Intelligent screen printing machine for special-shaped bottles

A technology of screen printing machine and special-shaped bottle, applied in screen printing machine, printing machine, rotary printing machine, etc., can solve the problems of incomplete display of printing pattern, inability to ensure complete removal of dust on the concave and convex surface, affecting printing effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing:

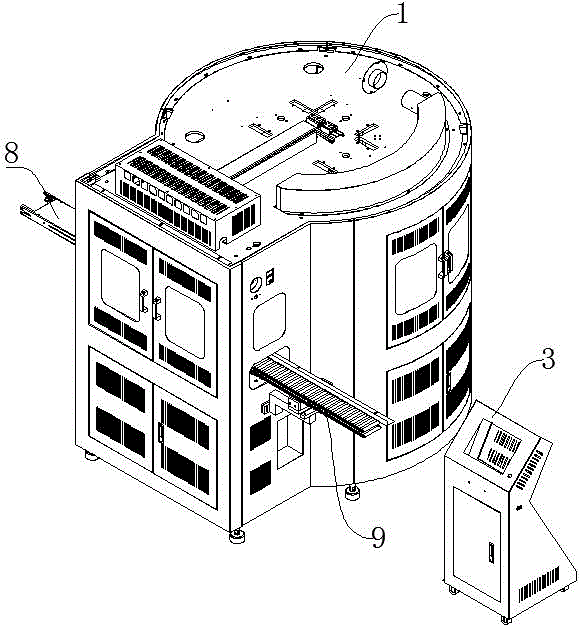

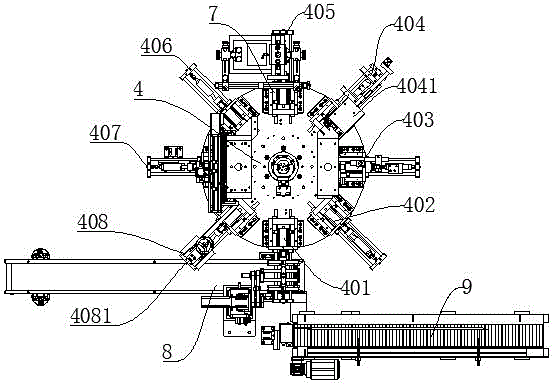

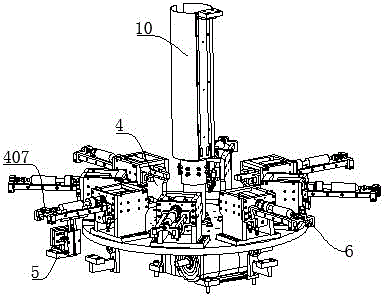

[0027] Such as Figure 1-Figure 9 As shown, a special-shaped bottle intelligent screen printing machine includes a frame 1, a turntable part 4, a bottle holder part 5 and a mobile electric box part 3. The turntable part 4 is installed inside the frame 1, and the turntable part 4 Used to drive the product to rotate, the center of the turntable part 4 is equipped with an electric slip ring part 10, and there are eight fixture parts 6 around it, which are eight different stations, which are the loading and unloading station 401 and the electrostatic dust removal station 402 in turn. , flame treatment station 403, vision positioning station 404, first color printing station 405, first color printing UV curing station 406, second color printing station 407, second color UV curing station 408, the above eight The silk screen printing process can be completed by making the produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com