Method and device for self-adaptive machining of motor base and vibration monitoring of vertical feed shaft

A vertical feed and vibration monitoring technology, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of CNC machine tool alarm, easy fatigue, shortened tool life, etc., to improve processing efficiency and protect machinery. parts, ensuring the effect of scrapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to make the purpose, technical solution and advantages of the present invention clearer, the following examples are given to further describe the present invention in detail.

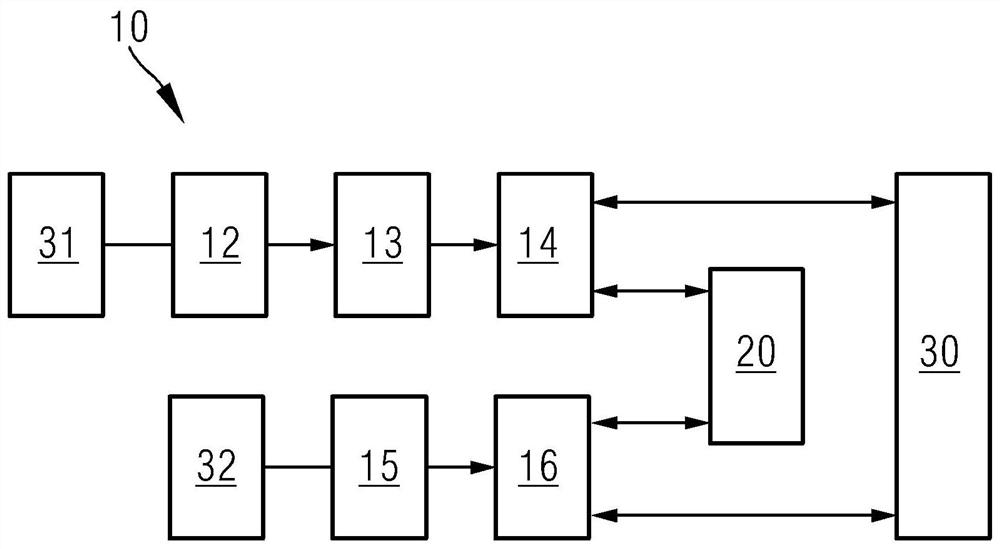

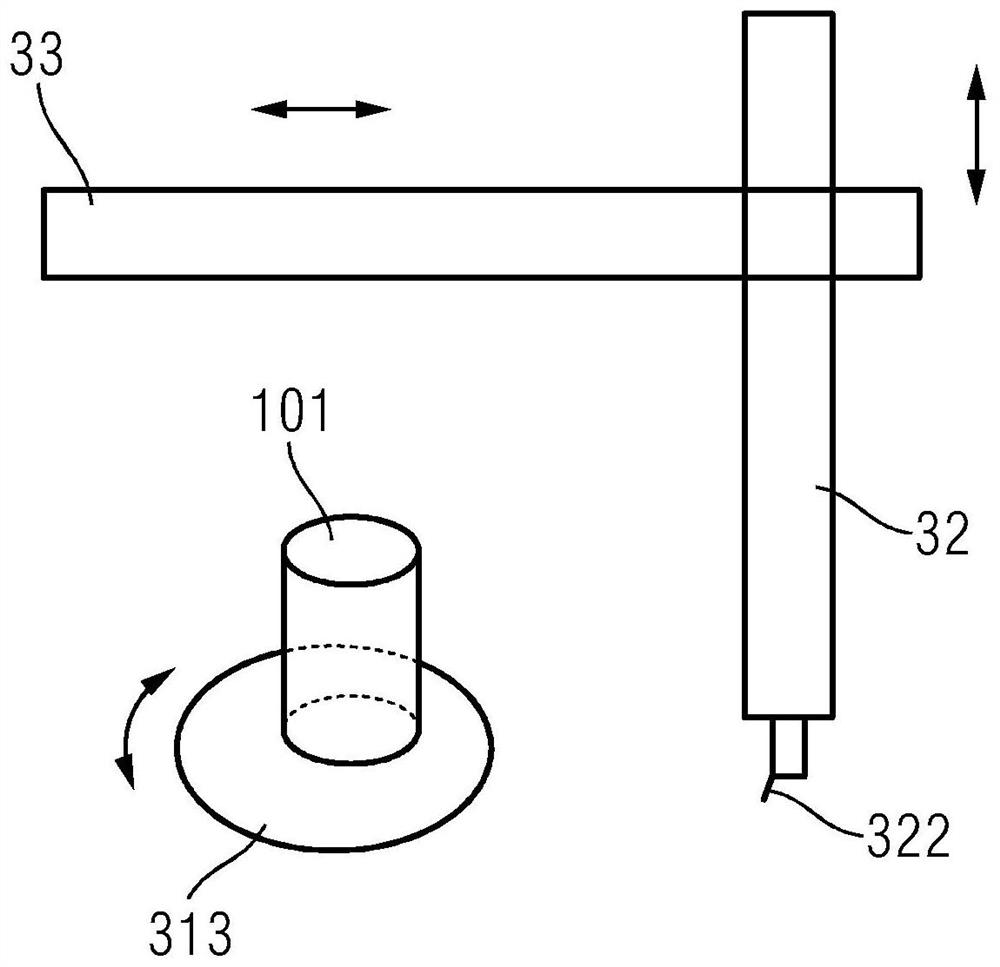

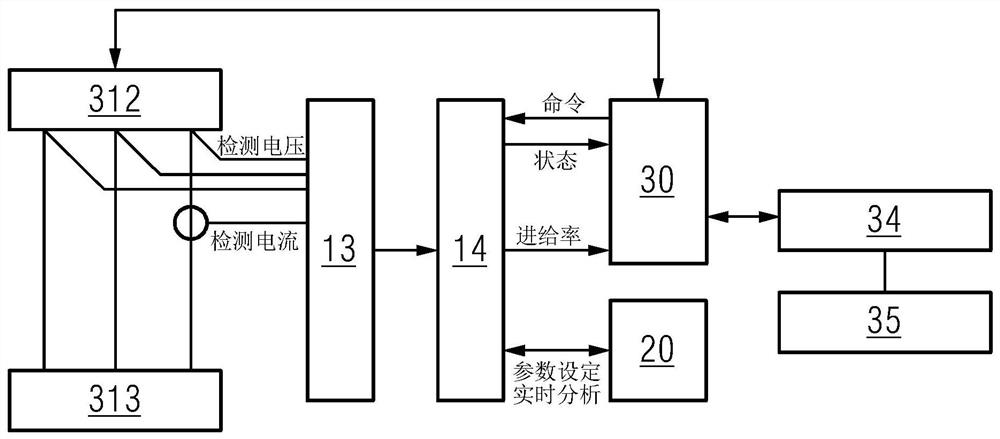

[0046] figure 1 It is a schematic diagram of the structure of the motor base adaptive processing and vertical feed axis vibration monitoring device according to an embodiment of the present invention, figure 2 For a schematic diagram of the machining of the motor base for a CNC machine, see figure 1 and figure 2, the motor base self-adaptive machining and vertical feed axis vibration monitoring method and device 10 of the present embodiment interact with the industrial computer 20 and the CNC machine tool controller 30 for real-time data, which includes a power detection sensor 12, a power calculation module 13, an adaptive A control module 14 , a vibration sensor 15 and a vibration monitoring module 16 . The power detection sensor 12 is installed on the spindle motor circuit 31 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com