PBT/ABS alloy material and method for preparing same

A technology of alloy material and composition, which is applied in the field of PBT/ABS alloy material and its preparation, can solve the problems of low heat resistance of bumpers, increased processing and logistics costs, bumper loosening or damage, etc., so as to omit processing Craftsmanship, short baking time, not easy to loosen or damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

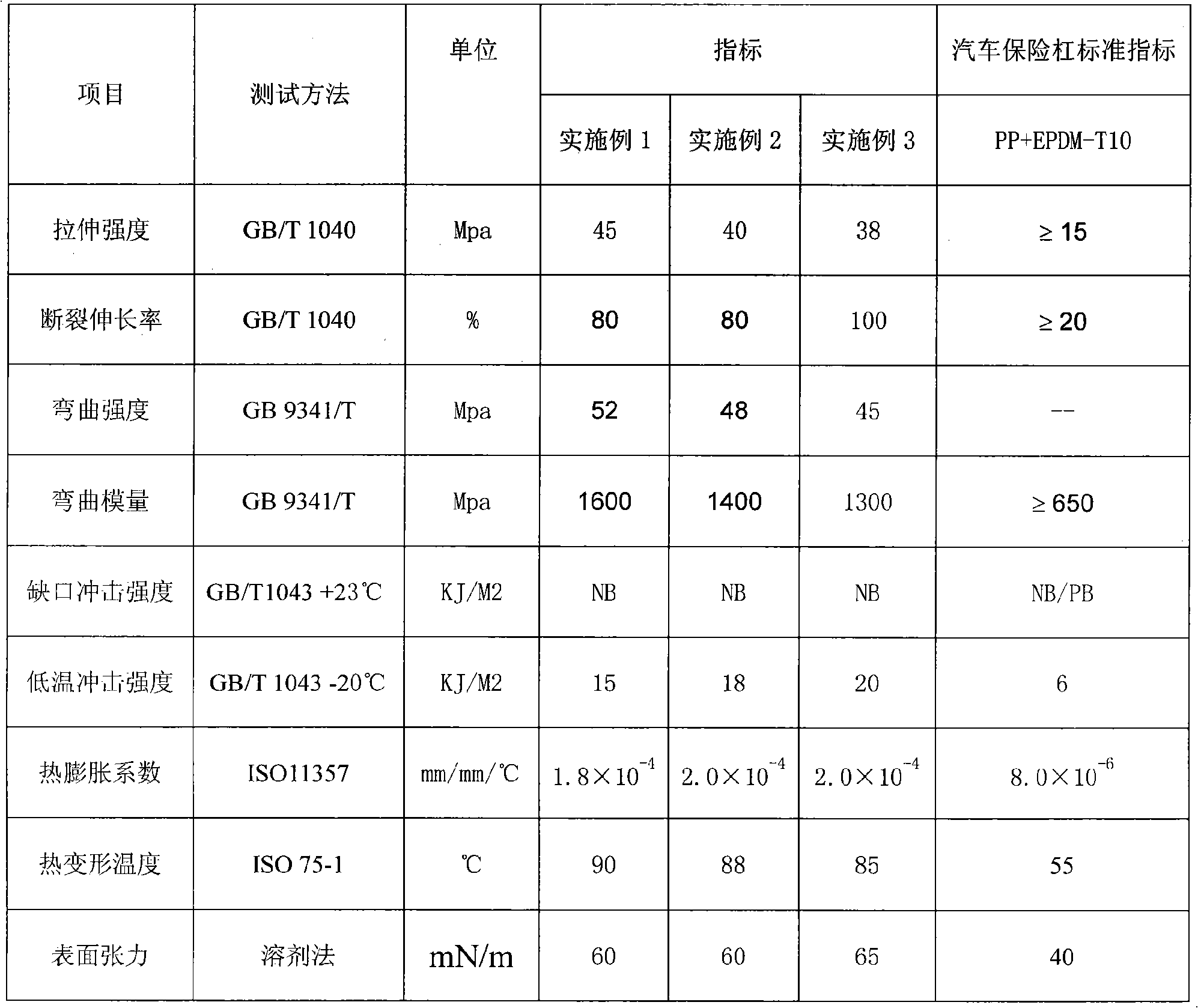

Examples

example 1

[0036] Preparation of activated compatibilizer: 2KG of activator glycine methacrylate, 56.5KG of acrylonitrile-styrene copolymer, 40KG of acrylonitrile-butadiene-styrene copolymer, initiator bis(tert-butyl peroxy 0.5KG of isopropyl) benzene peroxide, and 1KG of other additives are reacted and extruded in a twin-screw with a length of 48:1, and the reaction temperature is 240°C, and the reaction time is 40 seconds;

[0037] PBT 70%, ABS 25%, activated compatibilizer 4%, processing lubricant polysiloxane 0.4%, phenolic antioxidant 1076 (CIBA company) 0.3%, light stabilizer 2-(2 hydroxyl-3, 5-di-tert-amylphenyl)-benzotriazole light stabilizer (CYTEC company) 0.3%; Mix evenly and put into the hopper of twin-screw extruder, extrude through melting, granulate, fully plasticize, melt, Composite, then extruded, drawn, cooled, pelletized, dried and packaged; the processing technology is as follows: twin-screw extruder at 230°C in the first zone, 235°C in the second zone, 235°C in the t...

Embodiment 2

[0039] PBT 60%, ABS 31%, activated compatibilizer 8%, processing lubricant polysiloxane 0.4%, phenolic antioxidant 1076 (CIBA company) 0.3%, light stabilizer 2-(2 hydroxyl-3, 5-di-tert-amylphenyl)-benzotriazole light stabilizer (CYTEC company) 0.3%; Mix evenly and put into the hopper of twin-screw extruder, extrude through melting, granulate, fully plasticize, melt, Composite, then extruded, drawn, cooled, pelletized, dried and packaged; the processing technology is as follows: twin-screw extruder at 230°C in the first zone, 235°C in the second zone, 235°C in the third zone, 235°C in the fourth zone, and 235°C in the fifth zone Zone 235°C, Zone 6 230°C, Zone 7 230°C, Zone 8 230°C; screw speed controlled at 350 rpm; residence time 2-10min.

Embodiment 3

[0041]PBT 45%, ABS 44%, activated compatibilizer 10%, processing lubricant polysiloxane 0.4%, phenolic antioxidant 1076 (CIBA company) 0.3%, light stabilizer 2-(2 hydroxyl-3, 5-di-tert-amylphenyl)-benzotriazole light stabilizer (CYTEC company) 0.3%; Mix evenly and put into the hopper of twin-screw extruder, extrude through melting, granulate, fully plasticize, melt, Composite, then extruded, drawn, cooled, pelletized, dried and packaged; the processing technology is as follows: twin-screw extruder at 230°C in the first zone, 235°C in the second zone, 235°C in the third zone, 235°C in the fourth zone, and 235°C in the fifth zone Zone 235°C, Zone 6 230°C, Zone 7 230°C, Zone 8 230°C; screw speed controlled at 350 rpm; residence time 2-10min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com