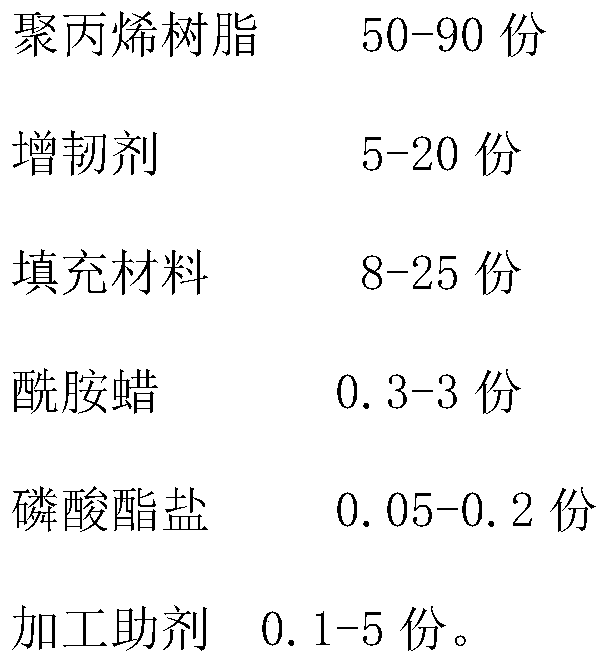

Flame-processing-free waterproof polypropylene composite material which can be coated easily, and preparation method thereof

A technology of composite materials and polypropylene, which is applied in the field of automotive plastics, can solve problems not related to water resistance, and achieve the effects of improving surface tension, improving surface paintability, and good solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solution of the present invention will be clearly and completely described below in conjunction with specific embodiments, but those skilled in the art will understand that the following described embodiments are some embodiments of the present invention, rather than all embodiments, and are only used They are used to illustrate the present invention, but should not be construed as limiting the scope of the present invention.

[0035] (1) The raw material source in the specific embodiment is as follows:

[0036] PP BX3900 Korea SK;

[0037] PP K9010 Taihua;

[0038] POE DF610 Japan Mitsui Chemicals;

[0039] Talc powder Haicheng Tianyuan;

[0040] Homemade toner;

[0041] Antioxidant SONOX 168 / Antioxidant SONOX 1010 Yingkou Scenery New Materials Co., Ltd.;

[0042] TR451 Shanghai Zhuangjing Chemical Co., Ltd.;

[0043] Amide wax is KF-027 Zhejiang Jiahua Fine Chemical Co., Ltd.;

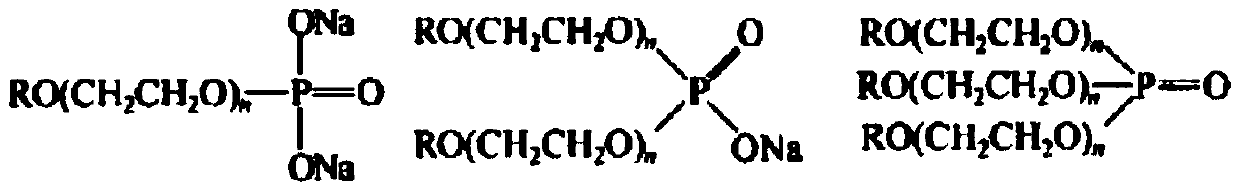

[0044] Phosphate salt is TMP-6 Shanxi Institute of Chemical Industry ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com