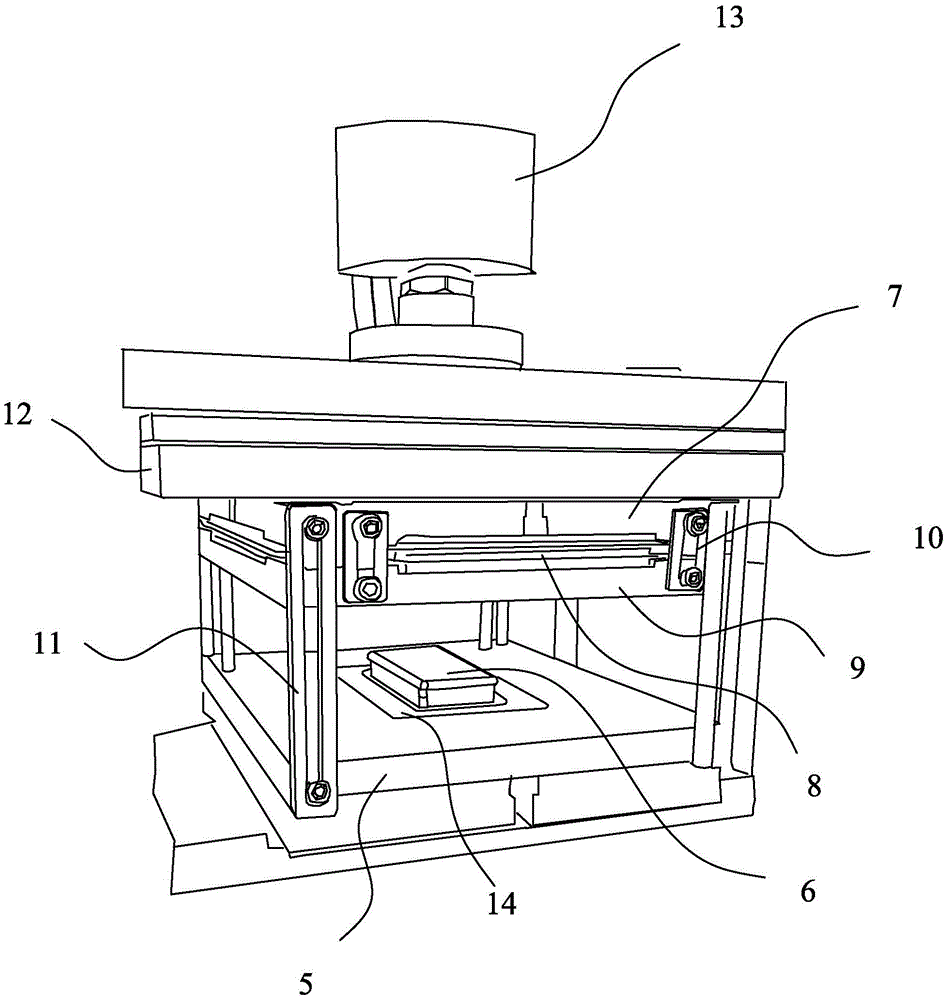

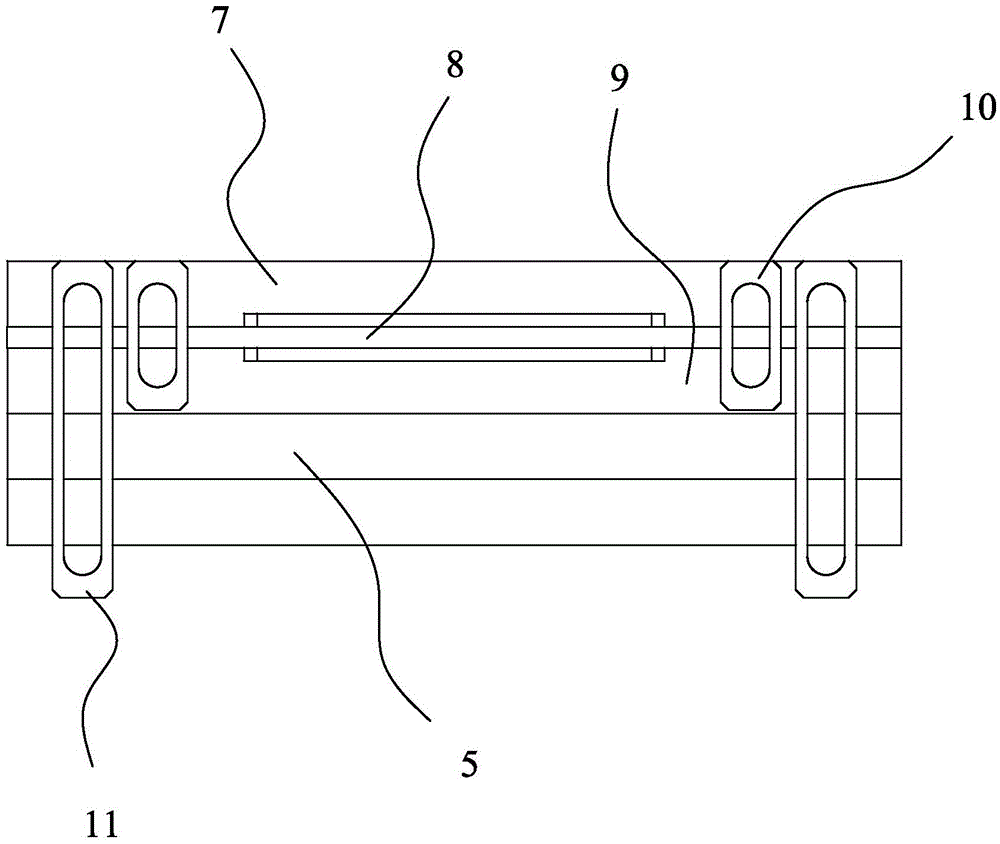

[0036] First please refer to figure 1 Shown, a kind of film pressing device that is used for the production of mobile phone shell, comprises positioning bottom plate 5, bottom mold 6, patrix, flexible membrane 8 and the driving element 13 that drives patrix to move, and described bottom mold 6 is for mobile phone profile A matched punch, the upper mold includes an upper template 7 positioned above the bottom mold 6, the driving element 13 is fixed on the top plate 12 above the upper template 7, the upper template 7 is connected with the driving element 13, and Driven by the driving element 13 to move up and down, the flexible diaphragm 8 is pressed on the upper template 7 through a pressure frame 9, and is located on the side facing the bottom mold 6, and the pressure frame 9 is connected to the upper mold through the short hanging plate 10 The template 7 is connected, the flexible membrane 8 is clamped between the upper template 7 and the pressure frame 9, an air cavity is fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com