Bench test device for power assembly of mixed power electric vehicle

A powertrain and electric vehicle technology, applied in the direction of measurement devices, motor generator testing, vehicle testing, etc., can solve the problem that the engine bench cannot meet the test requirements of the hybrid power bench

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

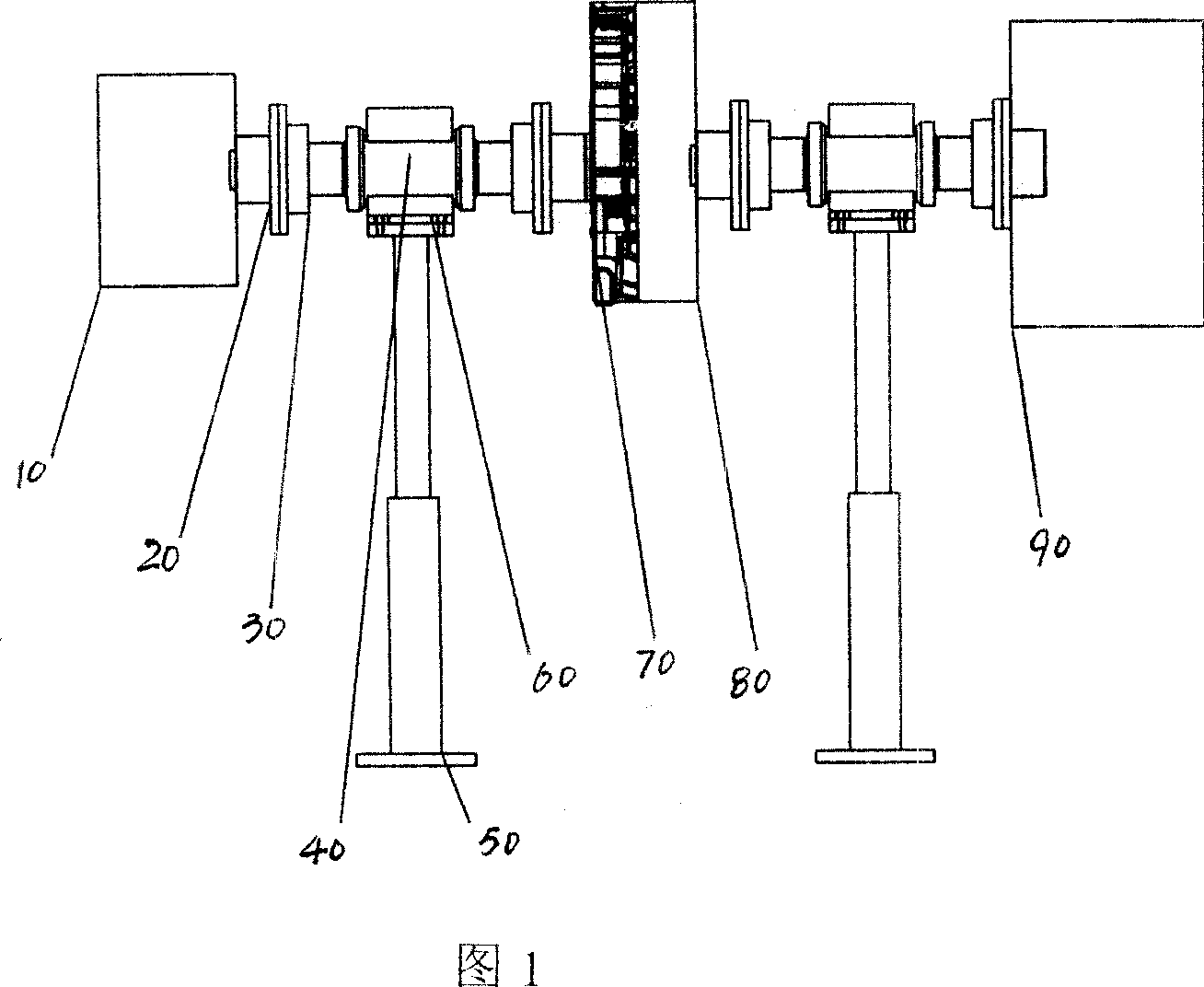

[0007] As shown in Figure 1, the hybrid vehicle powertrain bench test device is composed of front, rear, left and right brackets according to the installation method of the engine 10, the torque sensor 40, the motor 70, the gearbox 80 and the fixed position of the crankshaft position sensor. Bench, the powertrain is installed on the bench, the dynamometer 90 is connected to the power output end of the gearbox 80, and the torque sensor 40 is set between the engine 10 and the motor 70 and / or between the motor 70 and the dynamometer 90 .

[0008] The preferred solution is to set the torque sensor 40 between the engine 10 and the motor 70 and between the motor 70 and the dynamometer 90, the torque sensor 40 is fixedly arranged on the support 50, and each part of the powertrain and the torque sensor 40, the dynamometer Machine 90 is highly consistent with the centerline of the powertrain.

[0009] The torque sensor 40 has a base and a bracket 50 to fix it,

[0010] There is a bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com