Flexible package material of lithium ion battery

A lithium-ion battery and flexible packaging technology, which is applied in the direction of battery box/case materials, secondary batteries, battery pack parts, etc., can solve problems such as unexplained bond strength, exhaust performance, and reduced electrolyte resistance, so as to avoid The effect of cracking and high heat seal strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~15 and comparative example 1~4

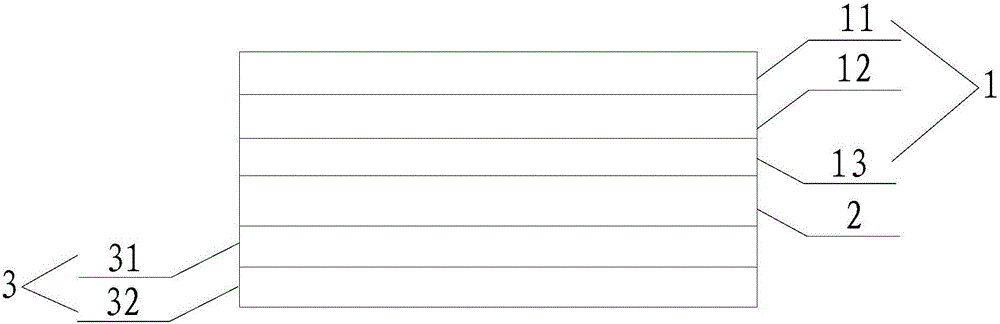

[0047] The two-component liquid polyurethane adhesive is coated on the aluminum foil layer 13 with a thickness of 40 μm by the gravure roller coating method to form an adhesive layer 12 with a thickness of 5 μm, which is dried with hot air at 80°C and bonded under pressure A biaxially stretched nylon film with a thickness of 25 μm is used to form a heat-resistant resin layer 11. After curing at 60°C for 24 hours, a laminate 1 of heat-resistant resin layer 11 / adhesive layer 12 / aluminum foil layer 13 is formed. Among them, the aluminum foil layer 13 is degreased in advance, and the chemically synthesized film is formed by chromate treatment on the side of the bonding resin layer 2, and the chromium content on the surface is 25 mg / m 2 .

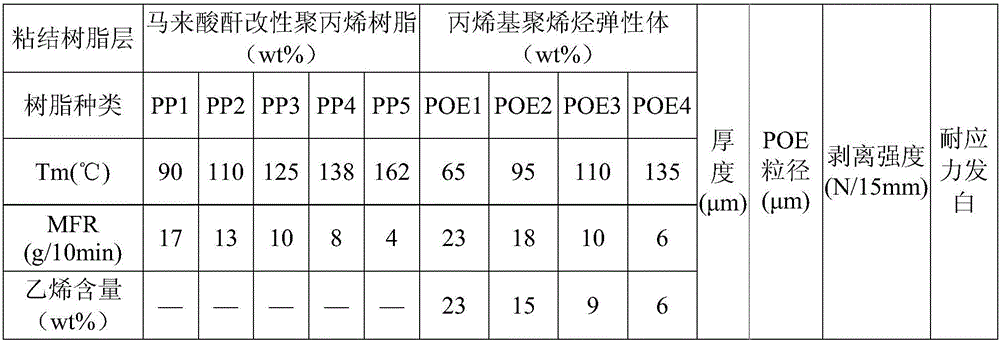

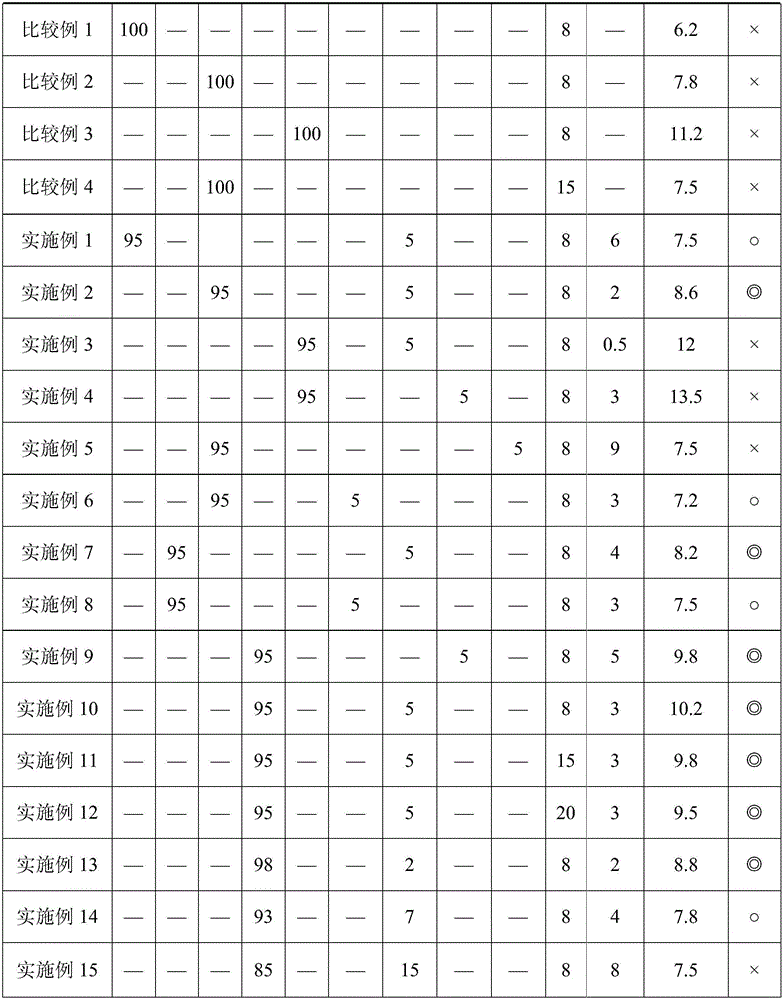

[0048] The maleic anhydride-modified polypropylene resin and the propylene-based polyolefin elastomer constituting the bonding resin layer 2 were simply blended in a high-speed mixer according to the formula shown in Table 1, and the blend const...

Embodiment 16~30 and comparative example 5~7

[0066] The two-component liquid polyurethane adhesive is coated on the aluminum foil layer 13 with a thickness of 40 μm by the gravure roller coating method to form an adhesive layer 12 with a thickness of 5 μm, which is dried with hot air at 80°C and bonded under pressure A biaxially stretched nylon film with a thickness of 25 μm is used to form a heat-resistant resin layer 11. After curing at 60°C for 24 hours, a laminate 1 of heat-resistant resin layer 11 / adhesive layer 12 / aluminum foil layer 13 is formed. Among them, the aluminum foil layer 13 is degreased in advance, and the chemically synthesized film is formed by chromate treatment on the side of the bonding resin layer 2, and the chromium content on the surface is 25 mg / m 2 .

[0067] The sealing layer 32a, which constitutes the sealing layer 32, has a high-Tm low-MFR polypropylene resin, the sealing layer 32b has a low-Tm high-MFR polypropylene resin, and the propylene-based polyolefin elastomer 32c is simply blended ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com