Method for determining engine crankshaft position

A crankshaft position and engine technology, applied in engine control, machine/engine, mechanical equipment, etc., can solve problems such as inability to accurately determine the crankshaft reversal and the angle of reversal, and inability to accurately determine the stop position of the crankshaft.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below according to the accompanying drawings, which is a preferred embodiment among various implementations of the present invention.

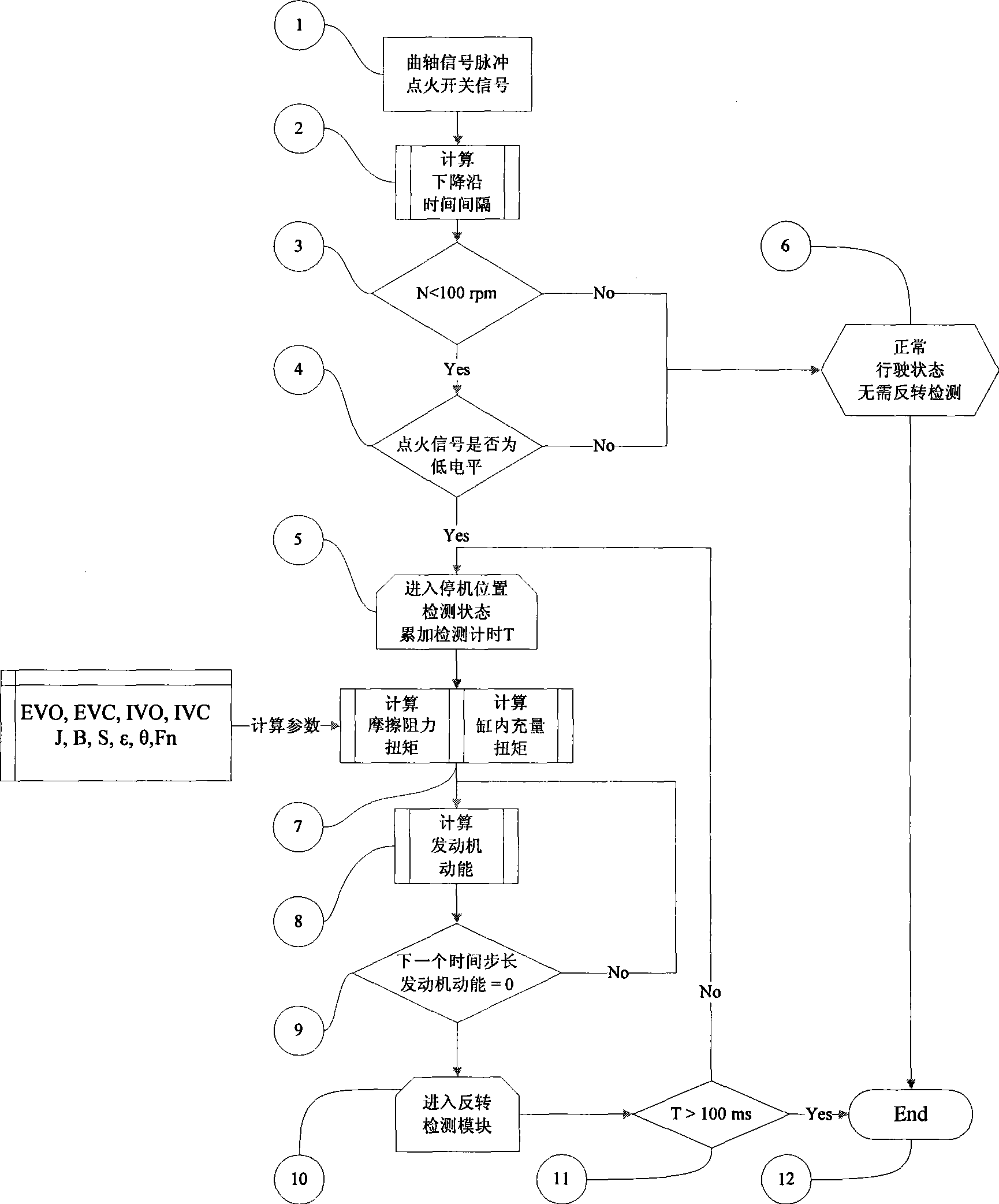

[0035] figure 1 It is each step of the present invention to detect the crankshaft position of the engine in the shutdown process.

[0036] In step 1, input the most important judgment signals of this method: crankshaft position signal pulse and ignition switch state. In step 2, the time interval of the crankshaft position signal pulse is calculated according to the falling edge, and the engine speed is calculated. In step 3, it is judged whether the engine speed enters the shutdown critical condition. If the speed is less than 100 RPM, the output is YES, continue to step 4. If the rotational speed is greater than or equal to 100 revolutions per minute, output No, go to step 6, enter the normal driving state, and do not perform reverse detection.

[0037] In step 4, it is another cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com