Automatic wave peak welding equipment

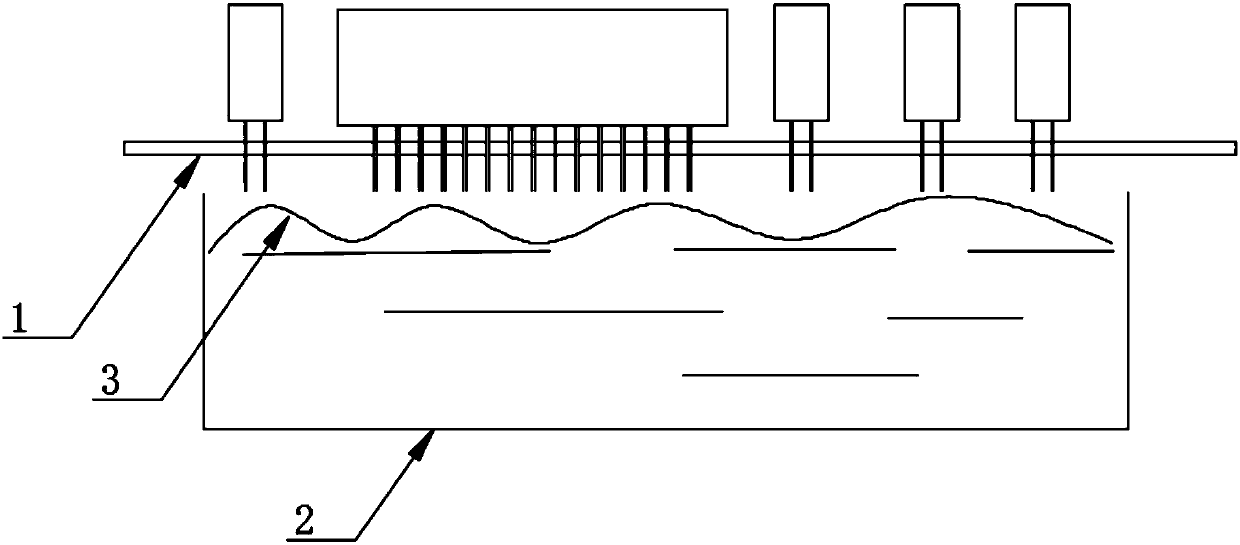

A wave soldering and equipment technology, which is applied in the field of automated wave soldering equipment, can solve problems such as inability to solder double-sided plug-ins or mixed PCB products, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

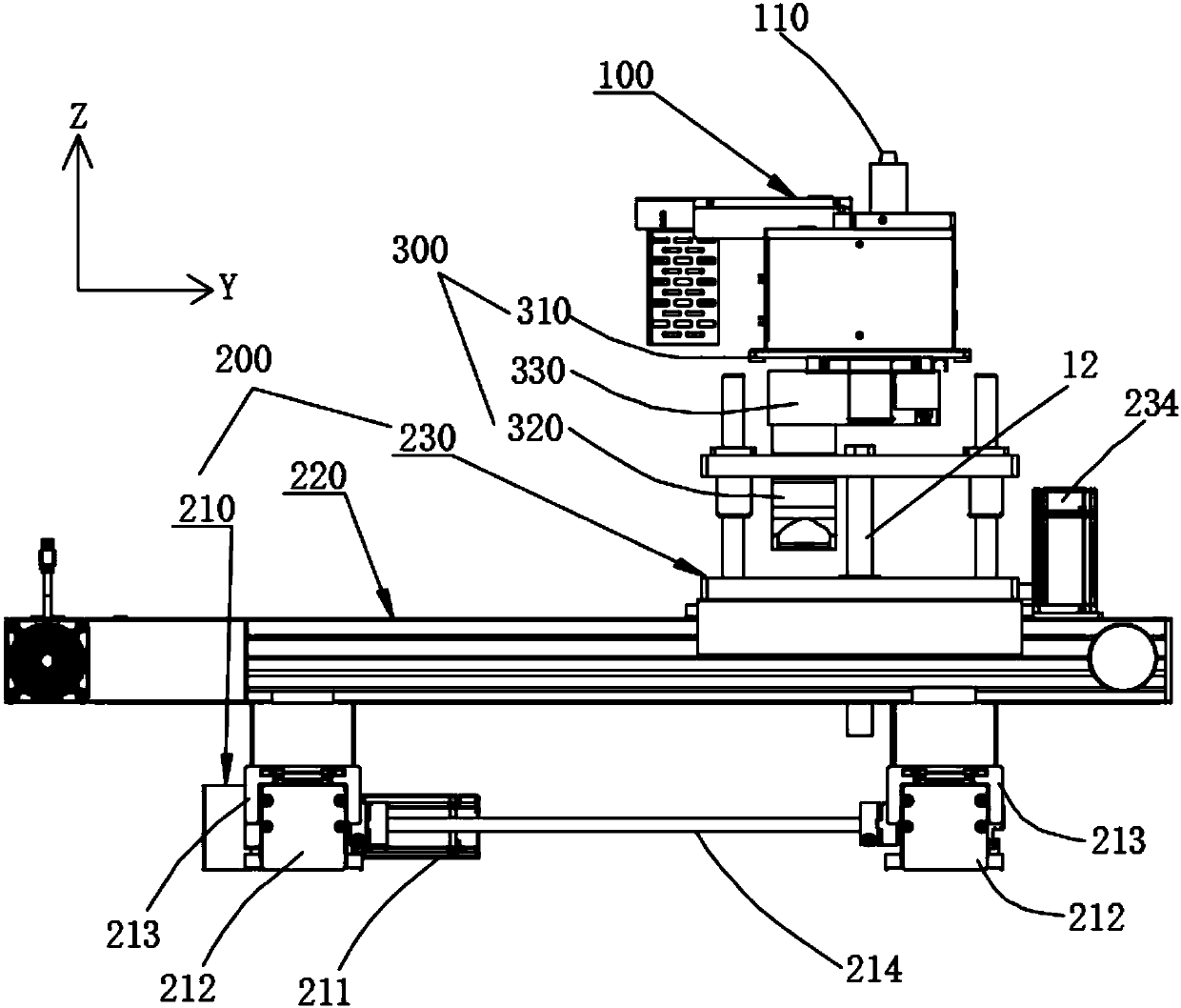

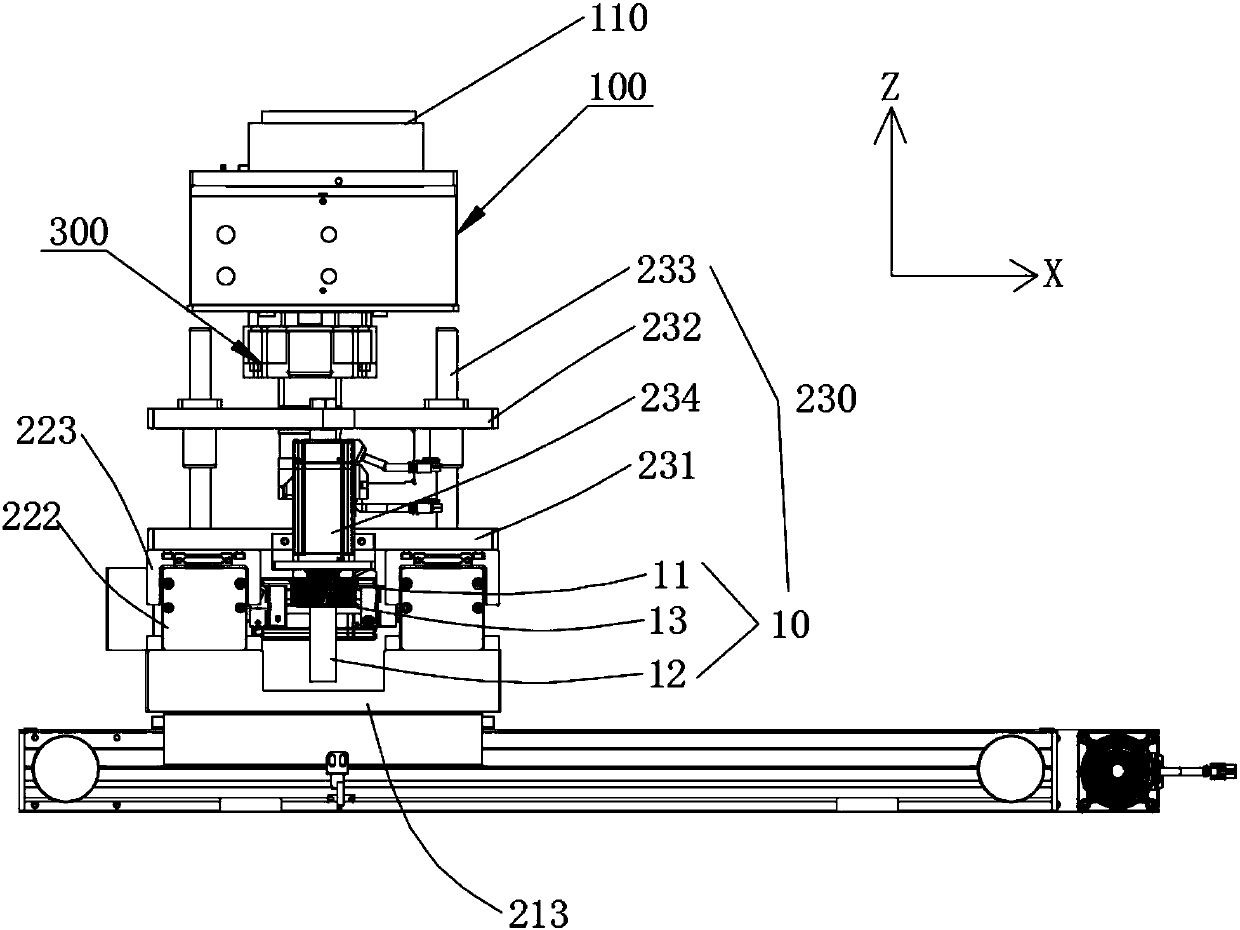

[0023] Now in conjunction with the accompanying drawings, the preferred embodiments of the present invention will be described in detail.

[0024] Such as figure 2 As shown, the present invention provides an automatic wave soldering equipment, including a tin furnace 100 and a nozzle 110 located on the tin furnace 100, the wave soldering equipment also includes a three-dimensional mobile device 200, the tin furnace 100 is installed on the three-dimensional mobile device 200, and the three-dimensional The moving device 200 drives the tin furnace 100 and the nozzle 110 to move along the X-axis direction, the Y-axis direction and the Z-axis direction respectively. The three-dimensional moving device 200 drives the tin furnace 100 to move along the X-axis direction, the Y-axis direction, and the Z-axis direction respectively, and then drives the nozzle 110 to avoid the parts to be protected, and accurately reach the position where the PCB product is to be soldered, so as to reali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com