Patents

Literature

45 results about "Selective soldering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Selective soldering is the process of selectively soldering components to printed circuit boards and molded modules that could be damaged by the heat of a reflow oven or wave soldering in a traditional surface-mount technology (SMT) or Through-hole technology assembly processes.This usually follows an SMT oven reflow process; parts to be selectively soldered are usually surrounded by parts that have been previously soldered in a surface-mount reflow process, and the selective-solder process must be sufficiently precise to avoid damaging them.

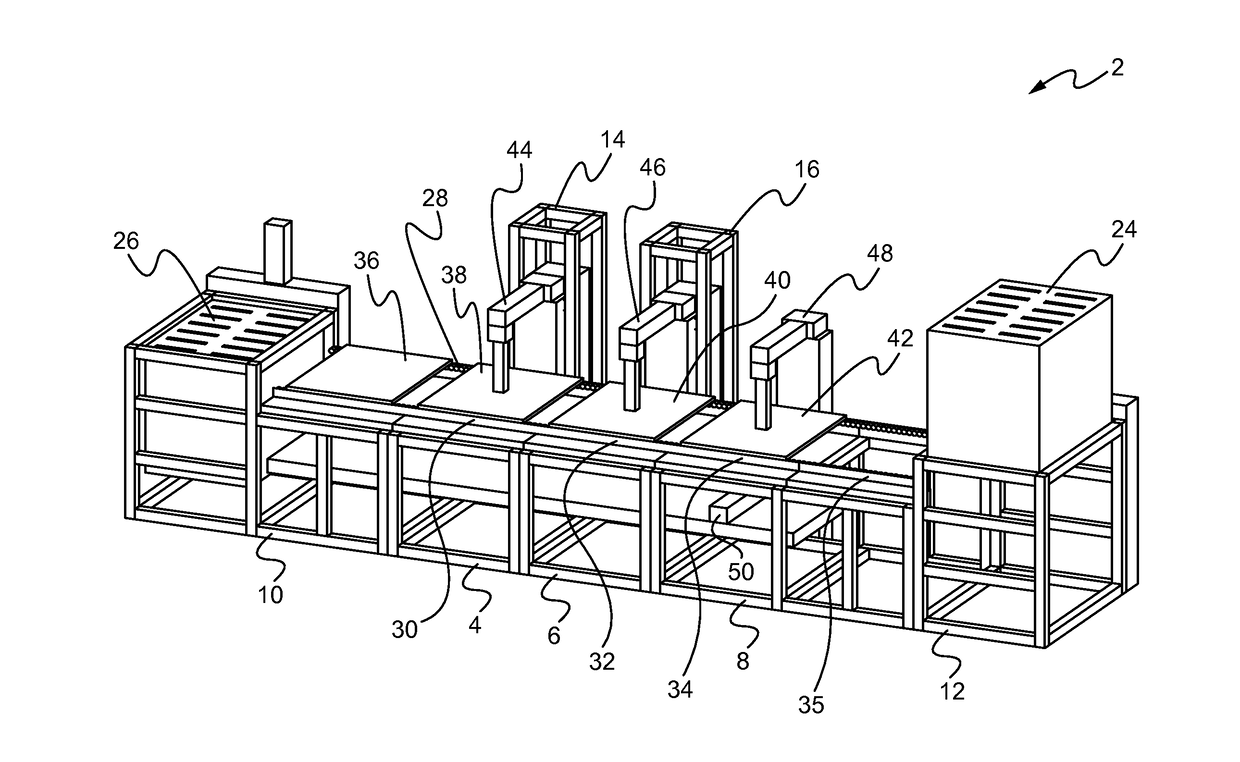

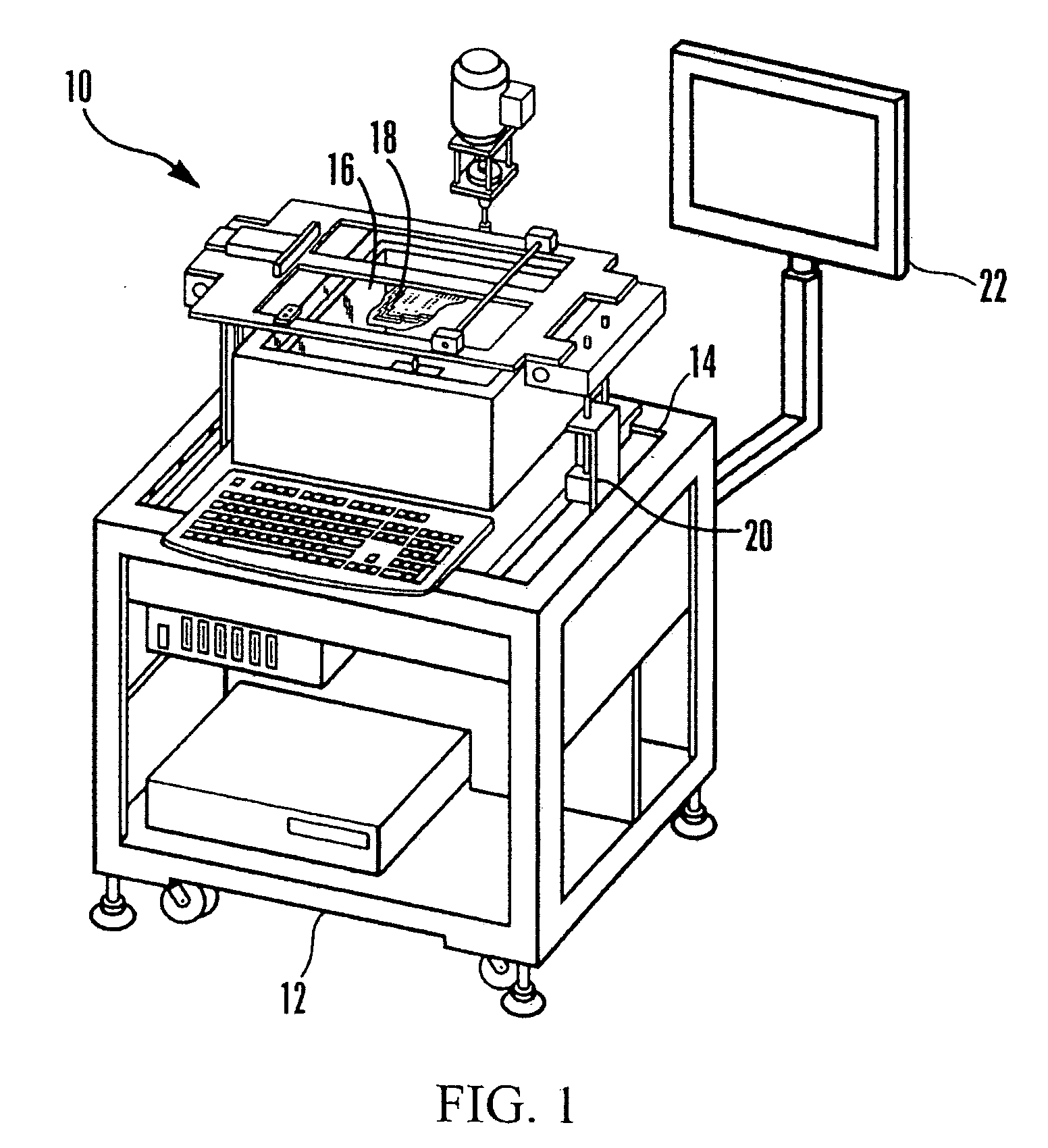

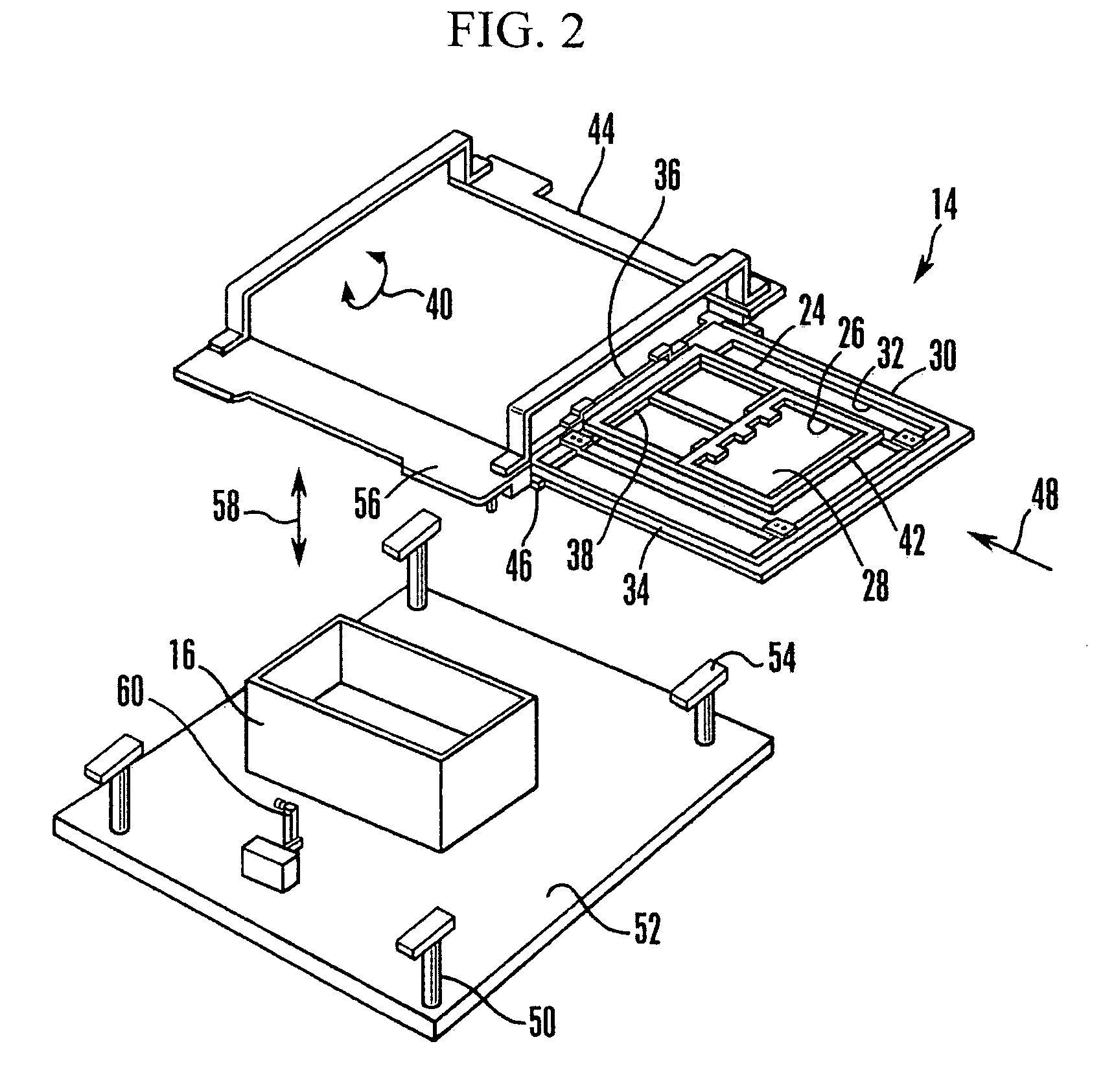

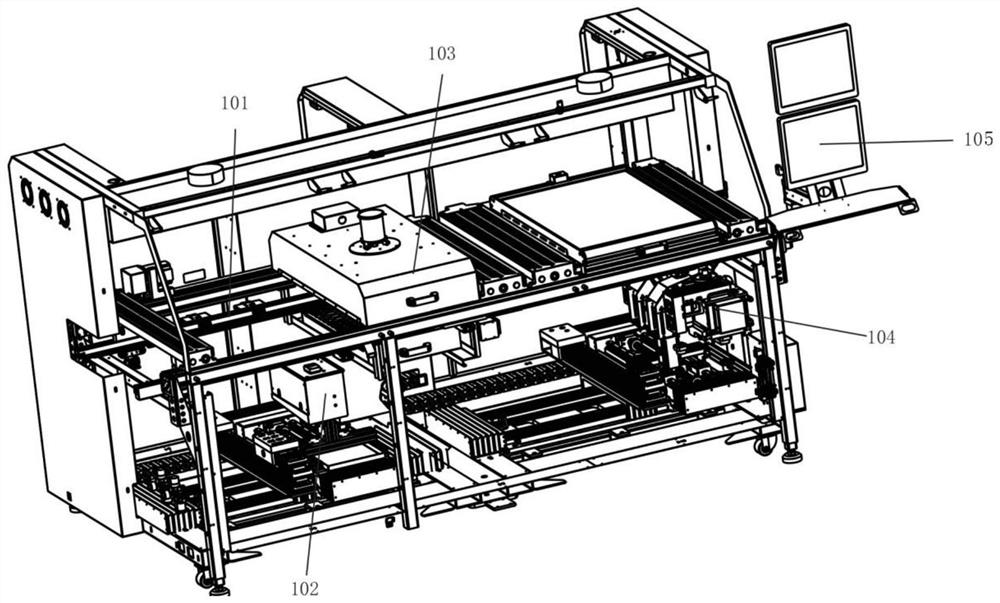

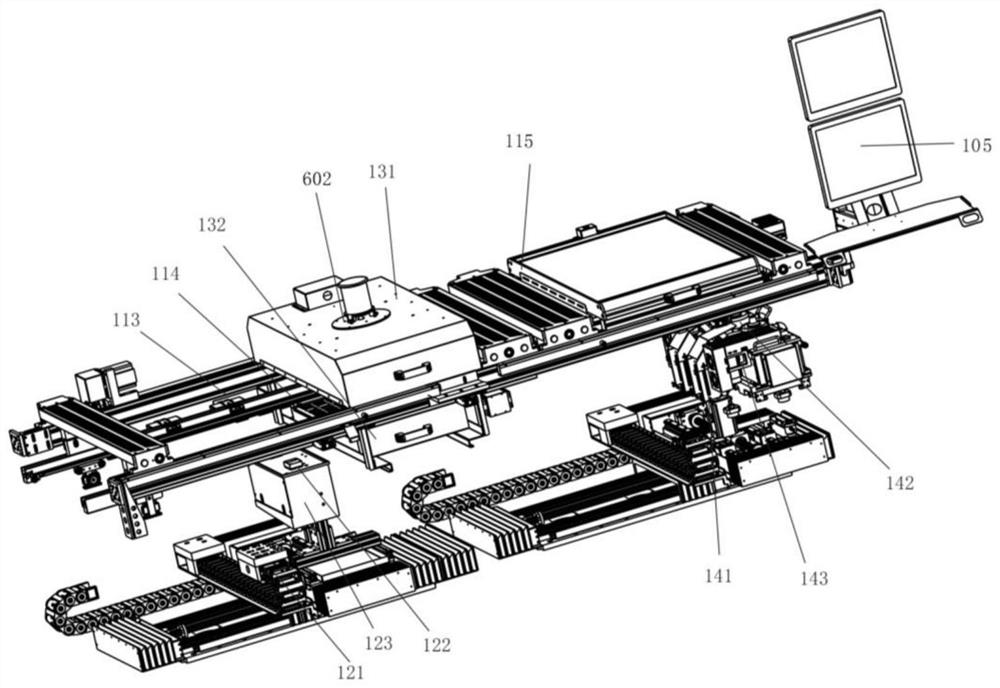

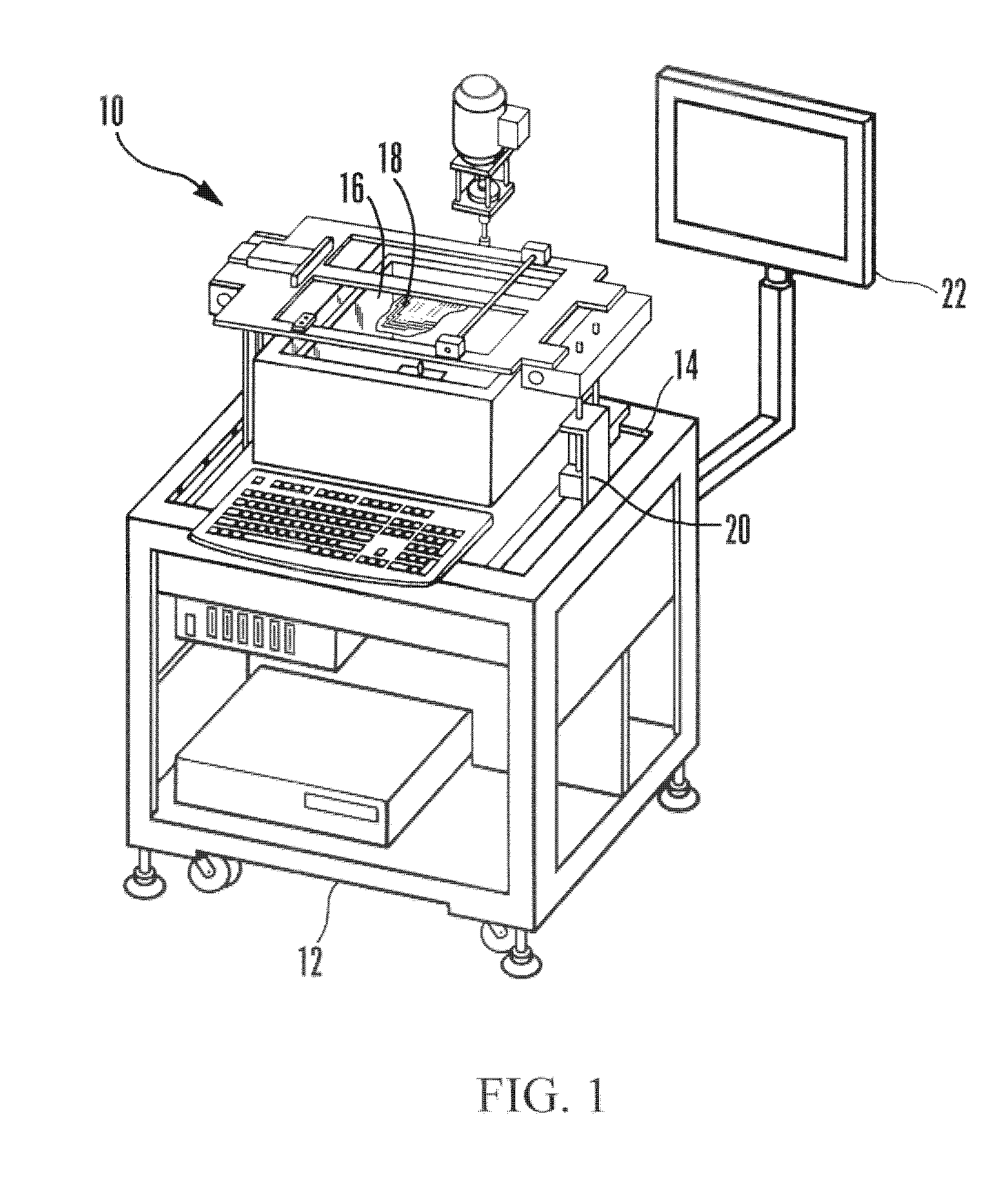

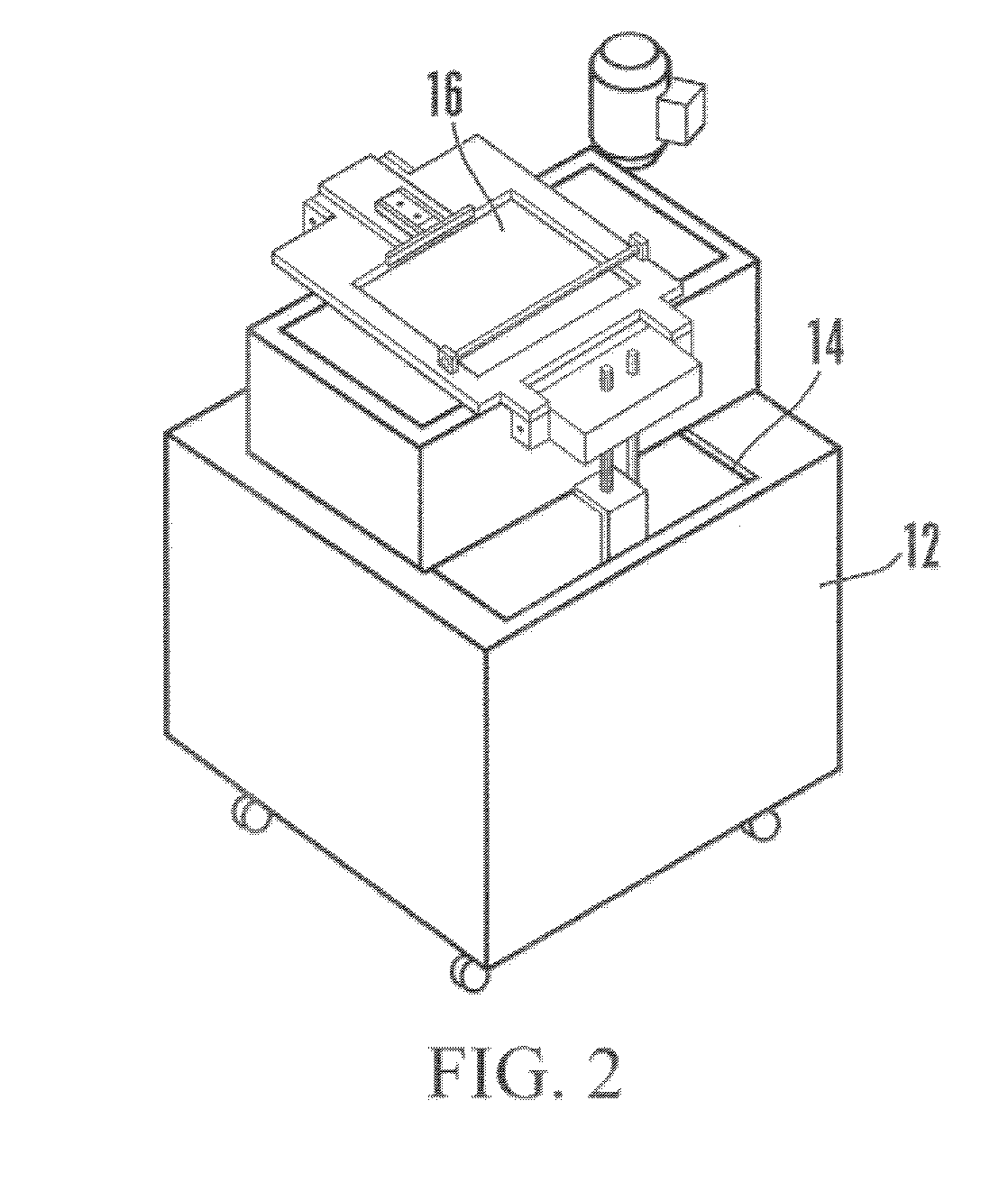

Universal automation line

A universal automation line is configured for the assembly of electronics and mechanical devices. The universal automation line includes universal cells or stations that can be programmed to perform a variety of automated assembly tasks such as glue dispensing, screw driving, pick and place, etc. The stations are interchangeable by different module design such as selective soldering, heat stacking, bottom lead trimming, bottom screwing and ultrasonic welding. Each station can also include an automated robot, which is also interchangeable, to perform different tasks and complete fully automated assemblies. The stations can be sequenced inline for a fully automated line or combined with some manual operation. The stations can communicate by standardized interfaces and local networks, and can be expanded to an intranet or the internet for remote control.

Owner:BRIGHT MASCH INC

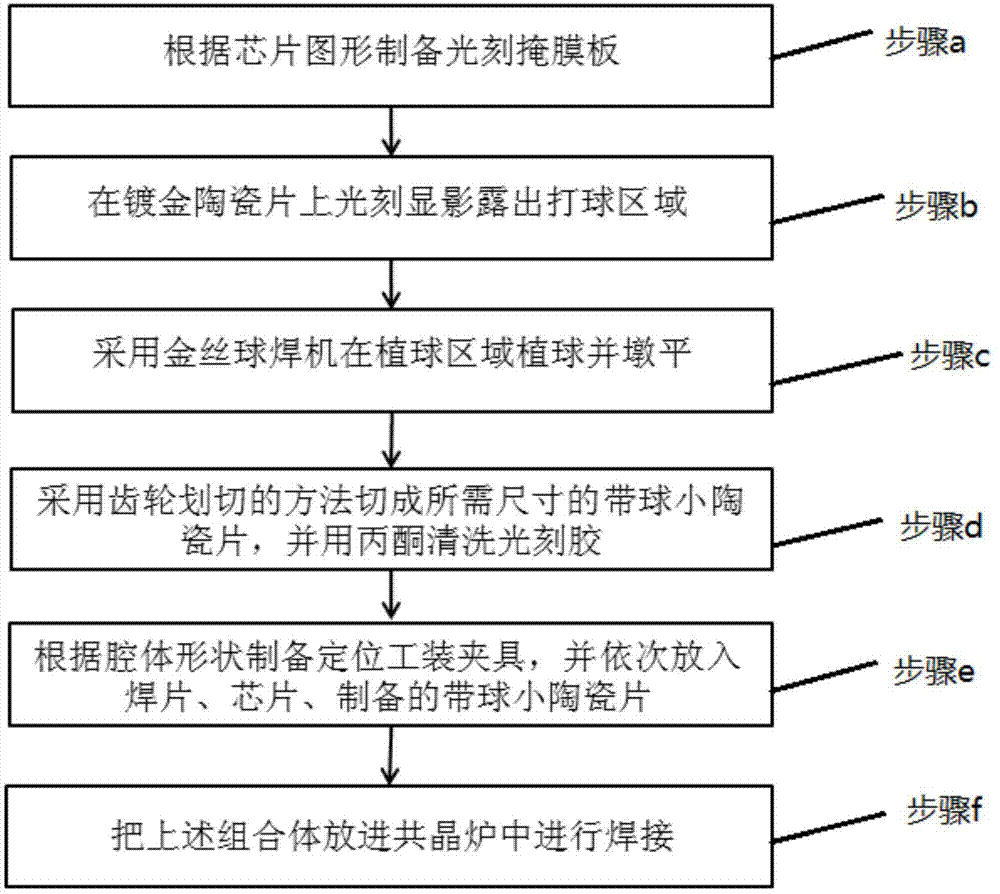

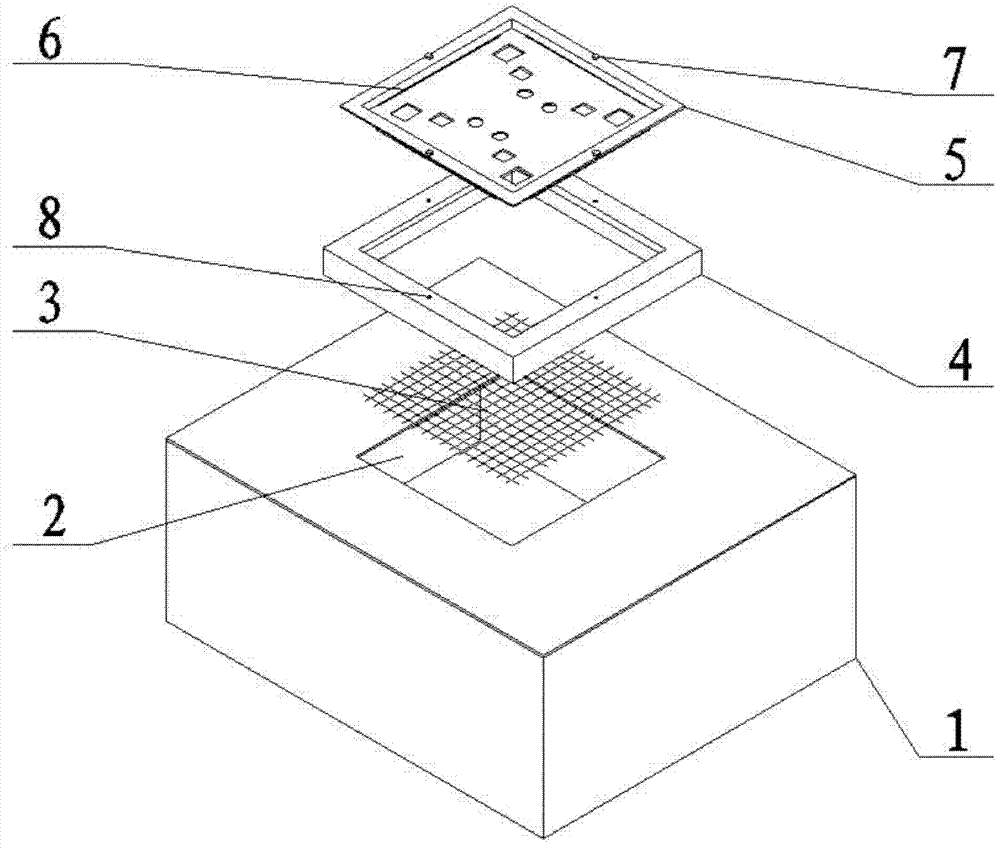

Method for achieving eutectic soldering of chips

ActiveCN103617957ASolve stressSolve the positioning problemSolid-state devicesSemiconductor/solid-state device manufacturingGold ballAdhesive

The invention provides a method for achieving eutectic soldering of chips. The method comprises the steps of a, compressible areas in the chips are determined, and a photoetching mask panel is manufactured; b, conducting adhesives in the compressible areas of the chips are removed through a photoetching develop method on a gilded ceramic wafer; c, ball points, used as protruding points, are planted at the position, where the adhesives are removed, on the ceramic wafer through a gold ball bonding method; d, the ceramic wafer is cut into small ceramic wafers consistent with the chips in size through a gear cutting method; e, a tool locating clamp is manufactured according to the shapes of cavities to be welded, and a small ceramic wafer pressing block clamp with gold protruding points makes contact with non-circuit areas of the chips through the protruding points; f, a pressing block is arranged on the small ceramic wafer pressing block clamp, and vacuum compressible soldering of the chips is indirectly achieved. The gilded ceramic wafer is used as the base material, the mature photoetching technology and the ball-bonding ball planting technology are used for manufacturing the protruding points to provide effective mechanical support for soldering, and the method is wide in application range.

Owner:THE 41ST INST OF CHINA ELECTRONICS TECH GRP

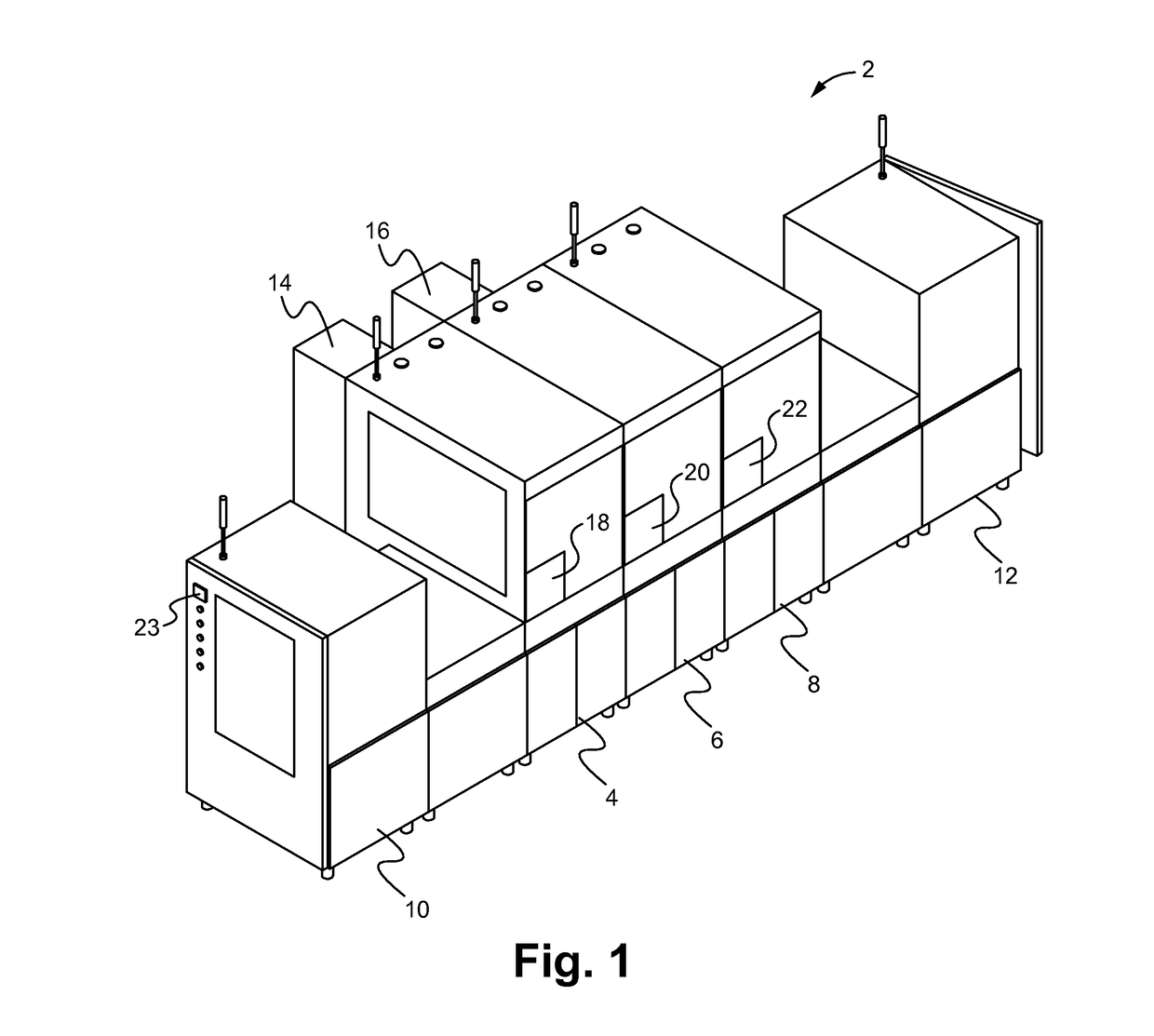

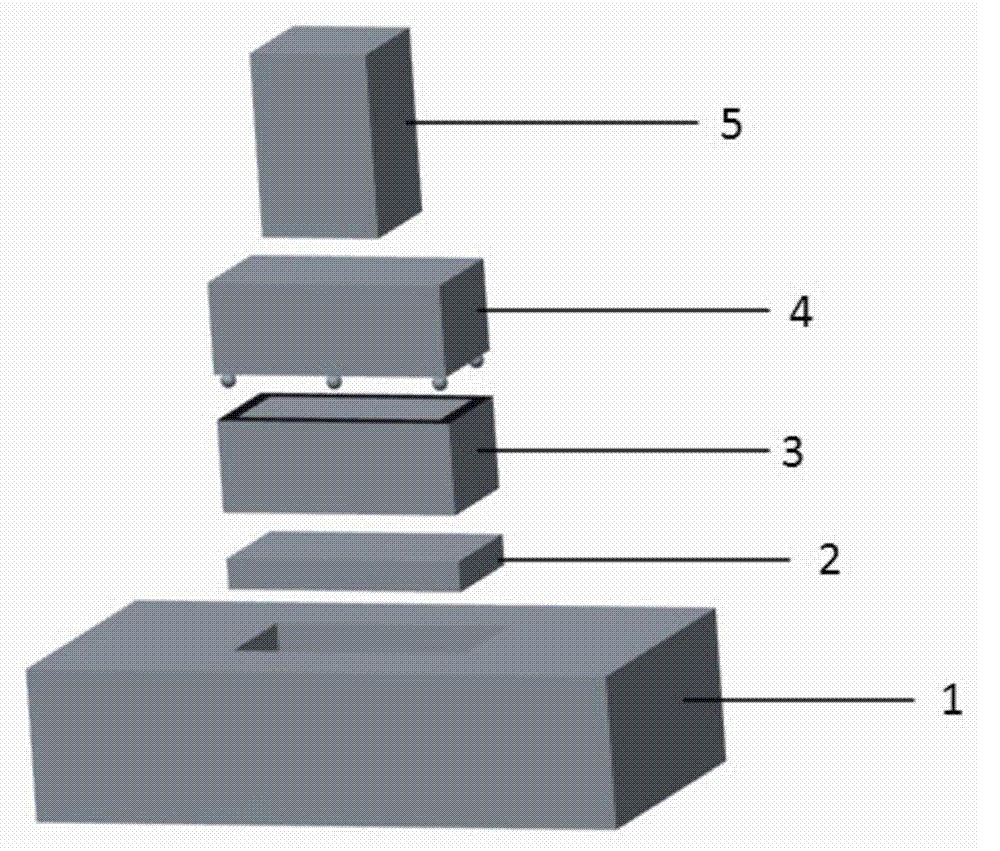

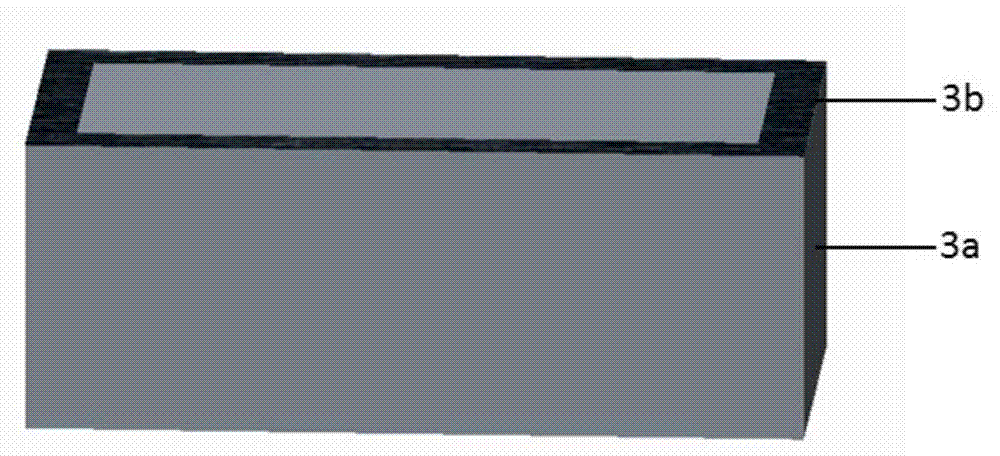

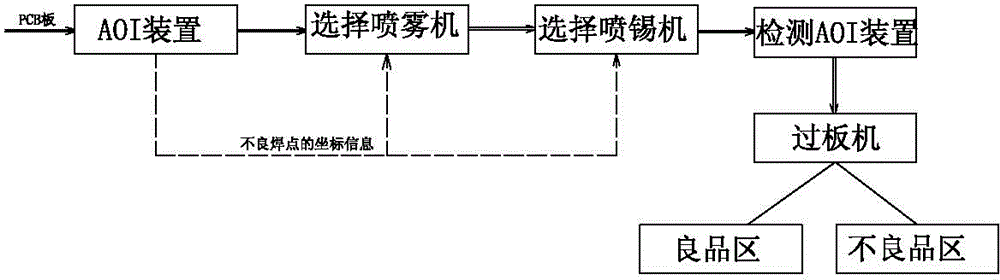

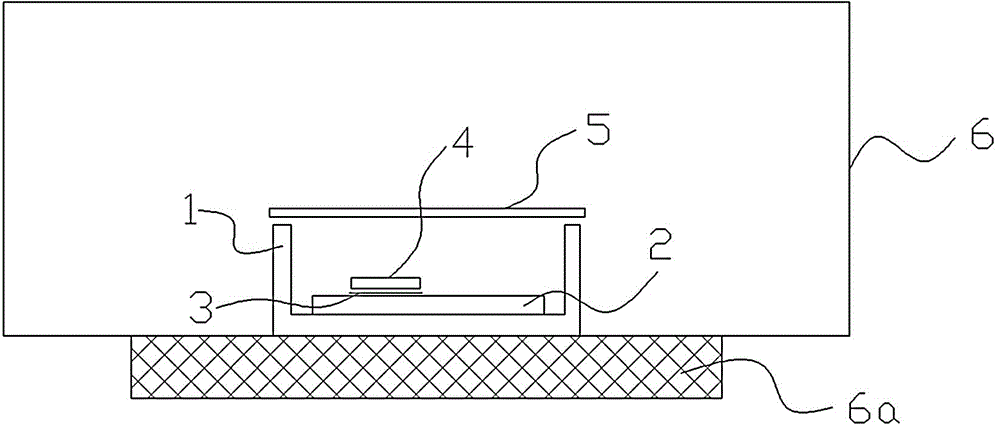

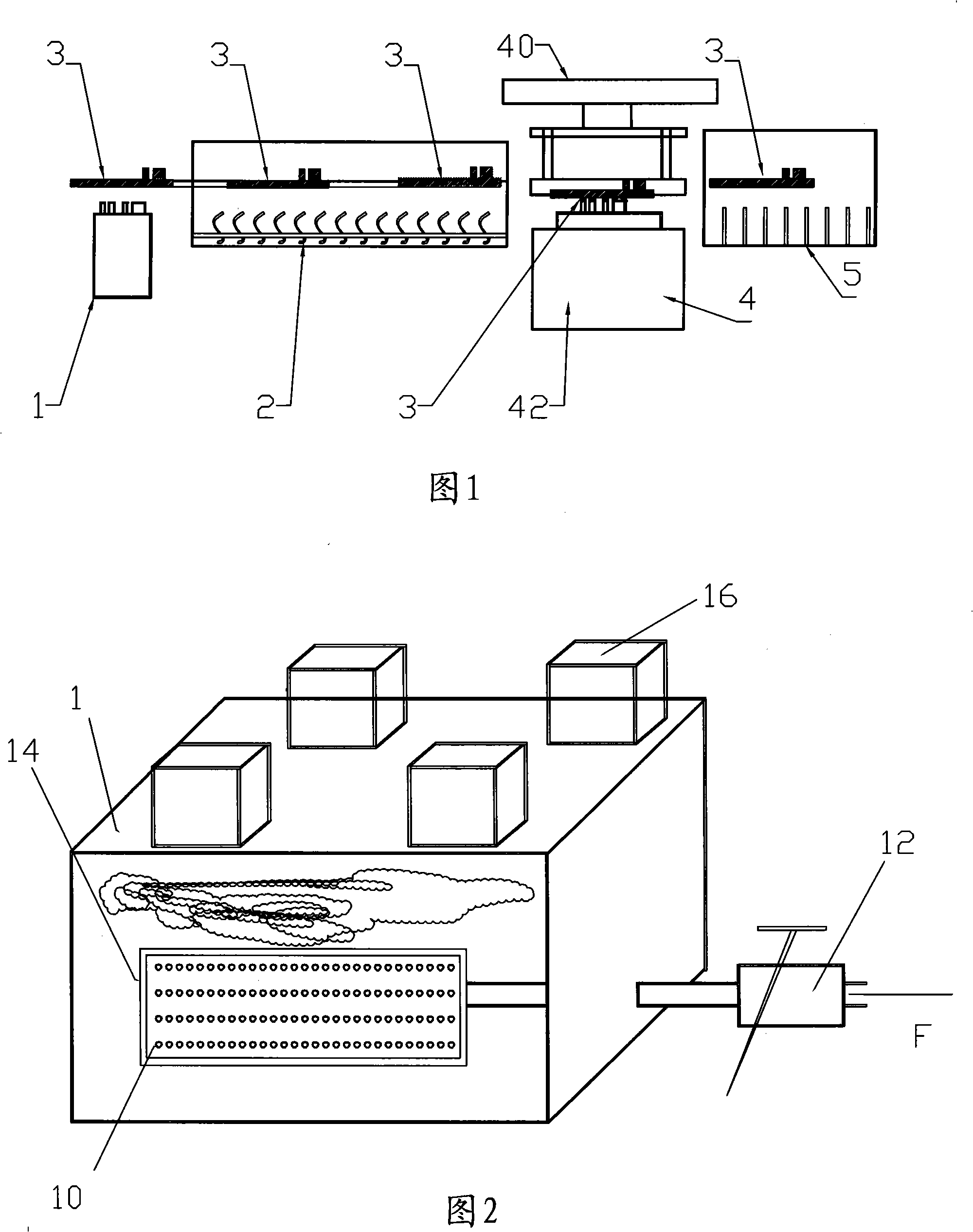

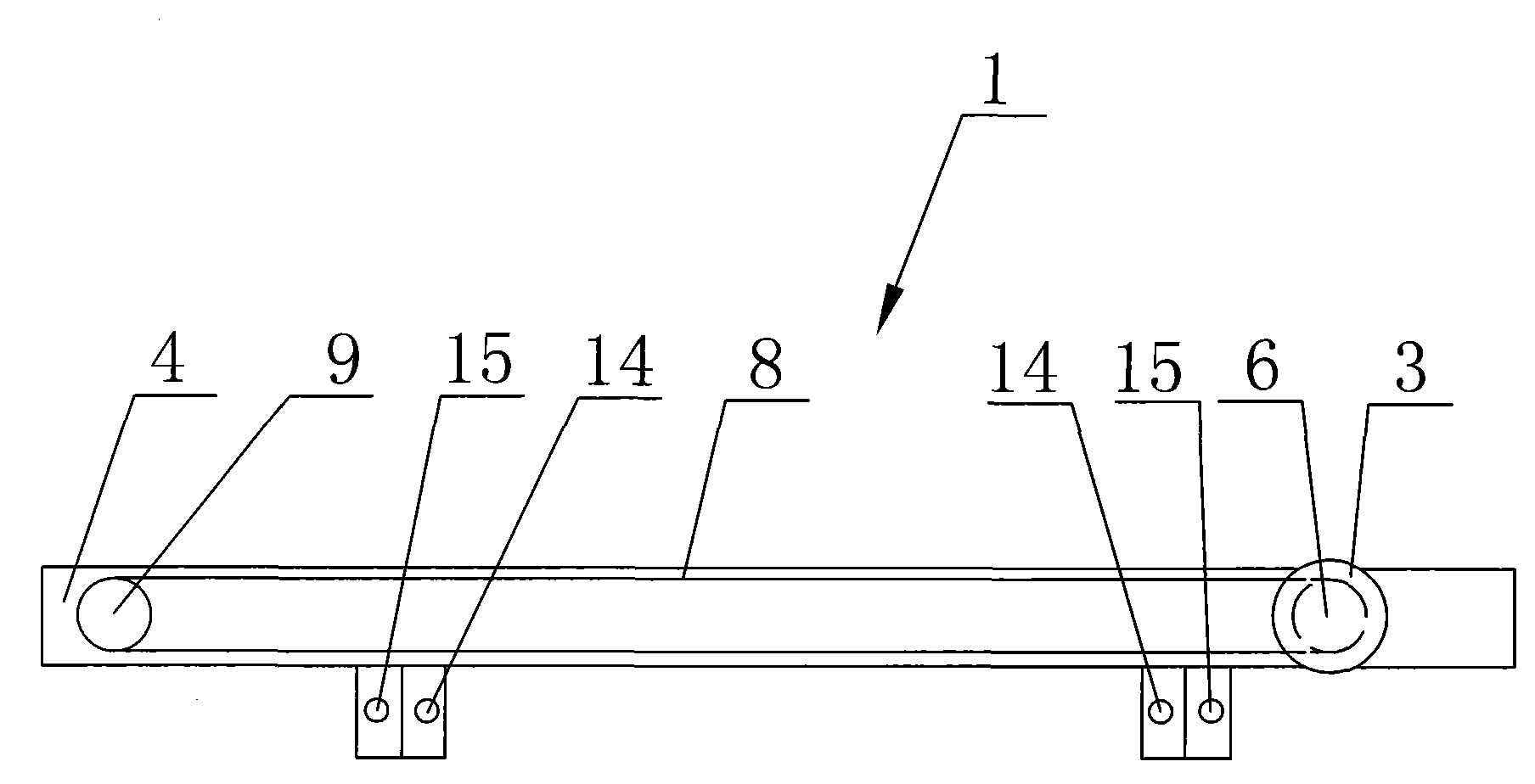

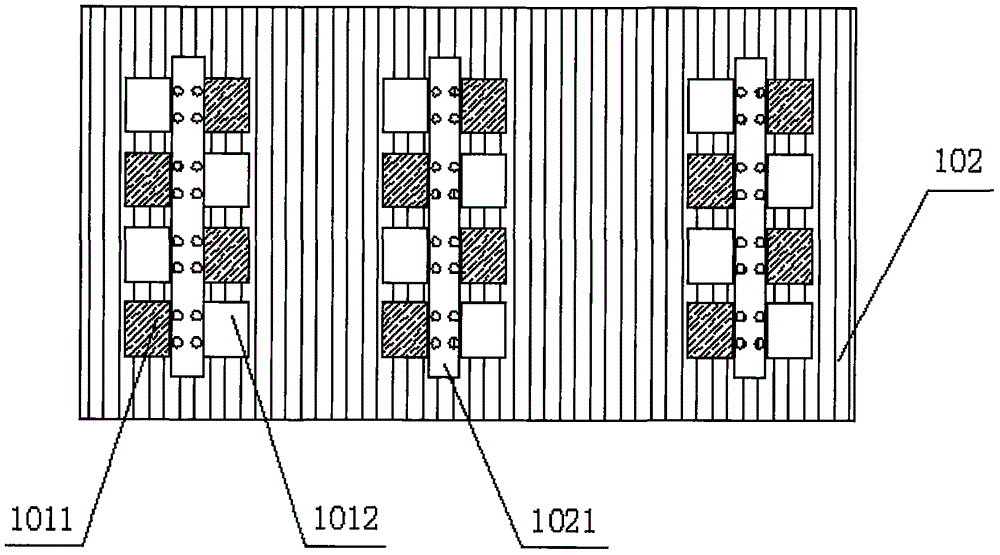

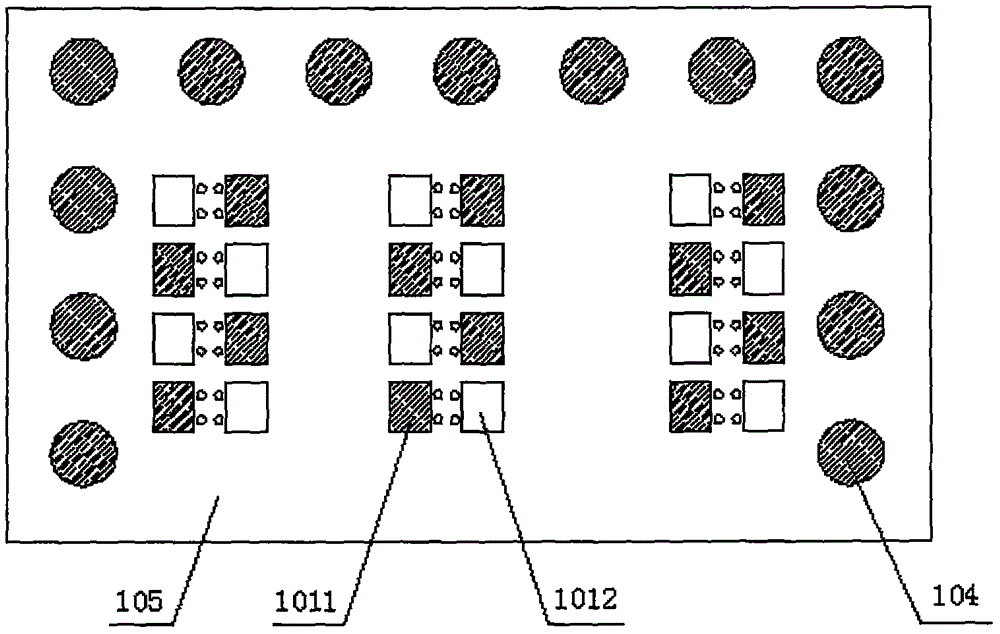

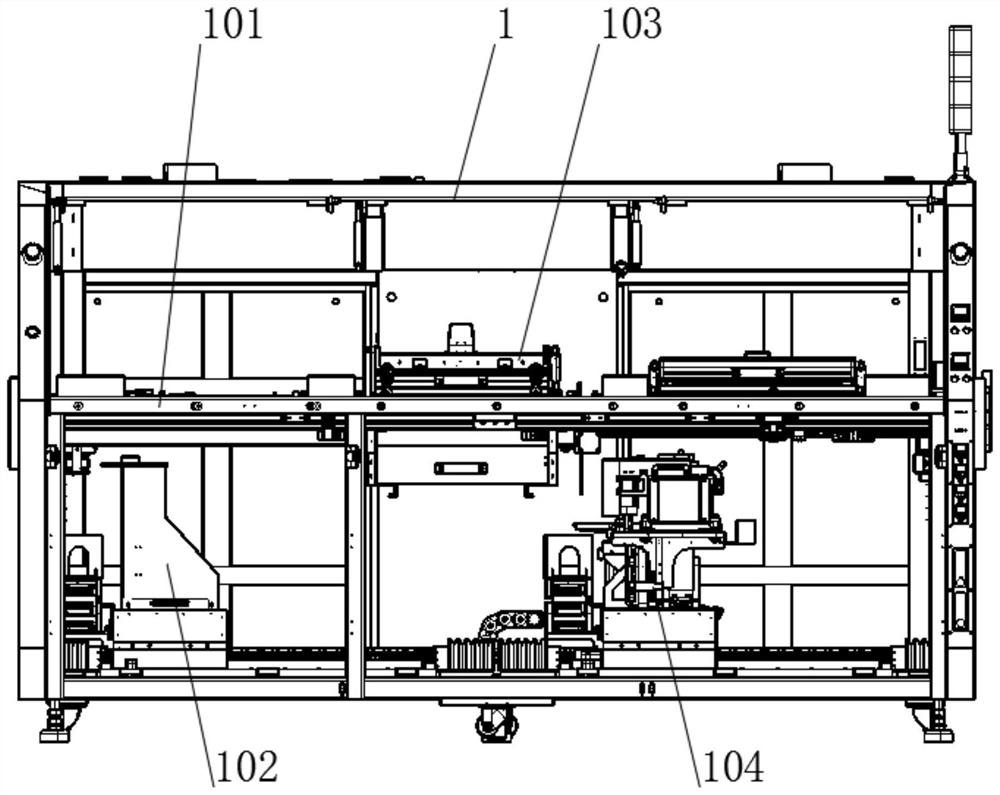

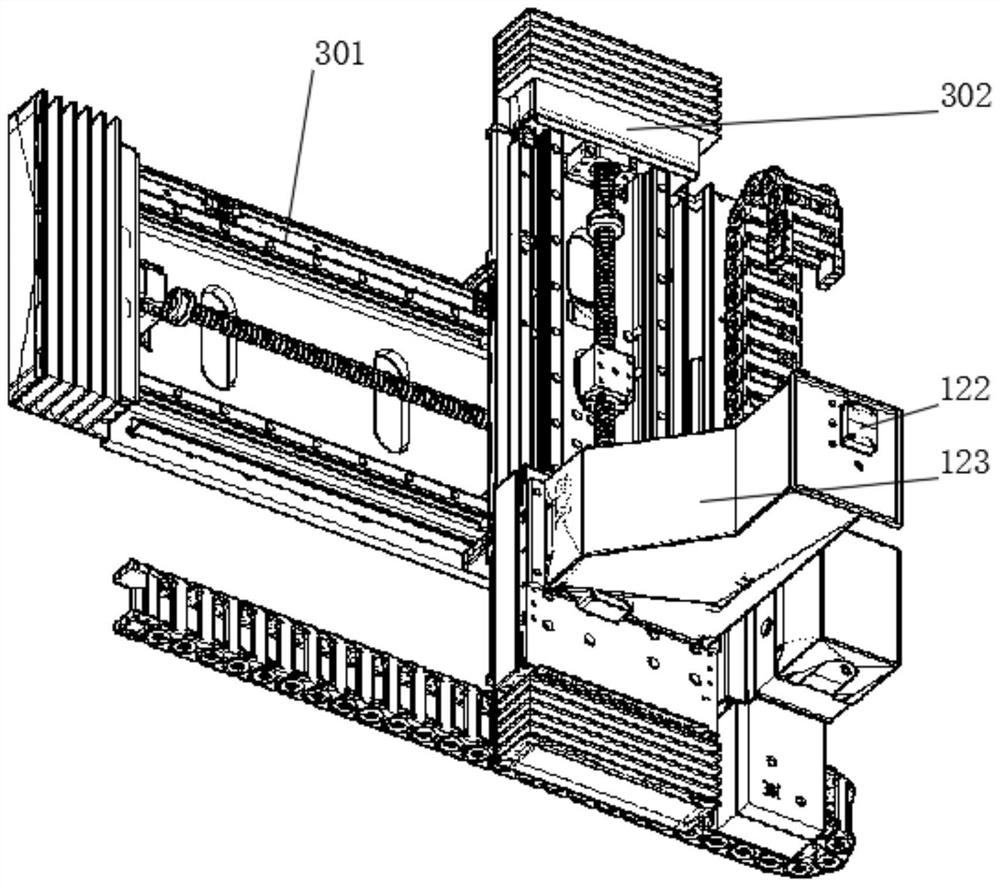

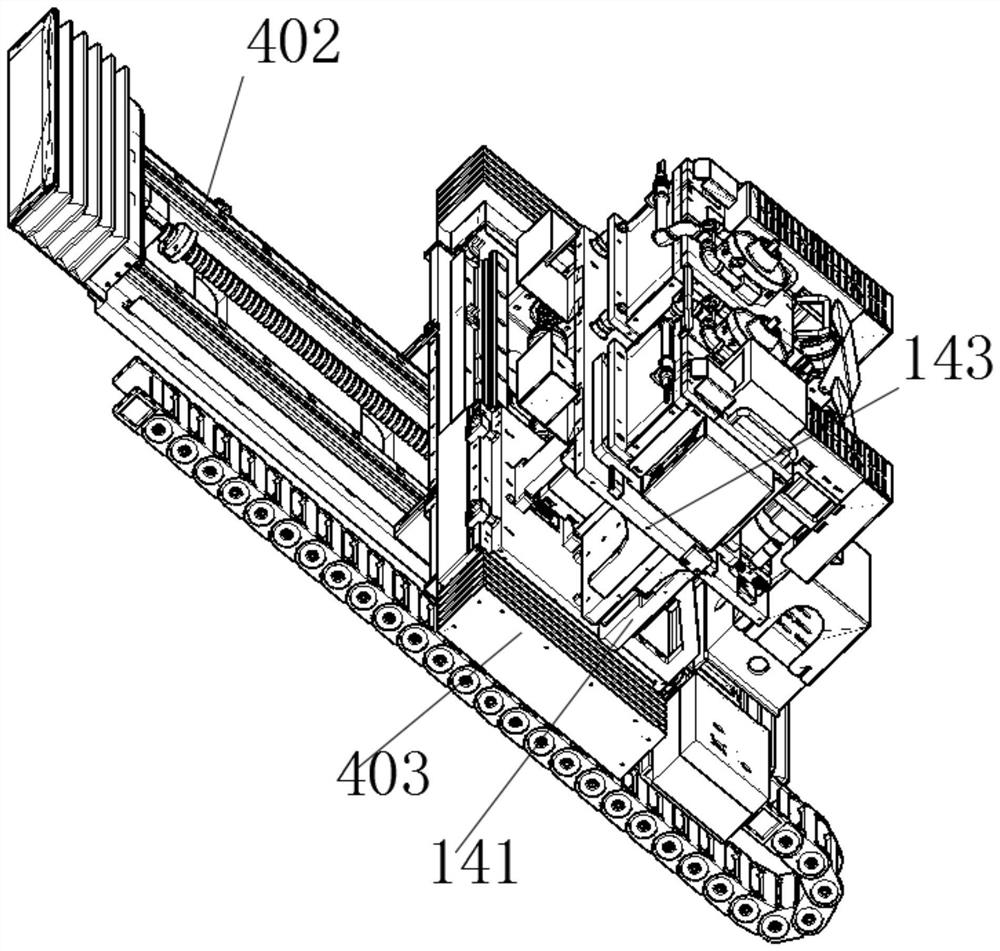

Full-automatic intelligent-welding assembly line

InactiveCN104551301APrecise positioningEasy to detectMetal working apparatusSoldering auxillary devicesProduction lineAssembly line

The invention relates to the technical field of manufacture of PCB (printed circuit board) electron and power control boards, in particular to a full-automatic intelligent-welding assembly line. The full-automatic intelligent-welding assembly line comprises an AOI device, a selective mist sprayer, a selective soldering machine and a conveying device, wherein the AOI device is used for photographing PCBs to be compared with images of non-defective PCBs and calculating coordinates of defective soldering points through software; the selective mist sprayer is used for spraying soldering flux to the defective soldering points on the PCBs; the selective soldering machine is used for correcting soldering of the defective soldering points; the conveying device is used for sequentially conveying the PCBs to the AOI device, the selective mist sprayer and the selective soldering machine. The defective soldering points can be accurately positioned, the soldering flux and soldering tin can be sprayed one to one, maintenance and repair rate is high, production efficiency and quality of products are improved, and labor cost is reduced.

Owner:OAEM TECH

Eutectic chip soldering method

InactiveCN104934336AGuaranteed surface qualityConvenient welding operationSolid-state devicesSemiconductor/solid-state device manufacturingTemperature curveNitrogen

The invention discloses an eutectic chip soldering method. The method comprises the steps that dirt at the surfaces of a soldering lug and a piece to be soldered is removed, the soldering lug is cut, the piece to be soldered, the soldering lug and a chip are placed in a metal container, the metal container is placed in an atmosphere controllable eutectic furnace, the temperature curve of the atmosphere controllable eutectic furnace is set according to technical requirements, eutectic soldering is carried out on the piece to be soldered and the chip, air in the atmosphere controllable eutectic furnace is exhausted before temperature rise, nitrogen of the flow of 2L / min is filled in the temperature rise process, it is ensured that the soldering lug is fused, the vacuum degree in the furnace in the temperature decrease process is lower than or equivalent to 1 Pa and kept for 30 to 60s, so that gas in the chip and the piece to be soldered and gas generated by fusing of the soldering lug can be smoothly extracted under the self-gravity of the chip and the high-vacuum condition, and thus, the chip is soldered with the piece to be soldered via the pressure of self gravity on the piece to be soldered instead of using additional pressuring device. Thus, the surface quality of the chip during soldering is ensured, and the soldering process is simplified.

Owner:EAST CHINA INST OF OPTOELECTRONICS INTEGRATEDDEVICE

Device for selectively welding through-hole component and welding method

The invention provides a device for selective welding an apparatus of a through hole and method thereof, which includes a flux spraying container which sprays the flux to the apparatus, a pre-heating device which preheats the apparatus and a welding device which carries out tin-spraying welding on the apparatus; the flux spraying container includes a foaming device which brings out the foams of the flux by entering air, a pore for the outlet of the foams and a spraying module which sprays the flux on the apparatus. The foaming device is arranged in the flux spraying container; the pore is arranged on the foaming device; the spraying module is arranged on the flux spraying container; the spraying module is opposite to the position on the apparatus needing to be sprayed with the flux. The foams of the flux of the selective welding device for an apparatus of a through hole get out from the pore of the foaming device and assemble in the foaming device with a large amount to carry out spraying on the place on the apparatus needing to be sprayed from the spraying module; a foaming jetting mode is adopted for realizing selectively uniform spray of the flux.

Owner:FORYOU GENERAL ELECTRONICS

Selective soldering bath

InactiveUS20100001046A1Unloading safetyEasy to weldWelding/cutting auxillary devicesAuxillary welding devicesThree degrees of freedomSolder ball

A solder machine uses various linear actuators to move a PWB carrier in three degrees of freedom relative to a solder bath, to facilitate safe loading and unloading of PWBs onto the carrier while the carrier is distanced from the bath, and then to move the carrier over the bath, lower it, and tilt it as necessary to effect soldering.

Owner:SONY CORP +1

Selective spraying machine

InactiveCN102039465ASimple structureEasy to usePrinted circuit assemblingConveyorsDrive shaftEngineering

The invention discloses a selective spraying machine, which comprises a conveying part and a selective soldering flux coating part, wherein the conveying part comprises a motor, the power output shaft of the motor is connected with a driving shaft, a driving chain wheel I and a driving chain wheel II are arranged on the driving shaft, the driving chain wheel I is connected with a driven chain wheel I through a special conveying chain wheel I, the driving chain wheel II is connected with a driven chain wheel II through a special conveying chain wheel II, guide rails I and II are arranged below the special conveying chain wheels I and II respectively, a lead screw and a feed rod are arranged in parallel between the guide rail I and the guide rail II, and one end of the lead screw is connected with a worm gear; and the selective soldering flux coating part comprises an automatic spraying gun which can move freely in X, Y and Z directions. The selective spraying machine has the characteristics of simple structure, convenience for use, flux saving capacity, high automation, pollution reducing capacity, subsequent washing process obviating capacity, low production cost and convenience for popularization.

Owner:XIAN ZHONGKEMAITE ELECTRONICS TECH EQUIP

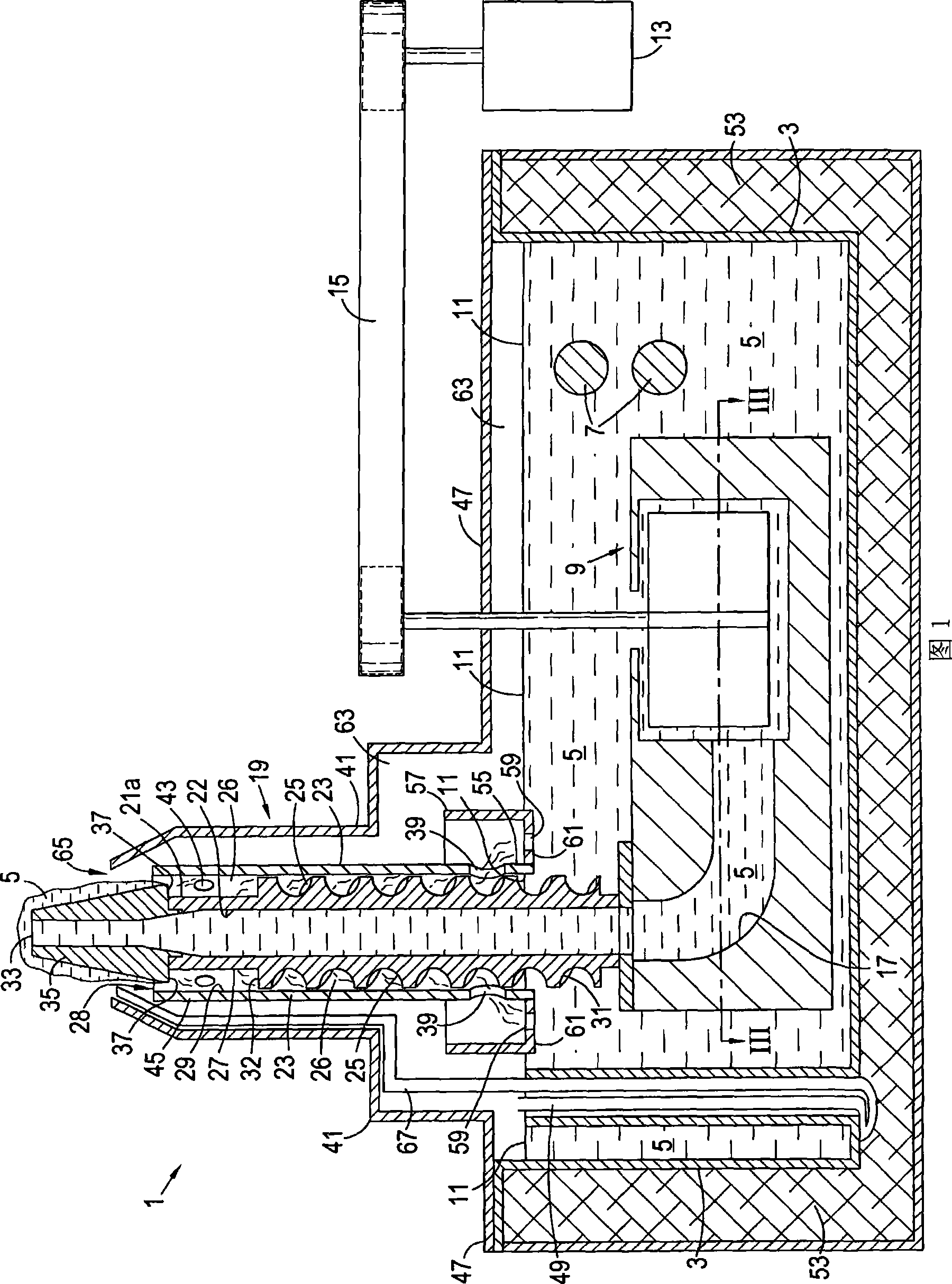

Soldering apparatus

InactiveCN101454109AControl flowReduce formationElectrical componentsSolder feeding devicesMetallurgySolder ball

A selective soldering apparatus comprises a bath (3) for molten solder (5), a solder nozzle (19) and a pump (9) for pumping molten solder (5) through the nozzle (19). The nozzle has a nozzle body (21) with an inner bore (22) through which solder is pumped to overflow a nozzle outlet (33). A jacket (23) provided around the nozzle body (21) to form an enclosed space (26) open at its upper end (28) to solder which has overflowed from the nozzle outlet (33) and the cover lower end being adjacent the surface (11) of molten solder in the bath, wherein a spiral pathway (25) is provided in the enclosed space (26) so that the overflowed solder runs down the pathway into the solder bath (3). A port (39) is provided at the lower end of the jacket for gas to flow into or out of the spiral pathway so that the pathway can be purged of air when solder is not flowing through the pathway.

Owner:PIRAAHAUSU INTERN

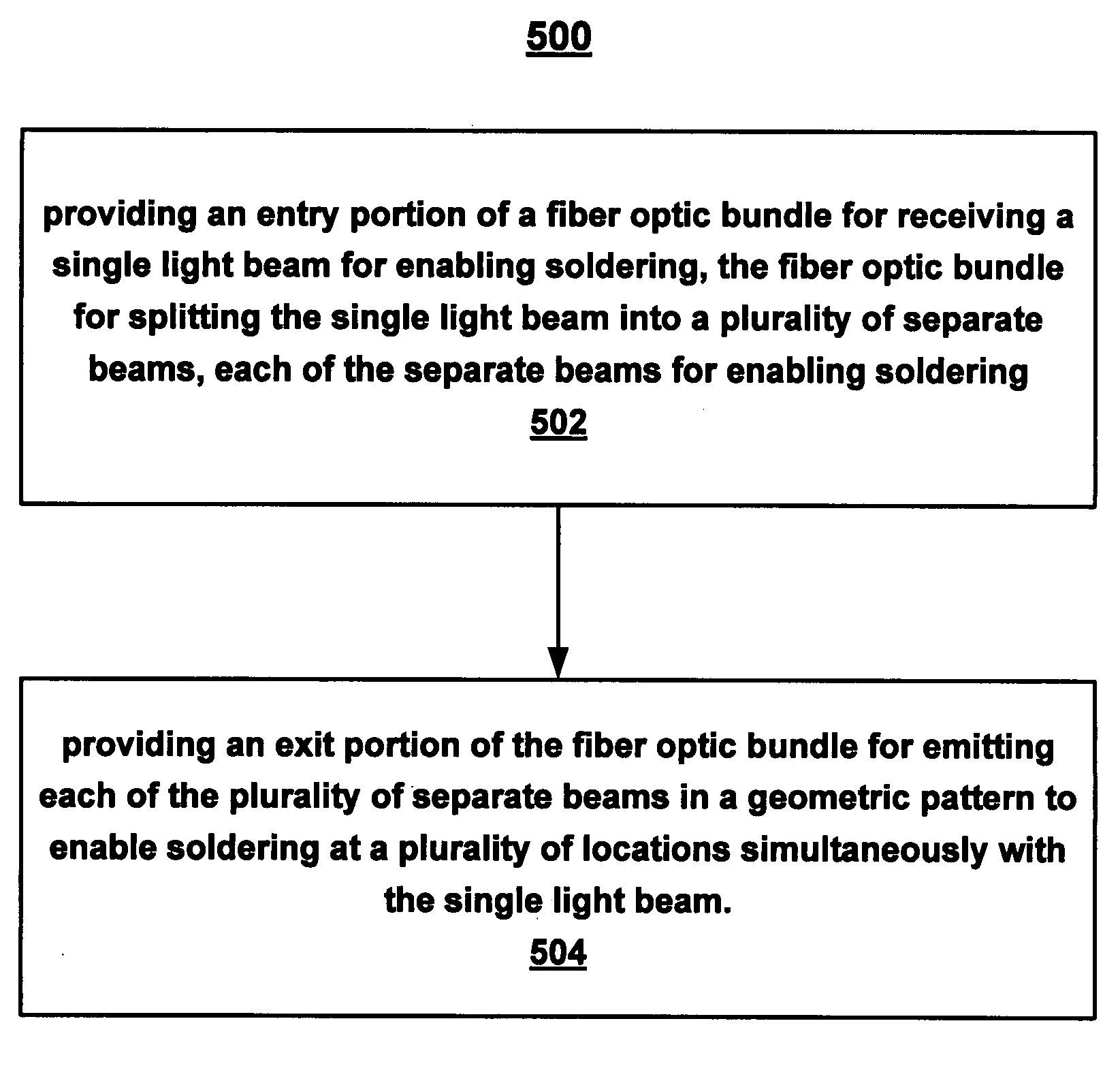

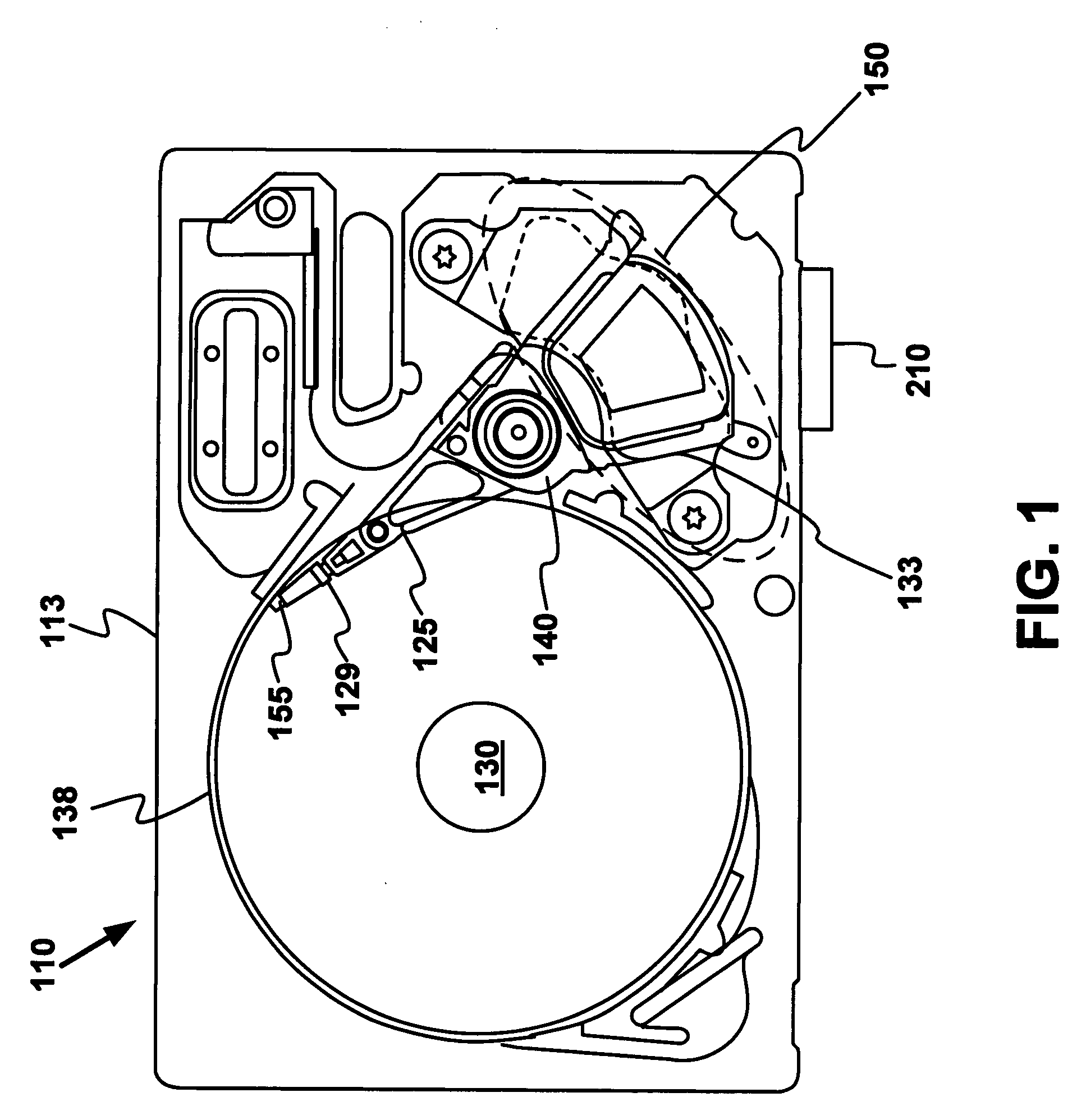

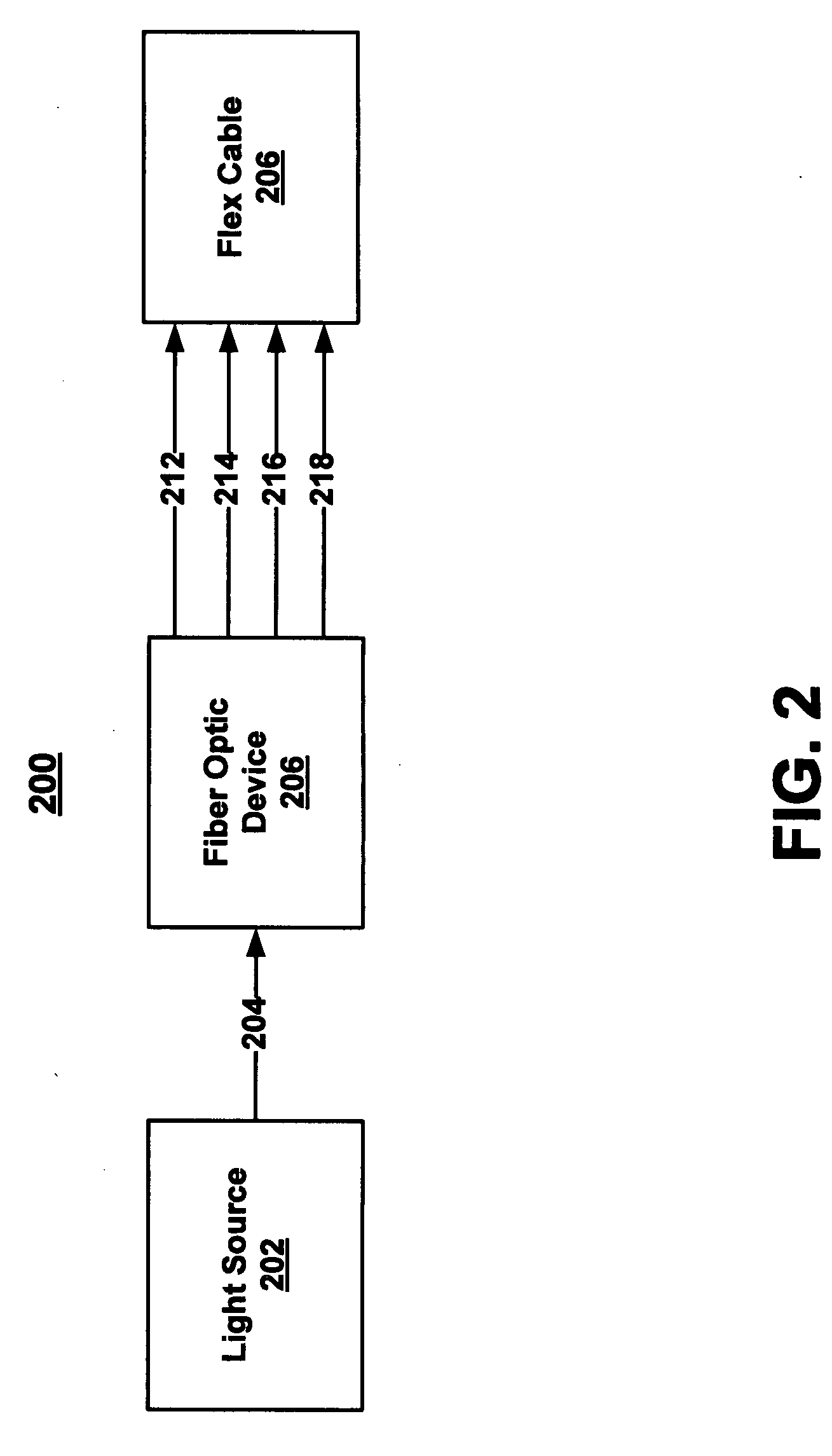

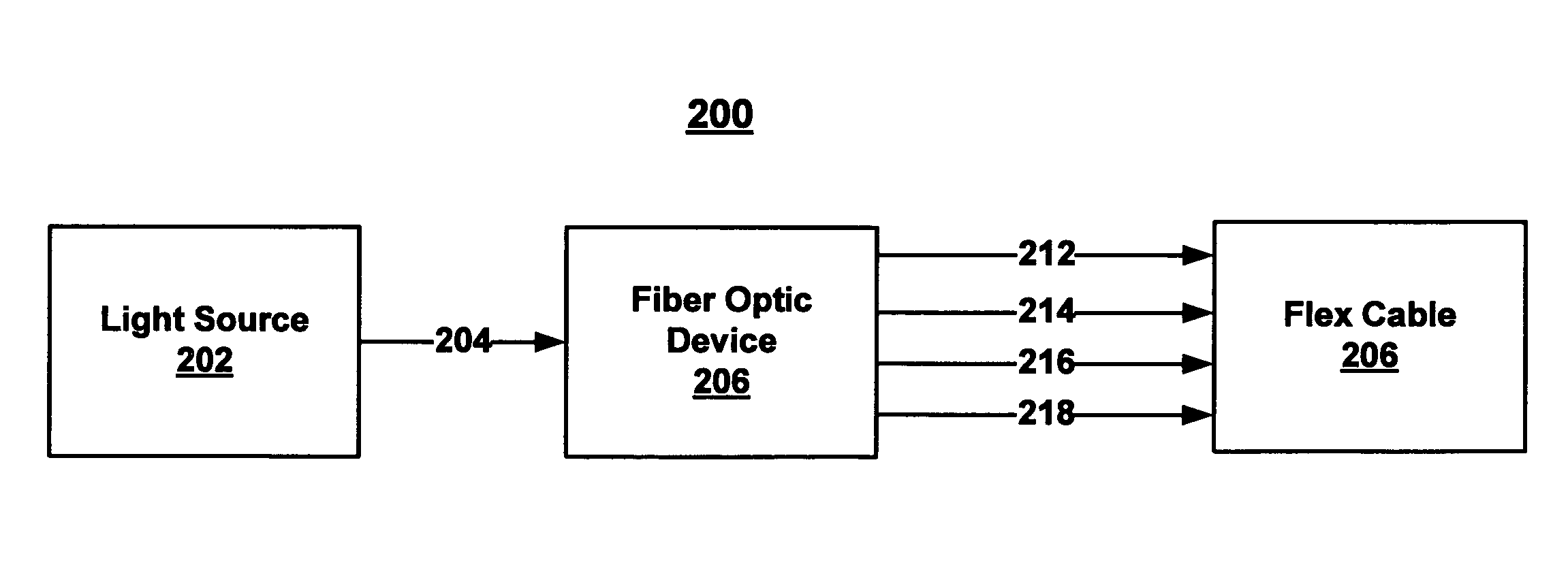

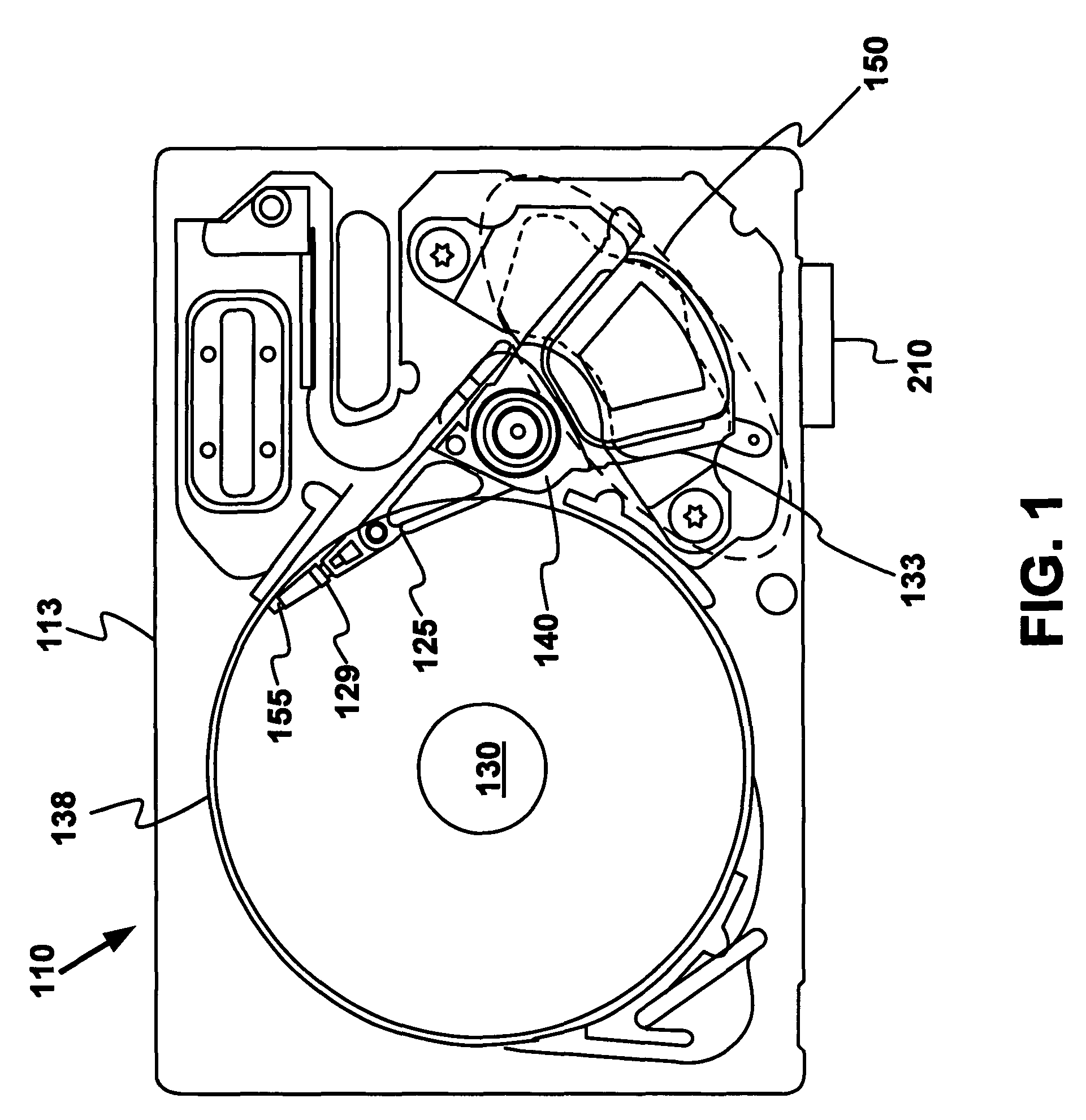

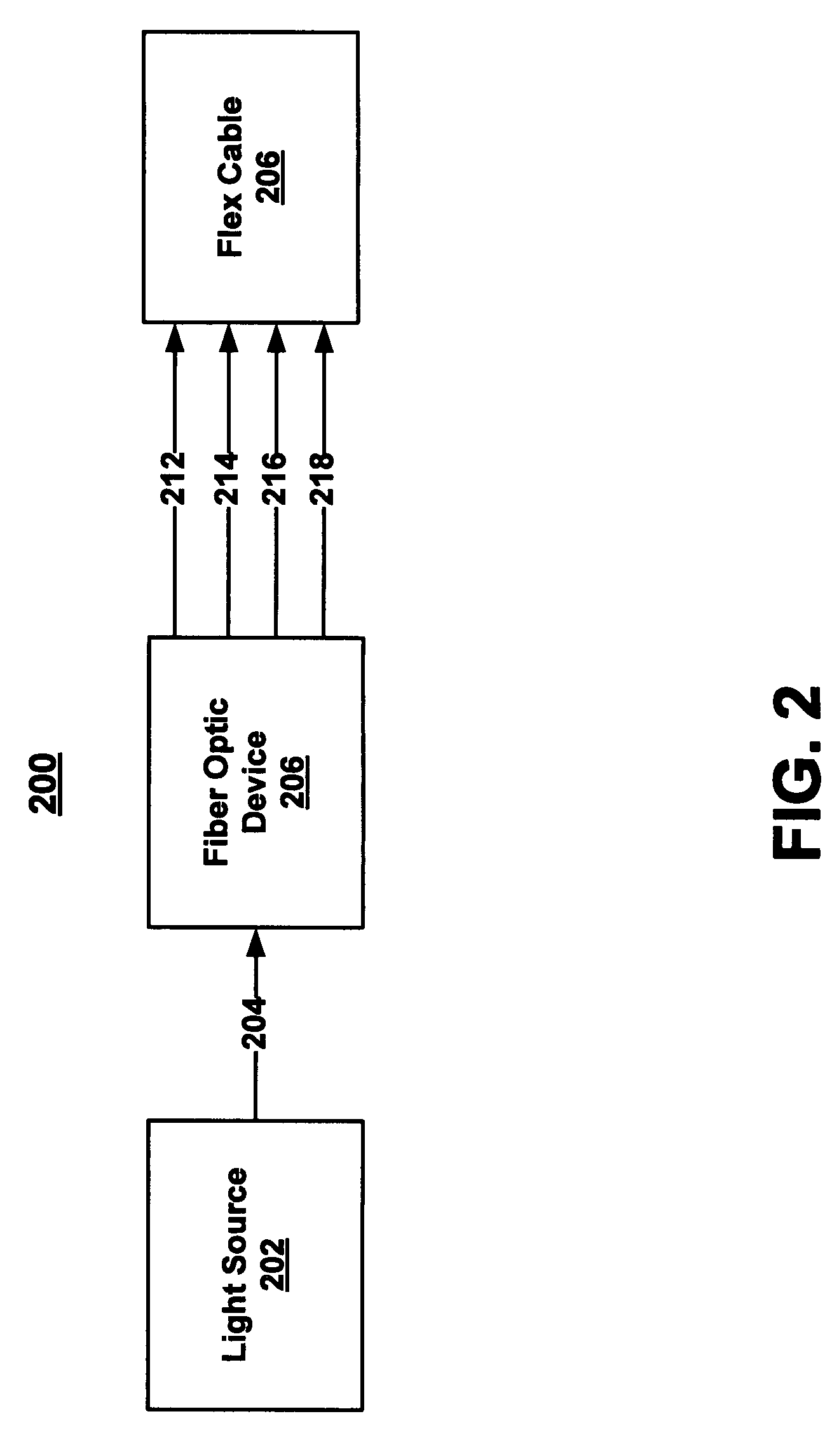

Selective soldering using fiber optic device

ActiveUS20090108052A1Well formedElectrical connection between head and armCoupling light guidesFiberLight beam

A fiber optic device for enabling soldering is described. The fiber optic device includes an entry portion comprising an optical fiber bundle for receiving a single light beam wherein the optical fiber bundle splits the light beam into a plurality of separate portions, each of the separate portions for enabling soldering. The fiber optic device further includes an exit portion for emitting each of the plurality of separate portions of the light beam in a pattern to enable soldering at a plurality of locations simultaneously utilizing the single light beam.

Owner:WESTERN DIGITAL TECH INC

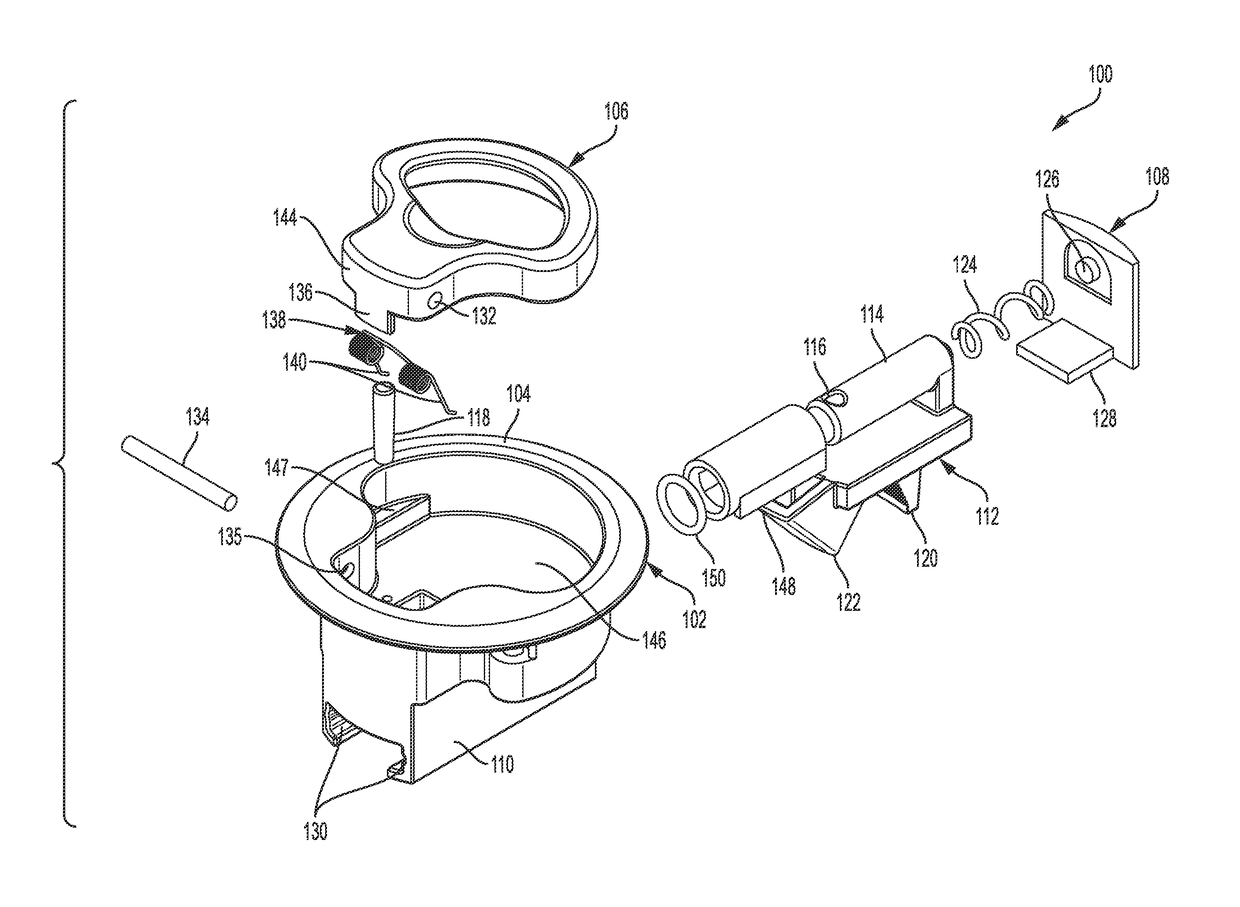

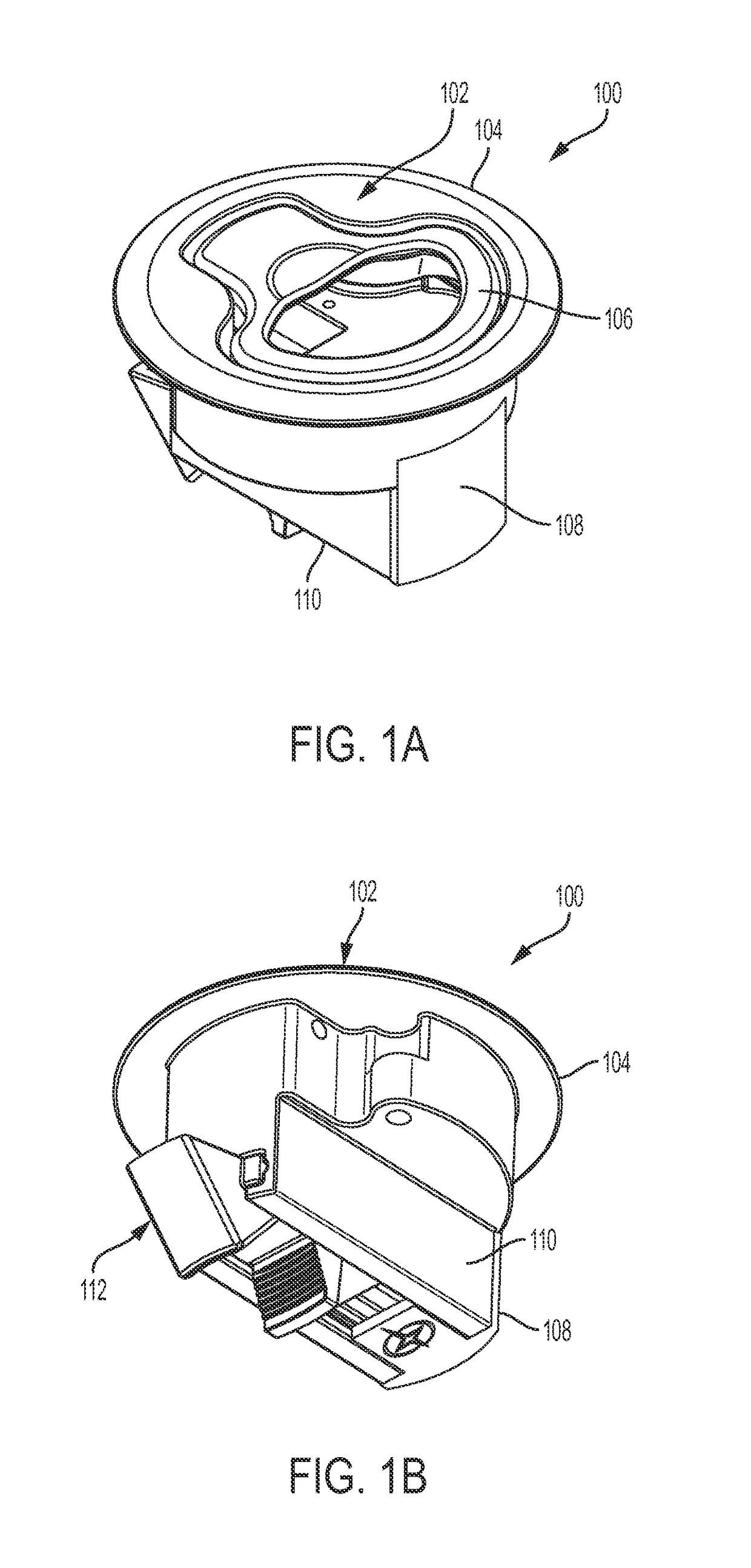

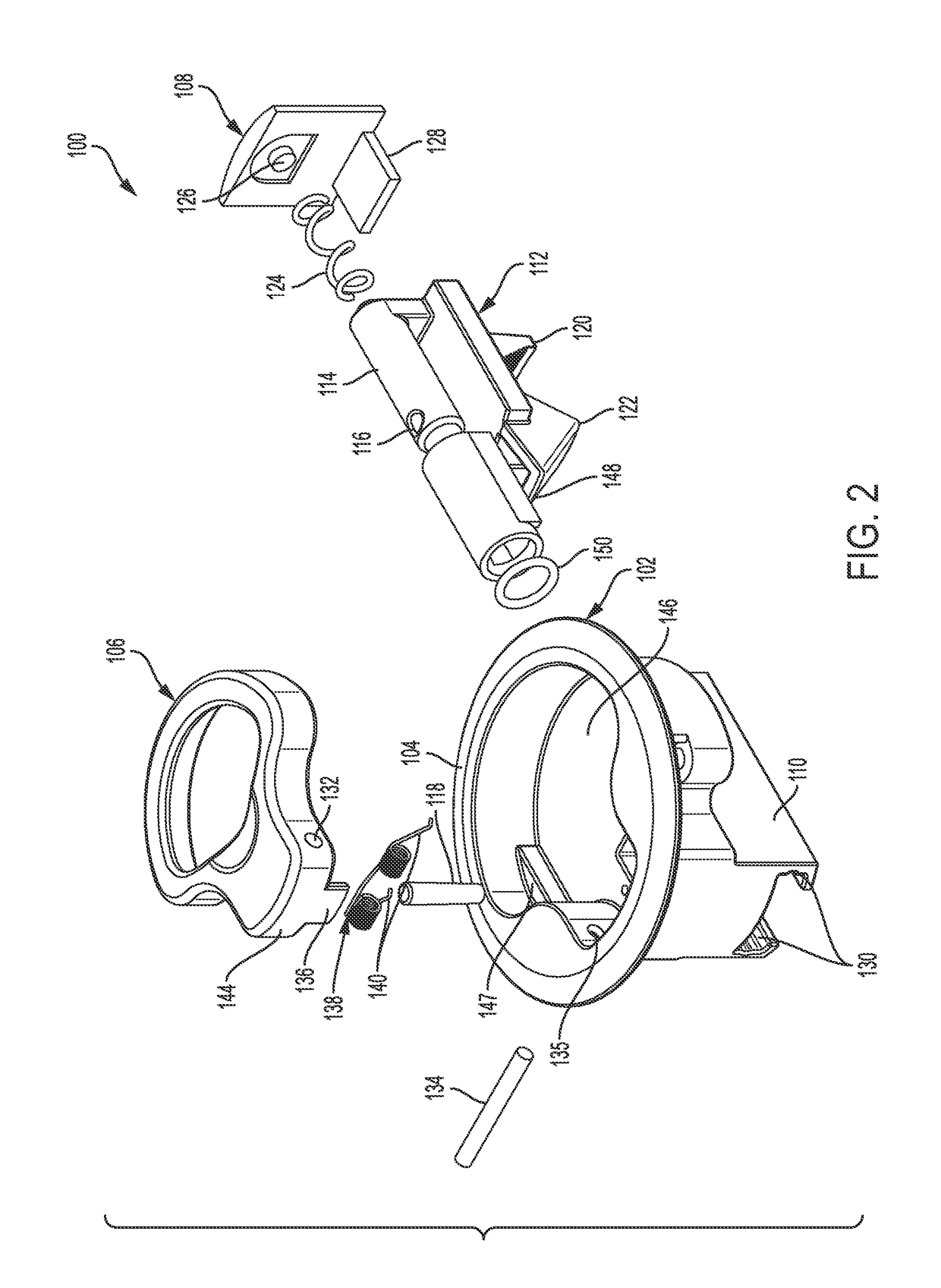

Latch

A latch that is waterproof or water-resistant so as to resist the entry of water through the latch. The latch can be a slam latch having a pawl with a shaft. A sealing element, for example, a collar and / or an O-ring, can be placed around the shaft of the pawl to resist water from entering through the latch. The pawl can also enclose the cavity in which the latch handle is maintained so water cannot enter through the cavity. Other measures, such as a gasket and selective welding, can also be implemented to improve the water-resistance of the latch.

Owner:GEM PROD LLC

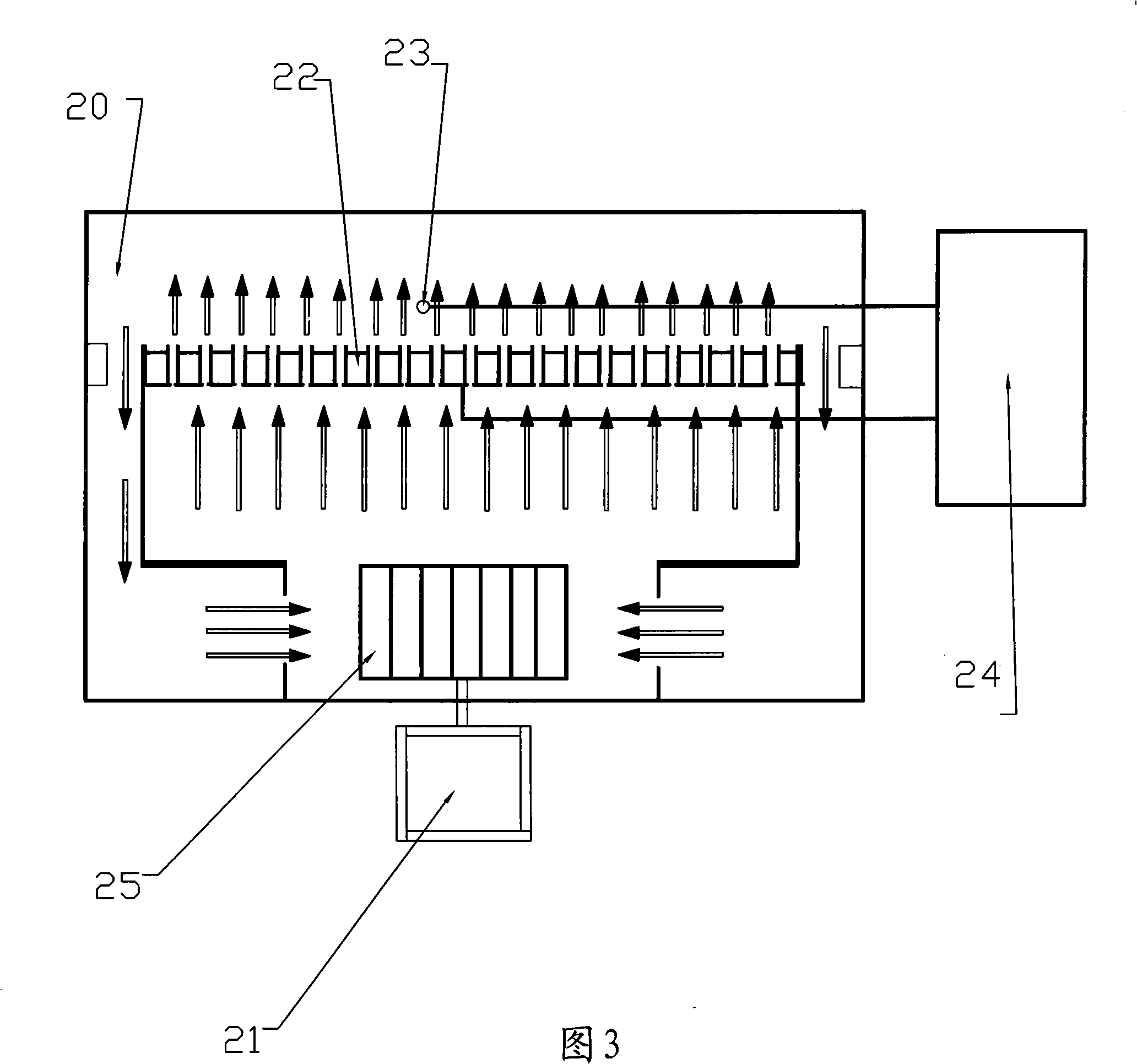

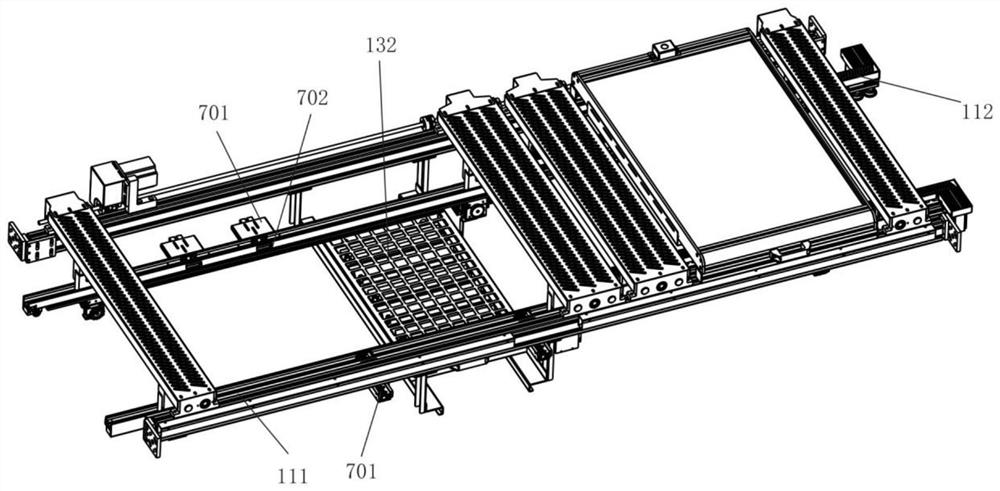

Full-automatic selective wave soldering device

PendingCN112045268AReduce welding operating costsReduce manpower expenditureHeating appliancesMetal working apparatusSprayerEngineering

The invention provides a full-automatic selective wave soldering device which comprises a transportation guide rail, a scaling powder spraying mechanism, a double-layer preheating mechanism, a selective soldering mechanism and a controller. The transportation guide rail is provided with a spraying fixing position, a preheating fixing position and a soldering fixing position, and is provided with asliding tray sliding along a board inlet guide rail and a board outlet guide rail, and a printed circuit board to be soldered is placed on the sliding tray. The scaling powder spraying mechanism is located at the spraying fixing position and located below the sliding tray and comprises a vertical double-axis moving table and a scaling powder sprayer. The double-layer preheating mechanism is located at the preheating fixing position and comprises an upper preheater and a lower preheater. The selective welding mechanism is located at the welding fixing position and located below the sliding tray and comprises a vertical three-axis moving table and a soldering tin furnace. The controller is connected with the conveying guide rail, the scaling powder spraying mechanism, the double-layer preheating mechanism and the selective welding mechanism. By means of the full-automatic selective wave soldering device, scaling powder can be saved, energy consumption is reduced, and automatic wave soldering with high consistency, repeatability, reliability and traceability is achieved.

Owner:HUANGSHAN UNIV

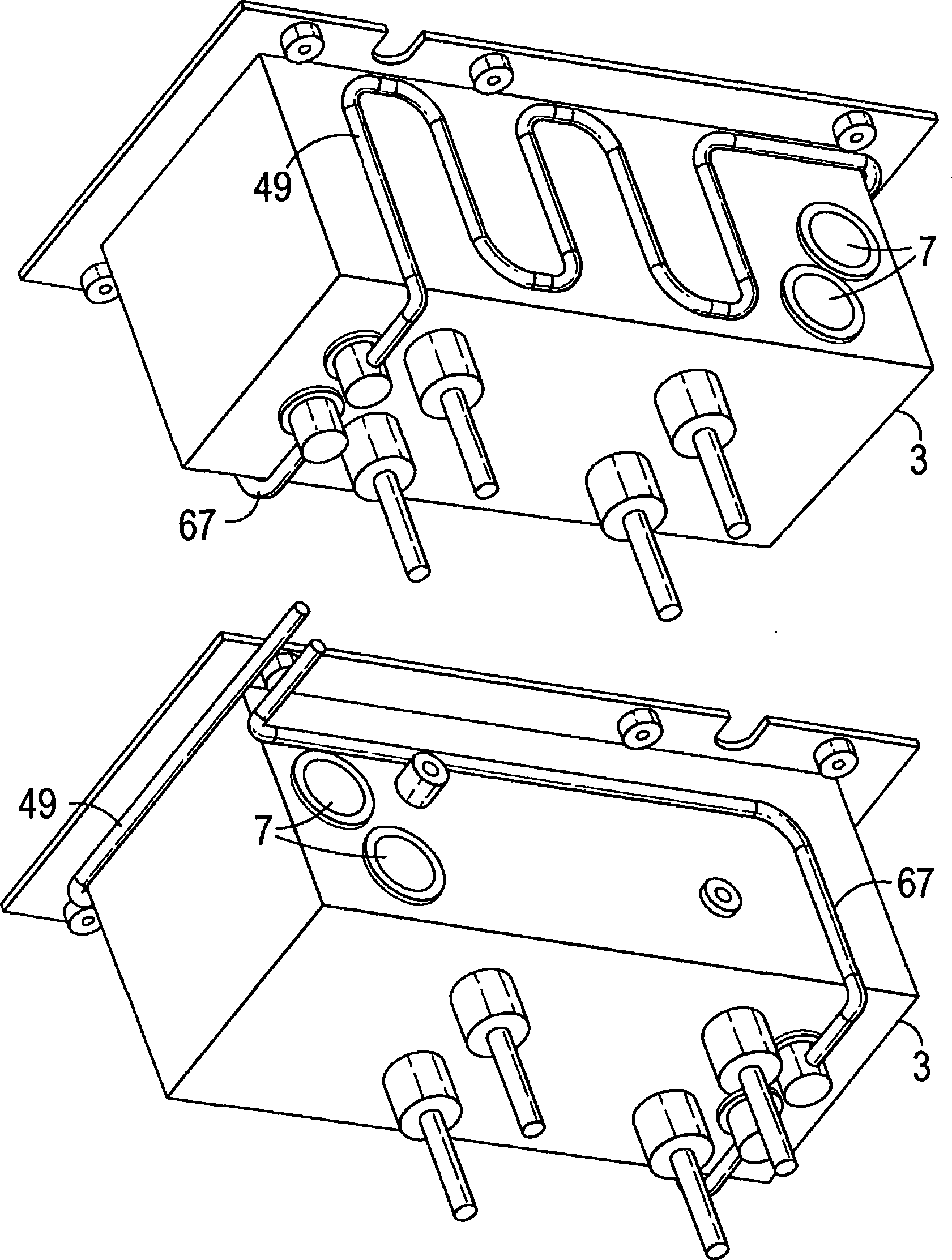

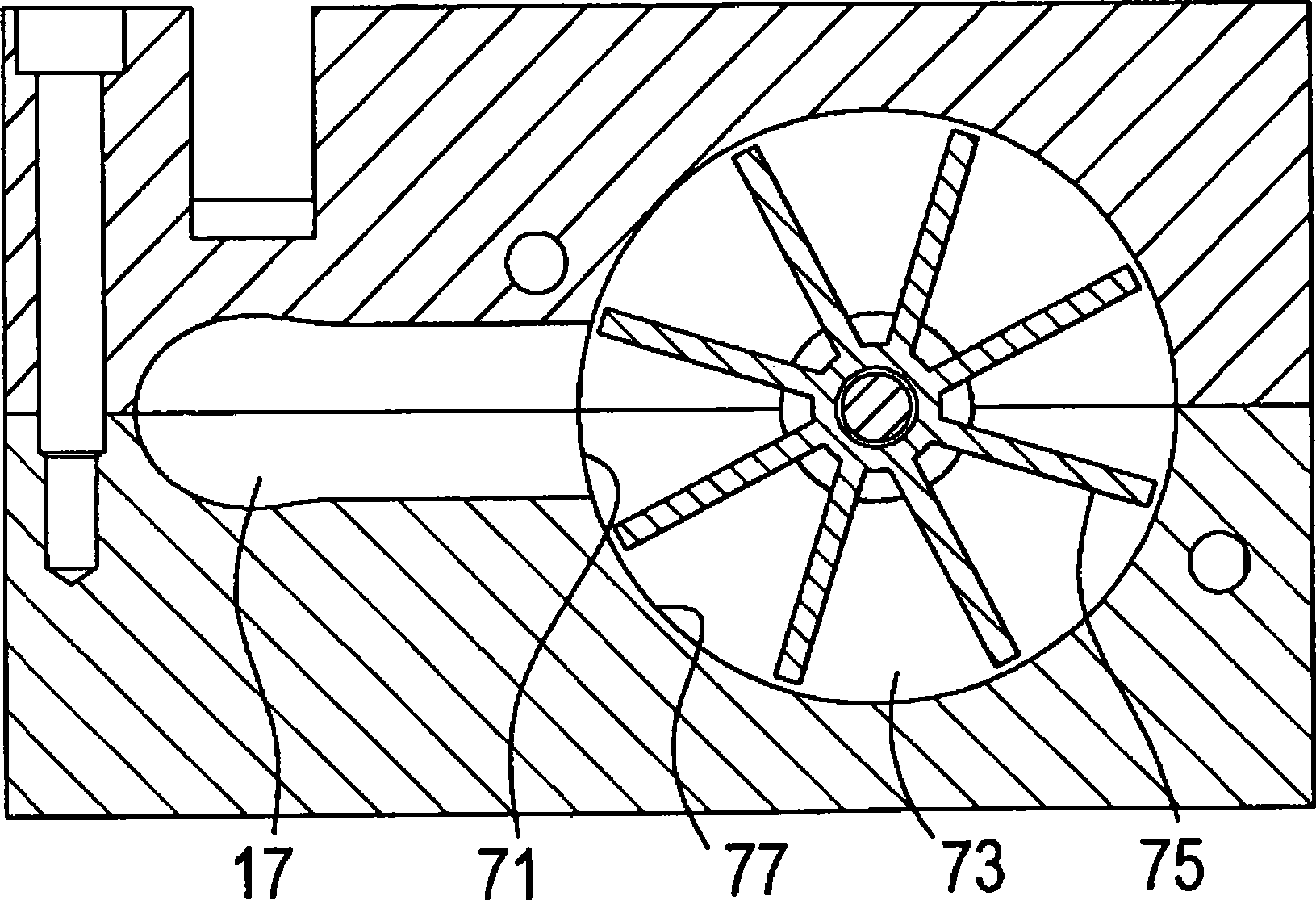

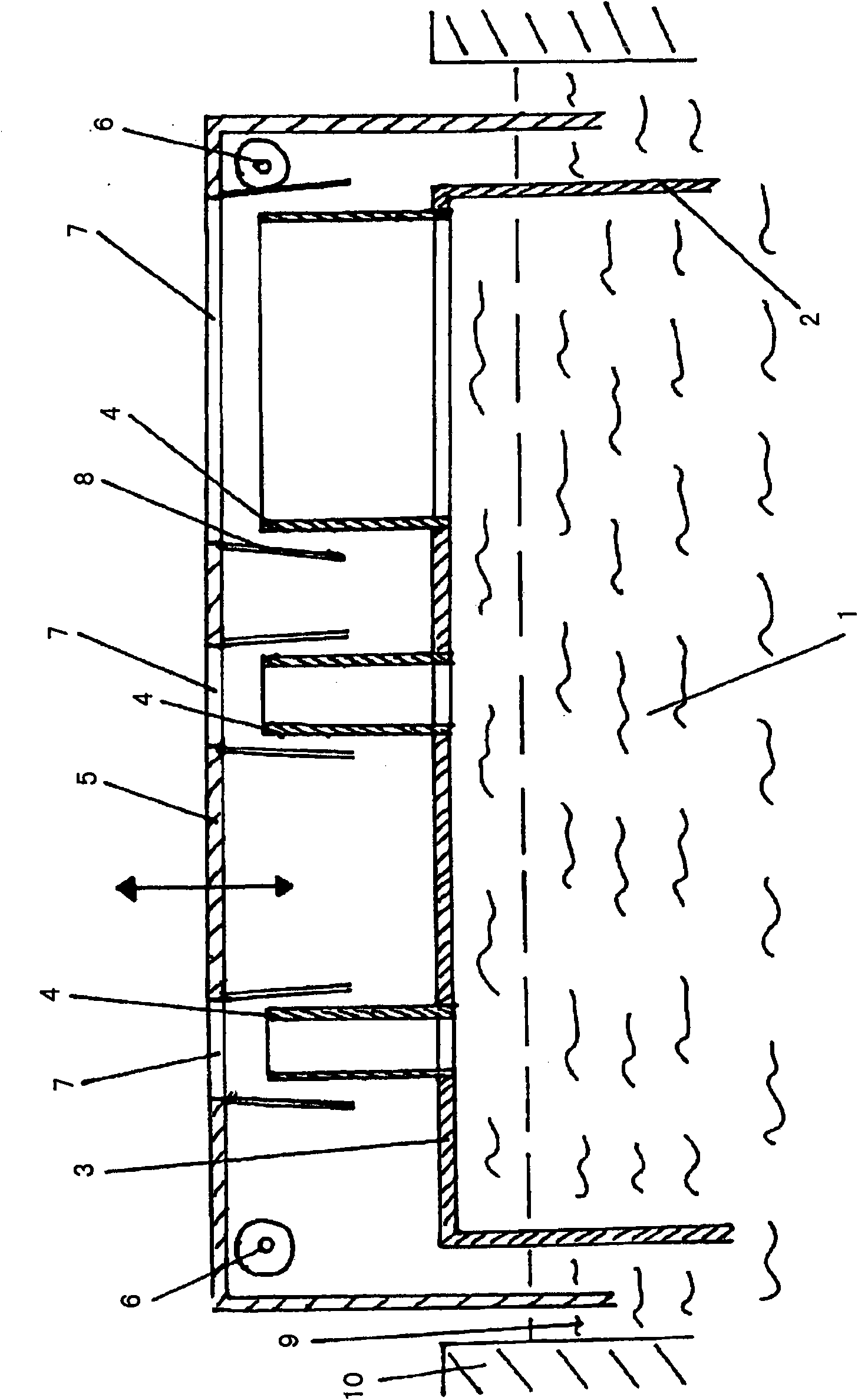

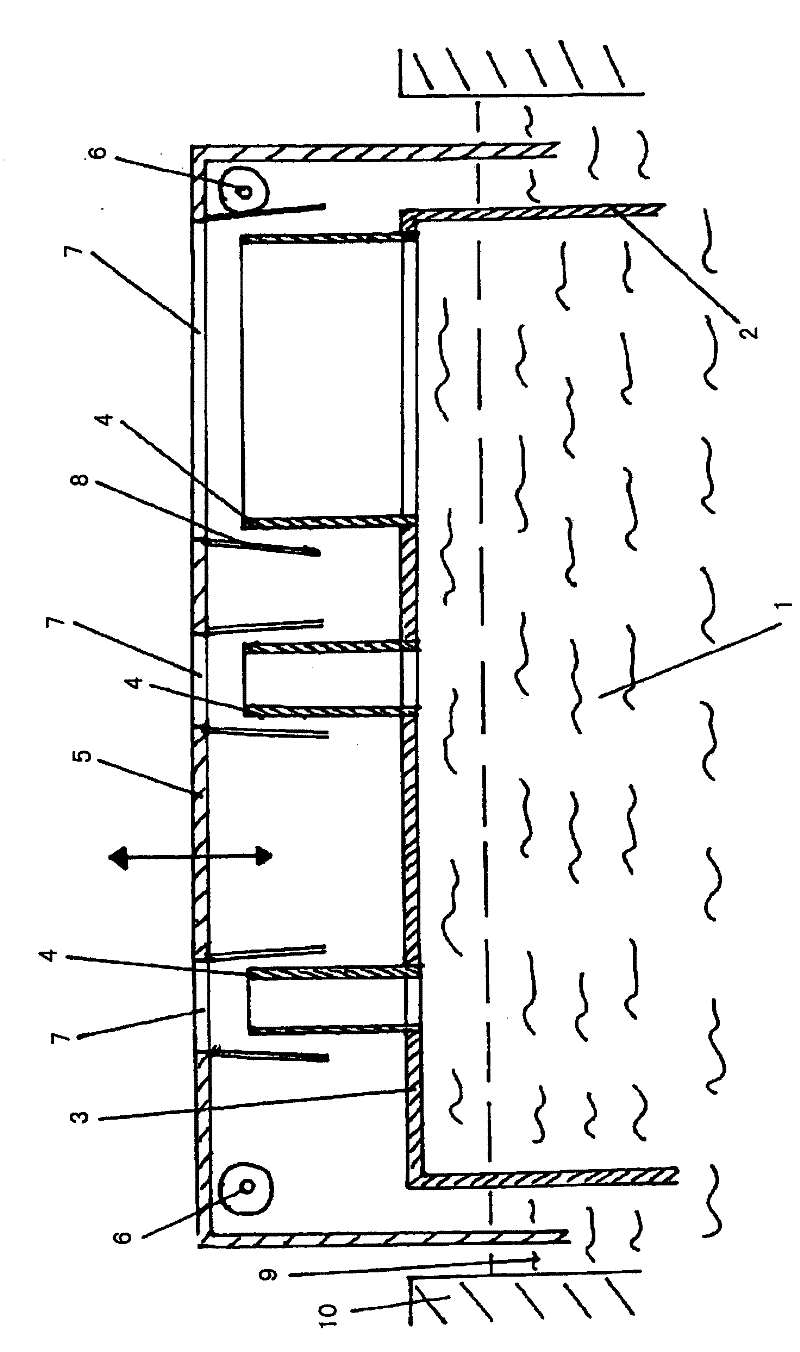

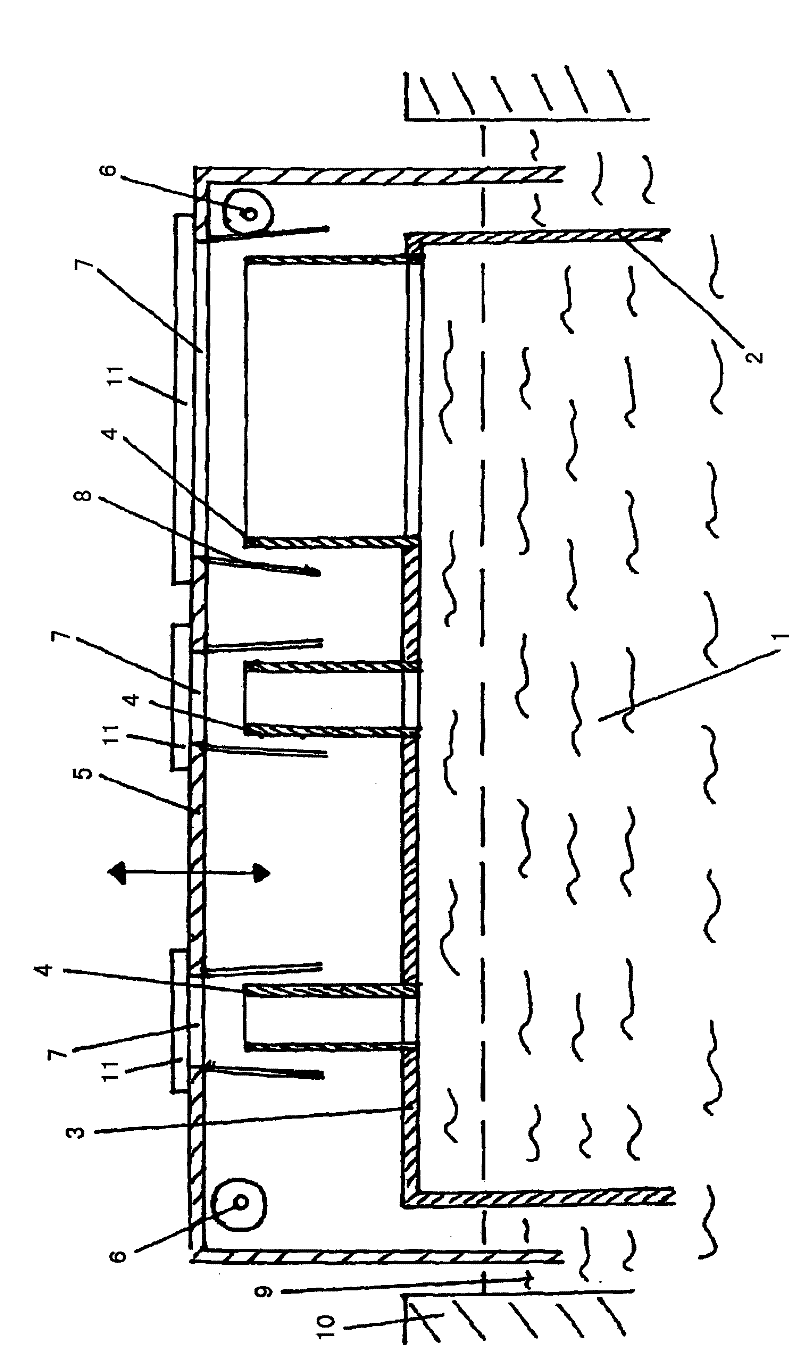

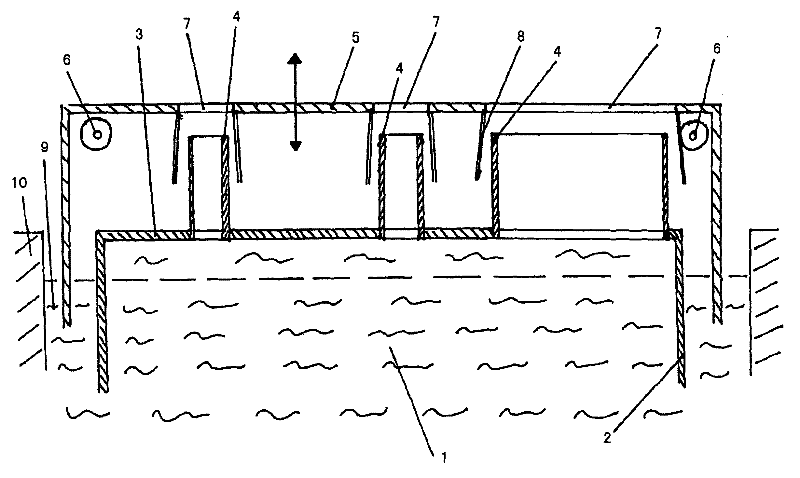

Device and method for selective soldering

InactiveCN101563181AReduce pollutionReduce error ratePrinted circuit assemblingMetal working apparatusSolderingSelective soldering

The invention relates to a first device for selective soldering, comprising a container (10) for liquid solder, with a so-called soldering bath (9), with a soldering channel (2) and at least one nozzle (4) mounted on the soldering channel (2), and with a soldering pump for pressurizing liquid solder (1) in the soldering channel (2), characterized in that the soldering channel (2) is surrounded by a vertically moveable hood (5), which immerses in the soldering bath (9), or which is sealed against the surface of the soldering bath (9) in another manner, and which comprises a passage (7) for each nozzle (4). The invention further comprises at least one feeding device (6) for protective and / or active gas underneath the hood (5), wherein flow plates (8) are attached to the hood (5), the plates extending substantially downward in the direction of the soldering bath from the hood. The invention further relates to a method for selective soldering.

Owner:LINDE AG +1

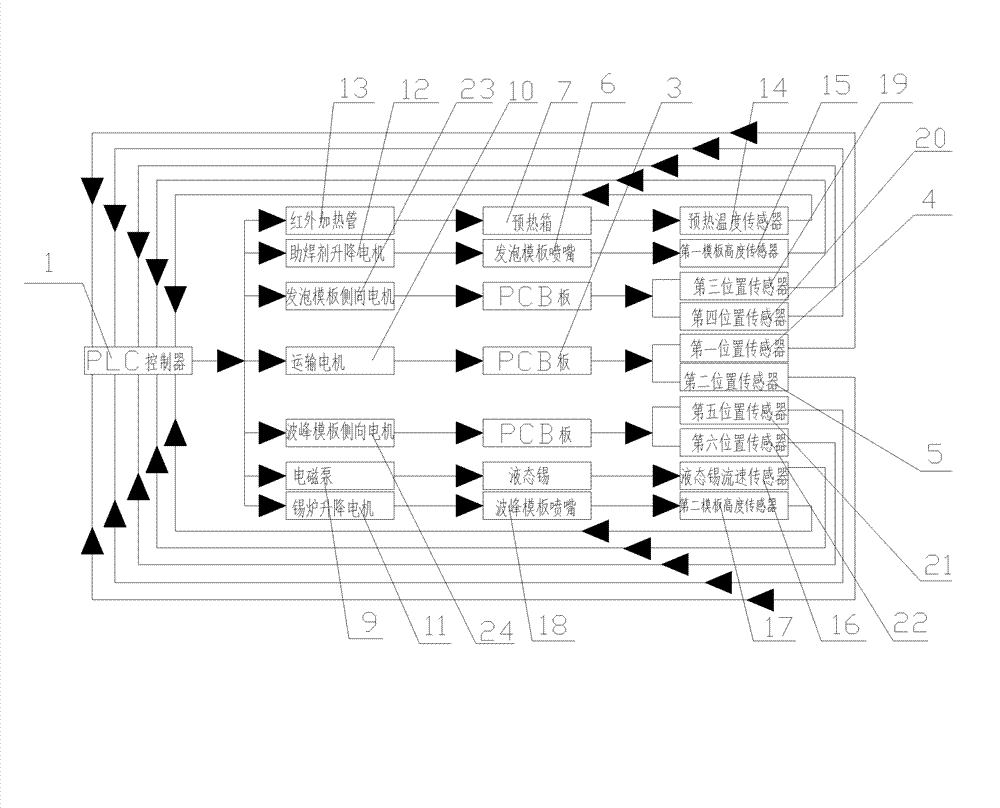

Reciprocating selectivity crest welder control system

InactiveCN103111703ASolve the problem of manual soldering that is not on the same side of the PCBSimple structurePrinted circuit assemblingMetal working apparatusAutomatic controlLiquid state

The invention discloses a reciprocating selectivity crest welder control system. The reciprocating selectivity crest welder control system comprises a system controller, an actuator, a printed circuit board (PCB) plate, a first position sensor, a second position sensor, a foaming template nozzle, a preheating box, an electromagnetic pump, a transport motor, a solder machine lifting motor, a scaling powder lifting motor, an infra-red heating tube, a preheating temperature sensor, a first height sensor, a liquid-state stannum flow sensor, a second height sensor, a wave crest template nozzle, a third position sensor, a fourth position sensor, a fifth position sensor, a sixth position sensor, a foaming template side-direction motor and a wave crest template side-direction motor. The reciprocating selectivity crest welder control system combines the automatic control theory and motor dragging to achieve the function that a crest welder selectively welds the PCB plate, and the function of reciprocating weld is provided, so that the whole process can be finished without worker operation.

Owner:XIAN ZHONGKEMAITE ELECTRONICS TECH EQUIP

Selective soldering bath

InactiveUS7648056B1Welding/cutting auxillary devicesAuxillary welding devicesThree degrees of freedomSolder ball

Owner:SONY CORP +1

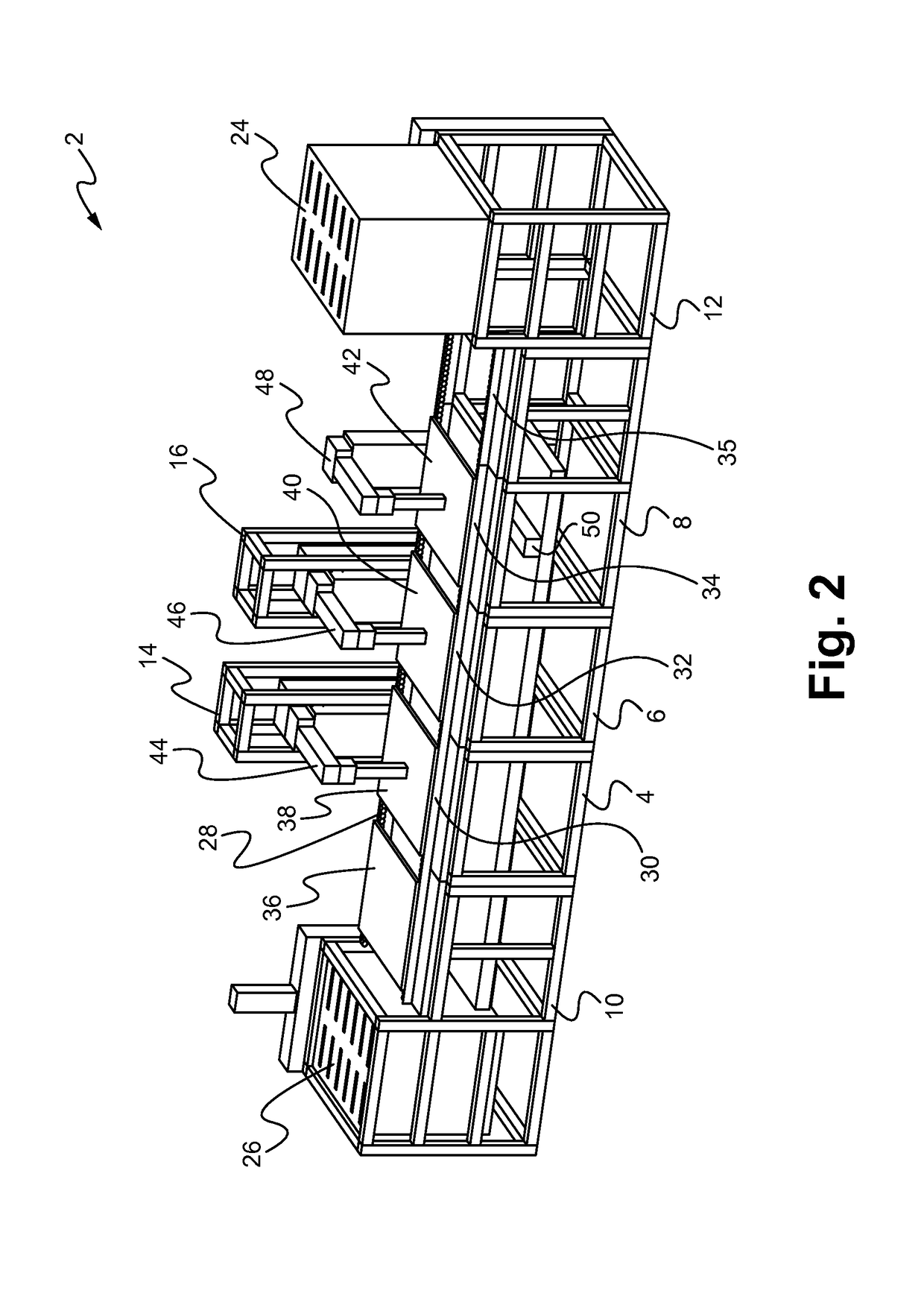

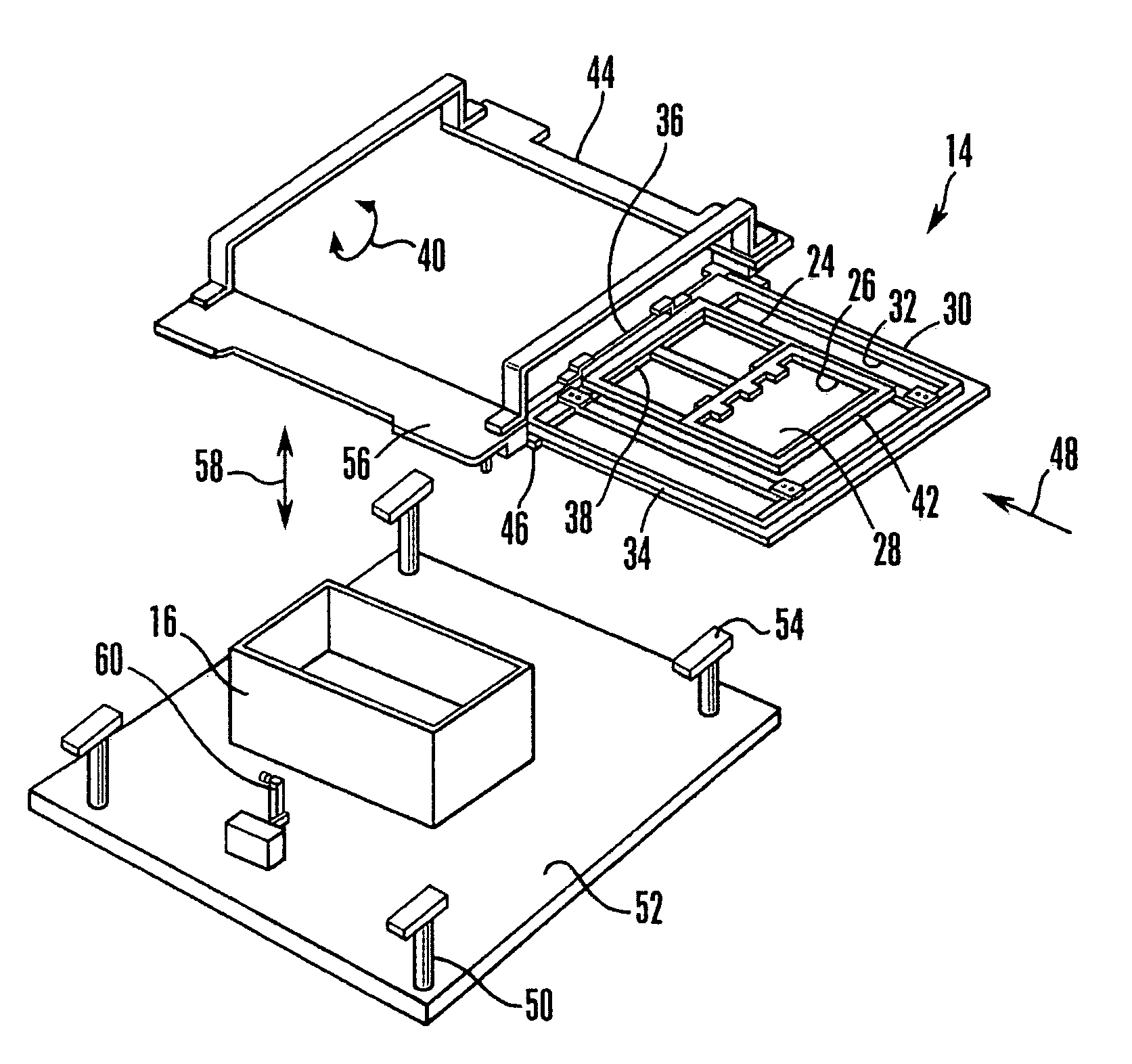

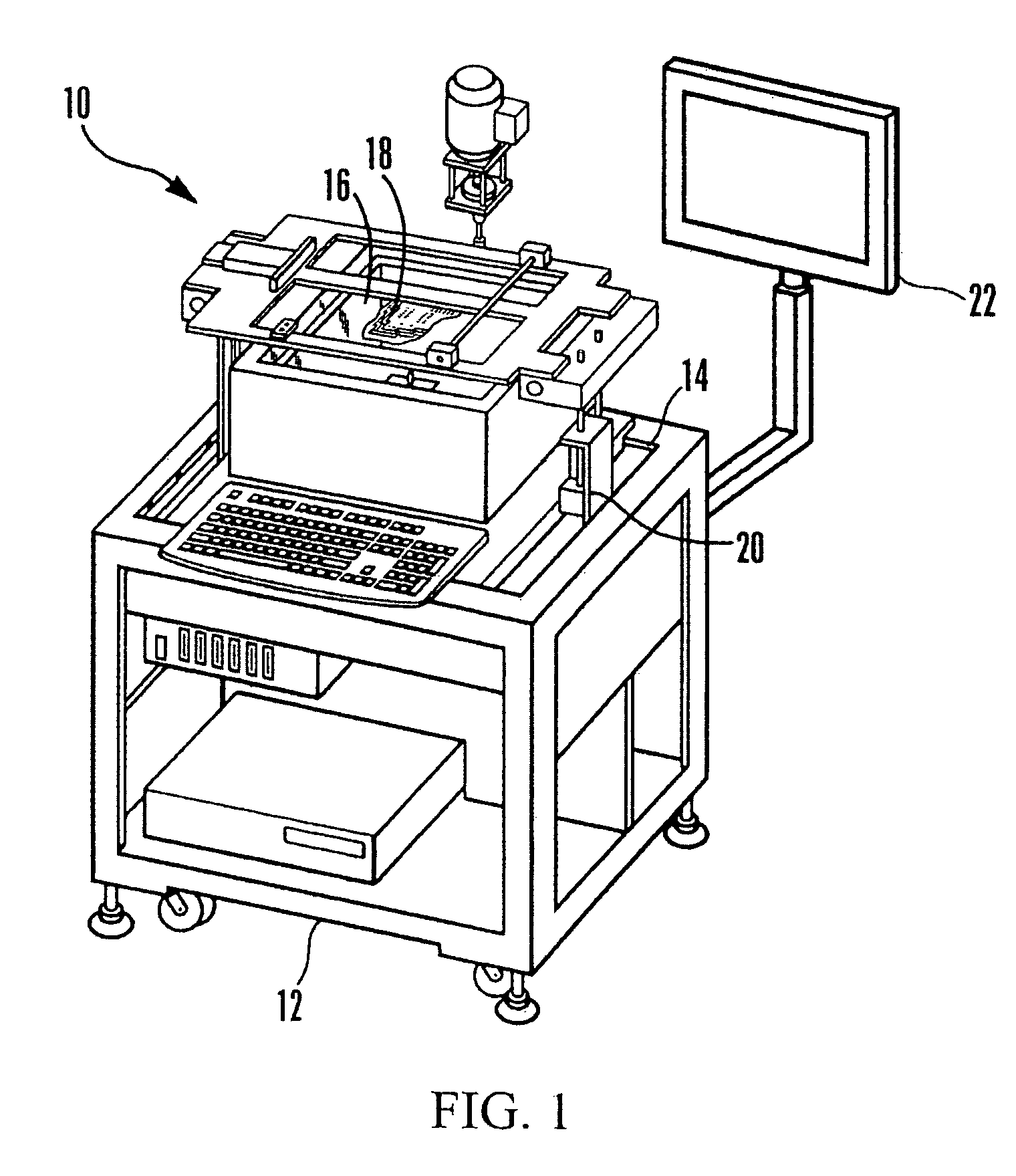

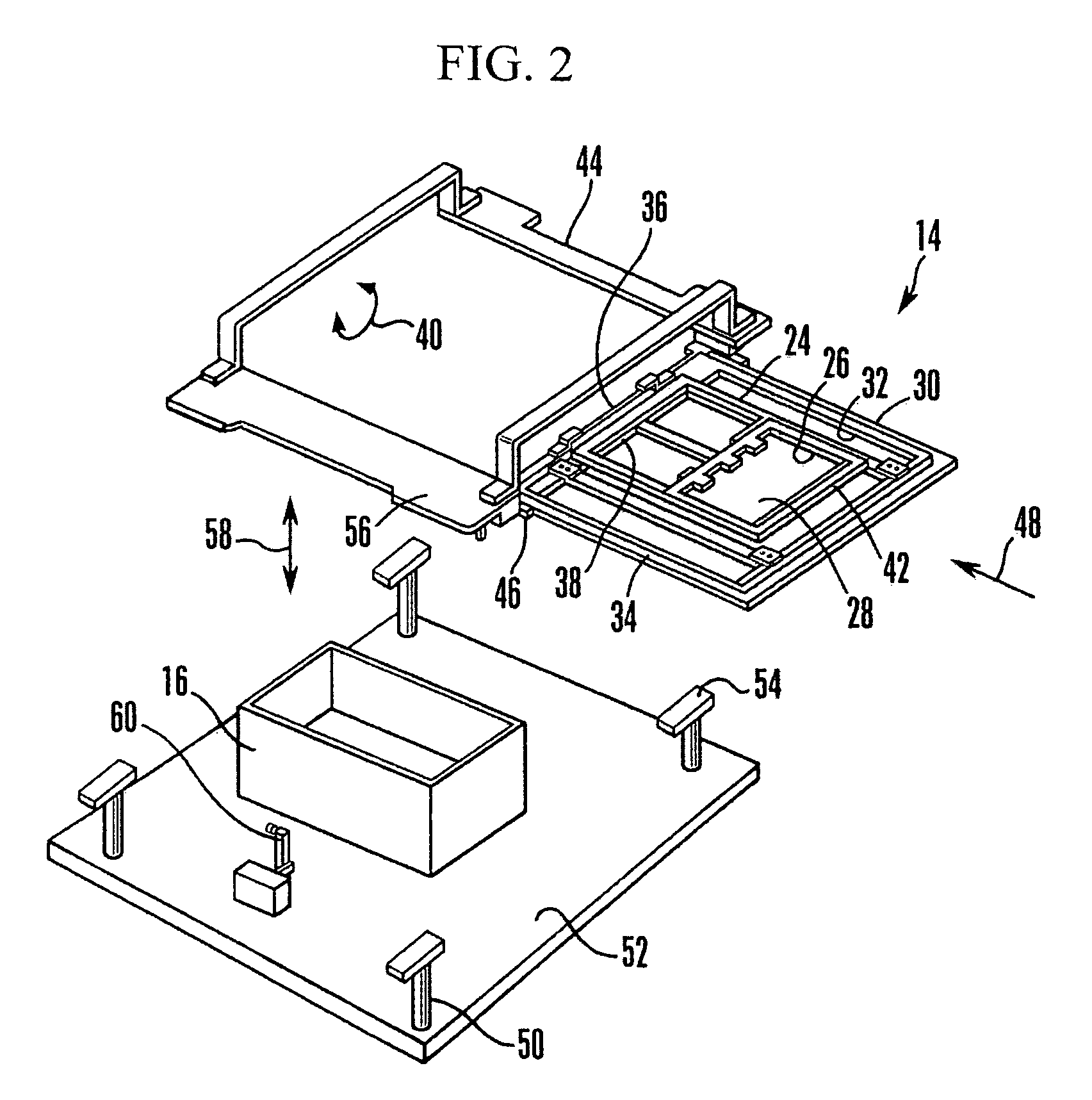

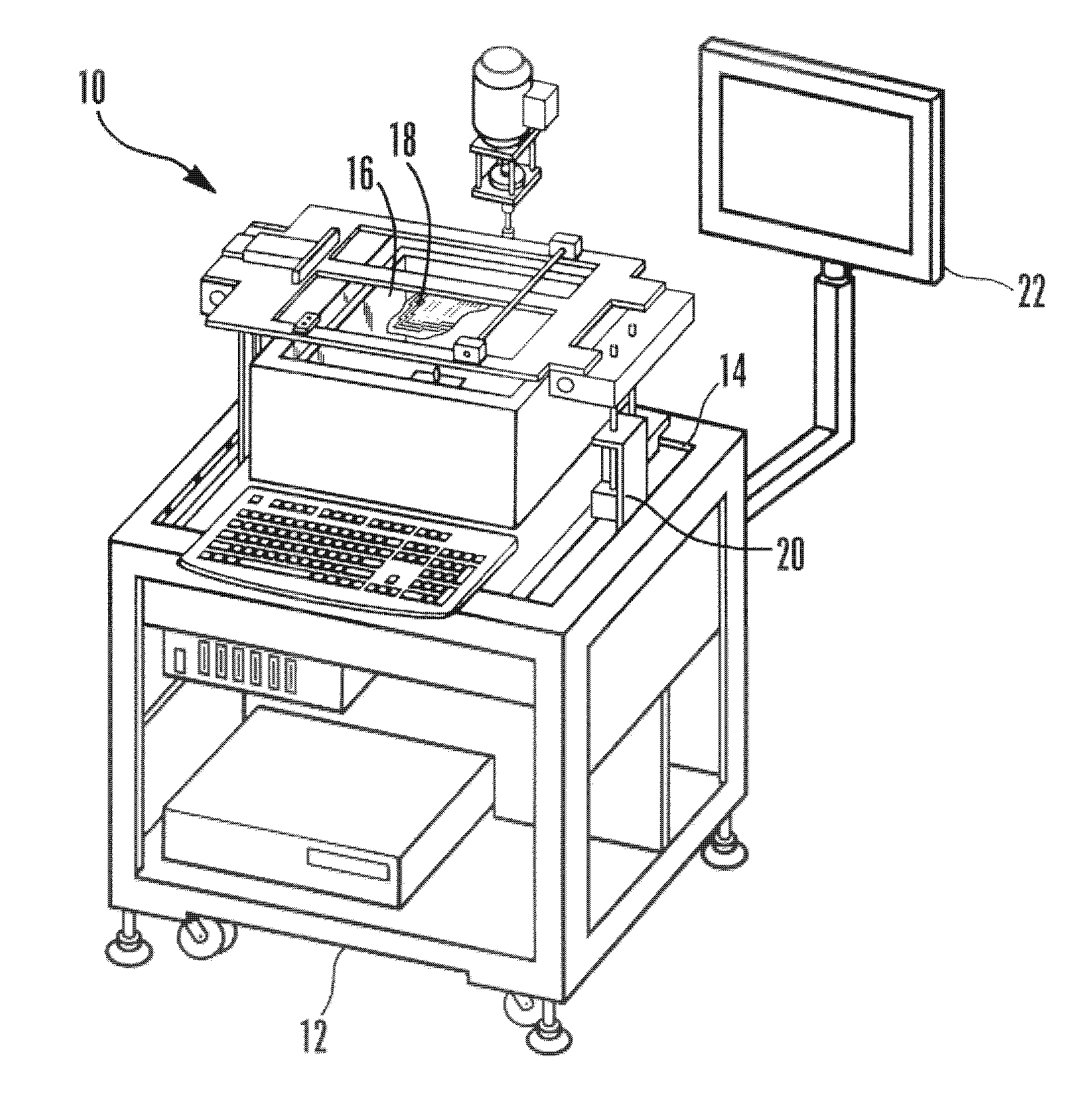

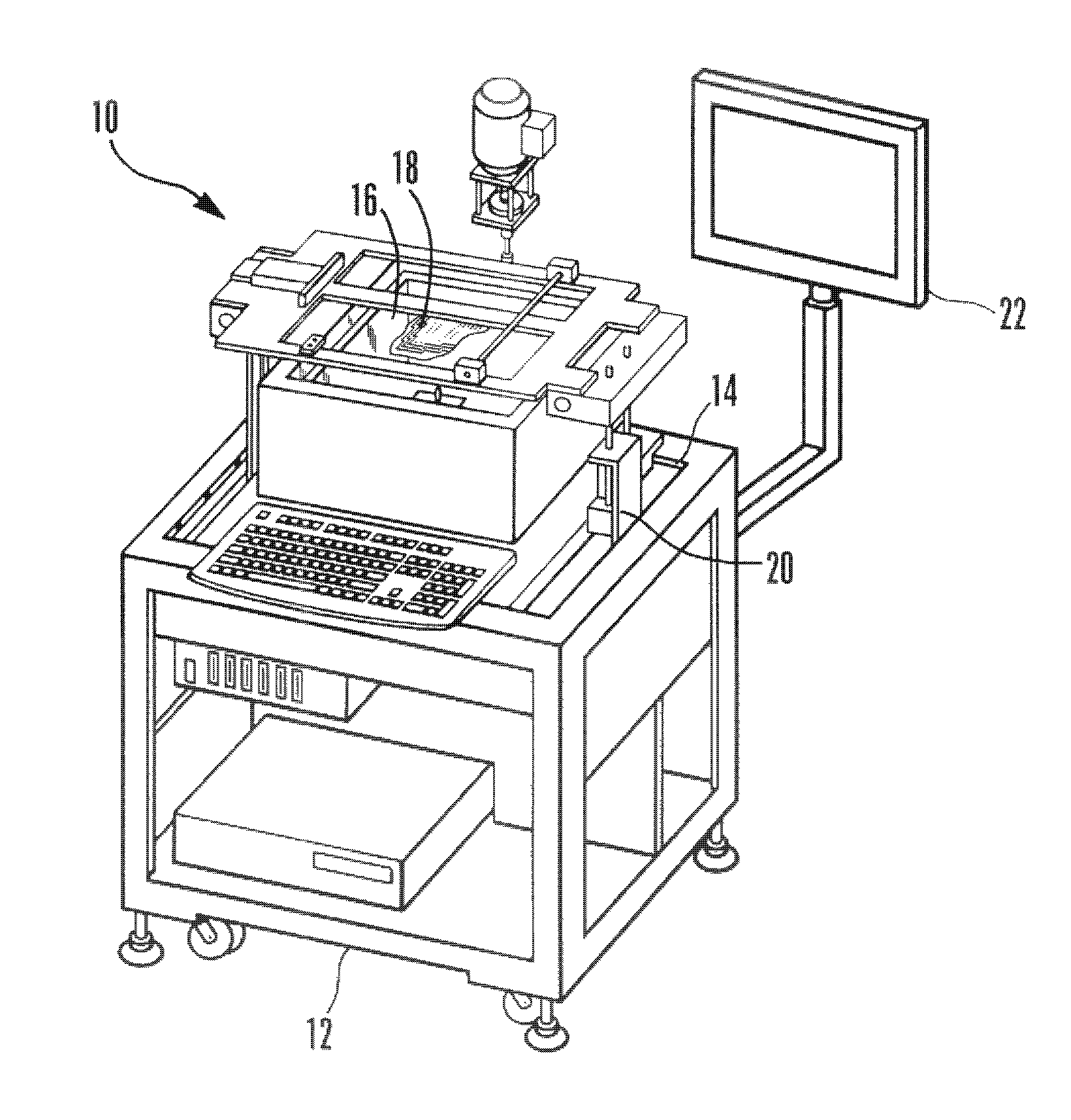

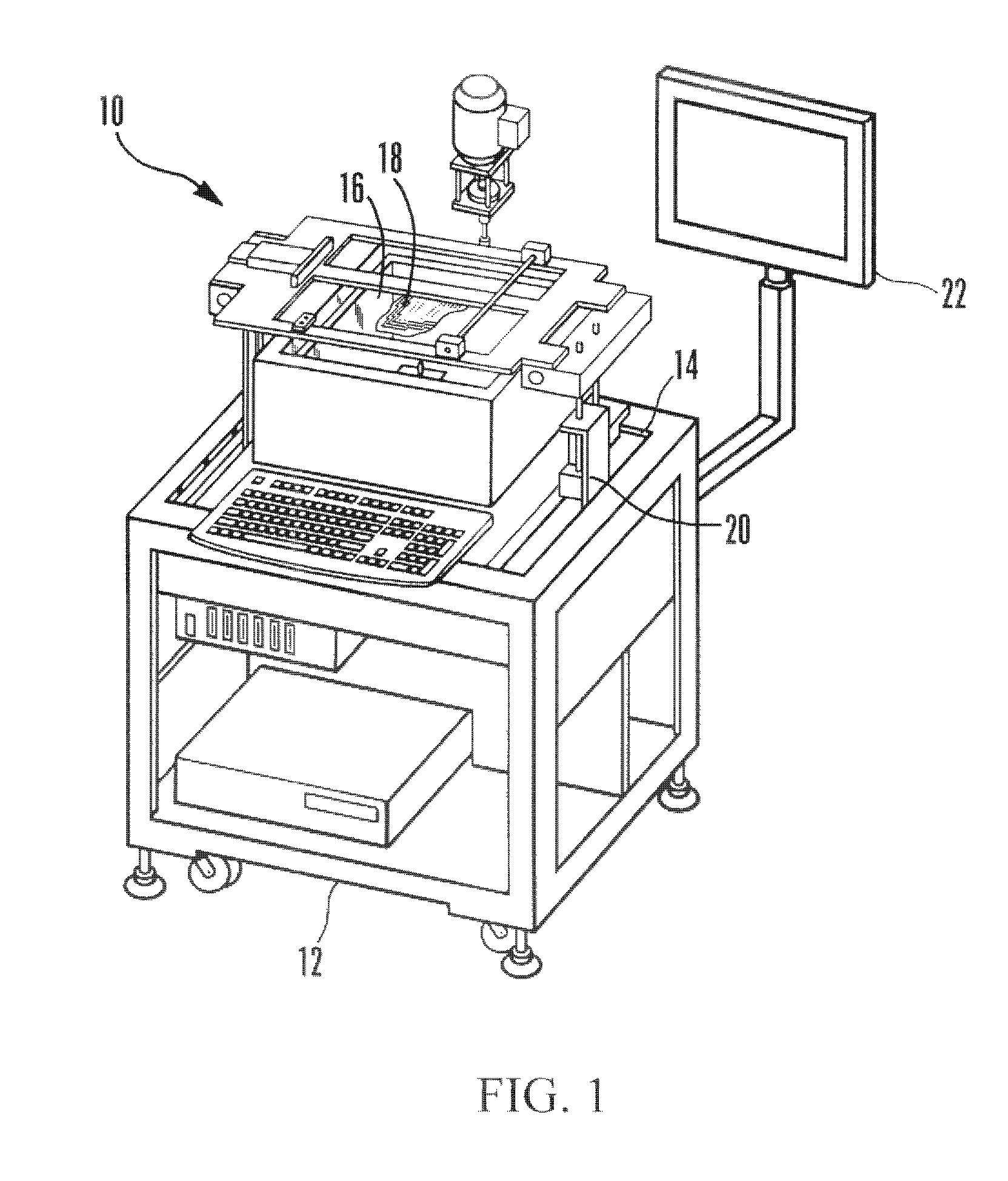

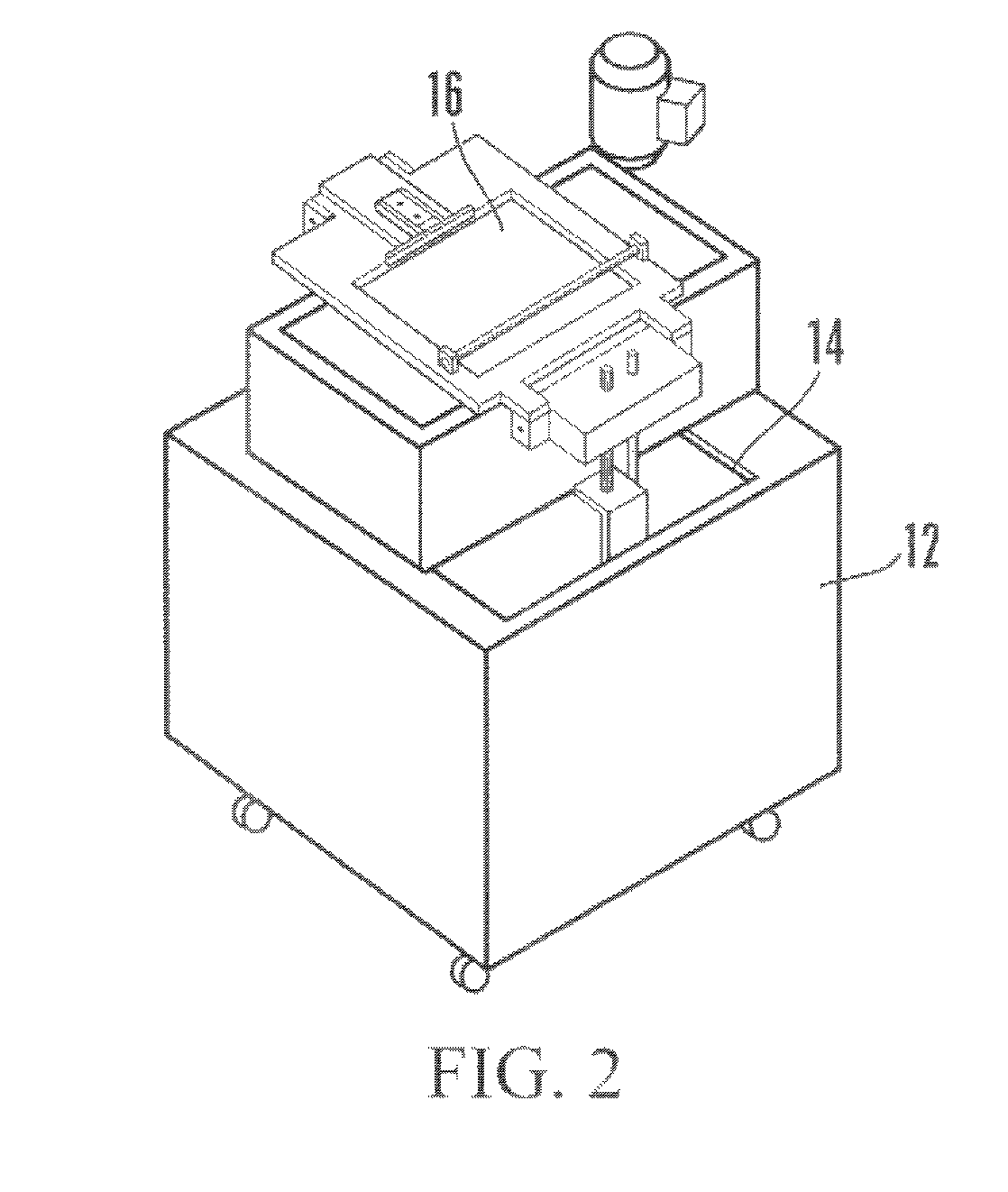

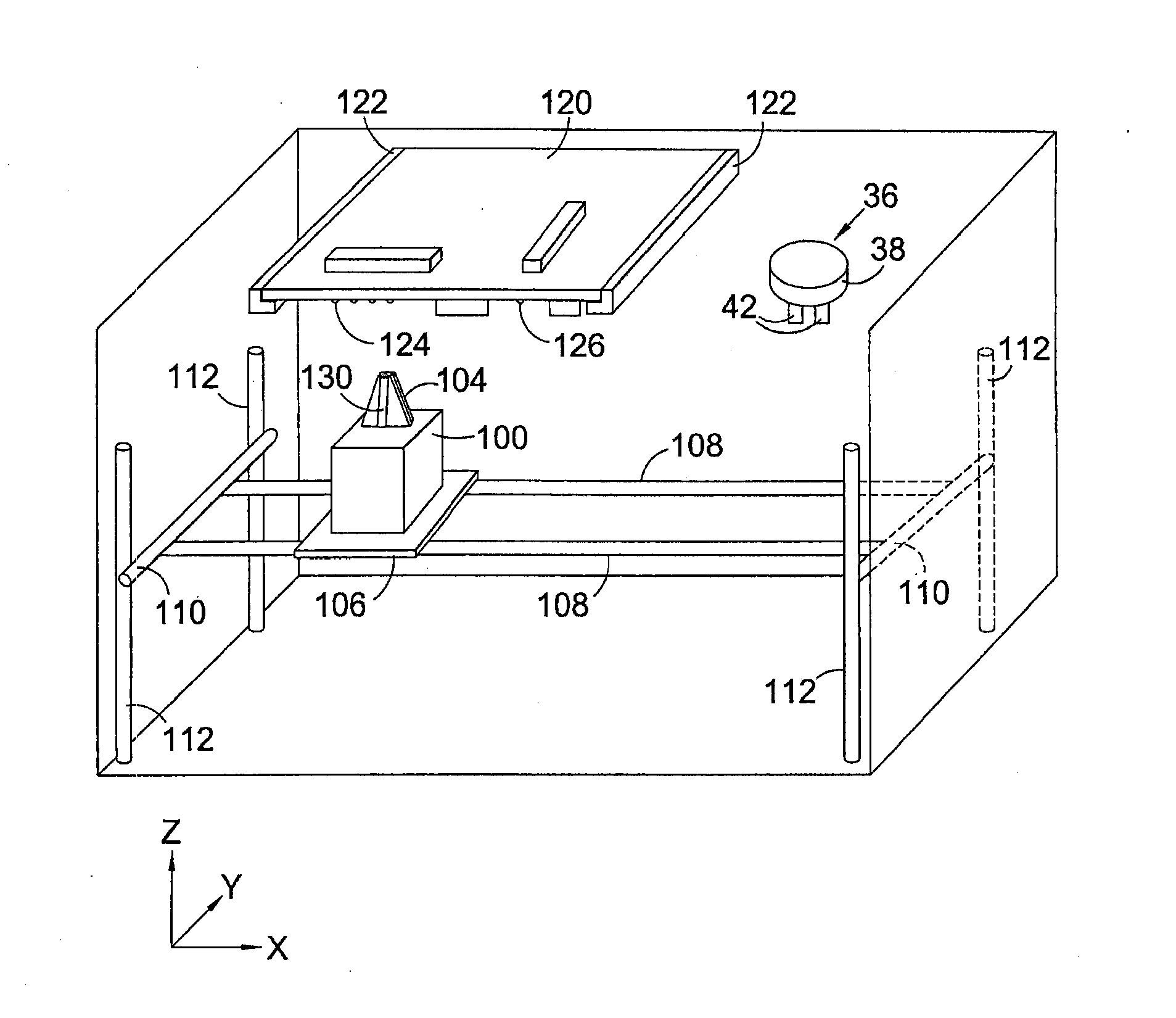

Selective soldering system

ActiveUS20090179067A1Great soldering precisionSmall footprintWelding/cutting auxillary devicesAuxillary welding devicesSolder ballDegrees of freedom

A solder machine includes a top flat carrier that holds PWBs just above a solder bath. Opposed edges of the carrier are coupled to a frame and each edge can be independently raised or lowered by a respective piston. Also, the base of the frame can pivot along one of its edges to provide a second degree of freedom of motion to the top flat carrier in dipping the PWBs relative to the solder bath, thereby providing a solder machine with a relatively small footprint that nonetheless can achieve precise soldering of PWBs.

Owner:SONY CORP +1

Wave crest nozzle installation structure

InactiveCN103118501AEasy to replaceSimple structurePrinted circuit assemblingLiquid stateEngineering

The invention relates to a wave crest nozzle installation structure comprising a nozzle stopping frame, wherein the nozzle stopping frame is fixedly welded on an opening of a solder machine to enable a wave crest to gush in a shape which is surrounded by the nozzle stopping frame, a separating net is installed at the bottom of the nozzle stopping frame to enable the wave crest to gush evenly, holes is formed in a nozzle, the position of the holes corresponds to that of a printed circuit board (PCB) needing to be welded, reflux grooves are formed in the periphery of the interior of the nozzle, the edge of the concave part of the nozzle is tightly attached to the inner edge of the nozzle stopping frame, and the extension of the nozzle is installed in a fastening mode through fastening screws and threaded holes in a nozzle flapper. So that, after a wave crest generator works, the whole wave crest gushes from the opening of the solder machine, evenly gushes upwards to the nozzle from the rectangular area surrounded by the nozzle stopping frame, and gushes out of the holes of the nozzle, the PCB is welded selectively, gushed liquid-state tin further flows toward the solder machine through the reflux grooves, and the whole welding process is completed. The wave crest nozzle installation structure is simple in structure, and high in weld efficiency, and the nozzle is easy to replace.

Owner:XIAN ZHONGKEMAITE ELECTRONICS TECH EQUIP

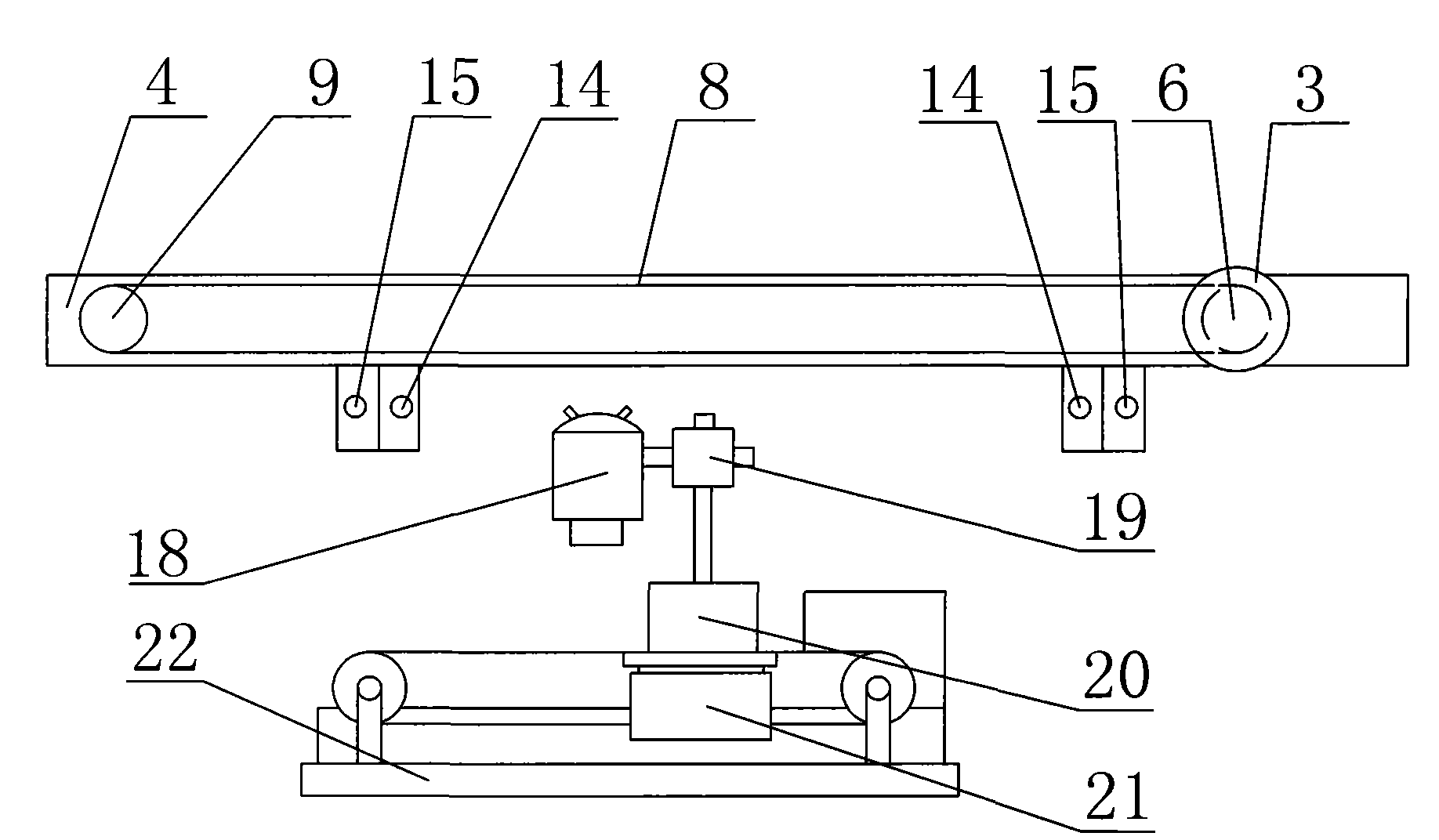

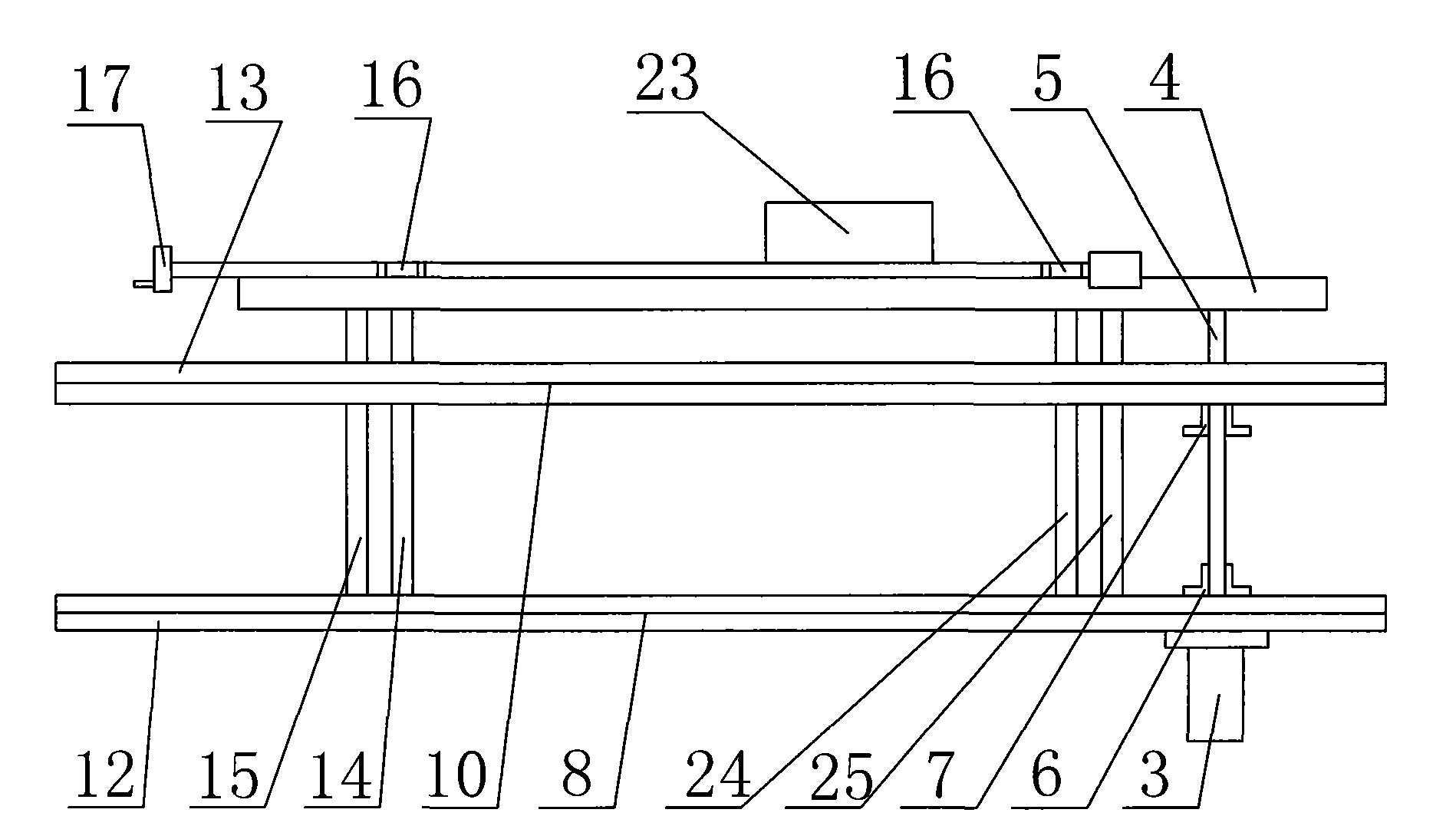

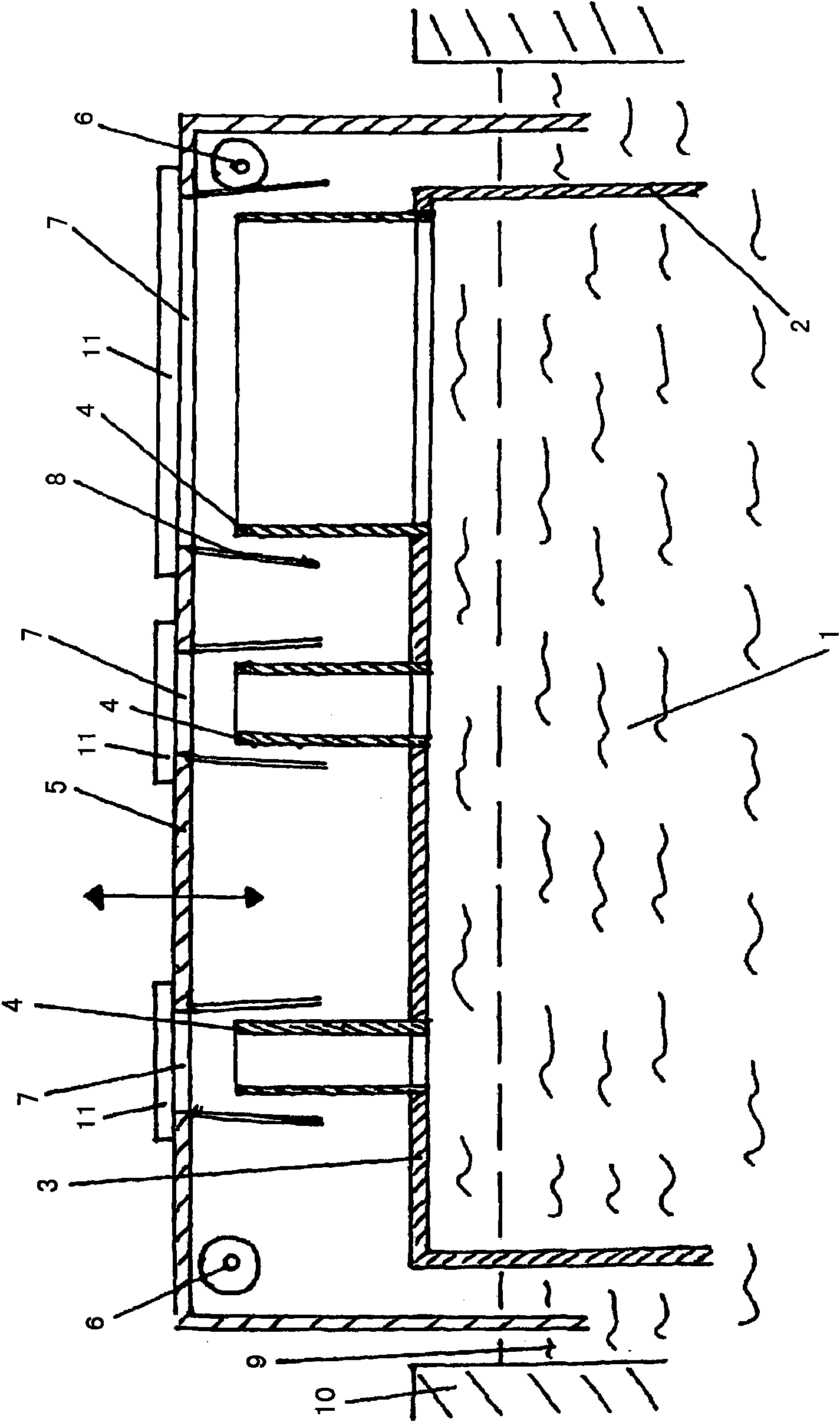

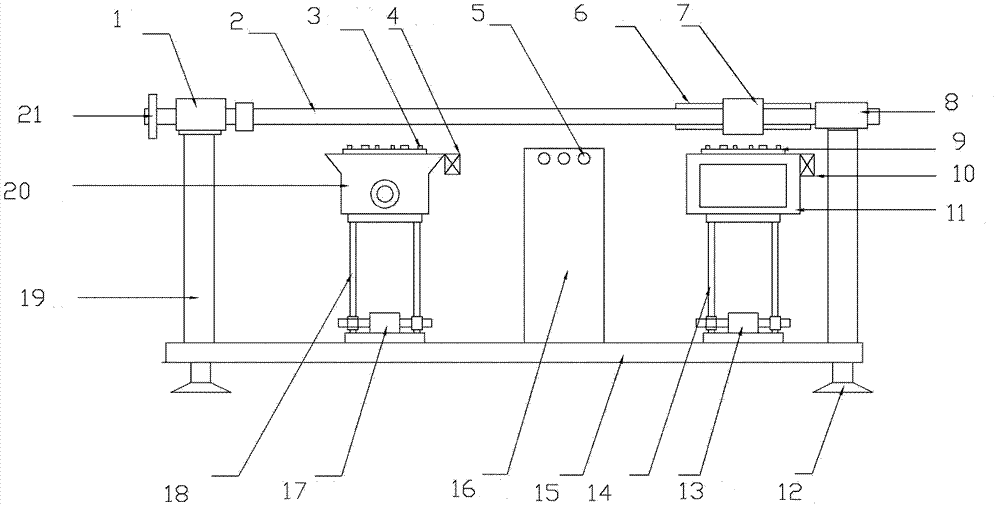

Reciprocating type printed circuit board (PCB) selective crest welder

InactiveCN103111708AAchieve accuracyPrinted circuit assemblingMetal working apparatusEngineeringPrinted circuit board

The invention discloses a reciprocating type printed circuit board (PCB) selective crest welder. The reciprocating type PCB selective crest welder is mainly comprises a selective scaling powder coating device, a pre-heating device, a welding device and a PCB transmission and positioning device. According to the reciprocating type PCB selective crest welder, a PCB to be welded is pre-heated after being coated with the selective scaling powder, selective welding is carried out on the PCB, and then the PCB is returned along the same track after the welding is finished, and therefore a reciprocating type welding process is achieved. The reciprocating type PCB selective crest welder is simple in structure, convenient to operate, high in precision, and universally applicable to selective welding of various PCBs.

Owner:XIAN ZHONGKEMAITE ELECTRONICS TECH EQUIP

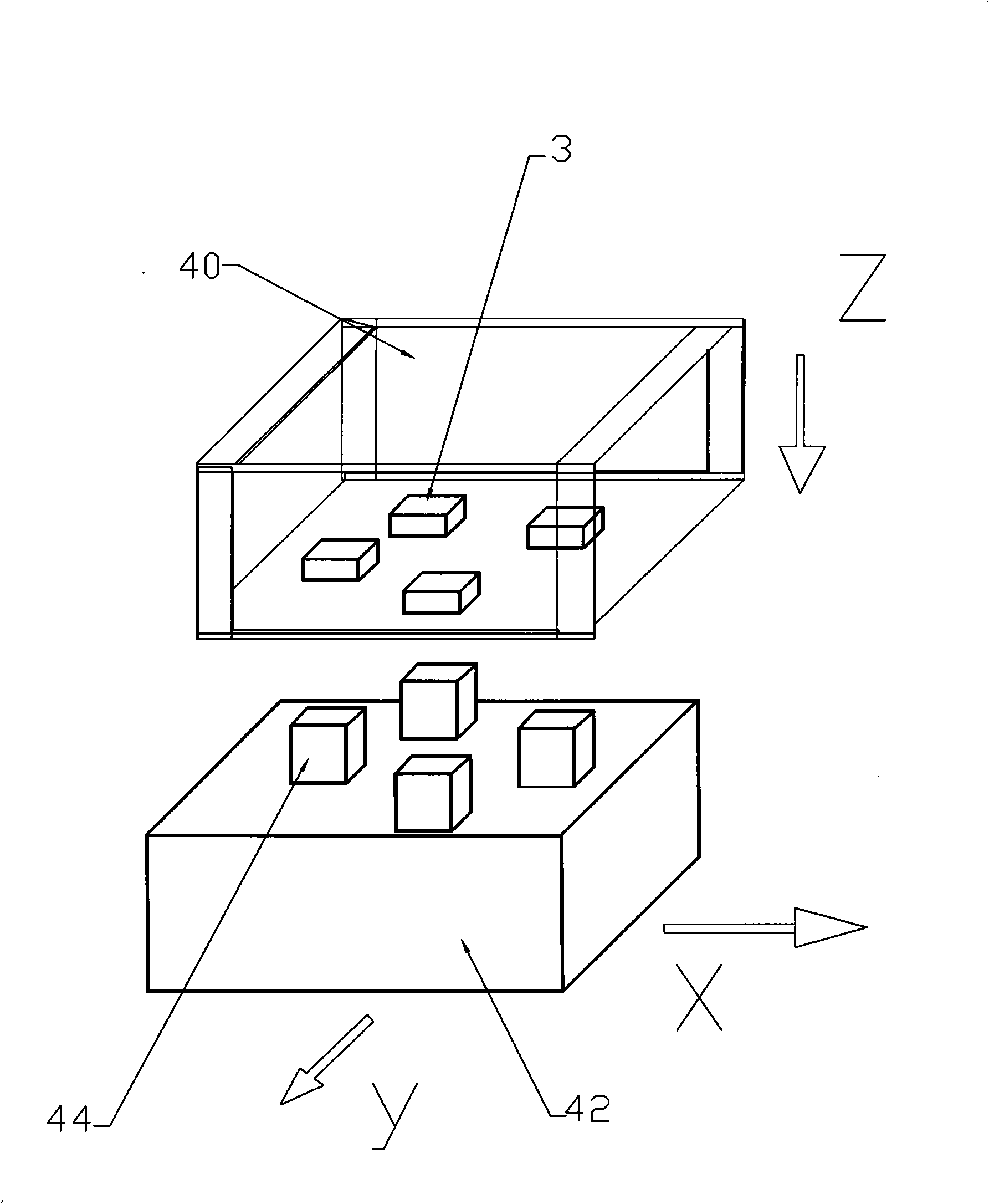

Automatic wave peak welding equipment

PendingCN108031943AEnables selective solderingIncrease productivitySoldering apparatusMetal working apparatusSpray nozzleEngineering

The invention relates to automatic wave peak welding equipment. The automatic wave peak welding equipment comprises a tin furnace, and a nozzle arranged on the tin furnace. The wave peak welding equipment further comprises a three-dimensional moving device; the tin furnace is mounted on the three-dimensional moving device; and the three-dimensional moving device drives the tin furnace and the nozzle to move in an X-axle direction, a Y-axle direction and a Z-axle direction. As the three-dimensional moving device drives the tin furnace and the nozzle to move in the X-axle direction, the Y-axle direction and the Z-axle direction, the nozzle is driven to avoid from protected parts to precisely reach welded positions of PCB products to realize selective welding of double-surface inserts or mixed PCB products; and the nozzle is flexibly controlled to greatly improve the production efficiency.

Owner:深圳市浩宝技术有限公司

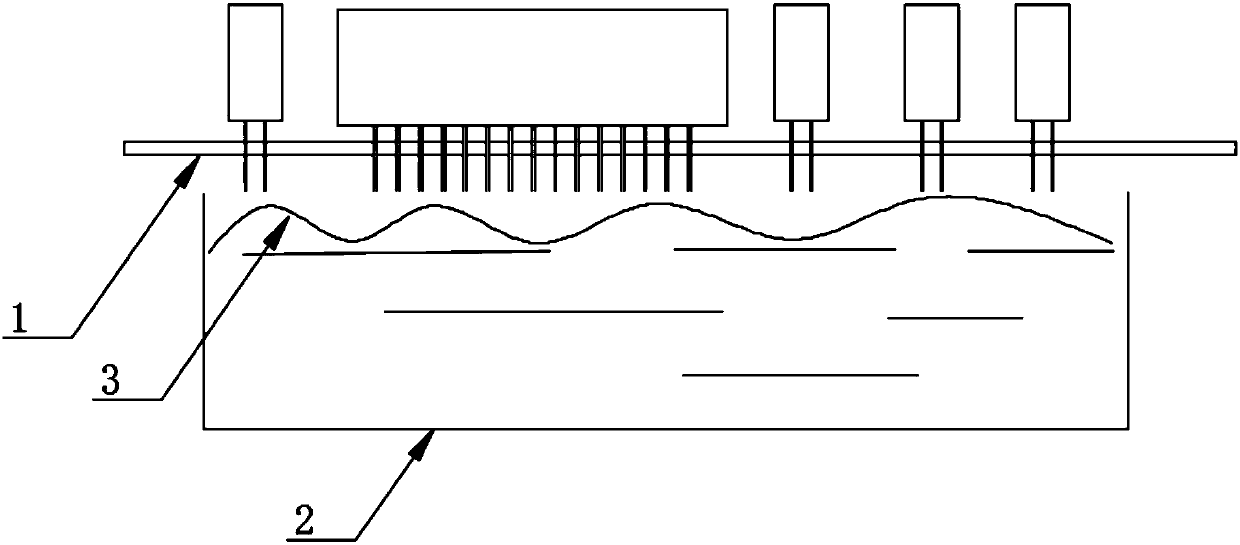

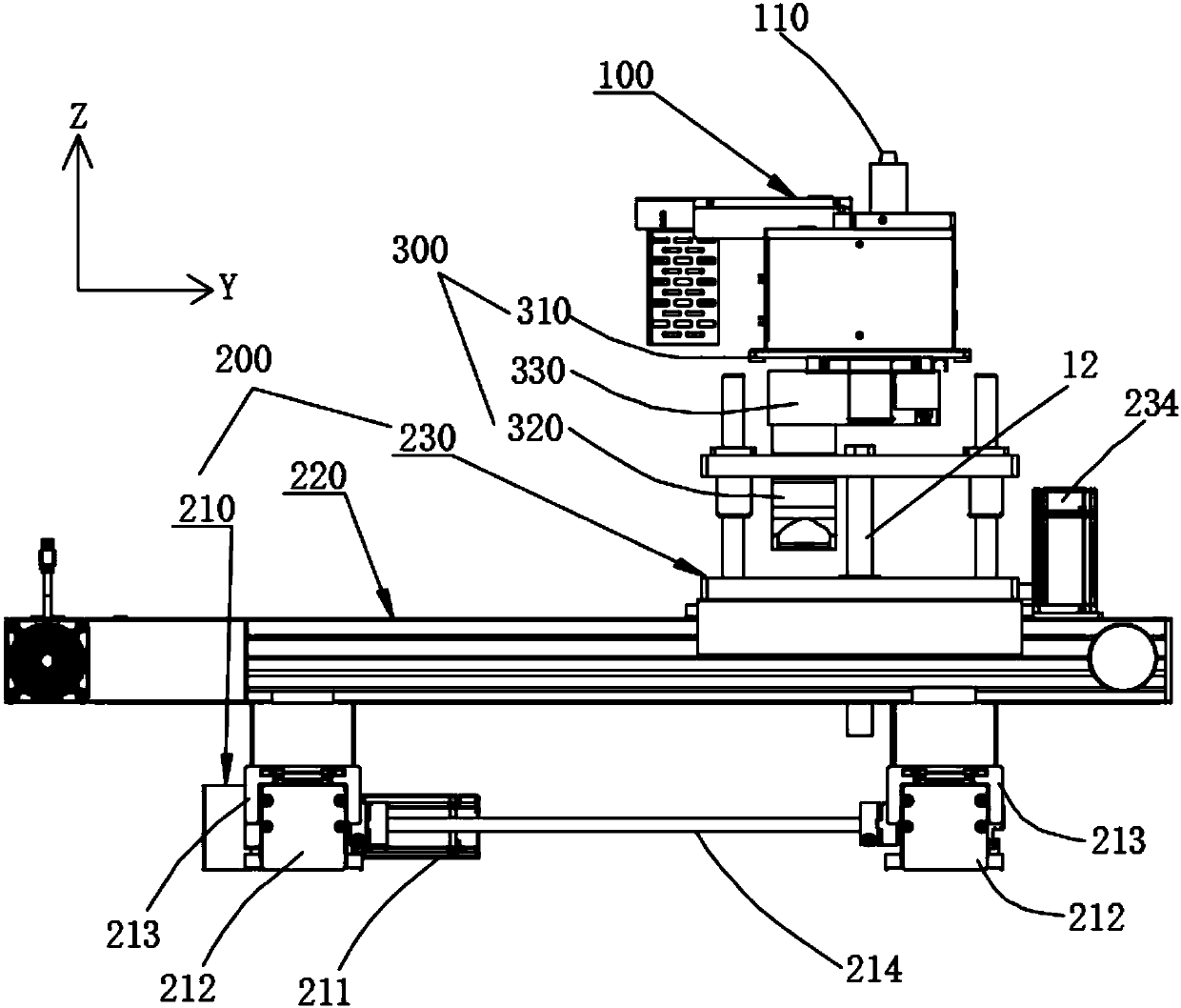

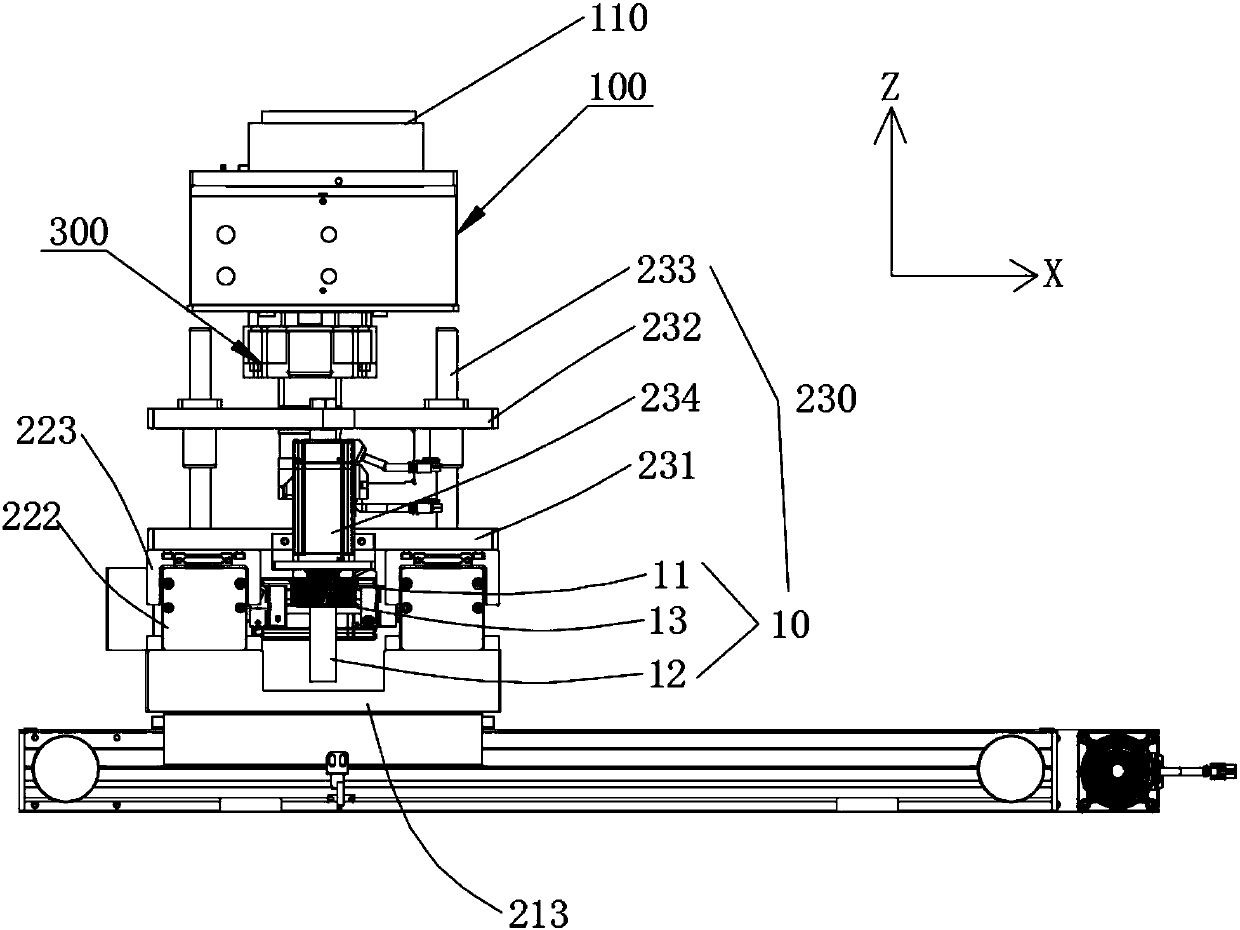

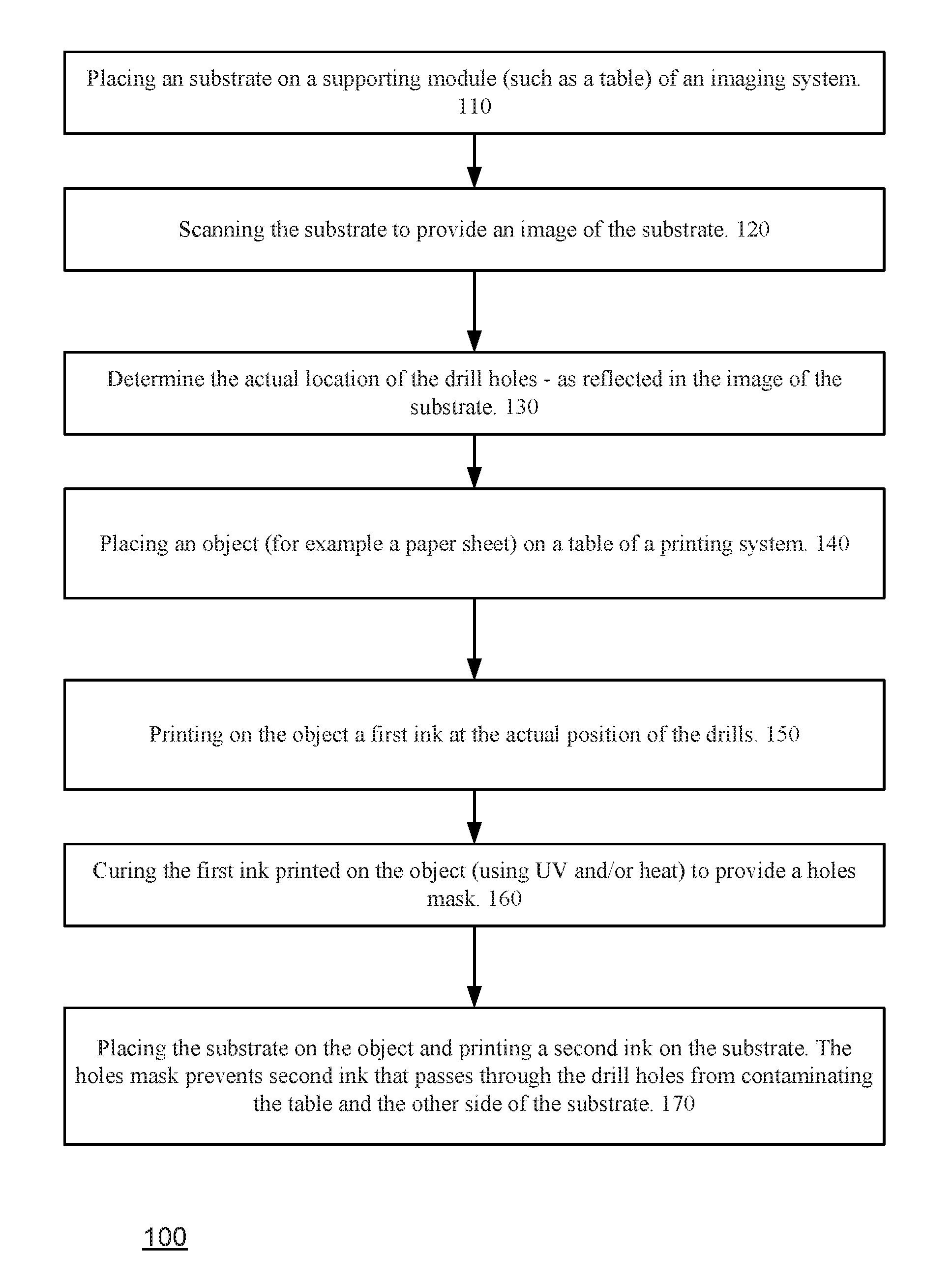

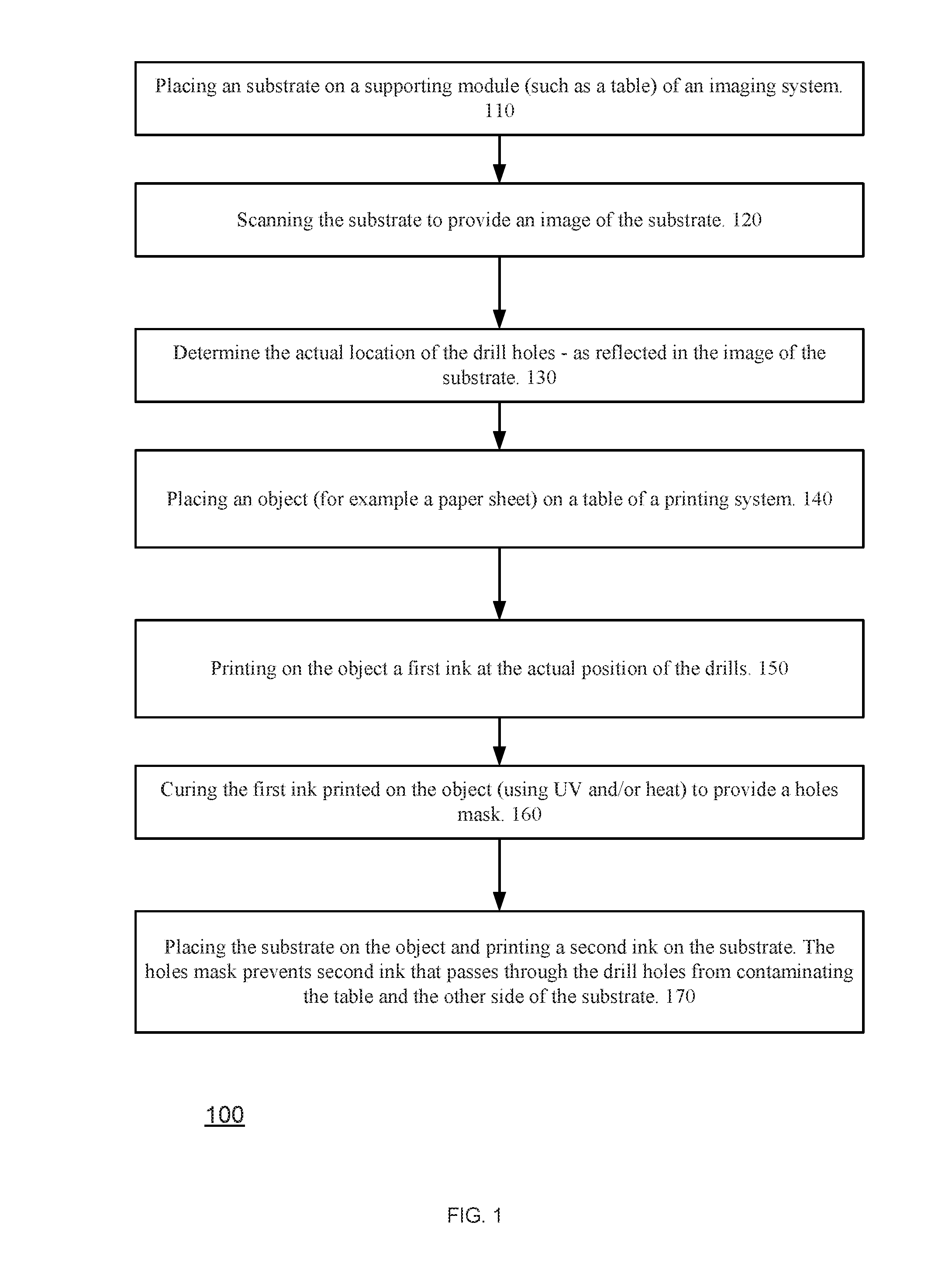

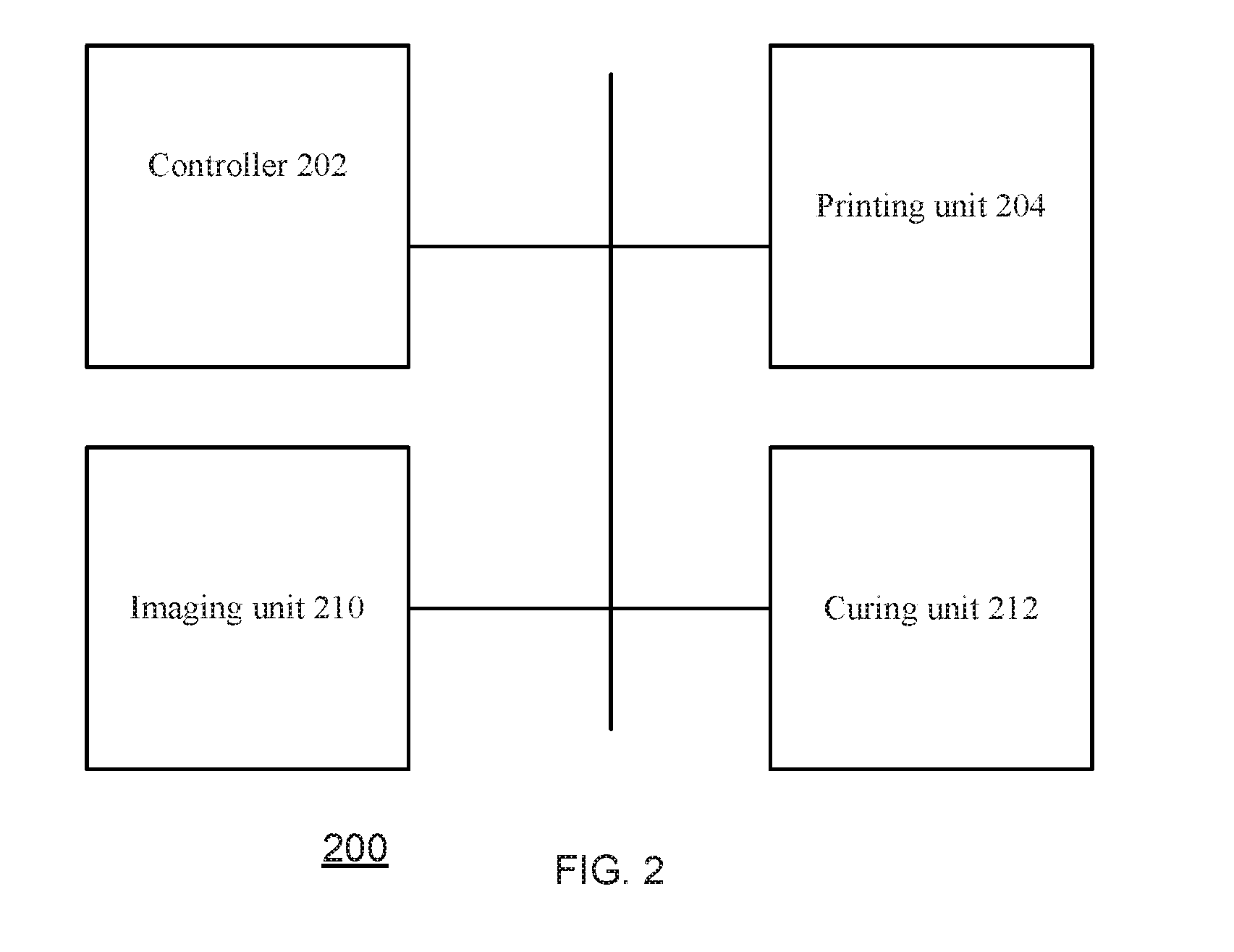

Selective solder mask printing on a printed circuit board (PCB)

ActiveUS20160286659A1Decrease printing speedTypewritersInspection/indentification of circuitsSolder maskEngineering

A method for printing on a substrate, the method may include determining actual locations of substrate holes; printing a first ink on an object at locations that correspond to the actual locations of the substrate holes and curing the first ink to provide a holes mask; and wherein after the substrate is positioned on the object so that holes mask seals bottoms of the substrate holes then printing the second ink on the substrate thereby forming a predefined pattern on the substrate.

Owner:CAMTEK LTD

Selective soldering using fiber optic device

A fiber optic device for enabling soldering is described. The fiber optic device includes an entry portion comprising an optical fiber bundle for receiving a single light beam wherein the optical fiber bundle splits the light beam into a plurality of separate portions, each of the separate portions for enabling soldering. The fiber optic device further includes an exit portion for emitting each of the plurality of separate portions of the light beam in a pattern to enable soldering at a plurality of locations simultaneously utilizing the single light beam.

Owner:WESTERN DIGITAL TECH INC

Selective soldering system

ActiveUS7631796B2Small footprintGood precisionWelding/cutting auxillary devicesAuxillary welding devicesSolder ballDegrees of freedom

Owner:SONY CORP +1

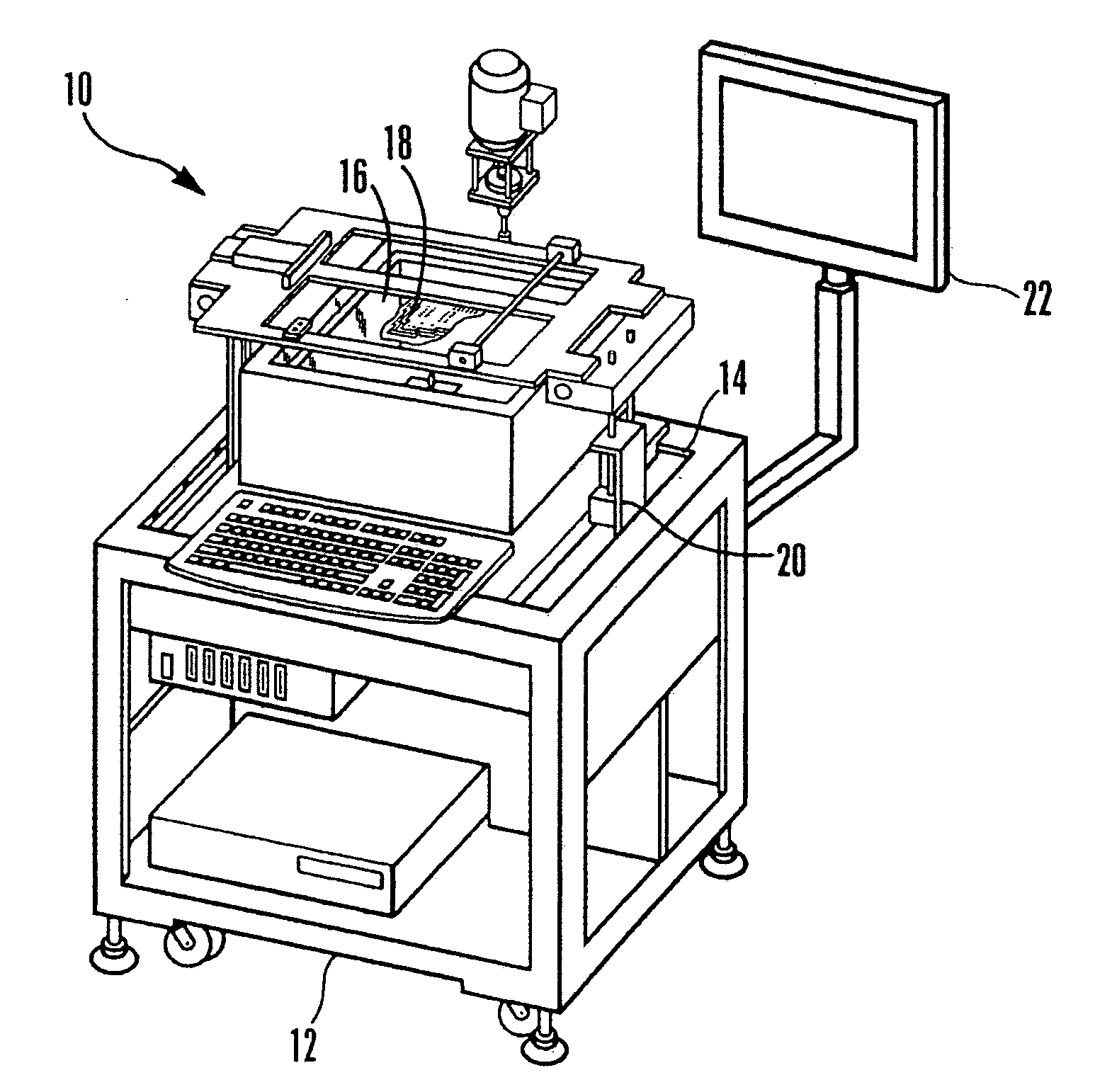

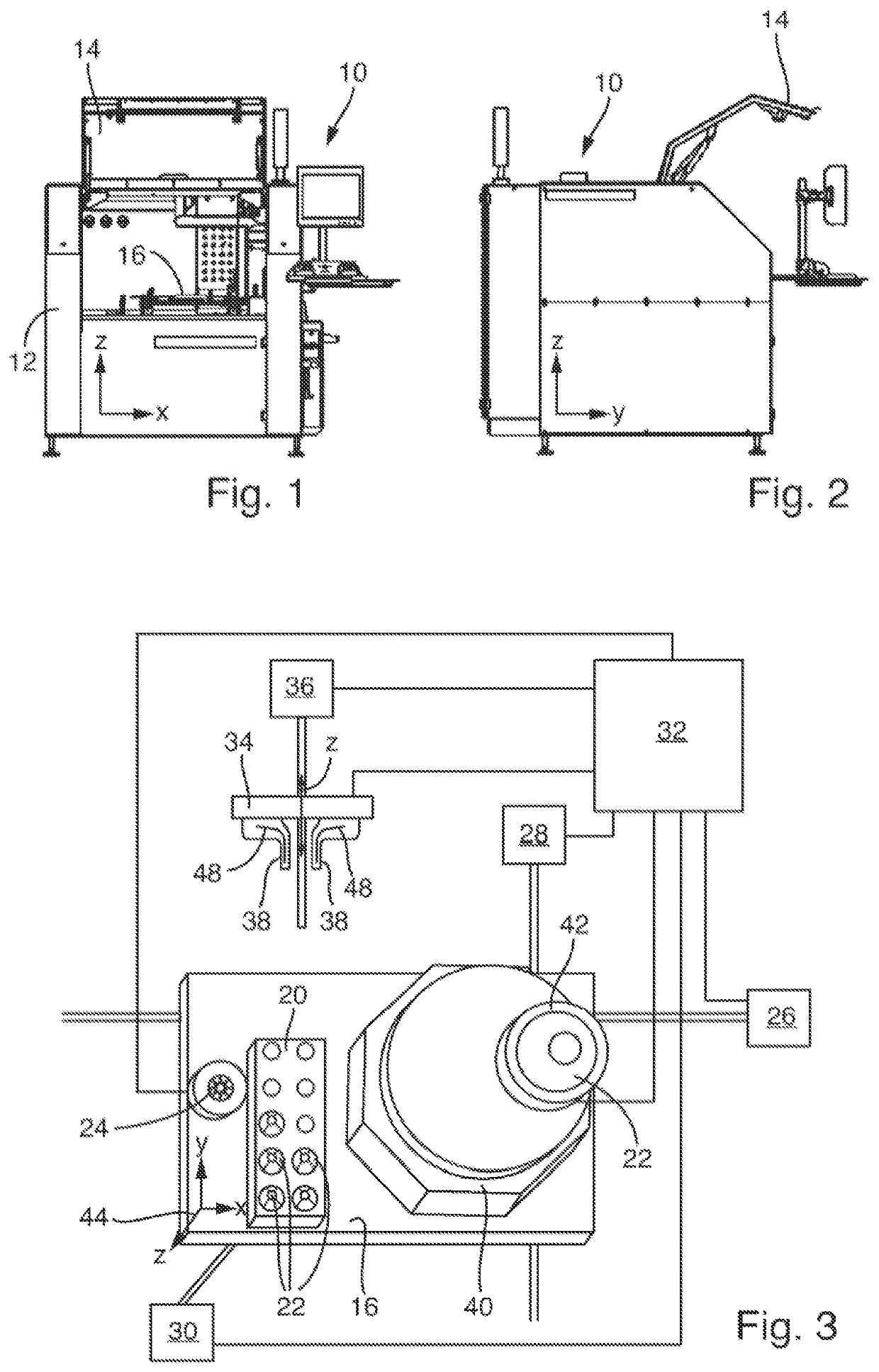

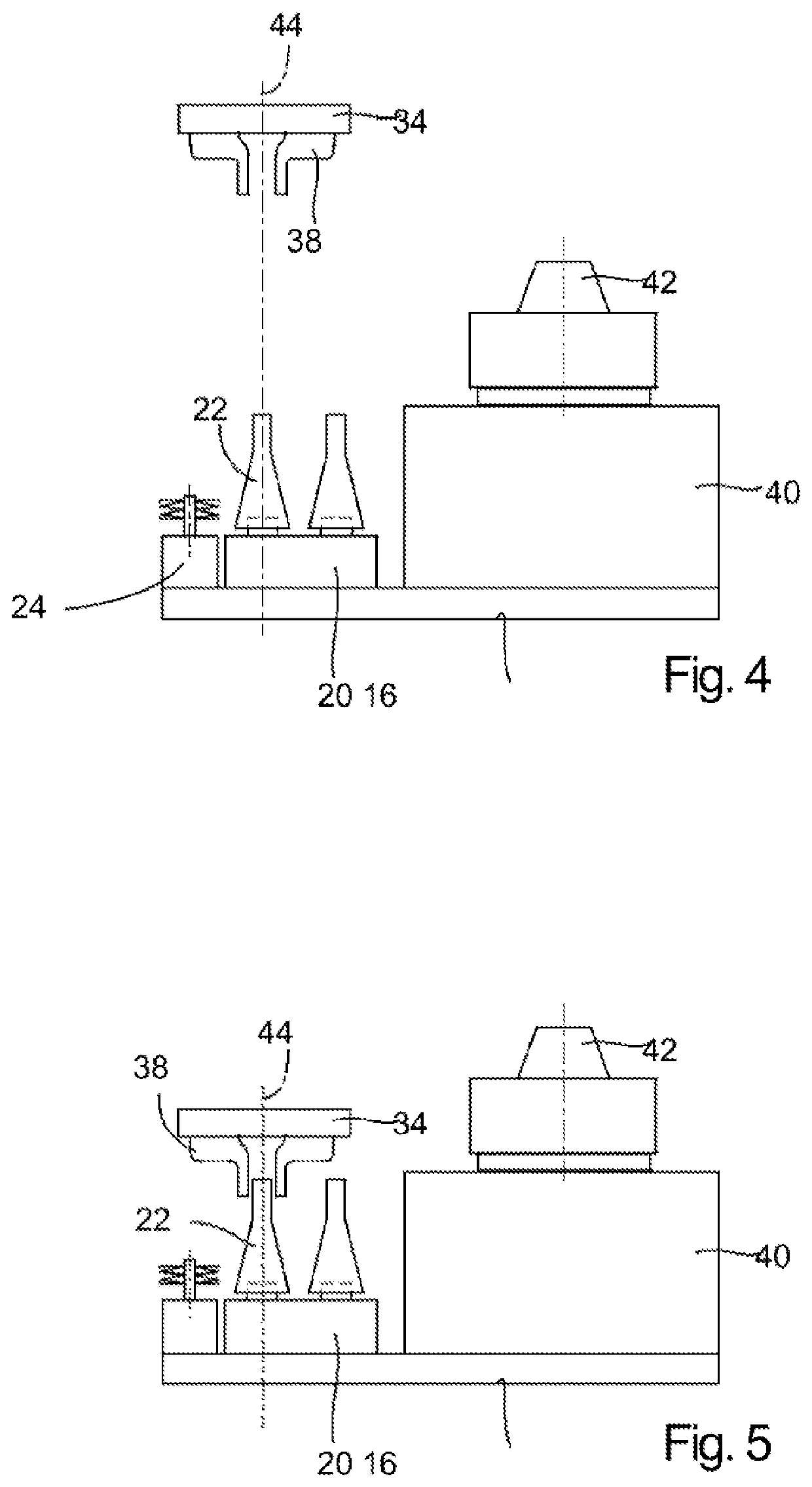

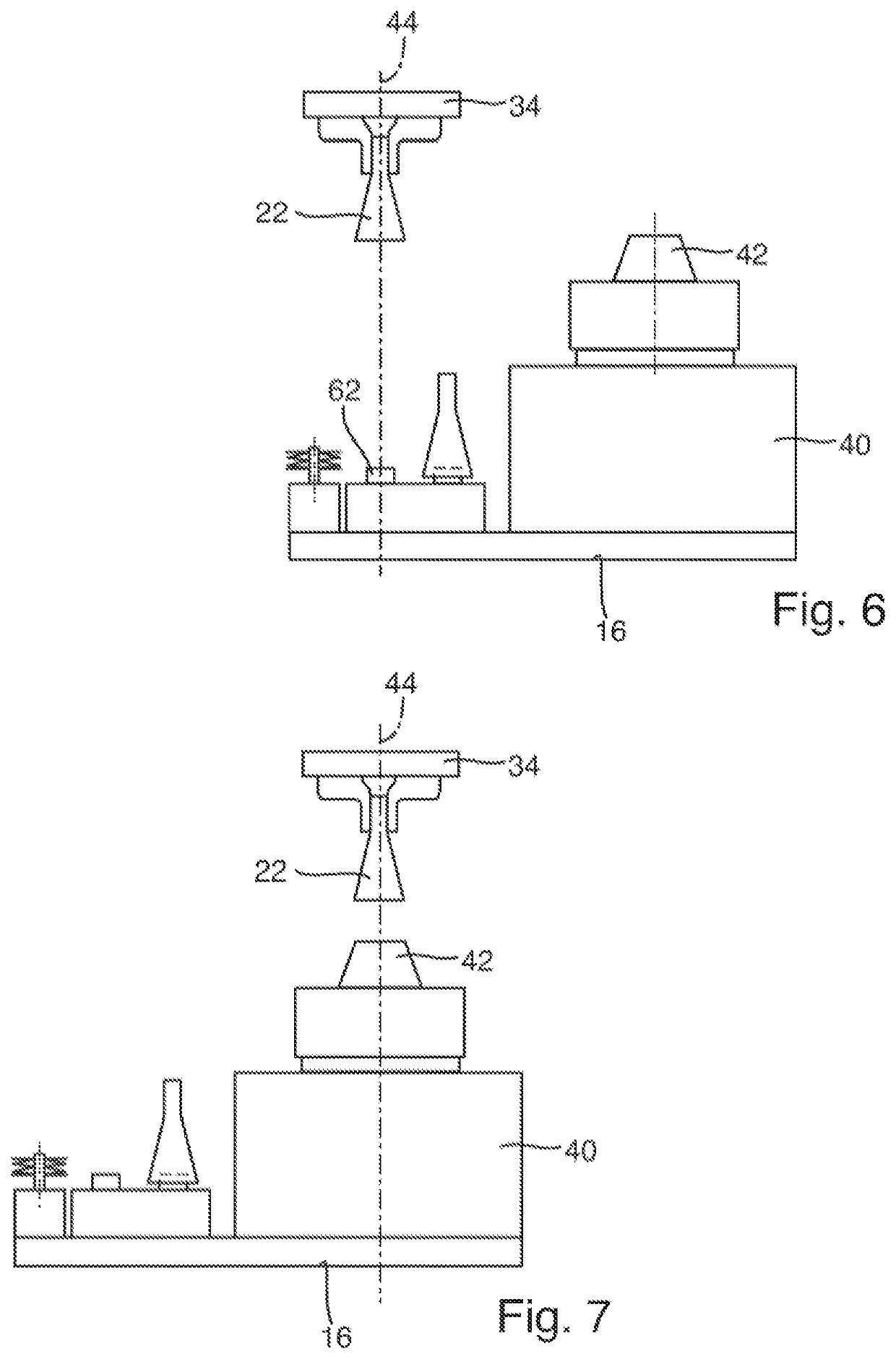

Selective soldering system for selective wave soldering of circuit boards comprising gripping unit for exchanging solder nozzles

ActiveUS20220184726A1Improve system efficiencyGuaranteed uptimePrinted circuit manufactureHeating appliancesStructural engineeringMechanical engineering

Selective soldering system for selective wave soldering of circuit boards, including a solder pot, a solder nozzle which can be detachably arranged on the solder pot, wherein the solder nozzle has a nozzle base and a nozzle neck, wherein at the free end of the nozzle neck a nozzle opening is provided, the solder pot being arranged on a moving unit, which can be moved along an x and y axis in a horizontal plane and along a z axis in the vertical direction, and a control unit for controlling the moving unit.

Owner:ERSA GMBH

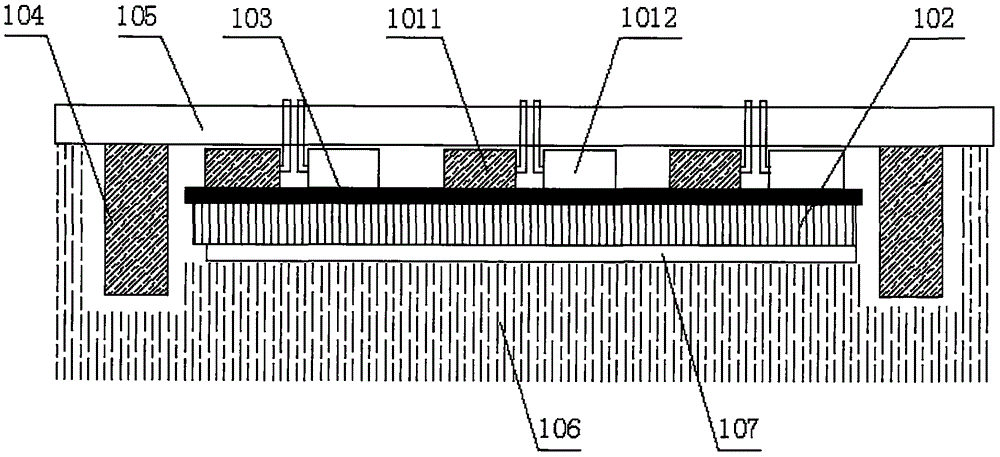

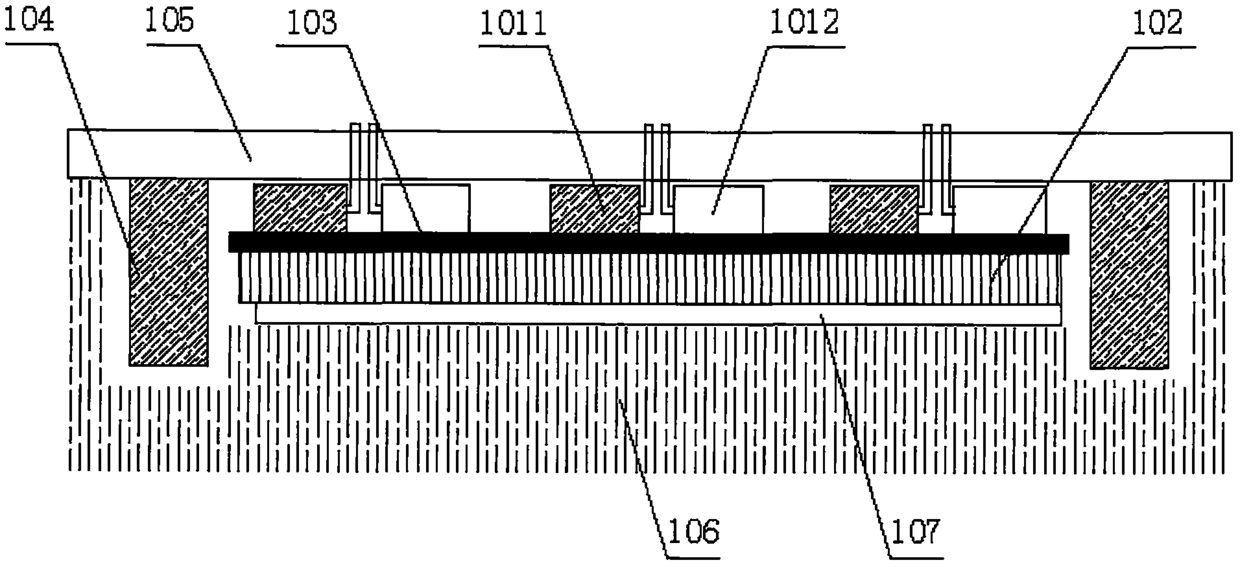

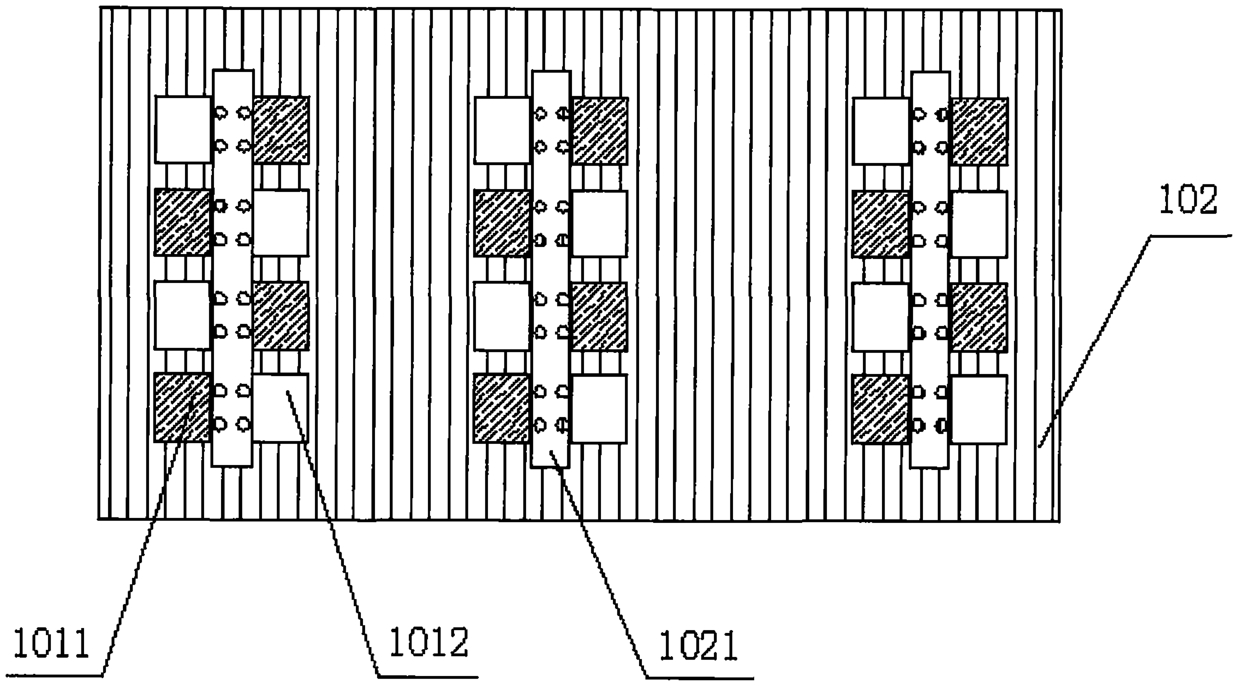

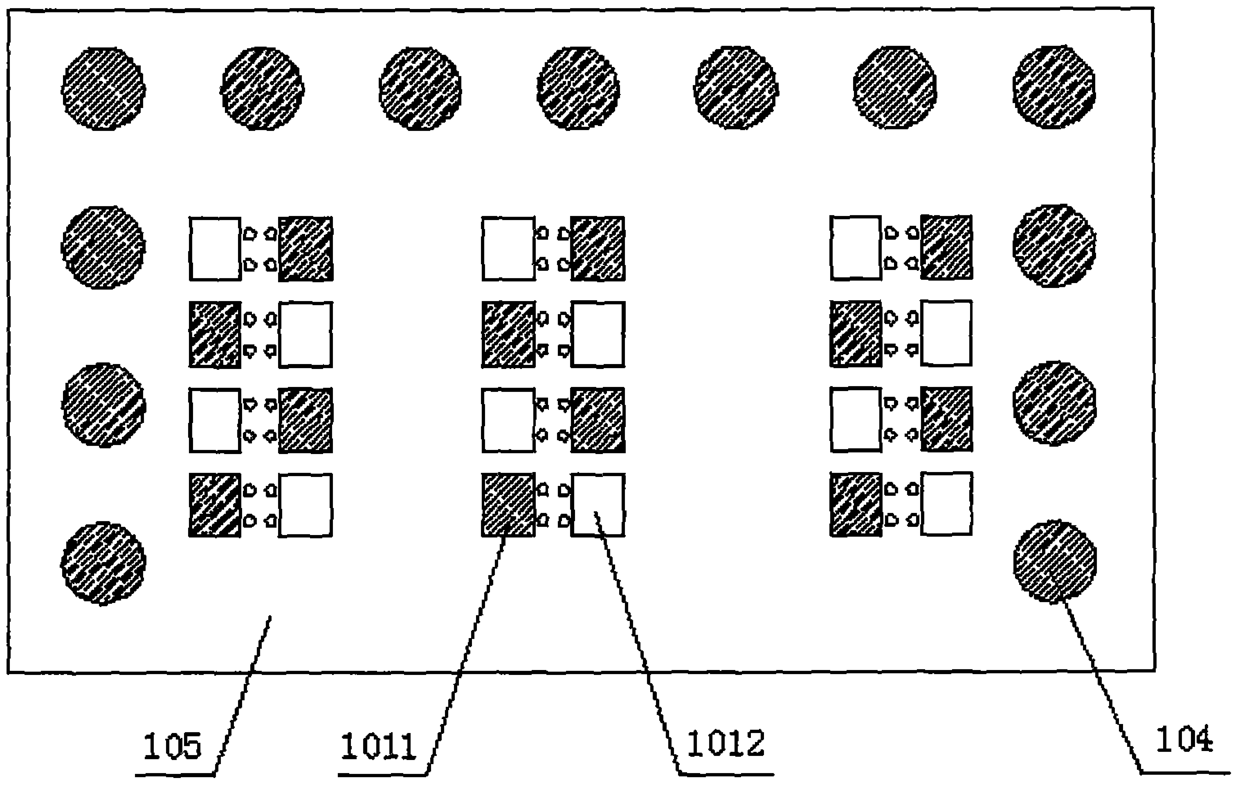

Pin type power single tube integration scheme applied to electric control product of electric vehicle

ActiveCN106206330AHigh feasibilityLow priceSemiconductor/solid-state device detailsSolid-state devicesCapacitanceNew energy

The invention discloses a pin type power single tube integration scheme applied to an electric control product of an electric vehicle, and relates to the technical field of a new energy vehicle. The pin type power single tube integration scheme comprises the following steps of firstly, pressing a pin type power device on a metal support plate by a press sheet or a press strip, wherein an insulation heat conduction gasket is arranged between the power device and the metal support plate; secondly, welding a pin of the power single tube and a bus capacitor on a thick copper printed circuit board (PCB); and finally, pressing the metal support plate integrated with the thick copper PCB on a cooling cold plate, wherein heat conduction silicon grease is coated between the metal support plate and the cooling cold plate. Compared with a package type power module, the cost is low, the design flexibility is greatly improved, the selective soldering or wave soldering feasibility of a power single tube pin is greatly improved, the power single tube is light in weight, the heat capacity of a product is low, and the welding quality is high; and the heat of the power single tube can be transversely diffused to the metal support plate, the cooling area is effectively extended, and the thermal resistance of the system is reduced.

Owner:王文杰

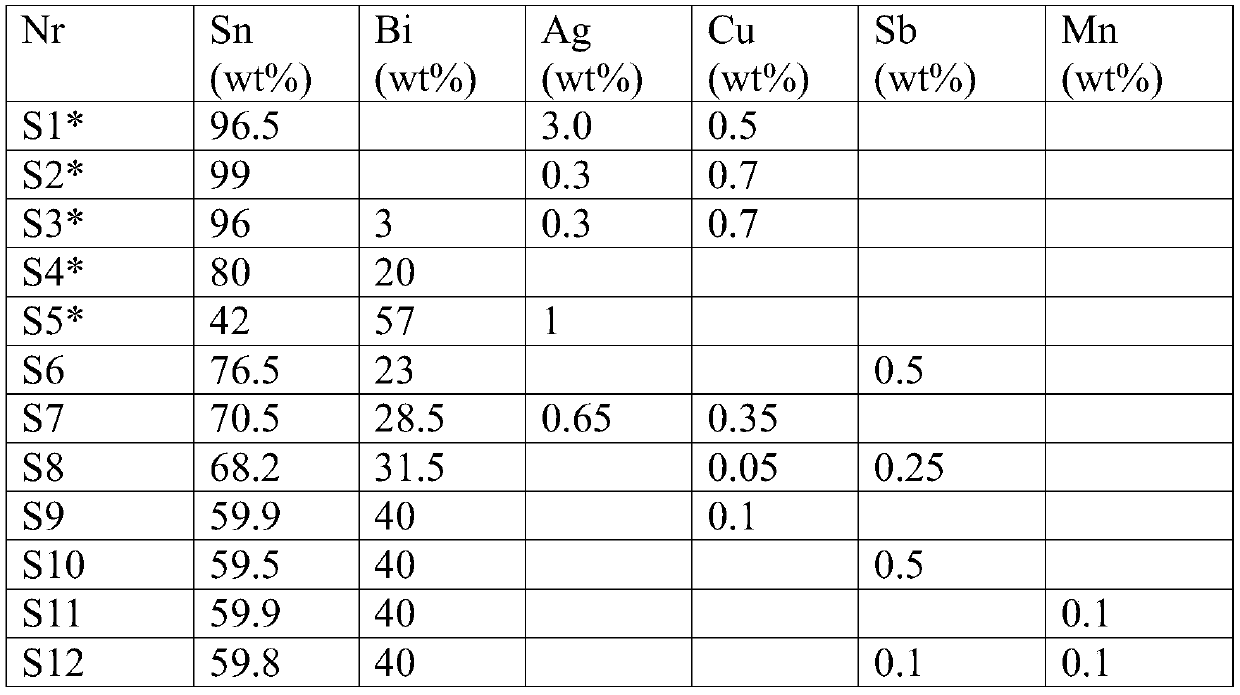

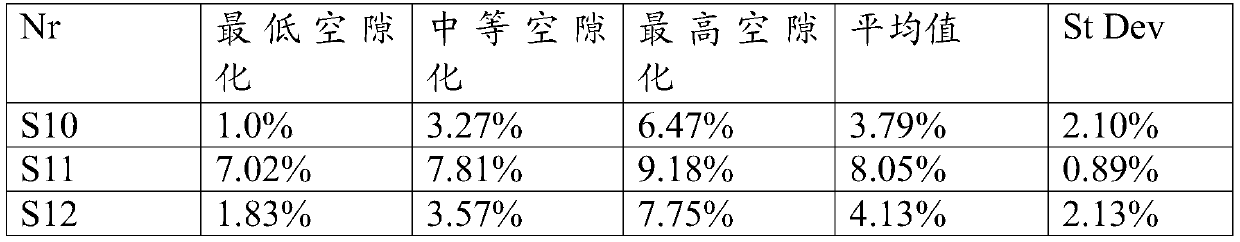

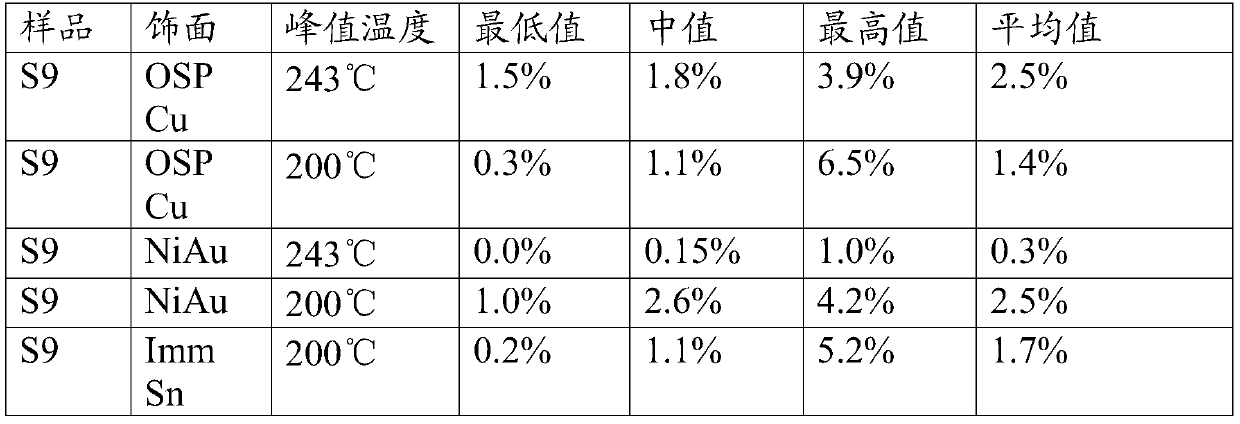

Lead-free solder alloy comprising sn, bi and at least one of mn, sb, cu and its use for soldering an electronic component to a substrate

InactiveCN109789518AThe result is obviousPrinted circuit assemblingSemiconductor/solid-state device detailsManganeseSolder paste

A solder alloy comprises 38.0-42.0 wt% bismuth (Bi), 0.01-2 wt% of at least one further element chosen from the group of manganese (Mn), antimony (Sb) and copper (Cu), the balance being tin (Sn), andis at least substantially free of nickel (Ni), and further preferably substantially free of silver (Ag). The solder alloy may be combined with a halide-free solder flux to constitute a solder paste, solder bath or solder wire. The solder paste is for instance used for soldering electronic component packages such as quad flat non-leaded (QFN) packages or for soldering surface mount devices (SMD), resulting in low void formation. The solder alloy may also be applied by means of wave-soldering or selective soldering.

Owner:英特福莱电子有限公司

Full-automatic control selective wave soldering device and method

PendingCN113182634AAvoid stressful situationsAvoid excessive heatPrinted circuit assemblingMetal working apparatusTemperature controlAutomatic control

The invention discloses a full-automatic control selective wave soldering device. The device is characterized by comprising a main body, a controller, a conveying guide rail, a scaling powder spraying mechanism, a double-layer preheating mechanism and a selective soldering mechanism, wherein the controller, the conveying guide rail, the scaling powder spraying mechanism, the double-layer preheating mechanism and the selective soldering mechanism are arranged on the inner side of the main body, the controller comprises a conveying controller, a spraying controller, a preheating controller and a soldering controller, the spraying controller comprises a pressure controller, a pressure sensor, a flowmeter and a pressure reducing valve, the pressure controller is connected with the pressure sensor, the flowmeter and the pressure reducing valve, the pressure sensor is mounted on a spraying valve, and the flowmeter and the pressure reducing valve are mounted on a spraying pipe at the bottom end of the spraying valve. Through the arrangement of the pressure sensor, the pressure controller, the pressure reducing valve, the flowmeter and other structures, the situation that the pressure of a sprayer on the spray valve is too high can be avoided; and through the arrangement of a temperature control chip, a temperature sensor and other structures, the situation that the temperature of the preheating controller in use is too high can be avoided.

Owner:埃斯特(深圳)智能科技有限公司

A pin-type power single-tube integrated structure applied to electric vehicle electronic control products

ActiveCN106206330BHigh feasibilityLow priceSemiconductor/solid-state device detailsSolid-state devicesCapacitanceNew energy

Owner:王文杰

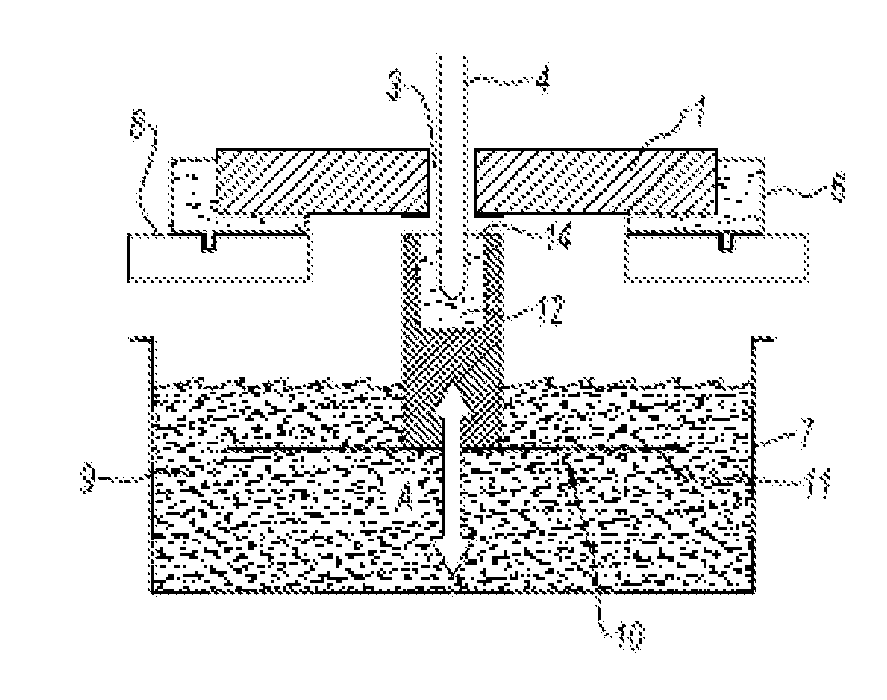

Apparatus and method for selective soldering

InactiveCN101563181BImprove efficiencyImprove welding qualityPrinted circuit assemblingMetal working apparatusSpray nozzleEngineering

The invention relates to a device for selective soldering comprising a container (10) for liquid solder containing a so-called solder bath (9) with a solder channel (2) and a At least one nozzle (4) on the top, also with a solder pump for pressurizing the liquid solder (1) in the solder channel (2), characterized in that the solder channel (2) is covered by a vertically movable cover (5) Surrounded, the shroud is immersed in the solder bath (9) or is otherwise sealed to the surface of the solder bath (9), the shroud includes a passage (7) for each nozzle (4) and is Below the cover (5) is provided with at least one protective gas and / or active gas delivery device (6), wherein on the cover (5) is attached a flow plate ( 8). The invention further relates to a method of selective soldering.

Owner:LINDE AG +1

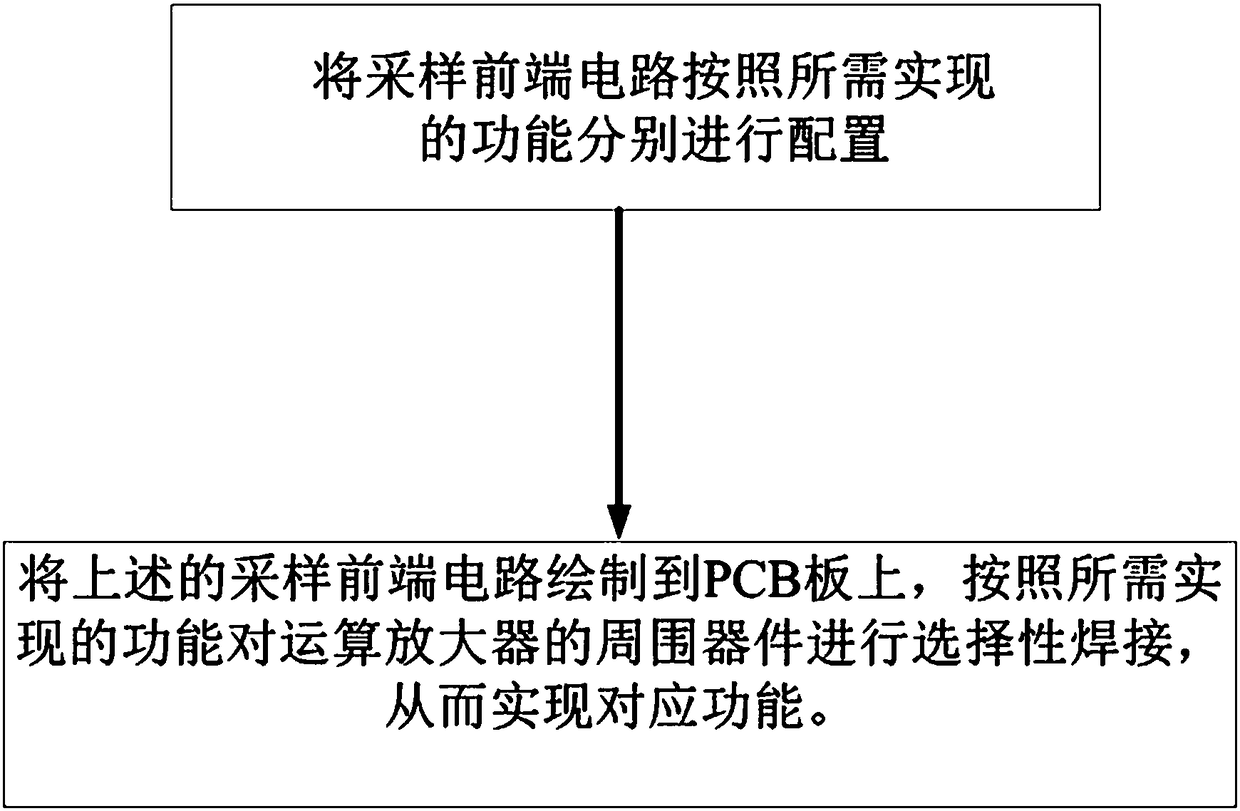

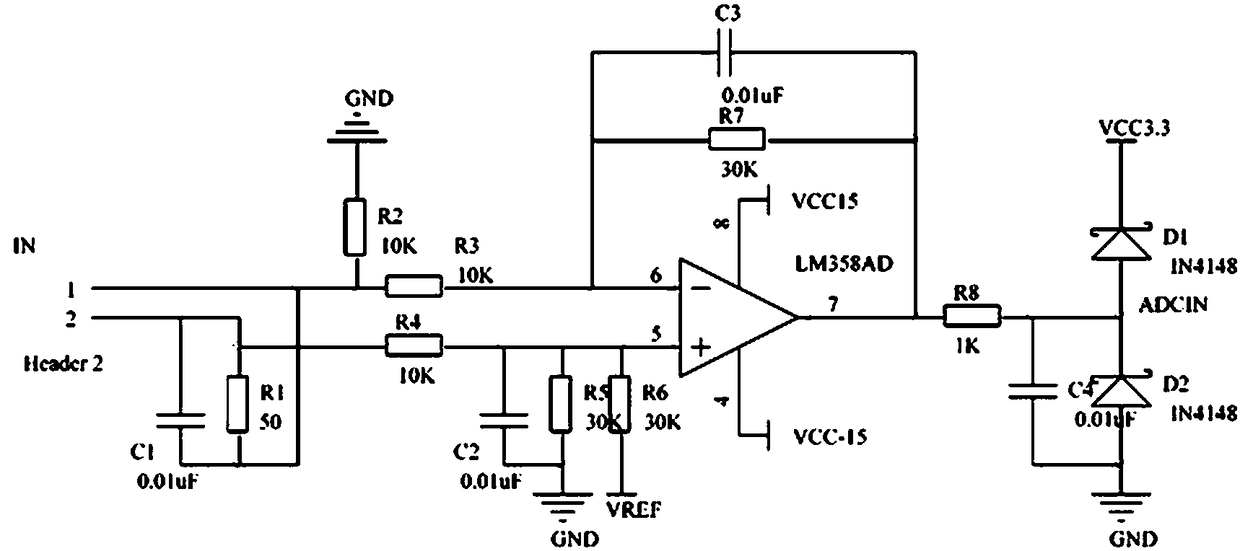

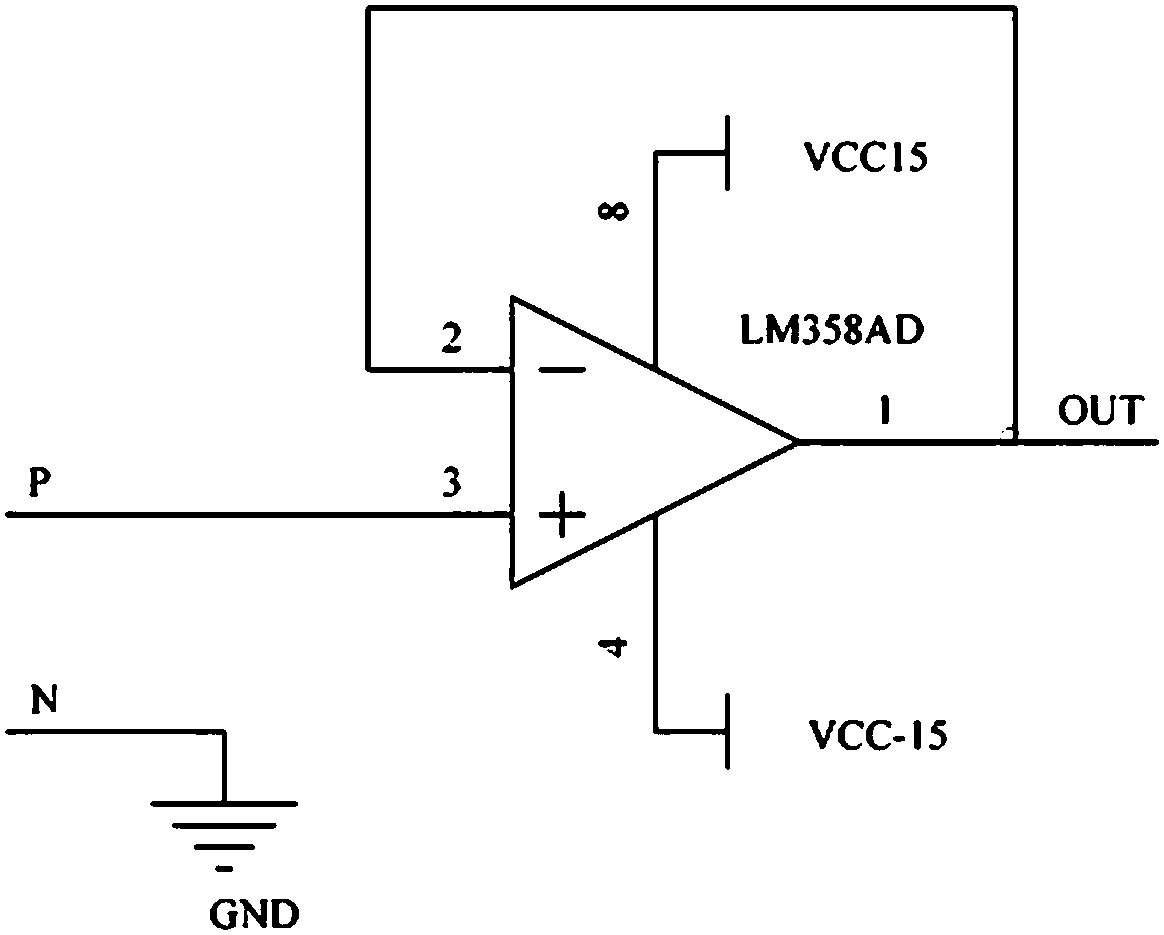

Realization method and device for multifunctional operational amplifier sampling front-end circuit

InactiveCN108540133AMeet different needsVersatileAnalogue-digital convertersAudio power amplifierOperational amplifier

The invention discloses a realization method and device for a multifunctional operational amplifier sampling front-end circuit. The method comprises the following steps of respectively configuring thesampling front-end circuit according to functions needing to be realized; and drawing the sampling front-end circuit on a PCB, and selectively welding peripheral devices of an operational amplifier according to the functions needing to be realized in order to realize the corresponding functions. The device comprises an input interface end, a middle conversion end and a voltage stabilization output end. The method and the device have the advantages of being simple to operate, good in universality and wide in application range and capable of realizing various sampling circuit functions.

Owner:徐晨旭

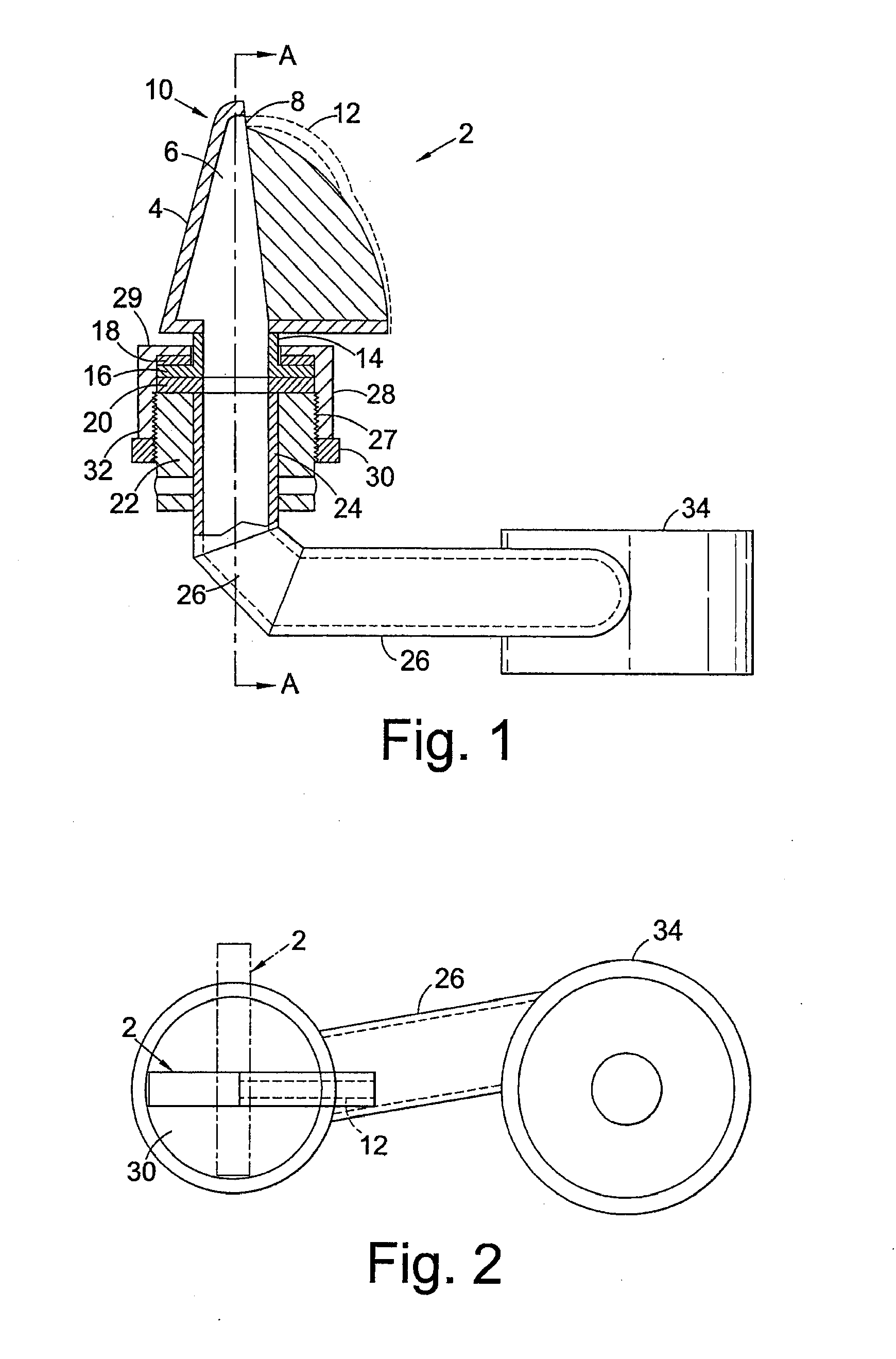

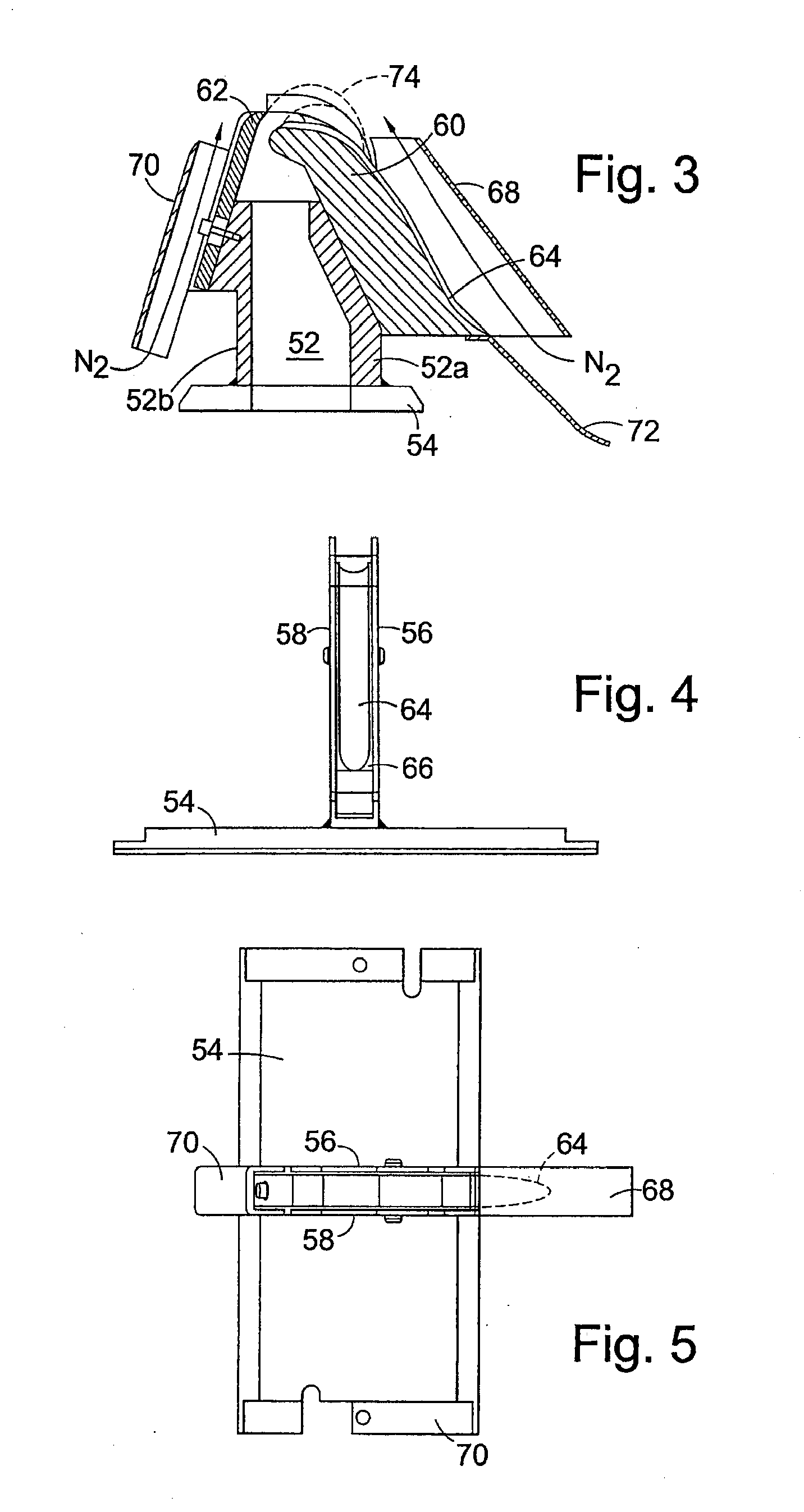

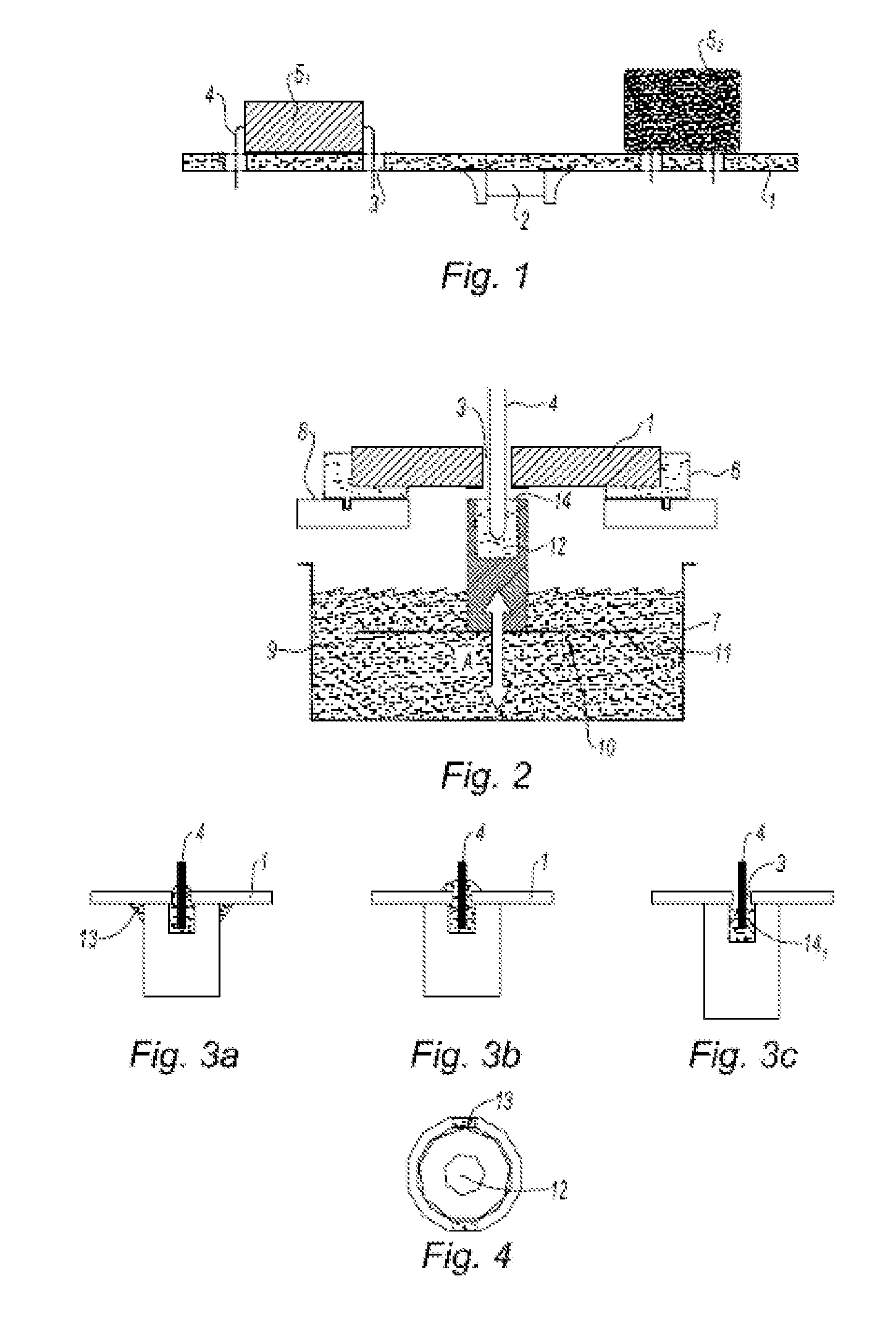

Selective soldering apparatus with jet wave solder jet and nitrogen preheat

InactiveUS20100243718A1Reduce thermal shockControl heating ratePrinted circuit assemblingWelding/cutting media/materialsNitrogenNitrogen atmosphere

Solder is pumped through a nozzle to produce a jet 12 of solder and leads on a printed circuit board are passed through the jet to solder them to the board tracks. The nozzle 2 is mounted on a flange 16 held between slip rings 18, 20 so that the nozzle can be rotated to change the direction of the jet. A nitrogen conduit 68, 70 may be provided in-line with the jet to provide a nitrogen atmosphere. A thin plate 92 downstream of the nozzle outlet to contact the jet and inhibit sideways fluctuations when leads are passed sideways through the jet. The apparatus may also include a tube 204, 212, 224 for delivering heated nitrogen gas to pre-heat a region to be soldered.

Owner:CINIGLIO ALEXANDER J +3

Solder pot

InactiveUS20120091188A1Improve personnel safetyImprove securityPrinted circuit manufactureWelding/cutting media/materialsEngineeringPrism

Solder pot intended for a machine for selective soldering of through-hole electronic components on a printed circuit board, characterized in that it is in the form of a right prism, preferably with a hexagonal base.

Owner:ROBERT BOSCH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com