Hollow fan blade for aircraft engine

A technology for aero-engines and fan blades, which is applied to machines/engines, liquid fuel engines, mechanical equipment, etc., can solve the problems of blade body and tenon or disc connection, high blank processing requirements, and complex shaping processes, and achieves the goal of manufacturing technology. Low requirements, simple manufacturing process, avoiding the effect of complex processes

Active Publication Date: 2010-11-10

BEIJING AVIATION MATERIAL INST NO 1 GRP CORP CHINA AVIATION IND

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

To sum up, whether it is the SPF / DB process adopted by Rolls-Royce or Pratt & Whitney’s two-half split process to manufacture titanium alloy hollow fan blades, the manufacturing process is very complicated, such as the three-layer plate SPF / DB process The control is difficult, and it also involves the connection between the blade body and the tenon or disk. The two-half split process requires high processing of the blank before diffusion welding. Diffusion welding requires high-precision centering control, and the shaping process after diffusion welding is complicated.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

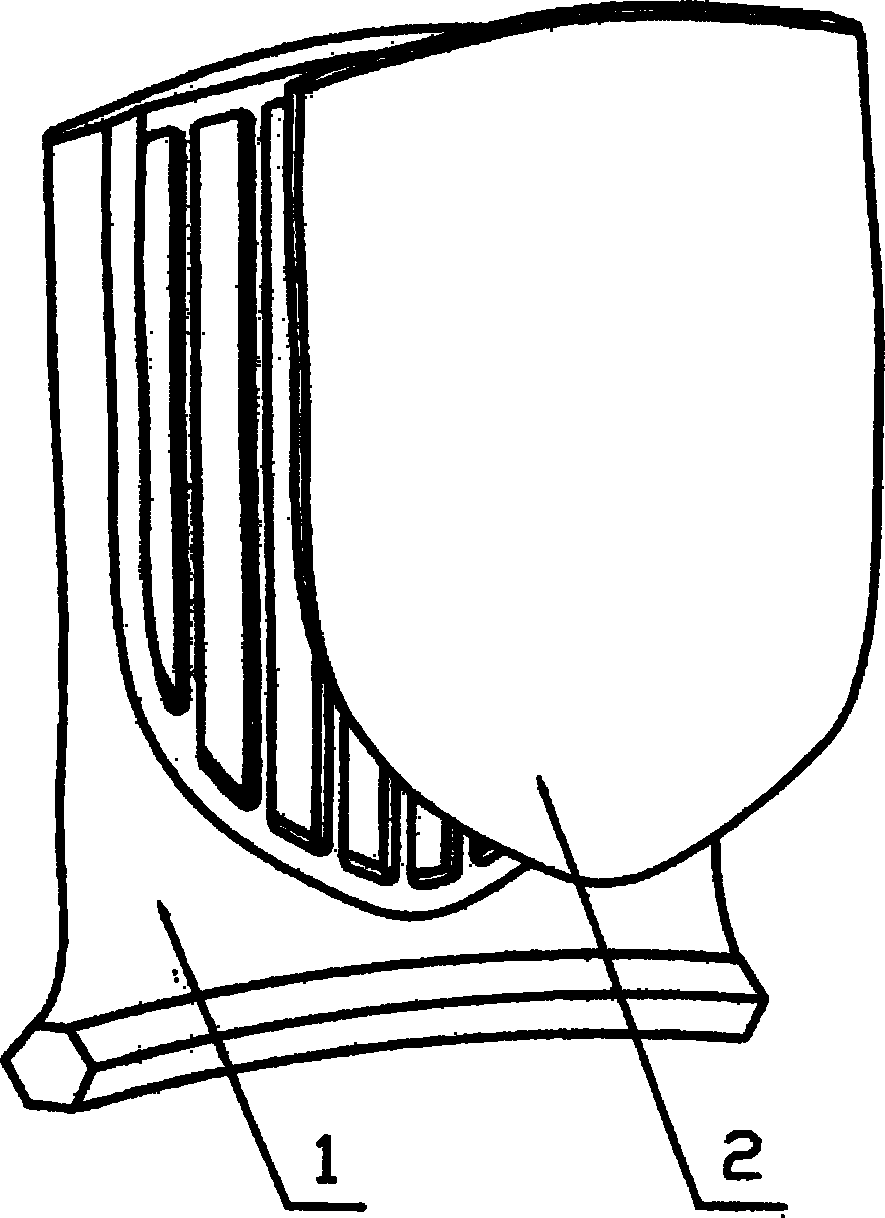

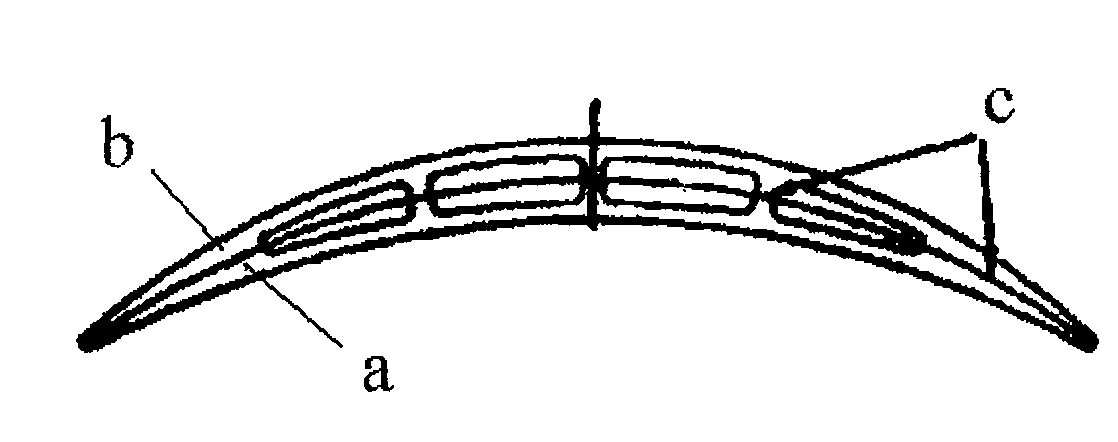

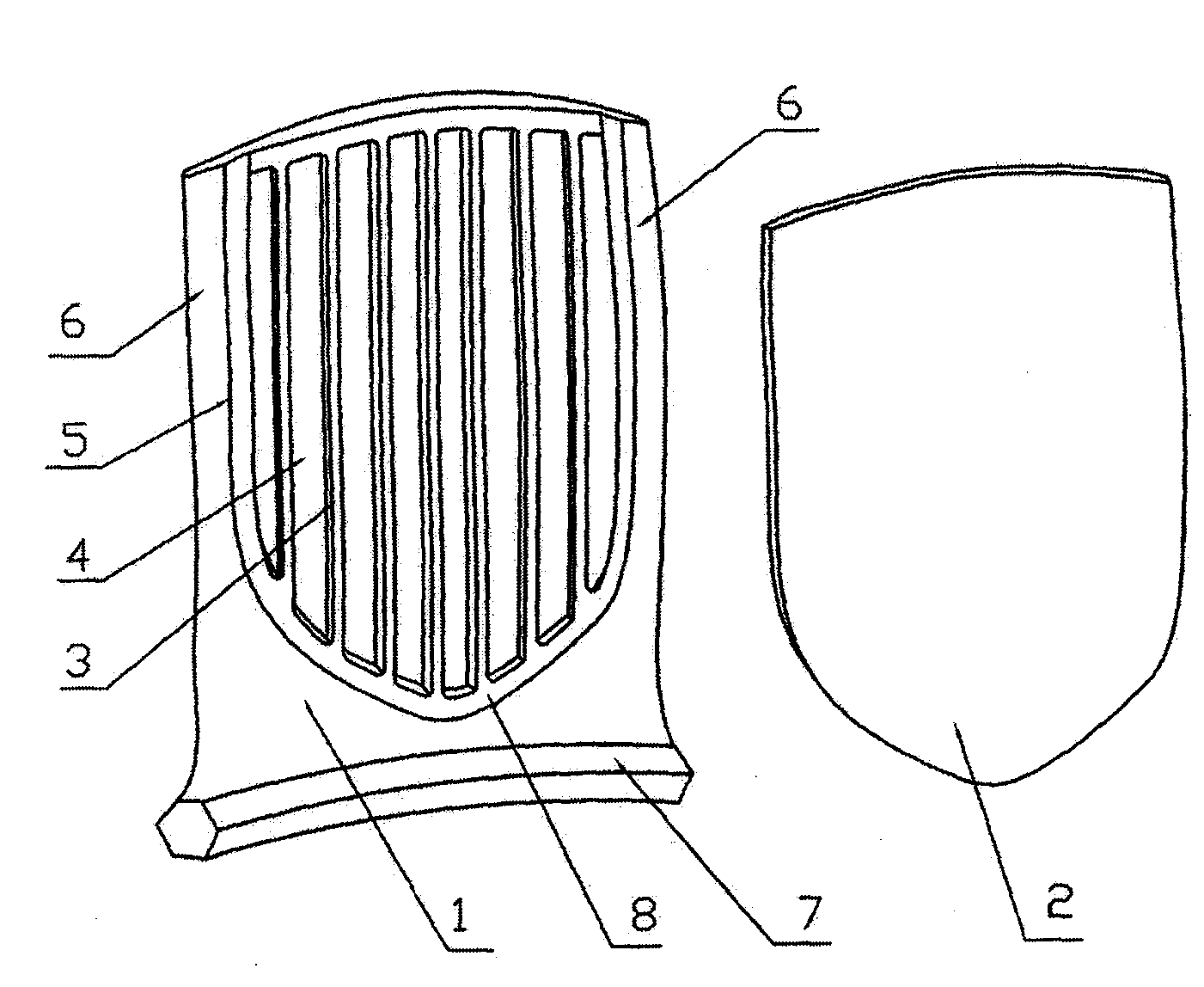

The invention belongs to the field of fan blade of turbofan engine, relating to an aeroengine hollow fan blade. The blade is a combined structure composed of a blade main body and a local panel, the blade main body comprises a blade body and a complete tenon, one side of the blade body is provided with a groove at the center, the edge of the blade body is solid, the local panel is a curved flat plate corresponding to the shape of the groove area of the blade main body, and the ribs of the groove on the blade body of the blade main body and the edge of the groove area are welded with the localpanel to form the hollow blade. Compared with the conventional titanium alloy hollow fan blade manufacturing scheme, the invention has the outstanding advantage of simple manufacturing process, and the blade use safety is also effectively improved. Compared with solid blade, the weight of the blade of the invention is obviously reduced.

Description

Aircraft engine hollow fan blade technical field The invention belongs to the field of turbofan engine fan blades, and relates to an aeroengine hollow fan blade. Background technique The fan diameter of turbofan engine with high bypass ratio is relatively large, generally greater than 1.5m. For example, the fan diameter of different models of CFM56 series engines ranges from 1549mm to 1836mm, and the fan diameter of GE90 engine even reaches 3124mm. The increase of the fan diameter makes the size of the fan blades longer, which directly brings about the increase of the centrifugal force during operation, and there are also a series of problems such as vibration and impact resistance. The wide-chord hollow blade structure becomes the best technical solution to solve the above problems. High bypass ratio engine fan blades are characterized by being long and thin. For example, the V2500 engine fan blade is 0.522m long, the engine fan blade used for Boeing 747 is about 0.8-0....

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): F04D29/38F04D29/30

Inventor 程耀永李晓红熊华平毛唯

Owner BEIJING AVIATION MATERIAL INST NO 1 GRP CORP CHINA AVIATION IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com