A temperature measuring component installed in a flute tube

A flute-shaped tube and component technology, which is applied in the field of temperature measurement components, can solve problems such as welding through, high hot gas velocity, and high probability of defective products, and achieve the effect of avoiding welding connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

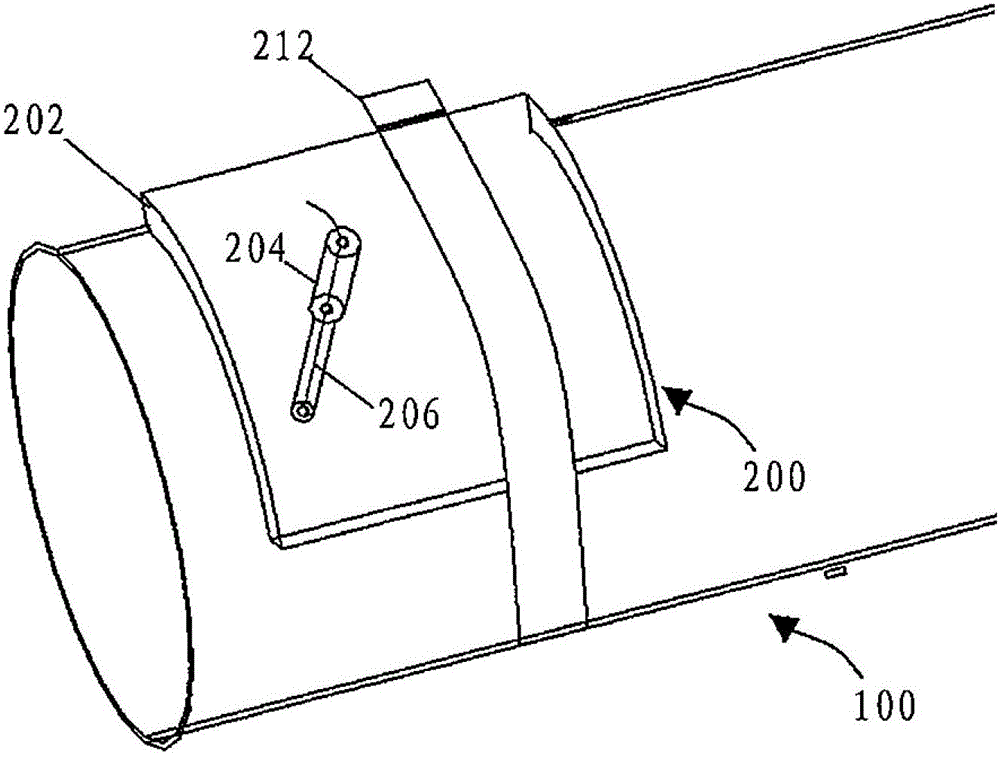

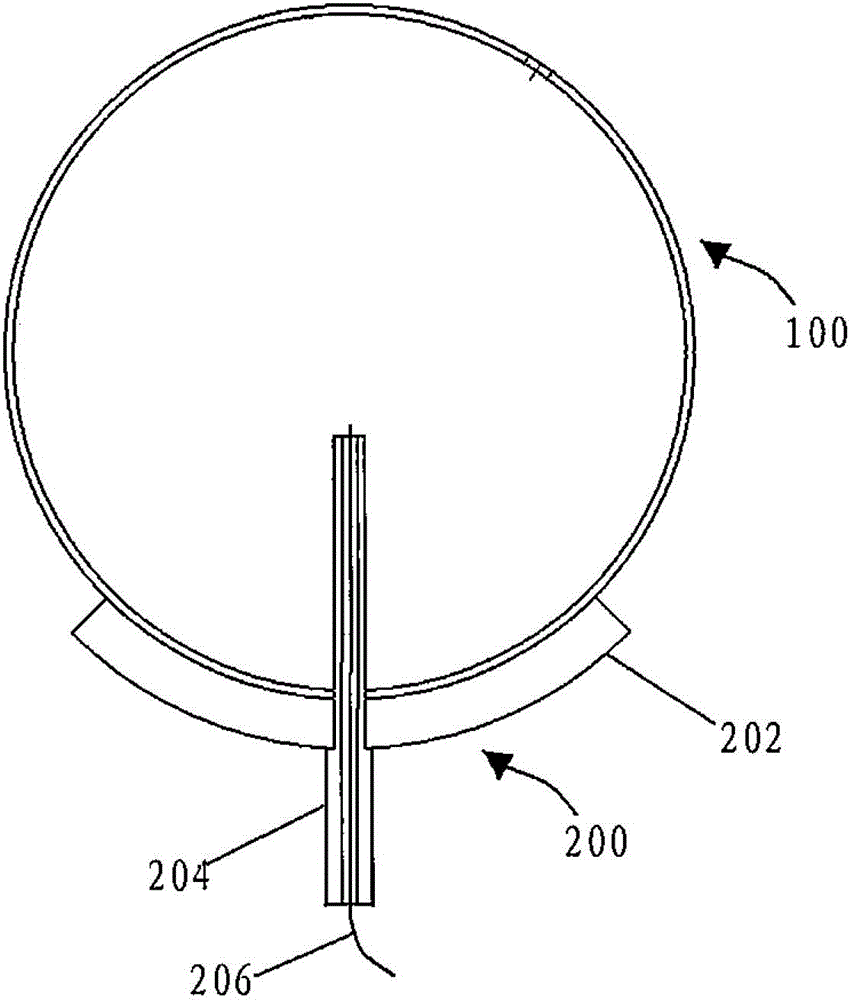

[0025] Such as figure 1 and figure 2 As shown, a temperature measuring assembly 200 installed on a piccolo 100 , wherein the piccolo 100 has a first through hole, the temperature measuring assembly 200 includes a base 202 , a tubular carrier 204 and a thermocouple 206 .

[0026] Specifically, the base 202 is a thin plate-shaped part made of aluminum material, which has a joint surface adapted to the outer surface of the piccolo 100. Specifically, as shown in the figure, the joint surface is arc-shaped and the curvature of the joint surface is the same as The outer surfaces of piccolo 100 have the same curvature. There is also a second through hole on the base 202. When the base 202 is bound to the pictograph 100 by the high temperature resistant tape 212, the joint surface of the base 202 and the outer surface of the pictograph 100 are attached to each other and make the The aforementioned second through hole and the first through hole are aligned with each other. Generall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com