System and control method of engine position management

A management system and engine technology, applied in the direction of engine control, machine/engine, electrical control, etc., can solve problems such as time-consuming, misjudgment of signal jump edge, slow vehicle start, etc., to improve driving comfort and increase fault tolerance , the effect of increasing safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

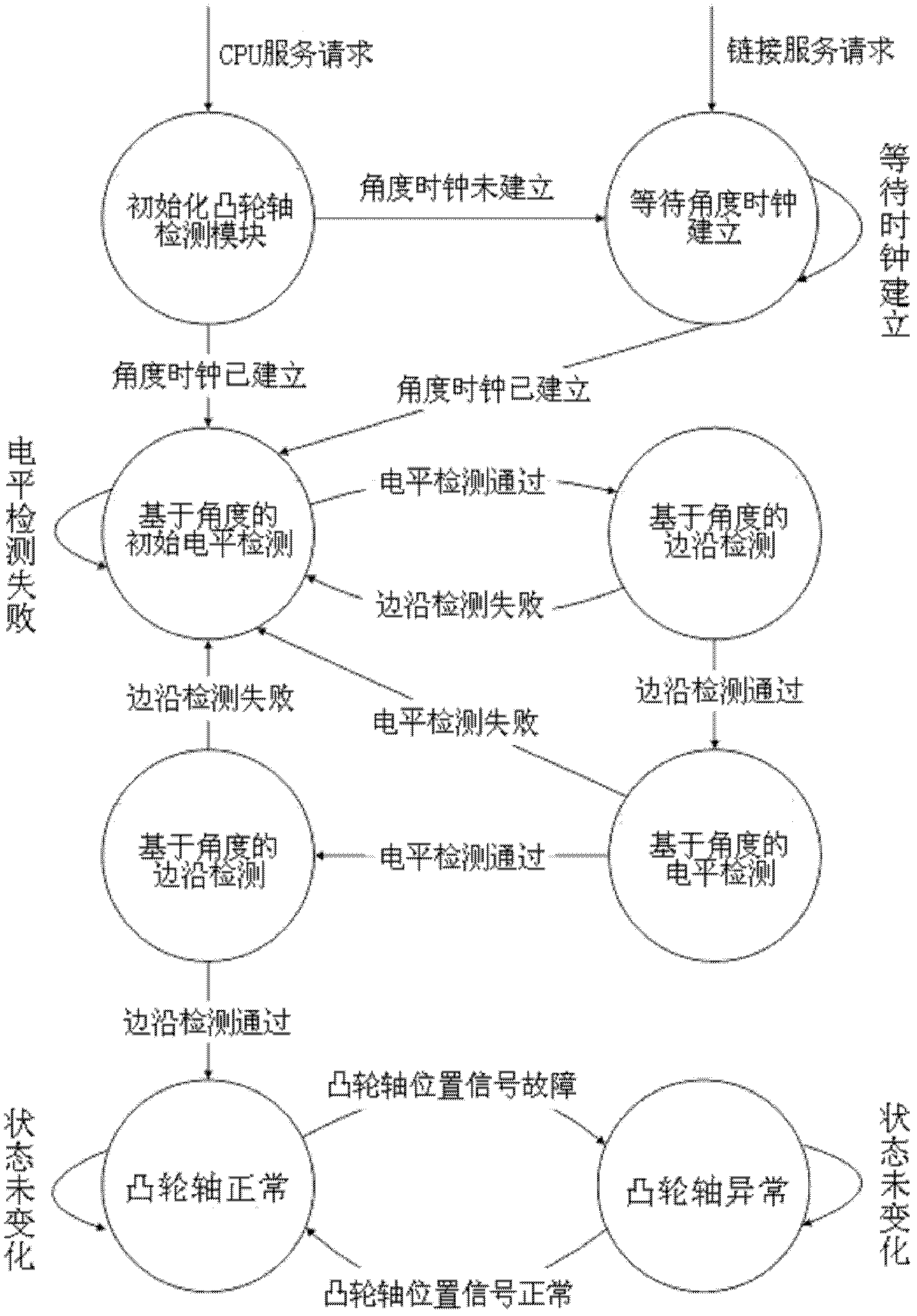

[0025] The structural block diagram of the engine position management system is as follows Image 6 As shown, it includes: crankshaft signal processing module, camshaft signal processing module and synchronous logic processing module.

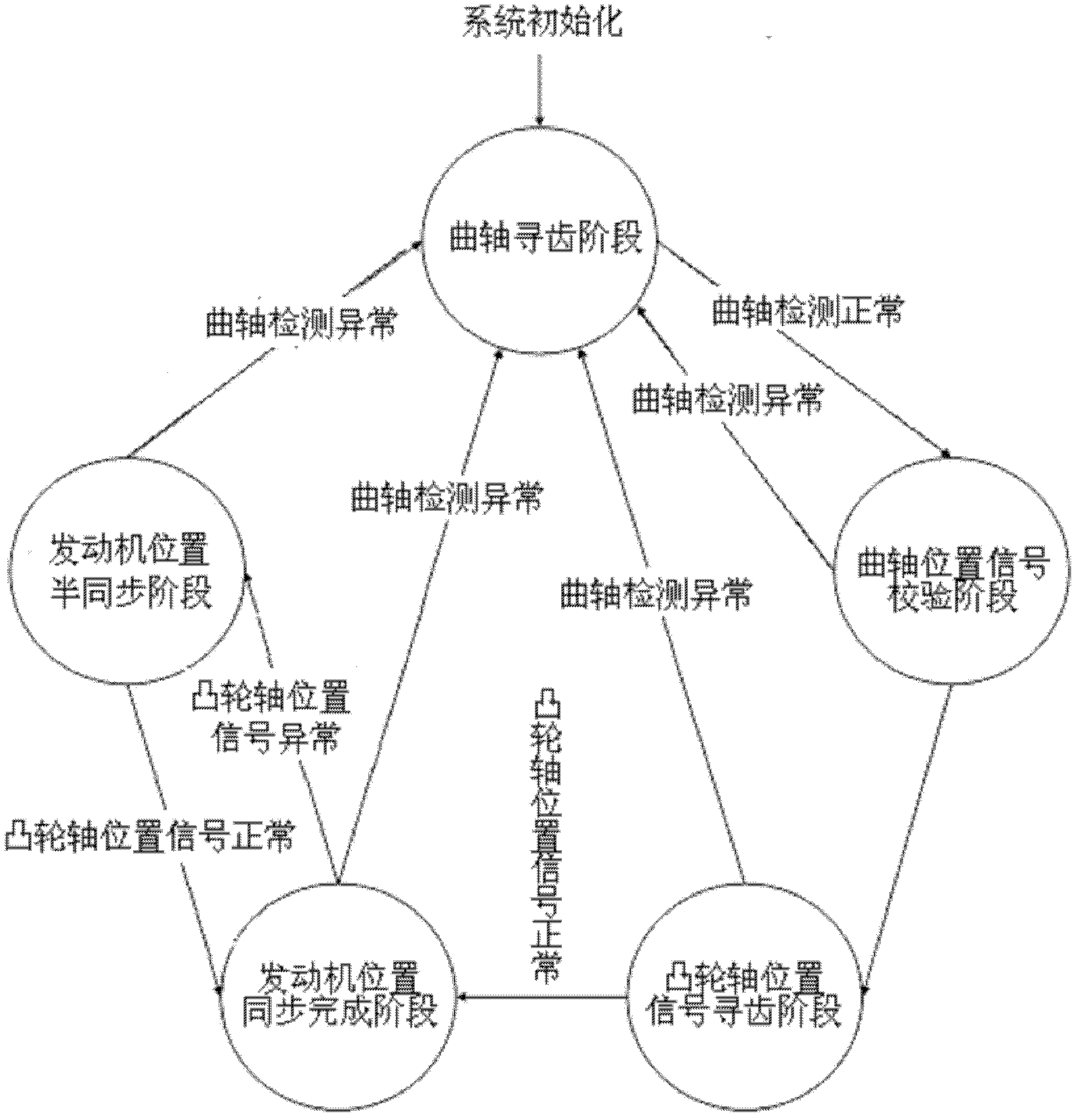

[0026] Such as figure 1 As shown, in the engine position management system, the engine position synchronization process includes five stages, namely: the crankshaft gear search stage, the crankshaft position signal verification stage, the camshaft position signal tooth search (search) stage, and the engine position synchronization completion stage Semi-synchronous phase with engine position.

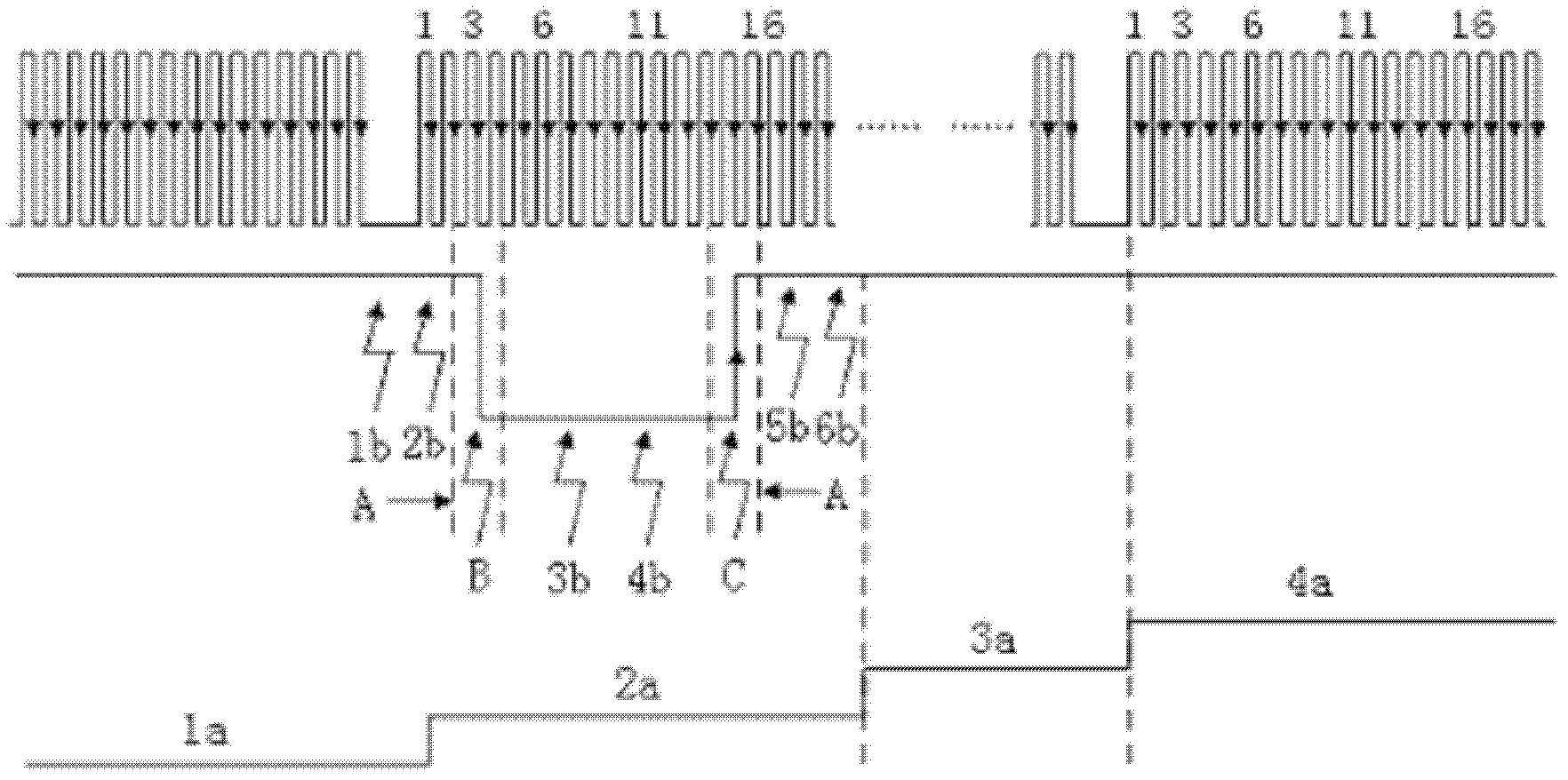

[0027] The crankshaft gear-seeking stage refers to debounce and filter processing before detection of the starting waveform of the crankshaft position signal during system initialization during engine control. When the engine is driven by the starter motor guided by the ignition key, in order to ensure the correctness and stability of the tooth signal, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com