Screen printing technique for polyolefin plastic products

A technology for screen printing and plastic products, which is applied in screen printing machines, exposure devices for photographic plate-making processes, printing, etc. It can solve the problems of high comprehensive printing cost, low solid content, low production efficiency, etc., and achieve a three-dimensional layering of patterns Strong, easy to scale production, good printing fastness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

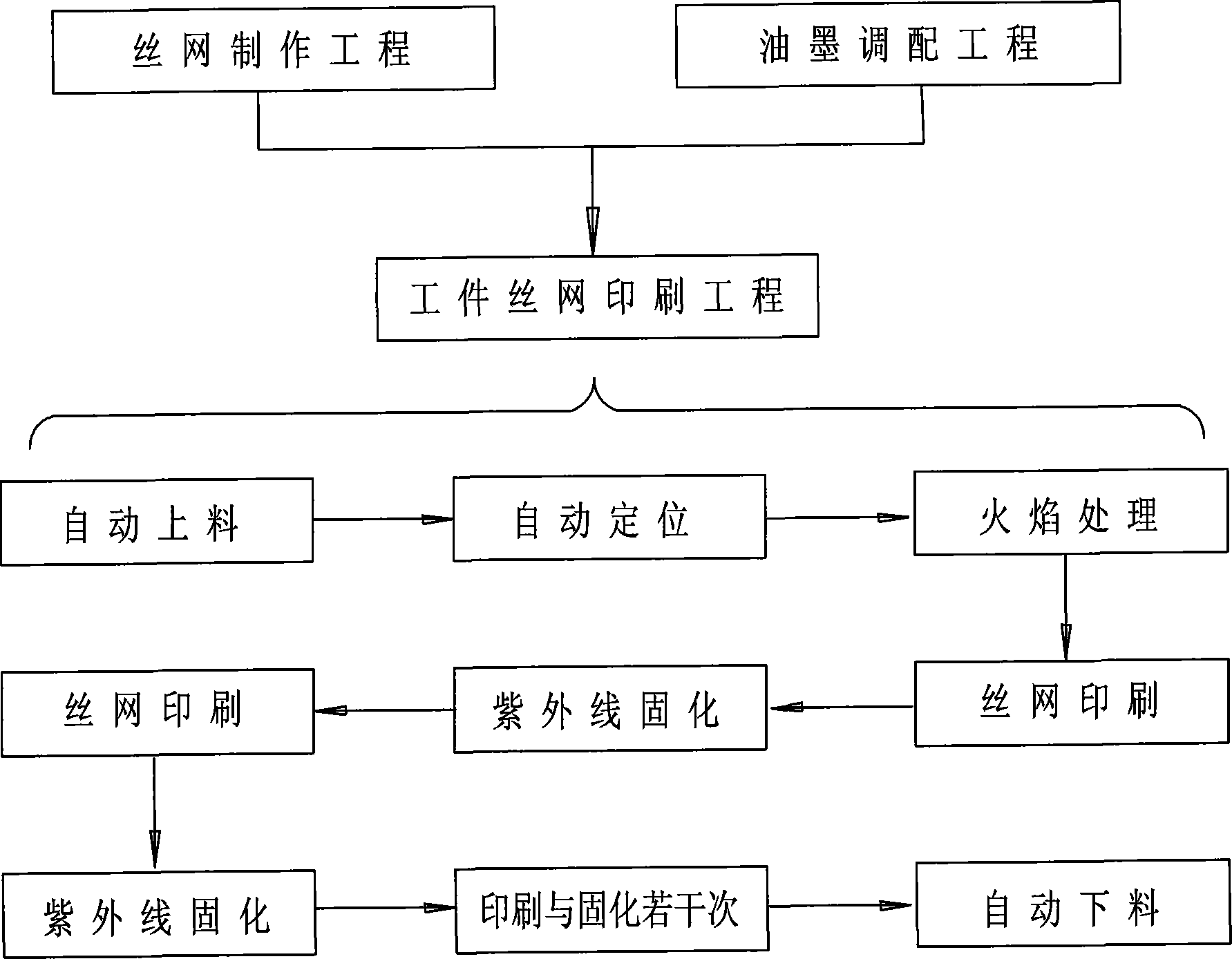

[0018] The following is a preferred embodiment of the present invention, a complete set of processes including silk screen plate making engineering, ink blending engineering and subsequent workpiece screen printing engineering. Among them, the screen printing process and the ink mixing process can be carried out separately or at the same time; the subsequent screen printing process of the workpiece is to implement high-quality and efficient multi-color overprinting on the polypropylene pen holder on the automatic five-color UV screen printing machine.

[0019] 1. Overview

[0020] UV is the abbreviation of Ultraviolet Rays in English, that is, ultraviolet light. Ultraviolet (UV) is invisible to the naked eye. It is a section of electromagnetic radiation other than visible violet light, with a wavelength in the range of 10-400nm. UV curing ink is an environmentally friendly ink developed rapidly in recent years. It adopts instant curing and drying method, and it does not conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com