Oil quantity management control system and method for diesel engine electric control voltage accumulation distributed type common rail system

A common rail system, management control technology, applied in electrical control, engine control, fuel injection control and other directions, can solve problems such as increasing development complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with specific drawings and embodiments.

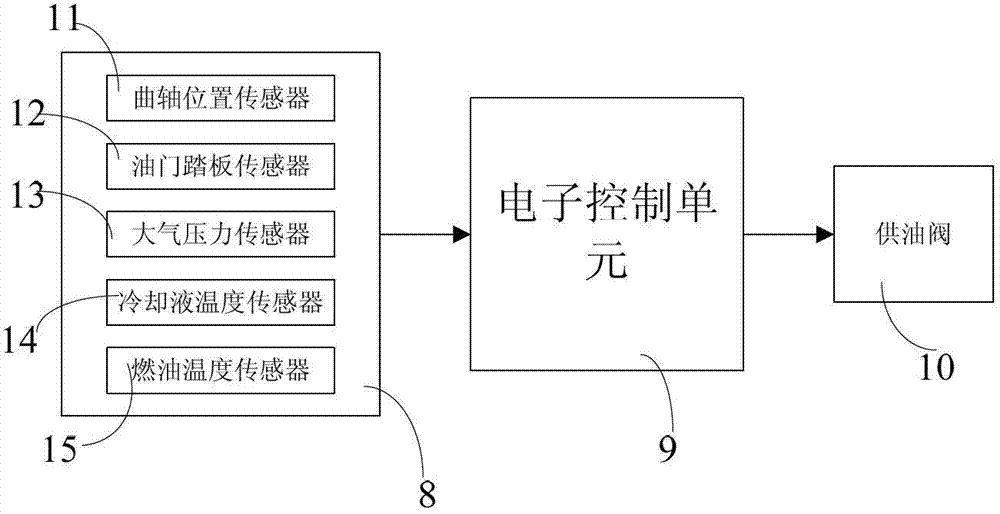

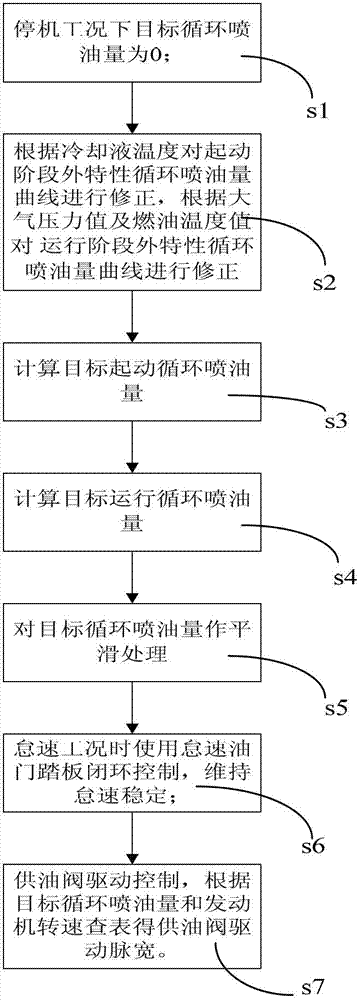

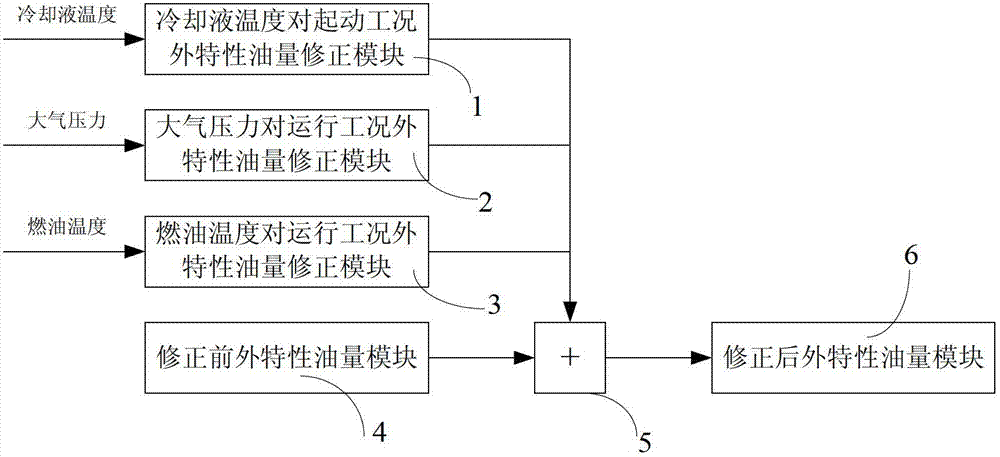

[0052] Such as figure 1 Shown: in order to be able to control the fuel injection quantity of the diesel engine to realize the control of the rotational speed and torque of the diesel engine, the present invention includes a fuel supply valve 10 and an electronic control unit 9 for driving and controlling the working state of the fuel supply valve 10; The electronic control unit 9 is connected with the sensor module 8 for detecting the state of the diesel engine and the environment state, and the sensor module 8 includes a crankshaft position sensor 11, an accelerator pedal sensor 12, an atmospheric pressure sensor 13, a coolant temperature sensor 14 and a fuel oil sensor. Temperature sensor 15; the electronic control unit 9 is pre-stored with the fuel injection quantity curve of the external characteristic cycle, and the fuel injection quantity curve of the ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com