Lithium battery aluminum-plastic film and preparation method thereof

A technology of aluminum-plastic film and lithium battery, which is applied in battery pack parts, battery box/coating, battery box/cover material, etc., can solve the problem of unsatisfactory electrolyte resistance, low heat-sealing strength, and restrict the development of aluminum-plastic film and other issues, to achieve the effect of improving corrosion resistance, safe and reliable use, and increasing the specific surface area of heat sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

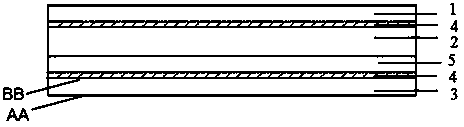

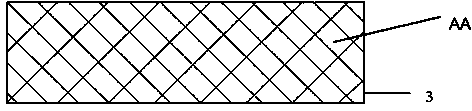

[0033] One side of the aluminum foil layer 2 is combined with the heat-resistant PI layer through the adhesive layer 4, and the corrosion-resistant coating 5 is first formed on the other side, and then the heat-sealing layer 3 is dry-type compounded through the adhesive layer 4. The thickness of the PI layer is 25 μm, the thickness of the aluminum foil is 20 μm, the heat-sealing layer is cast polypropylene (CPP) with a thickness of 20 μm, the corrosion-resistant coating 5 is 3 μm thick, the adhesive layer 4 is 3 μm thick, and the heat-sealing layer is The surface of the inner surface of 3 is provided with a rectangle (such as figure 2 Shown) the concave-convex grid structure AA, the density of the concave-convex grid structure is 2 cells / mm 2 , the depth of the concave part is 2μm, and the outer layer (adhesive bonding surface) is a smooth surface BB (such as Figure 5 shown), the initial heat-sealing strength of the tested product is 35N / cm (heat-sealing conditions: 190°C, ...

Embodiment 2

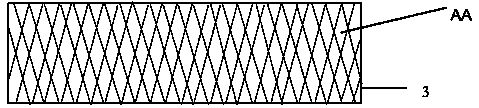

[0035] One side of the aluminum foil layer 2 is combined with the heat-resistant PI layer through the adhesive layer 4, and the corrosion-resistant coating 5 is first formed on the other side, and then the heat-sealing layer 3 is dry-type compounded through the adhesive layer 4. The thickness of the PI layer is 20 μm, the thickness of the aluminum foil is 25 μm, the heat-sealing layer is cast polypropylene (CPP) with a thickness of 30 μm, the corrosion-resistant coating 5 is 3 μm thick, the adhesive layer 4 is 5 μm thick, and the heat-sealing layer is 3 is provided with rhombus (such as image 3 Shown) the concave-convex grid structure AA, the density of the concave-convex grid structure is 6 cells / mm 2 , the depth of the concave part is 3μm, and the outer layer (adhesive bonding surface) is a smooth surface BB (such as Figure 5 shown), the initial heat-sealing strength of the tested product is 40N / cm (heat-sealing conditions: 190°C, 3s, 0.4Mpa).

Embodiment 3

[0037] One side of the aluminum foil layer 2 is combined with the heat-resistant PI layer through the adhesive layer 4, and the corrosion-resistant coating 5 is first formed on the other side, and then the heat-sealing layer 3 is dry-type compounded through the adhesive layer 4. The thickness of the PI layer is 15 μm, the thickness of the aluminum foil is 25 μm, the heat-sealing layer is cast polypropylene (CPP) with a thickness of 35 μm, the corrosion-resistant coating 5 is 3 μm thick, the adhesive layer 4 is 5 μm thick, and the heat-sealing layer 3 is provided with a hexagonal surface (such as Figure 4 Shown) the concave-convex grid structure AA, the density of the concave-convex grid structure is 10 cells / mm 2 , the depth of the concave part is 5μm, and the outer layer (adhesive bonding surface) is a smooth surface BB (such as Figure 5 shown), the initial heat-sealing strength of the tested product is 42N / cm (heat-sealing conditions: 190°C, 3s, 0.4Mpa).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com