A multi-block main cable saddle structure

A main cable saddle and block technology, used in bridge parts, bridges, buildings, etc., can solve the problems of high-altitude hoisting and transportation of saddles, restricting saddle design and construction, large welding residual stress, etc. Transportation and hoisting, easy installation and positioning, and the effect of improving stress performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and a specific example.

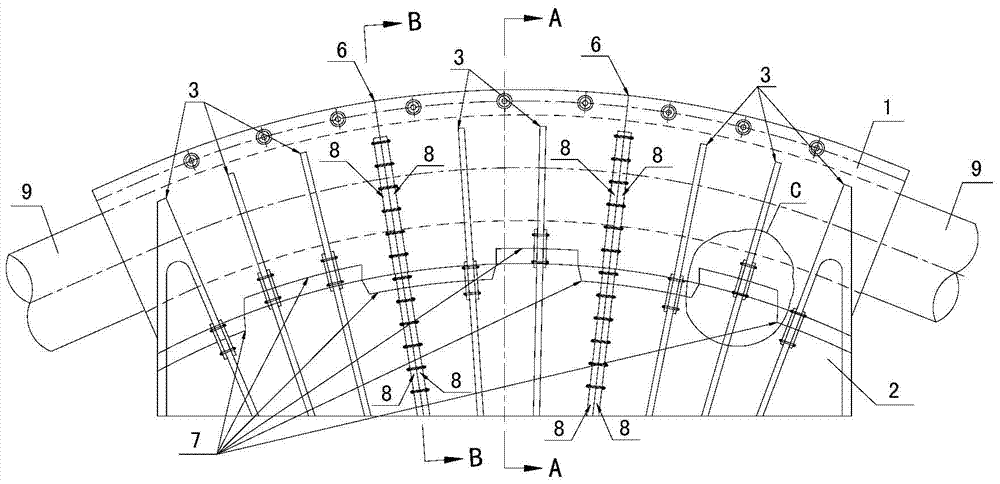

[0018] refer to figure 1 , the present invention divides the main cable saddle of the suspension bridge into the upper saddle head 1 and the lower saddle body 2 through the block interface in the height direction. The block interface is located 30±5cm below the bottom plate of the main cable 9 cable trough, and the block interface adopts concave-convex joints 7. In this way, the large-volume, large-tonnage saddle can be divided into six pieces along the longitudinal and height directions, and cast, transported, and installed in blocks.

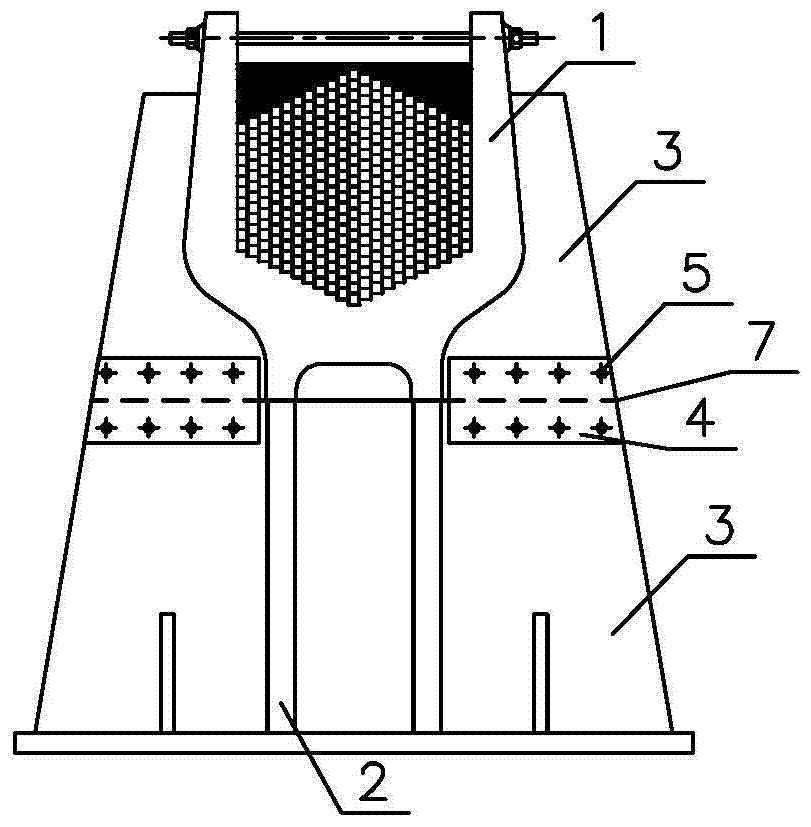

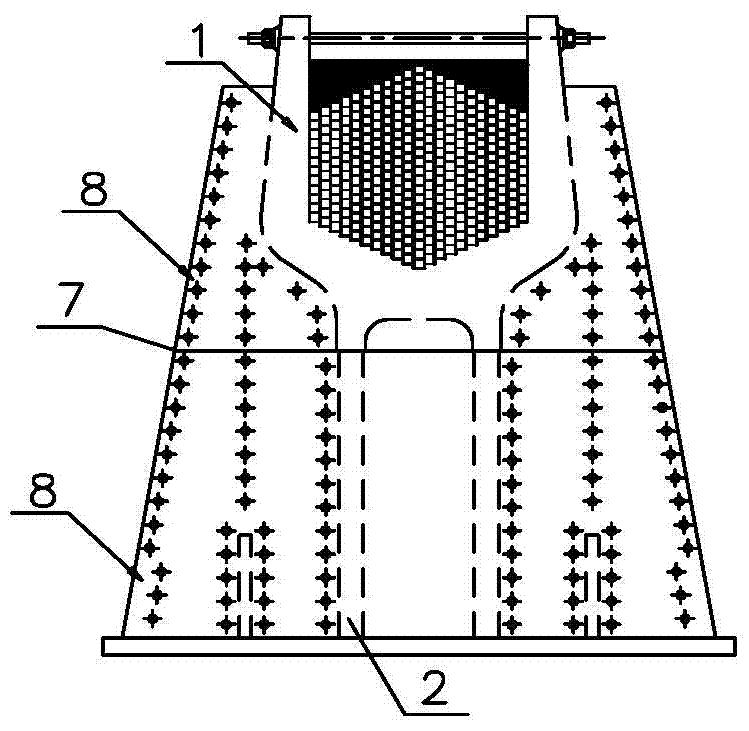

[0019] refer to figure 2 , 4 , The transverse rib 3 is connected at the concavo-convex seam 7 with a splicing plate 4 and a high-strength bolt 5 for lateral positioning.

[0020] refer to figure 1 , 3 , the upper saddle head and the lower saddle body are equally divided into three pieces by the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com