Automobile sensor detection equipment and method for detecting performance of sensor by utilizing same

A technology for automotive sensors and detection sensors, applied in instruments and other directions, can solve the problems of inconvenient detection, low efficiency, poor product controllability, etc., to ensure product stability and reliability, high product controllability, and good stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

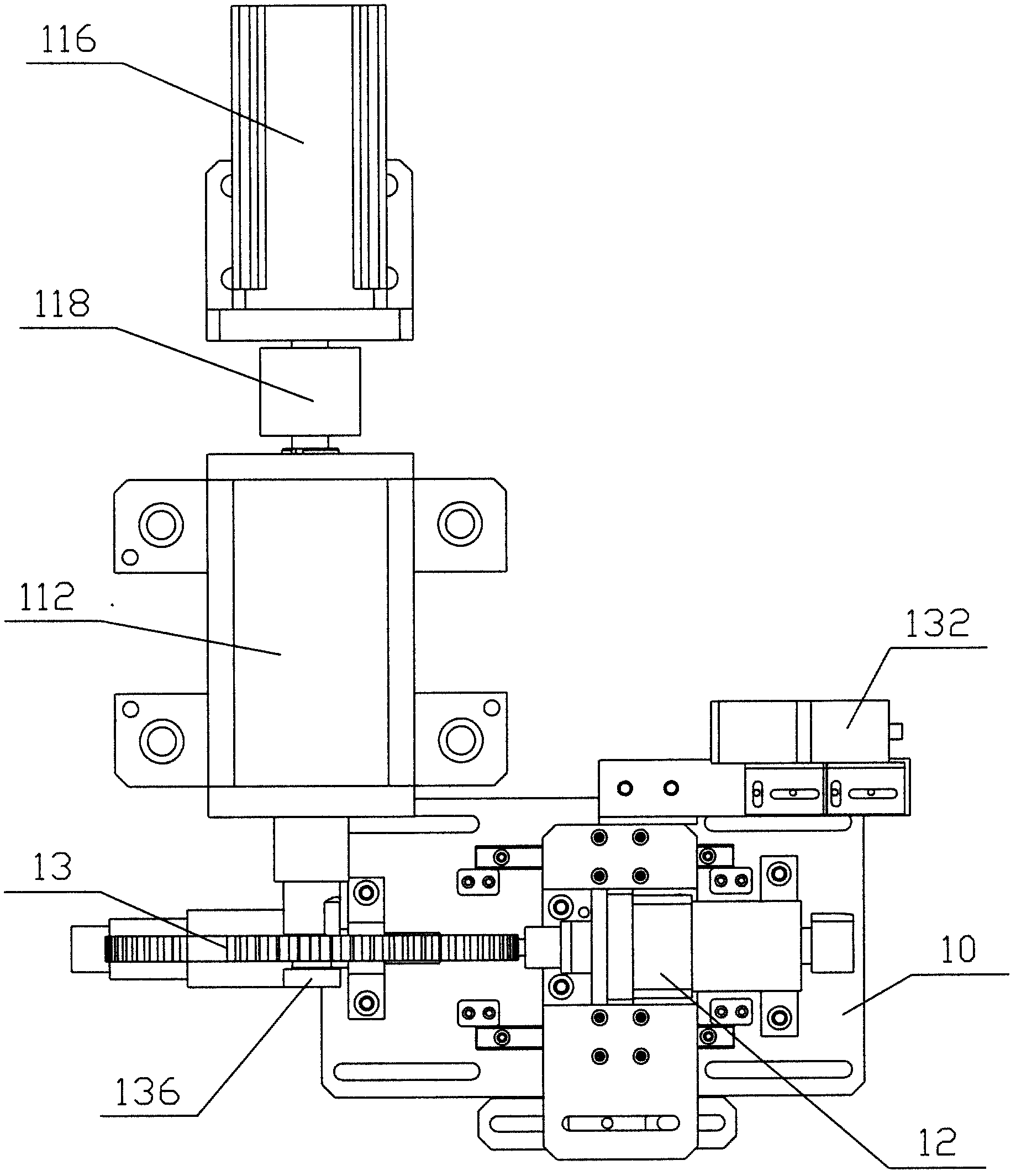

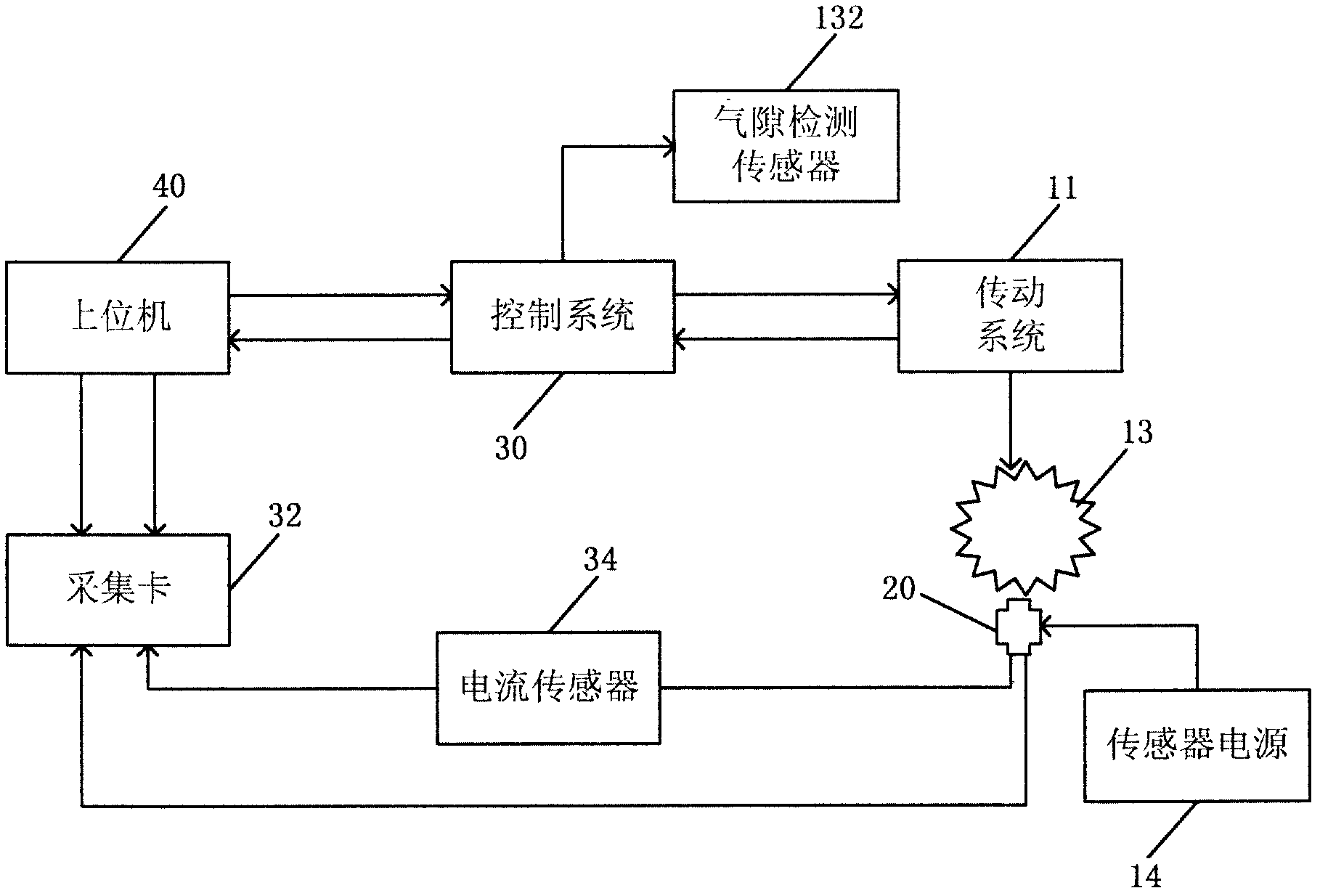

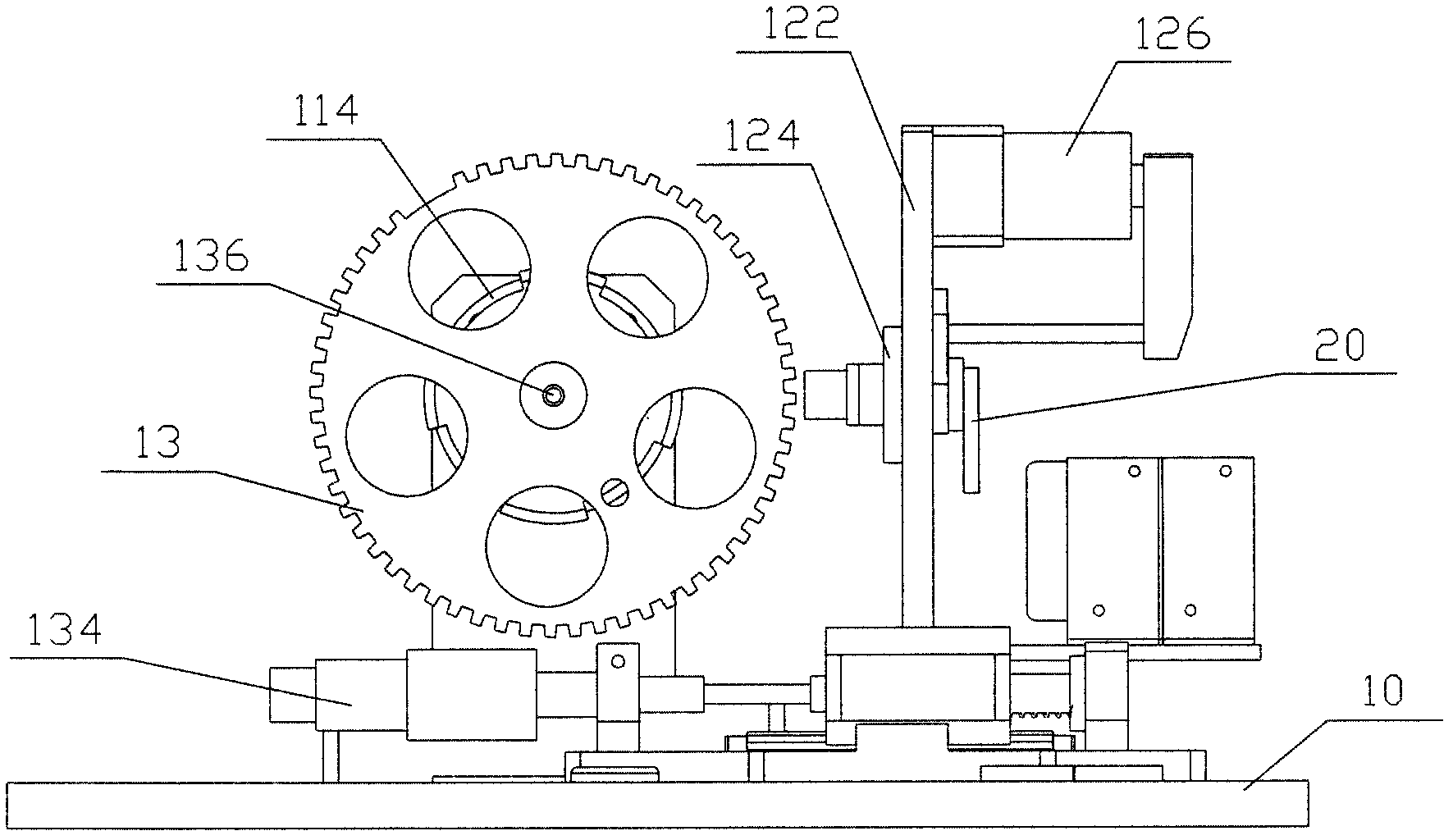

[0030] Such as Figure 1-4 As shown, the present invention provides a kind of automobile sensor testing equipment, which includes: a worktable 10, and also includes a digital transmission system 11 installed on the worktable 10, a workpiece clamping mechanism 12, a detection air gap adjustment and detection mechanism , a signal system, a control system 30 located in the workbench 10, a data acquisition system, and a signal analysis system. Wherein, the signal system includes a signal wheel 13 and a sensor power supply 14 , and the data acquisition system includes an acquisition card 32 and a current sensor 34 .

[0031] In the present invention, the digital transmission system 11 includes a bearing seat 112 , a transmission shaft 114 , a motor 116 , and a shaft coupling 118 installed between the bearing seat 112 and the motor 116 . Wherein, the motor 116 can be a servo motor or other motors. As a kind of optional embodiment of the present invention, can be provided with one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com