Wave crest nozzle installation structure

A mounting structure and nozzle technology, which is applied in the direction of assembling printed circuits with electrical components, can solve problems affecting the placement of components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

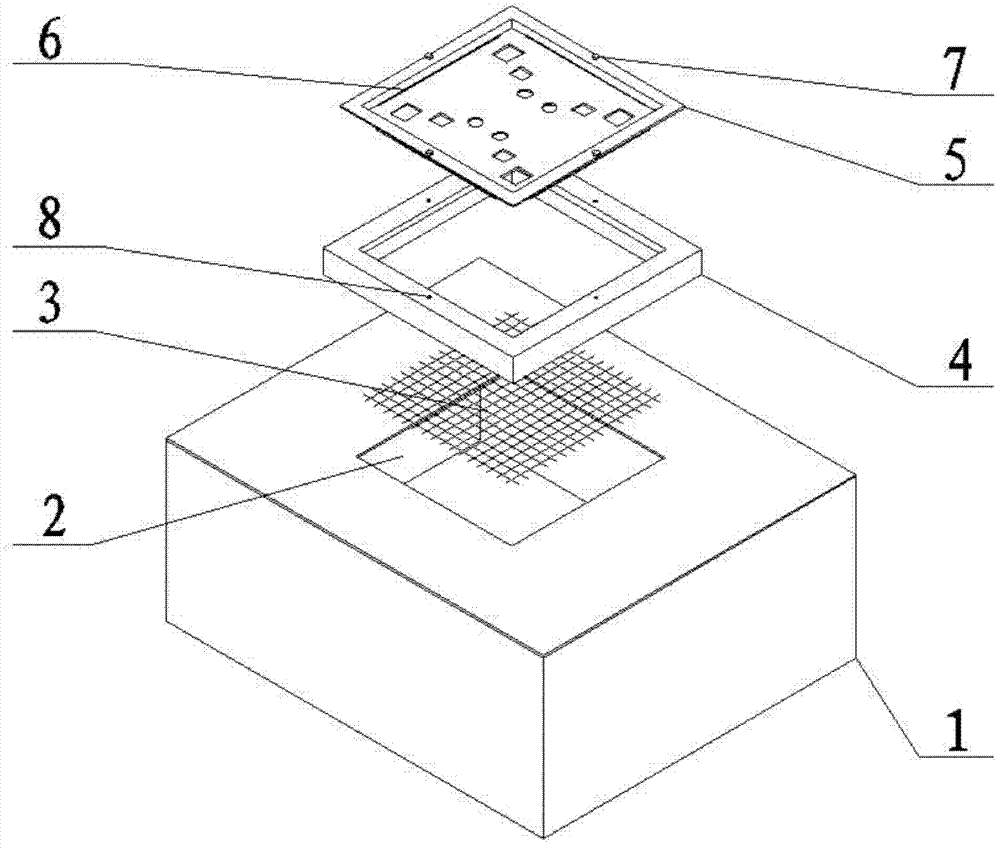

[0009] As shown in the accompanying drawings, the present invention is a mounting structure for a wave crest nozzle, including a nozzle retaining frame 4, which is fixedly welded at the opening 2 of the tin furnace, so that the wave crest gushes out in a shape surrounded by the nozzle retaining frame 4, and the The net 3 is installed on the bottom of the nozzle retaining frame 4 to make the wave crest evenly emerge. There is an opening on the nozzle 5, which corresponds to the position of the PCB board to be soldered. It is in close contact with the inner edge of the nozzle baffle frame 4, and the spout 5 is extended through the fastening screw 7 and the threaded hole 8 on the nozzle baffle 4 to be fastened and installed.

[0010] In this way, when the crest generator is working, the entire crest emerges from the opening 2 of the tin furnace, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com