Mounting aid and method for mounting electrical components on printed circuit board

A printed circuit board and installation auxiliary technology, applied in the direction of printed circuit, printed circuit, printed circuit, etc. connected with non-printed electrical components, can solve problems such as long cycle time, sensitive operating range, complicated quality control, etc., to avoid Mechanically unreliable, improving mechanical reliability, avoiding the effect of soldered connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

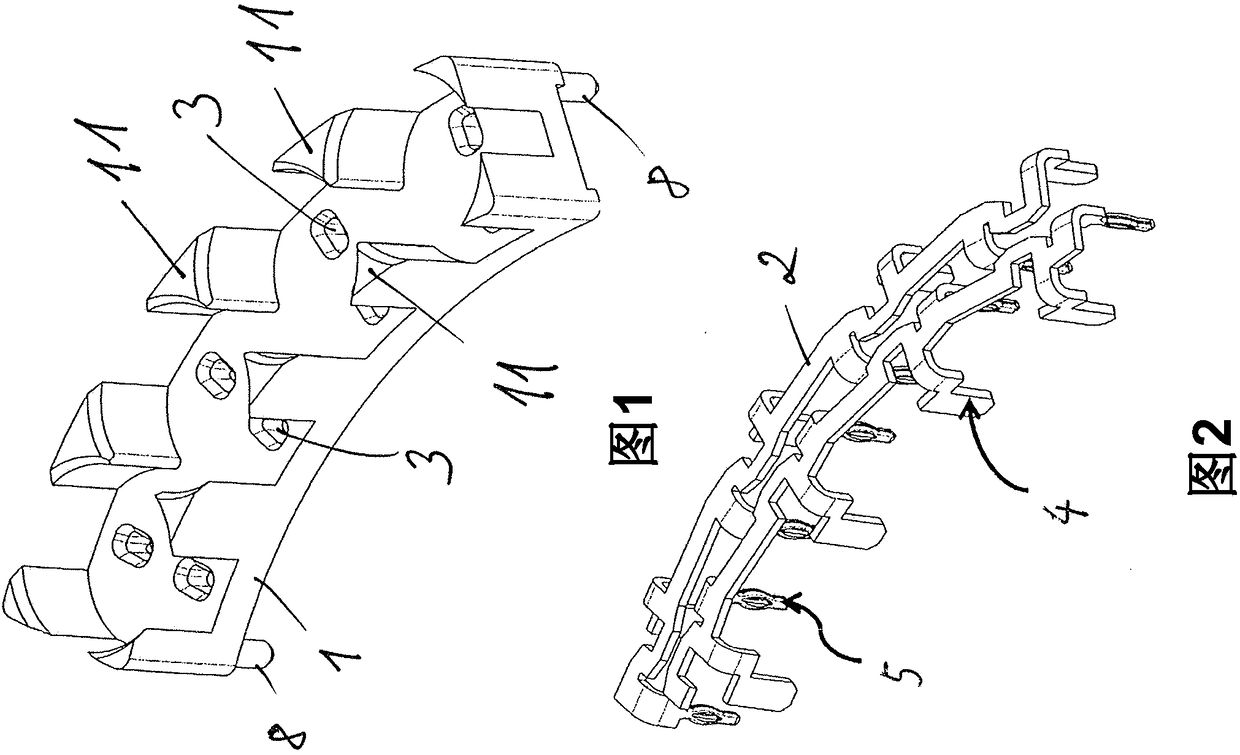

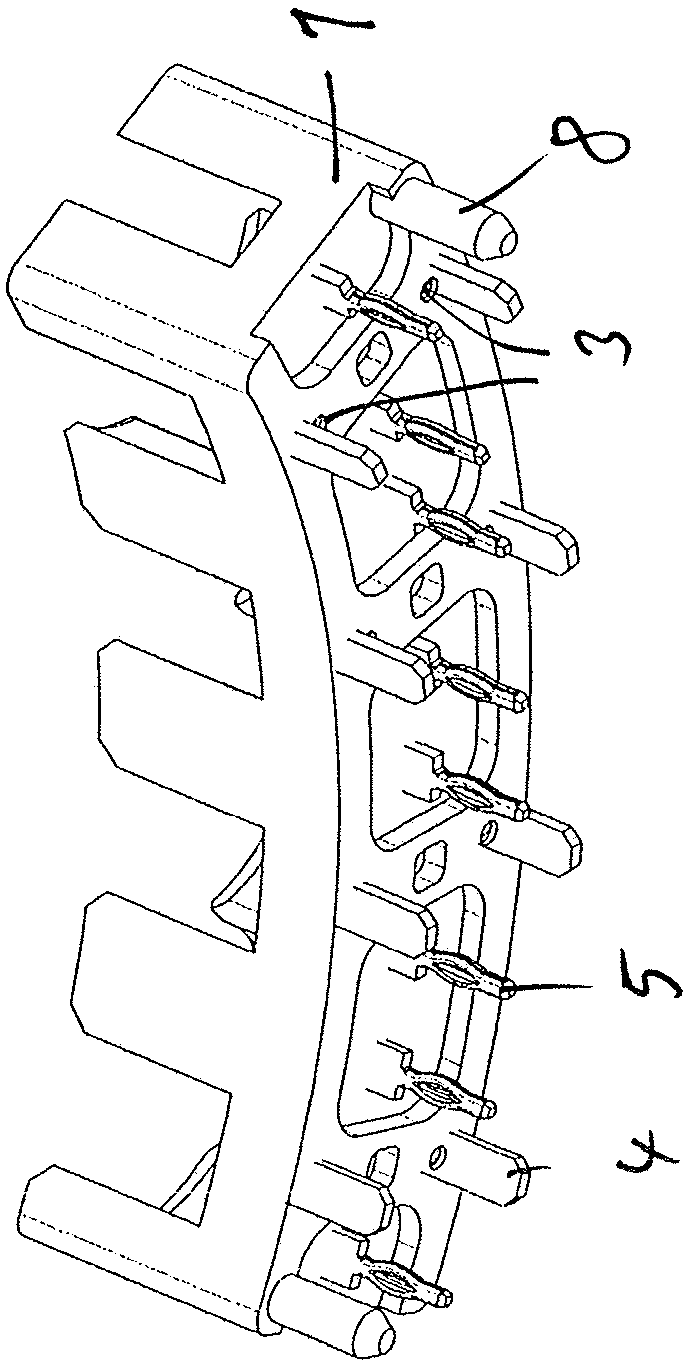

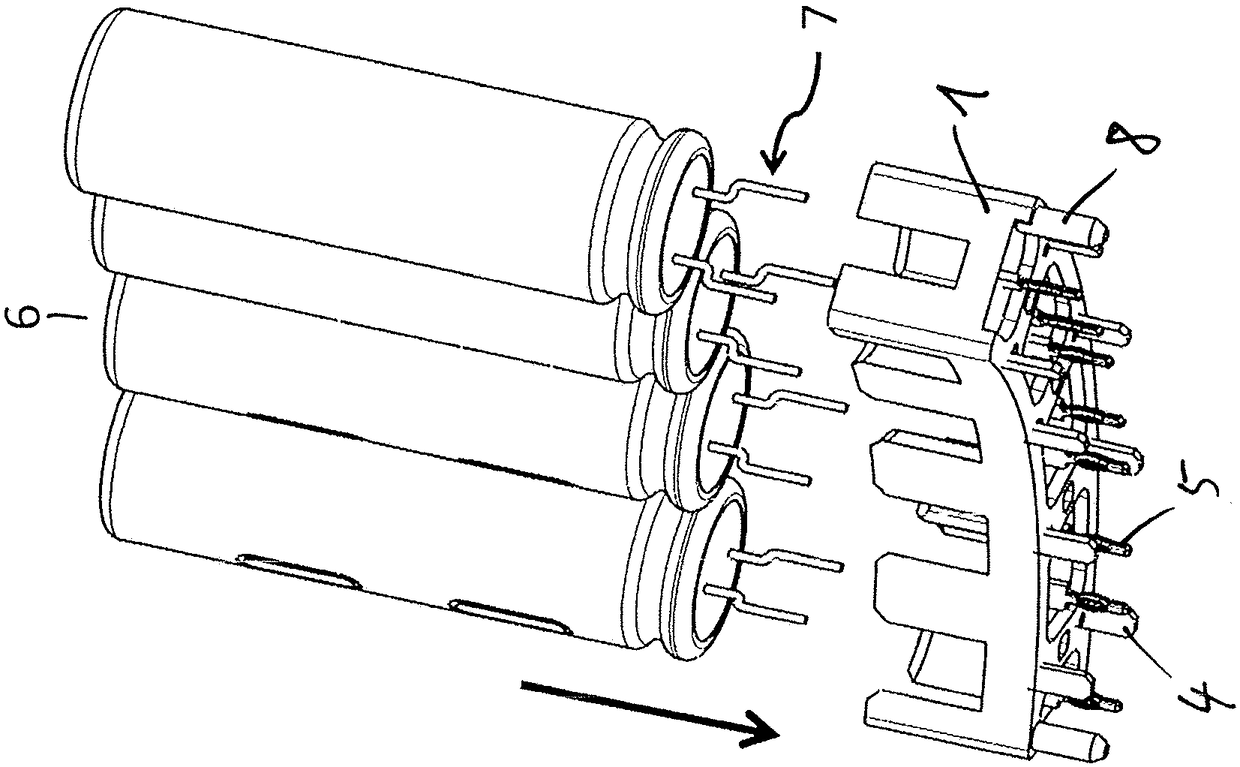

[0035] figure 1 and 3 The mounting aid shown in is composed of a polymer body 1 and figure 2 Composition of metal parts 2 shown in . The polymer body 1 forms a holder for electrical components 6, for which purpose it has on its upper side compartments for electrical components 6, such as electrolytic capacitors, in Figure 5 and 6 In , electrical components 6 are shown together with mounting aids.

[0036] Openings 3 for connecting wires 7 of electrical components 6 are formed in the base of the compartment. Once the part 6 is inserted into the compartment of the body 1, the connection wire 7 of the part 6 is electrically connected to the metal part 2, for example by welding or soldering or the like. The metal parts 2 each form a bus bar enabling the insertion of the part 6 into the compartment.

[0037] The metal part 2 may be embedded into the polymer body 1 by eg overmoulding, or may be fastened to the underside of the polymer body by eg gluing. The metal part 2 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com