Pump for distributing liquid product and dispenser comprising such a pump

A technology for fluid products, dispensing pumps, applied in a single hand-held device, spray device, etc., to solve problems such as unfavorable gaskets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

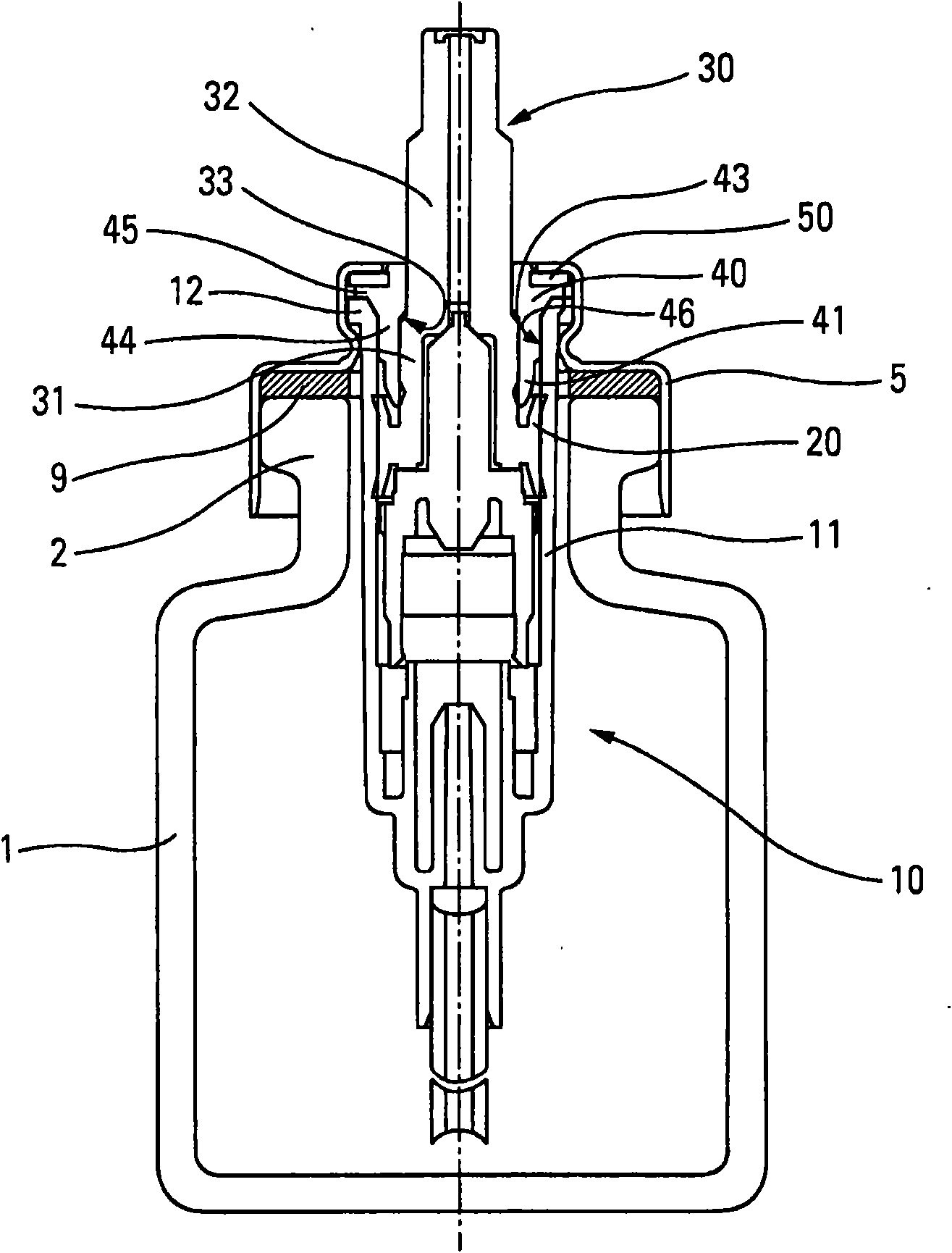

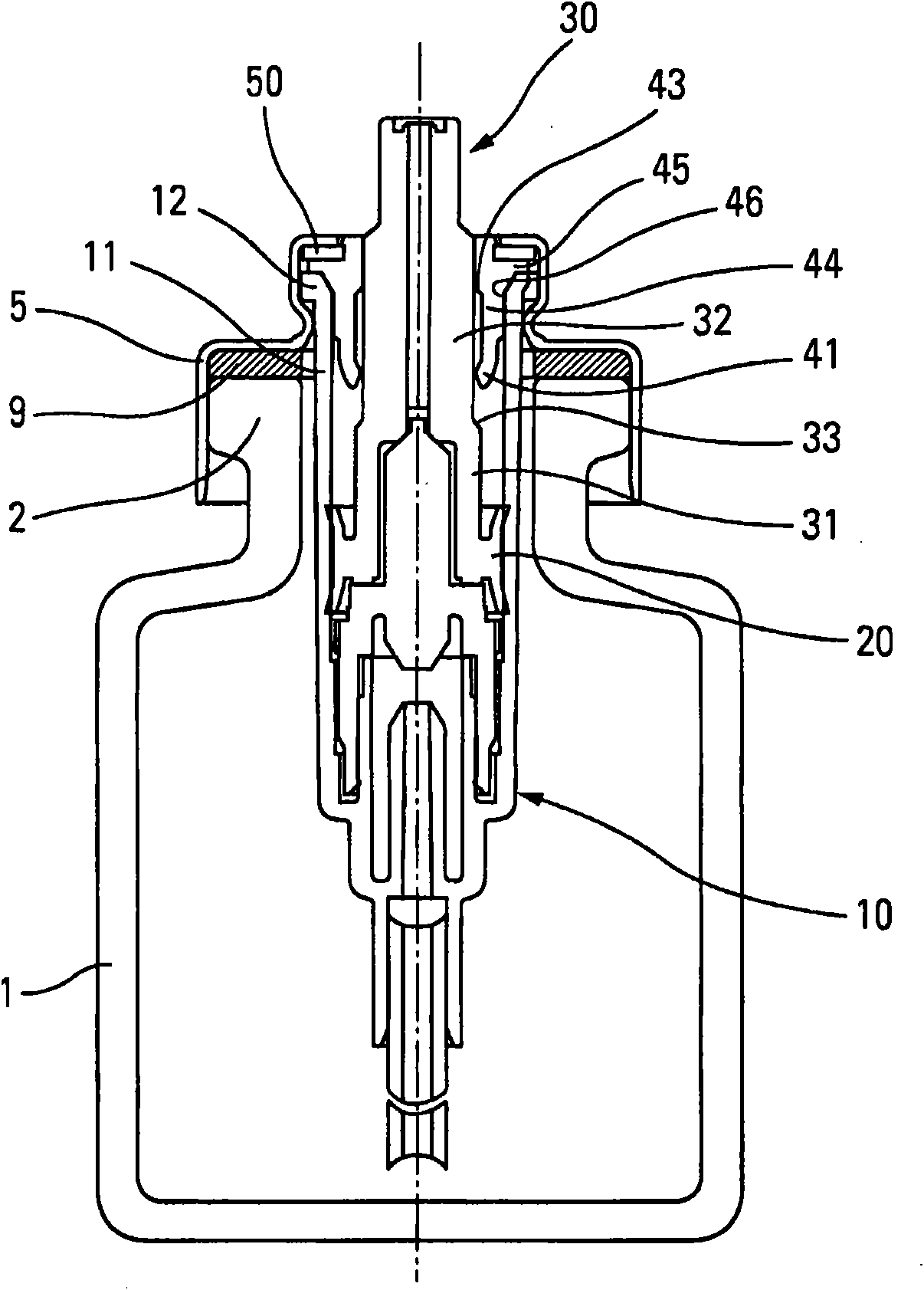

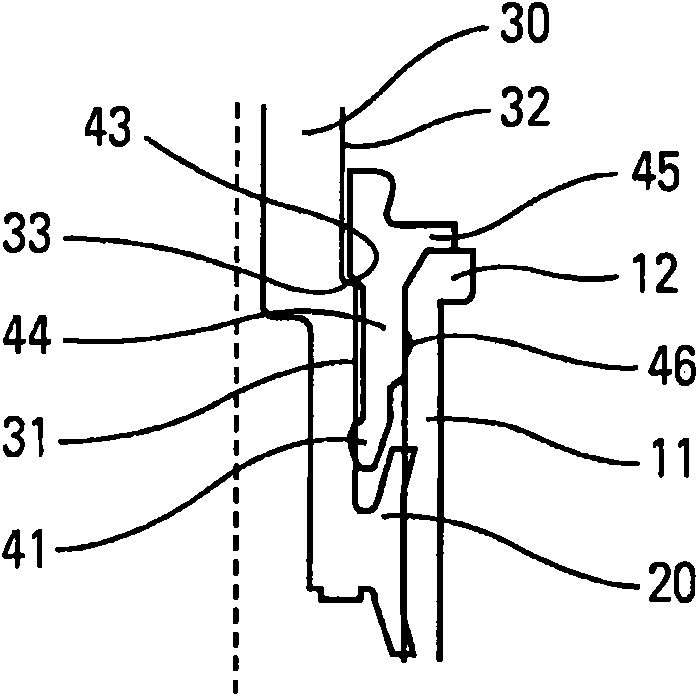

[0025] refer to figure 1 and 2 , shows a fluid dispensing device according to an advantageous embodiment of the present invention. The device has a container 1 with a neck 2 in which a pump 10 is assembled by means of a retaining ring 5 and preferably inserted with a sealing gasket 9 called a neck gasket. The pump has a pump body 11 with an upper edge 12 . A piston 20 slides in a sealed manner inside said pump body 11 at each actuation in order to dispense a dose of product from the container 1 . The internal structure of the pump will not be described in further detail below, since the invention is applicable to all types of pumps and is in no way subject to figure 1 , 2 The limitations of the specific characteristics of the pump are given as examples. In conventional manner, as shown in the figures, the piston 20 is connected, in particular integral, with an actuating lever 30, on which a dispensing head or button (not shown) is assembled, in order to enable The pump i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com