Two-component polyurea coating and application thereof

A two-component, polyurea technology, used in polyurea/polyurethane coatings, coatings, devices for coating liquids on surfaces, etc. The effect of wiping performance, fast surface drying, and low VOC content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

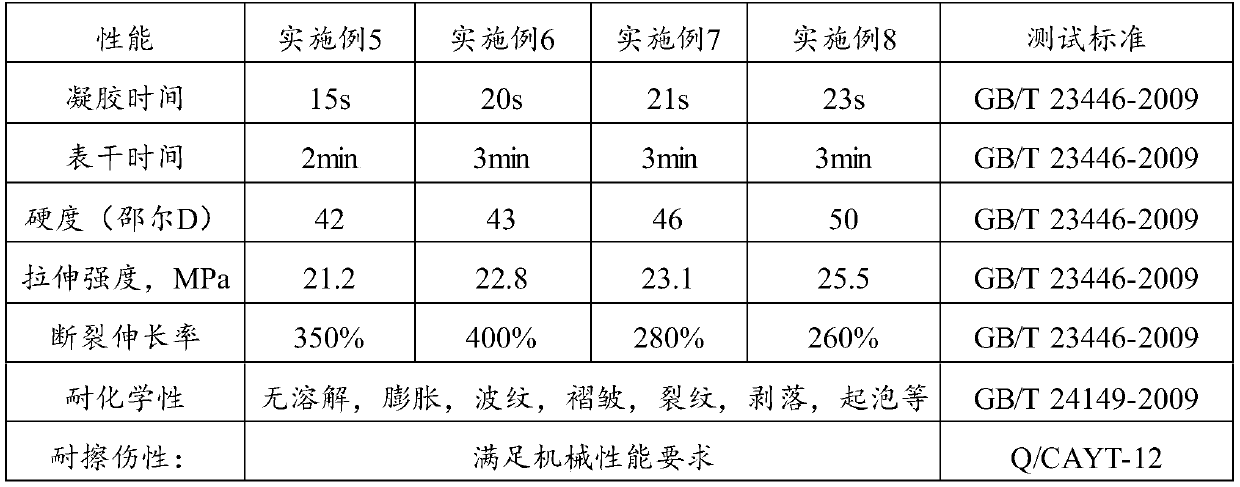

Examples

preparation example Construction

[0075] The present invention also provides a method for preparing the two-component polyurea coating described in the above technical solution, comprising the following steps:

[0076] a) mixing and reacting the main material with the diluent to obtain component A;

[0077] b) Grinding after mixing the amino-terminated polyether, amino-terminated chain extender, auxiliary agent and colorant to obtain component B;

[0078] c) mixing component A obtained in step a) with component B obtained in step b) to obtain a two-component polyurea coating;

[0079] The steps a) and b) are not limited in sequence.

[0080] In the present invention, the main material and the diluent are stirred until uniform to obtain the A component. In the present invention, the main material and the diluent are the same as those described in the above technical solution, and will not be repeated here. The present invention has no special limitation on the process of stirring until uniform; after obtaini...

Embodiment 1

[0099] Preparation of Aromatic Single-layer Polyurea Coatings

[0100] (1) Preparation of component A: In a three-necked bottle containing 58.2 parts by weight of 4,4'-MDI (Lupranate MI, BASF, Germany), nitrogen gas was introduced, the temperature was raised to 50°C, and 6.6 parts by weight of The polyε-caprolactone polyol (PlaccelL205AL, Nippon Chemical Industry Co., Ltd. Daicel Company) and the polyether diol (Acclaim 2200, U.S. Arco Company) of 28.7 parts by weight are gradually warming up to 80° C. after adding, Continue to react for 2h to 3h to obtain a semi-prepolymer;

[0101] Sampling and determination of NCO% content in the semi-prepolymer is 18.4%;

[0102] Then the semi-prepolymer of 93.5wt% and the diluent propylene carbonate of 6.5wt% (trade name ArconatePC, Holland LyondellBasell company) are stirred evenly, obtain A component; Be placed in airtight container, degassing and nitrogen filling stand-by.

[0103] (2) Preparation of component B: 62.5 wt% of amino-t...

Embodiment 2

[0106] Preparation of Aliphatic Single-layer Polyurea Coatings

[0107] (1) The preparation of A component: in the isophorone diisocyanate ( IPDI, in the there-necked flask of Evonik Degussa Company of Germany), feed nitrogen, drop the amino-terminated polyether (the copolyetherdiamine of the difunctionality of 20wt% of 41 weight parts at room temperature) THF-170, American Huntsman Company and 21wt% difunctional amino-terminated polyether BASF D2000, German BASF Company), after the addition is completed, the temperature is gradually raised to 80 ° C, and the reaction is continued for 2h to 3h to obtain a semi-prepolymer;

[0108] Sampling and determination of NCO% content in the semi-prepolymer is 19.7%;

[0109] Then after the semi-prepolymer of 96wt% and the diluent propylene carbonate of 4wt% (trade name Arconate PC, Holland LyondellBasell company) are stirred, obtain A component; After stirring, be A component; In a closed container, degassed and filled with nitrogen ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com