Engine variable valve timing system performance testboard

A valve timing and system performance technology, applied in the direction of internal combustion engine testing, etc., to achieve the effects of accurate measurement data, easy installation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing by embodiment:

[0021] preferred embodiment

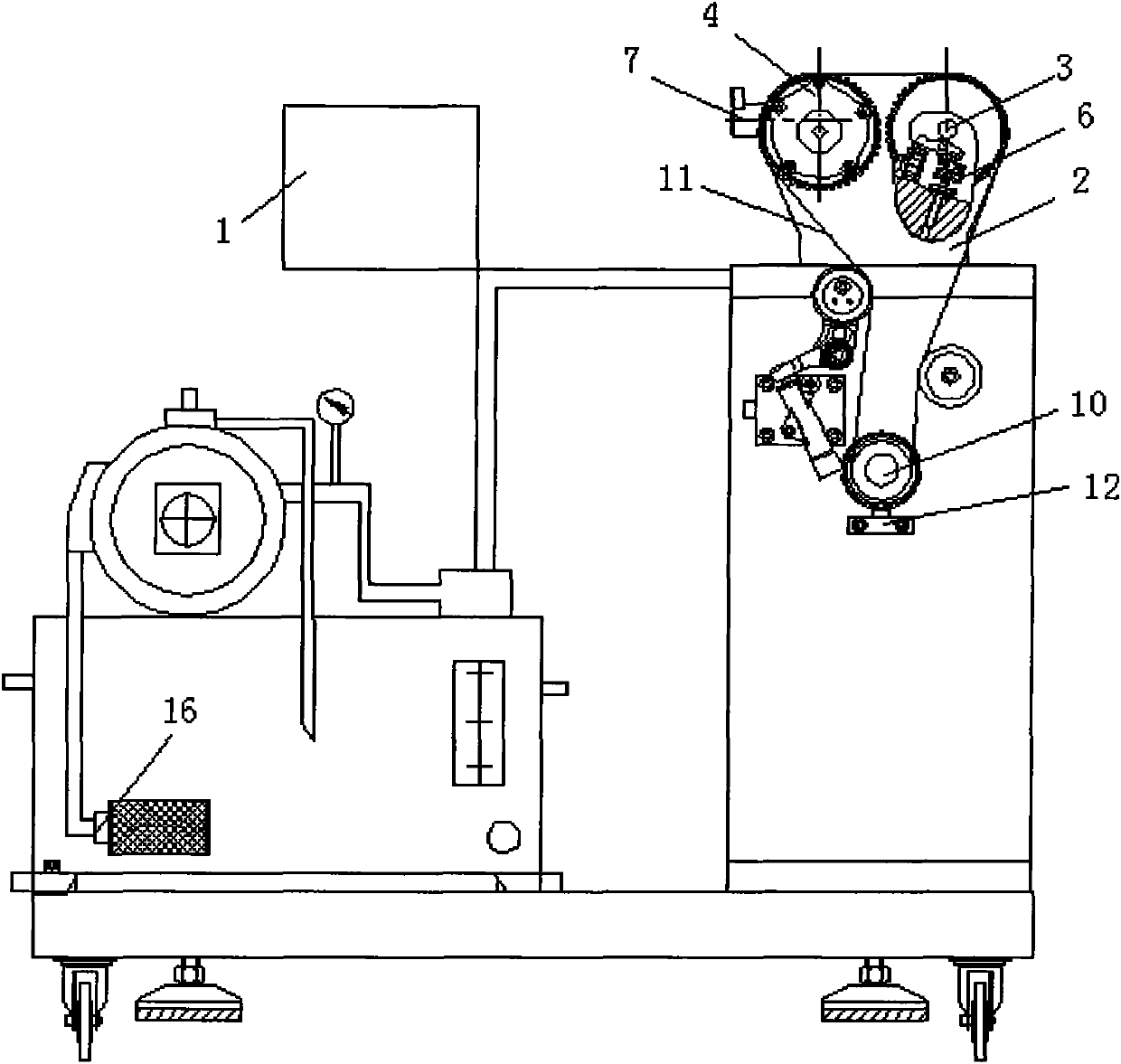

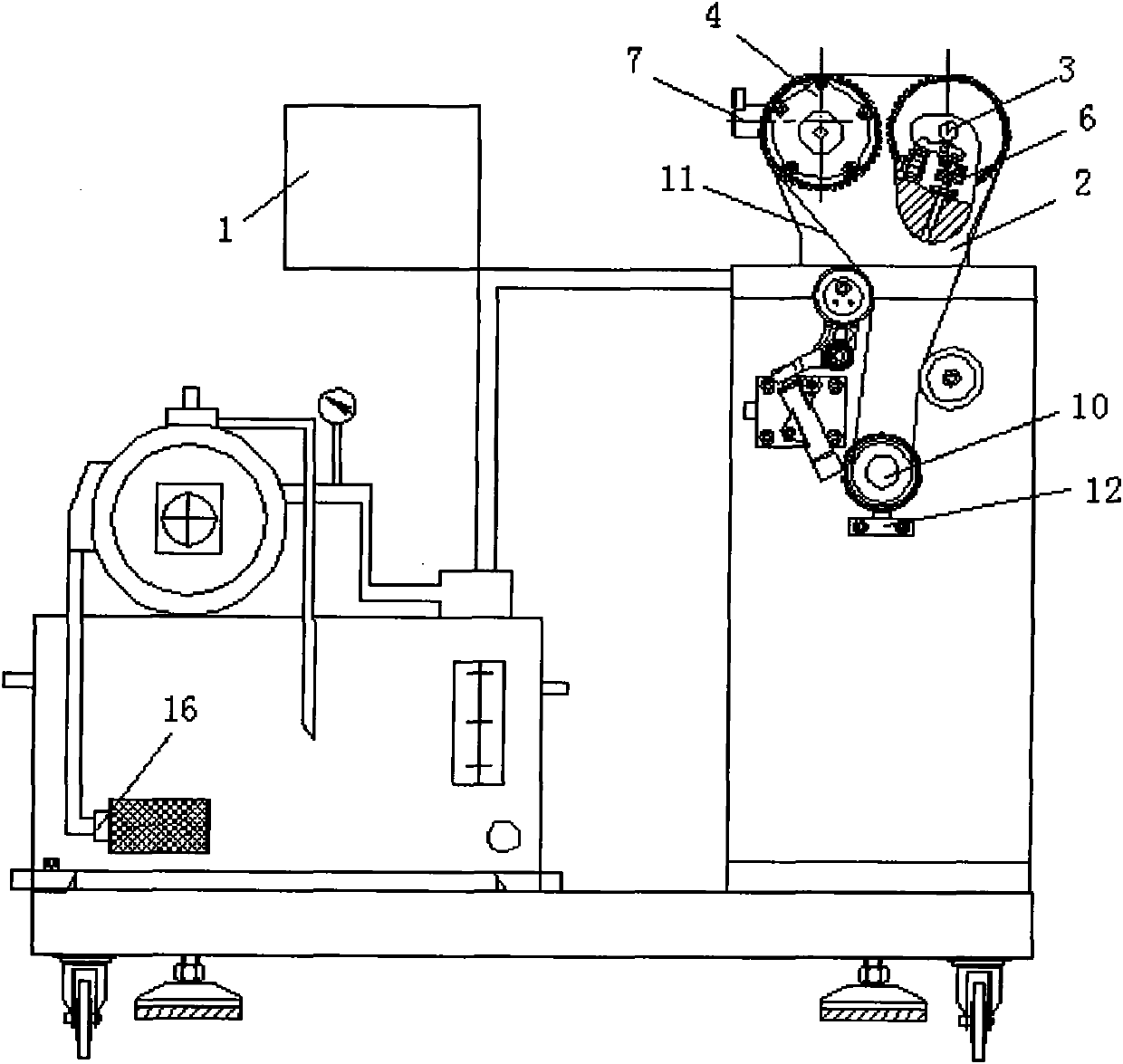

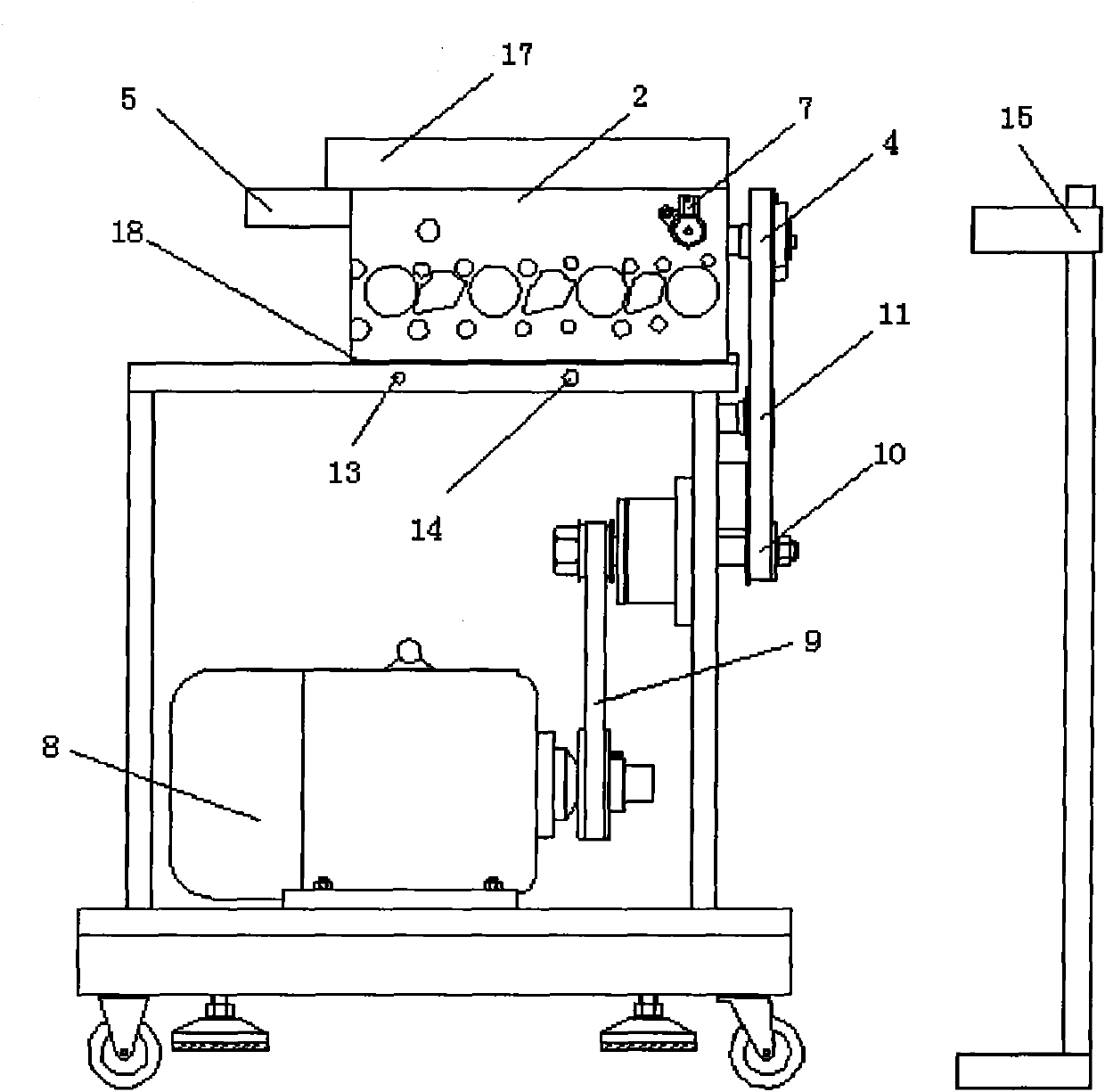

[0022] Such as figure 1 with figure 2 The shown engine variable valve timing system performance test bench is controlled by the control system 1 as a whole, including the cylinder head 2, the camshaft 3 is installed in the cylinder head 2, the front end of the camshaft 3 is connected with the phase shifter 4, and the camshaft 3 A camshaft position sensor 5 is connected to the rear end of the cylinder head. The valve assembly 6 is installed in the cylinder head 2 and moves with the rotation of the camshaft 3. The oil control valve 7 is installed on the cylinder head 2. The drive motor 8 drives the crankshaft through the transmission timing belt 9. The sprocket 10, the crankshaft sprocket 10 drives the phase shifter 4 through the chain 11, the crankshaft angle sensor 12 is arranged below the crankshaft sprocket 10, and the hydrau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com