Paper plastic glue-free composite bidirectional stretching polypropylene film and its preparation method

A polypropylene film, biaxial stretching technology, applied in chemical instruments and methods, applications, household appliances, etc., can solve the problems of difficulty, the composition of the film layer and its preparation method are not disclosed, and it is difficult to reproduce in production, and achieves heat sealing. High strength, saving glue method and gluing process, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

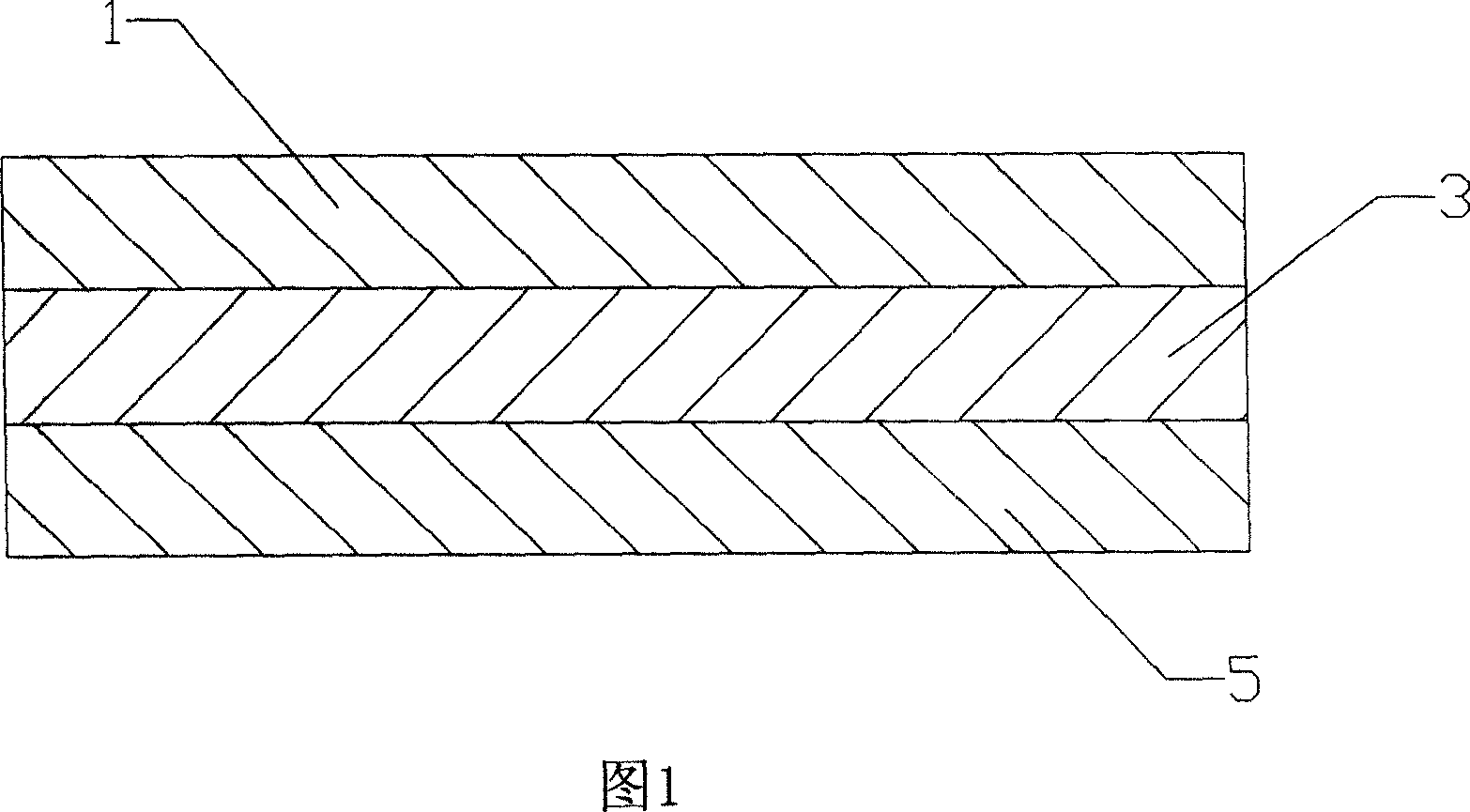

[0027] In embodiment 1 shown in Fig. 1:

[0028] Functional layer 1 is 70% ethylene-butene copolymer 4090S plus 30% ethylene-butene copolymer maleic anhydride graft modification 9015;

[0029] The core layer 3 is 98% isotactic polypropylene FS3011 plus 2% antistatic agent ASPA2446;

[0030] Surface layer 5 is matting material DUL3636DP17.

[0031] The total thickness of the prepared product is 20 μm, the thickness of functional layer 1 is 8 μm, and the thickness of matting layer is 3 μm.

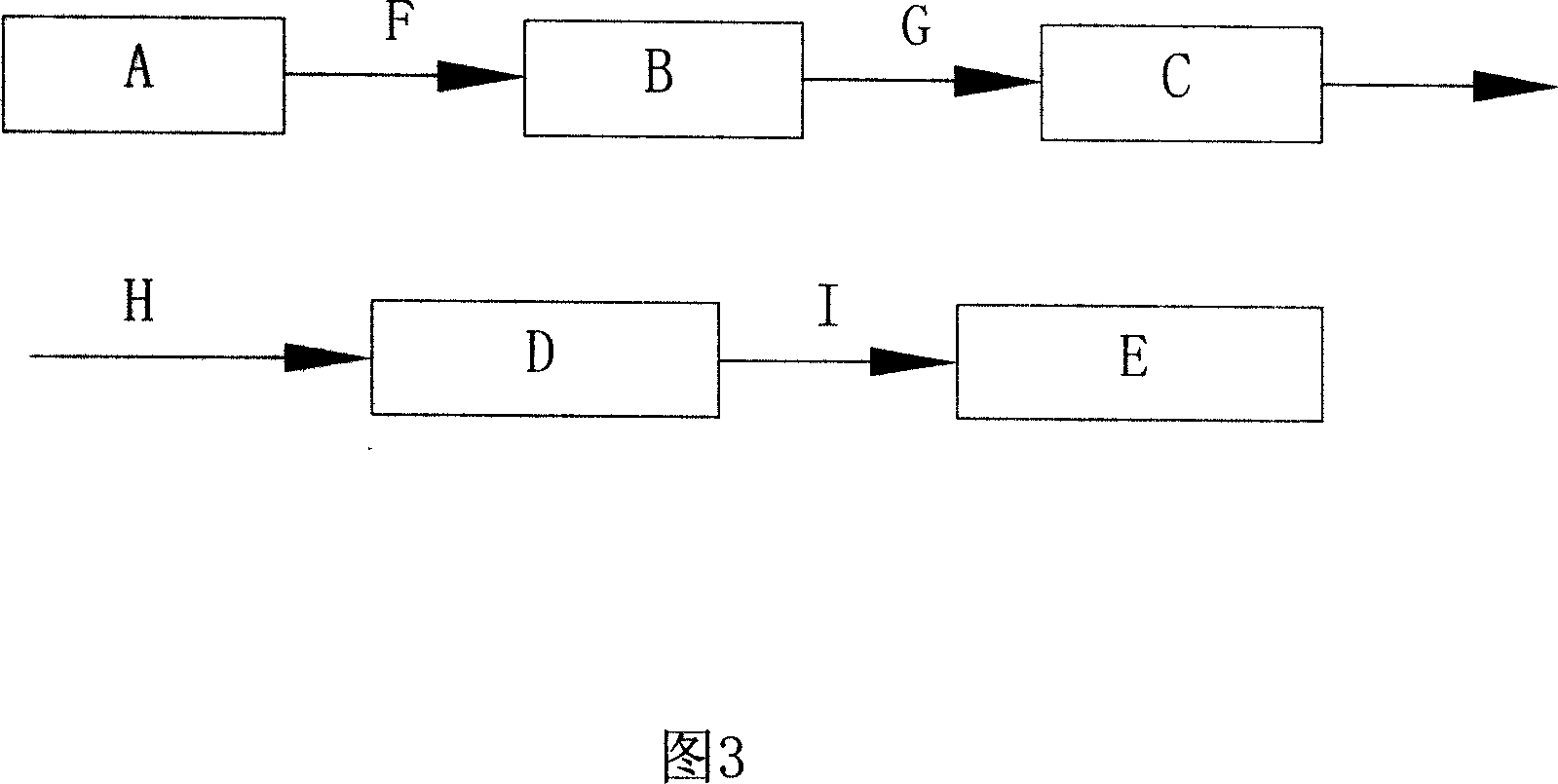

[0032] The preparation method is: premix the screened raw material A (including the main raw material, modified material, and additive masterbatch) according to the designed formula, stir evenly, and after the resin is measured, send it into the extruder to be processed into plasticized and homogenized F The melt B is transported through pipelines, filtered by filters, distributed through runners and dies, and cast into thick slices C through casting sheet G, and the thick slices are stret...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com