High-solid coating containing polyvinylidene chloride for paper coating and preparation method of coating

A polyvinylidene chloride, high solid content technology, applied in paper coating, coating, papermaking, etc., can solve the problems of limited application, no barrier performance, no heat sealing performance, etc., to achieve enhanced thermal stability and stable reaction. , the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

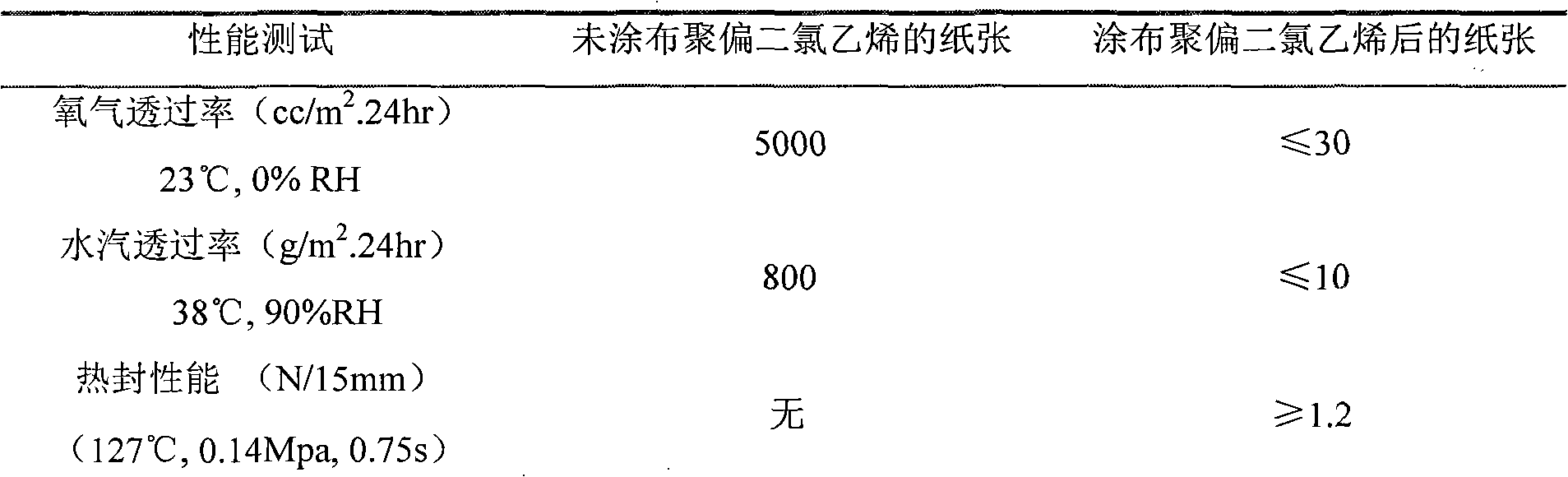

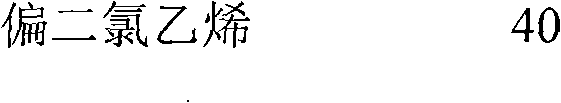

[0021] Prepare raw materials according to the following components (unit: kg)

[0022]

[0023]

[0024] Synthetic method: First, mix and stir 0.4kg sodium paraffin sulfonate, 0.5kg sodium lauryl sulfate, all reaction monomers and 4kg deionized water for 1 hour at a stirring speed of 100 rpm to obtain a pre-emulsion A; Dissolve 0.005kg of potassium persulfate and 0.005kg of tert-butyl hydroperoxide with 2kg of deionized water to form solution B; dissolve 0.01kg of sodium formaldehyde sulfoxylate with 2kg of deionized water to form a solution c. First add 22kg of deionized water, 10% of pre-emulsion A, and 1% of solution B into the polymerization kettle, start stirring at a stirring speed of 70 rpm, protect with nitrogen, raise the temperature to 50°C for 0.5h, etc. The reaction material changed from milky white to translucent with blue halo. At the same time, the remaining pre-emulsion A, remaining solution B and solution C were continuously added dropwise, kept at 53°...

Embodiment 2

[0026] Prepare raw materials according to the following components (unit: kg)

[0027]

[0028]

[0029] Synthetic method: First, mix and stir 0.6 kg of sodium paraffin sulfonate, 0.8 kg of sodium lauryl sulfate, all reaction monomers and 7 kg of deionized water for 2 hours at a stirring speed of 90 rpm to obtain a pre-emulsion A; Dissolve 0.01 kg of tert-butyl hydroperoxide with 2.5 kg of deionized water to form solution B; dissolve 0.015 kg of sodium formaldehyde sulfoxylate with 3 kg of deionized water to form solution C. First add 24.5kg of deionized water, 15% of pre-emulsion A, and 2% of solution B into the polymerization kettle, start stirring at a stirring speed of 60 rpm, protect with nitrogen, raise the temperature to 50°C for 1 hour, etc. The reaction material changed from milky white to translucent with blue halo. At the same time, the remaining pre-emulsion A, remaining solution B and solution C were continuously added dropwise, kept at 50°C for 5 hours, an...

Embodiment 3

[0031] Prepare raw materials according to the following components (unit: kg)

[0032]

[0033] Synthetic method: First, mix and stir 0.05kg sodium paraffin sulfonate, 0.08kg sodium lauryl sulfate, all reaction monomers and 1kg deionized water for 1 hour at a stirring speed of 150 rpm to obtain a pre-emulsion A; Dissolve 0.001 kg of tert-butyl hydroperoxide with 0.2 kg of deionized water to form solution B; dissolve 0.001 kg of sodium formaldehyde sulfoxylate with 0.2 kg of deionized water to form solution C. First add 2.1kg of deionized water, 7% of pre-emulsion A, and 3% of solution B into the polymerization kettle, start stirring at a stirring speed of 65 rpm, protect with nitrogen, heat up to 52°C for 0.5h, Waiting for the reaction material to change from milky white to translucent with blue halo. At the same time, the remaining pre-emulsion A, remaining solution B and solution C were continuously added dropwise, kept at 54°C for 4.5 hours, and the pre-emulsion A was d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com